Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

34results about How to "Guaranteed wall thickness uniformity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

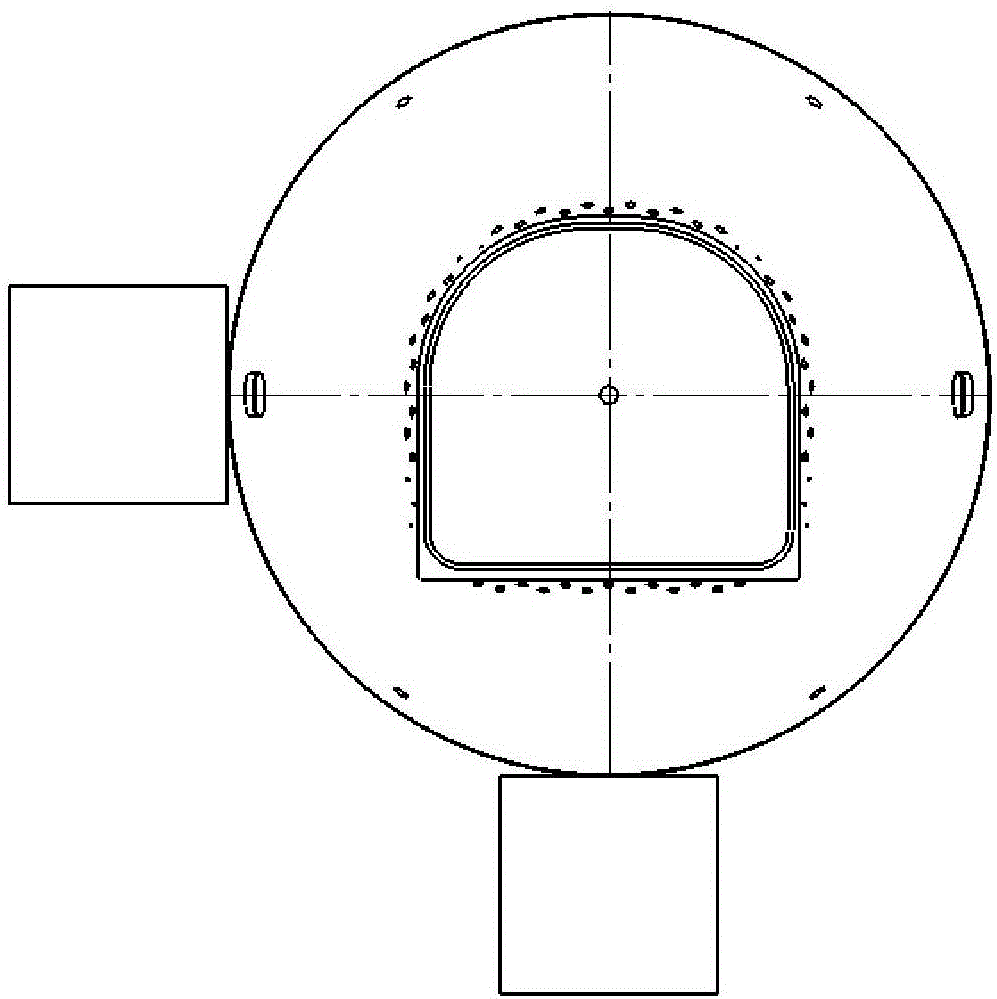

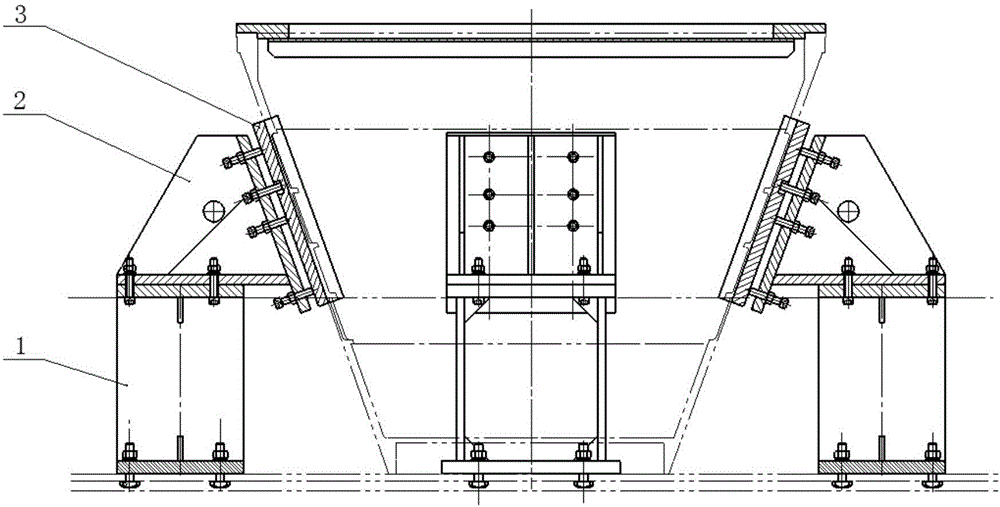

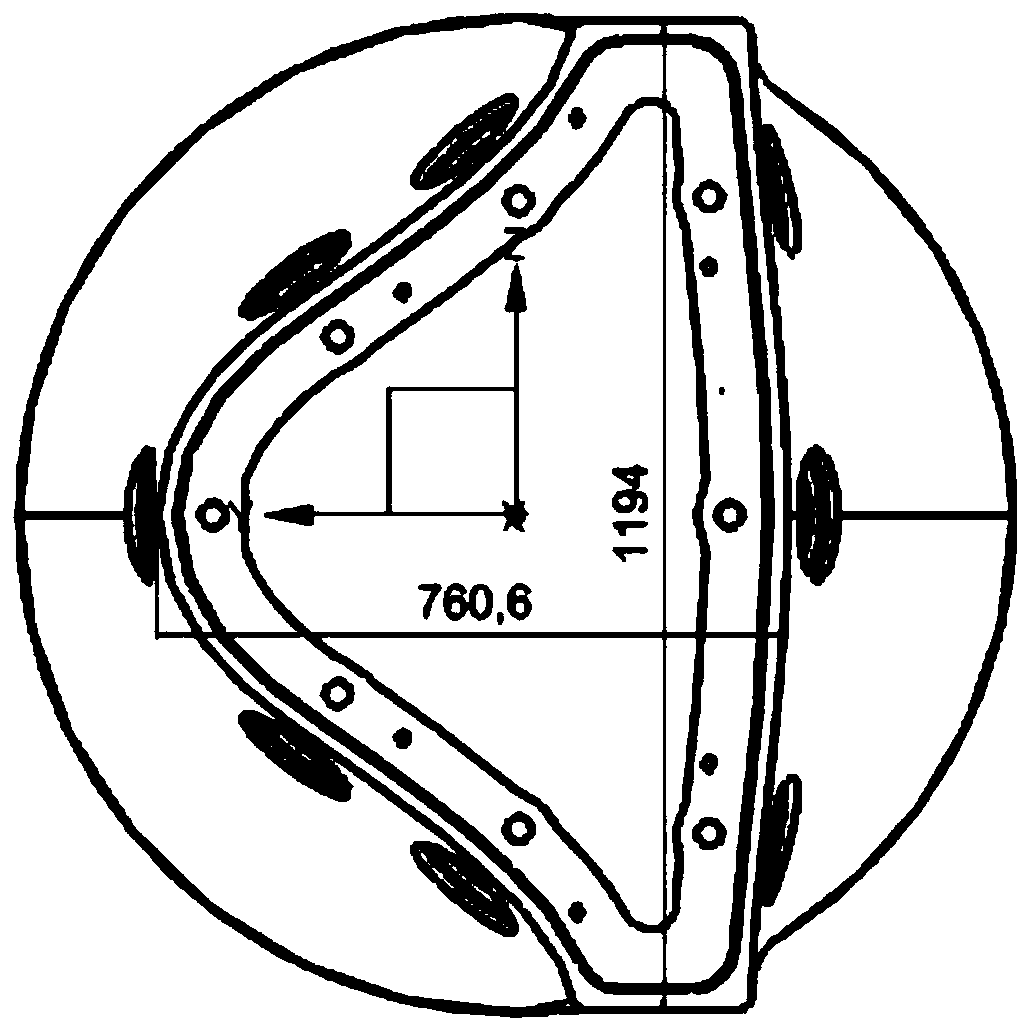

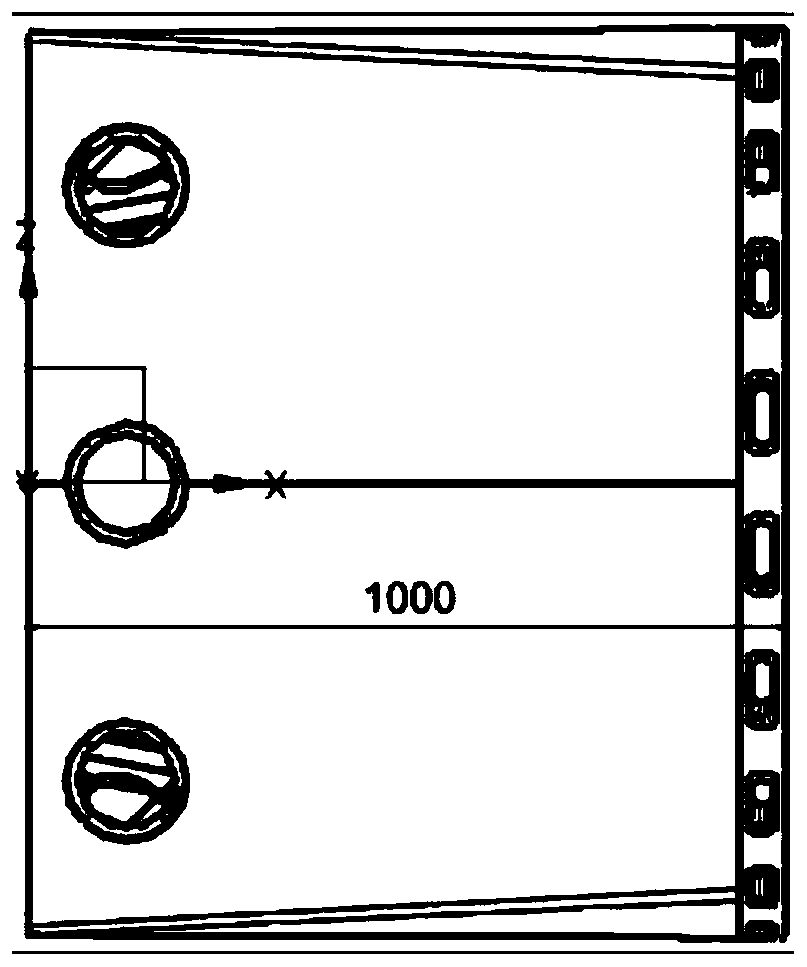

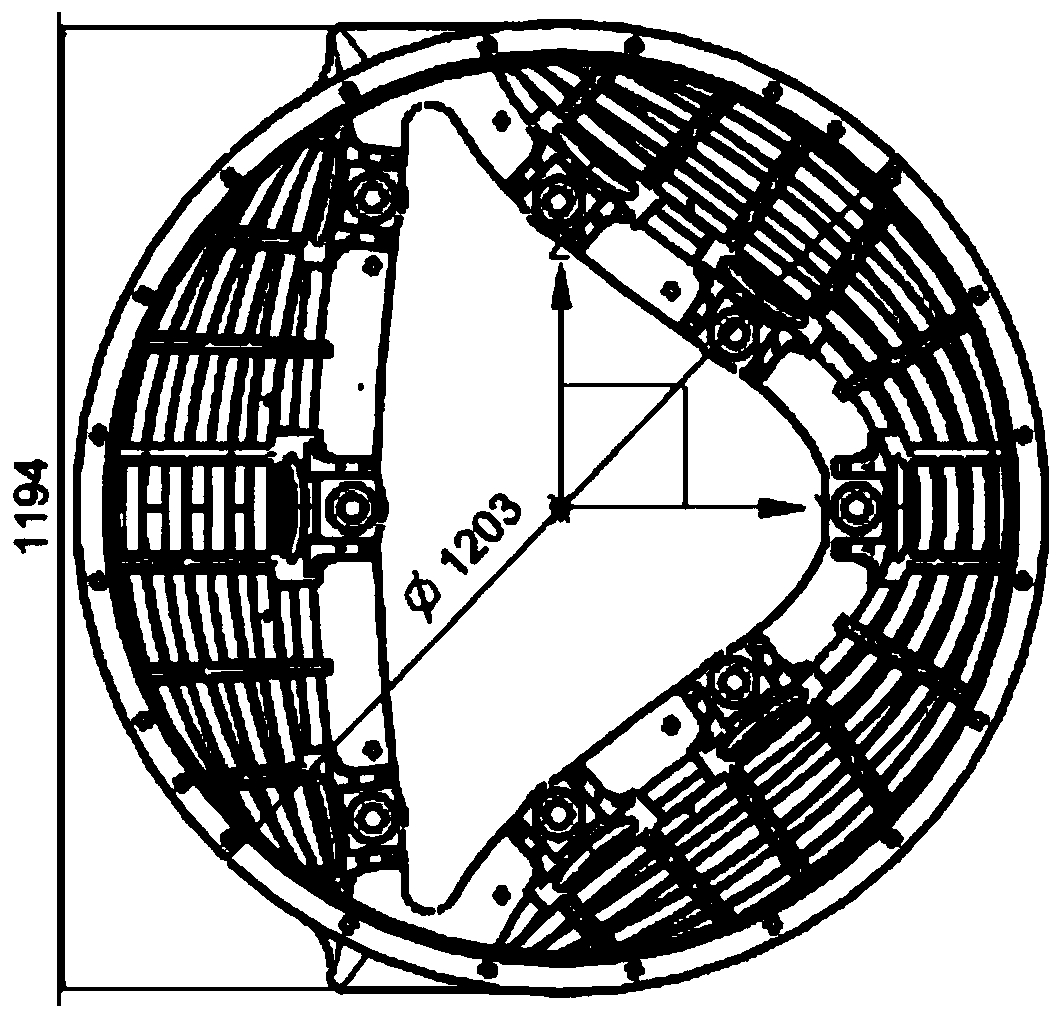

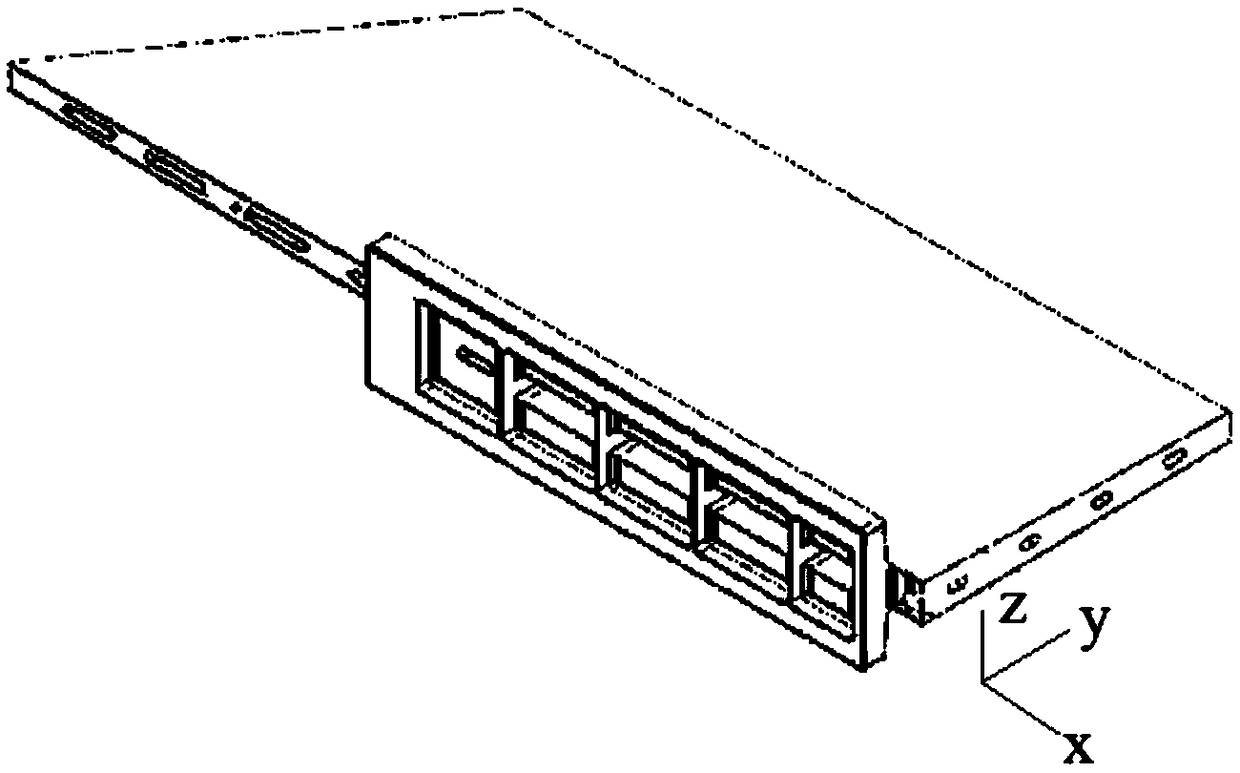

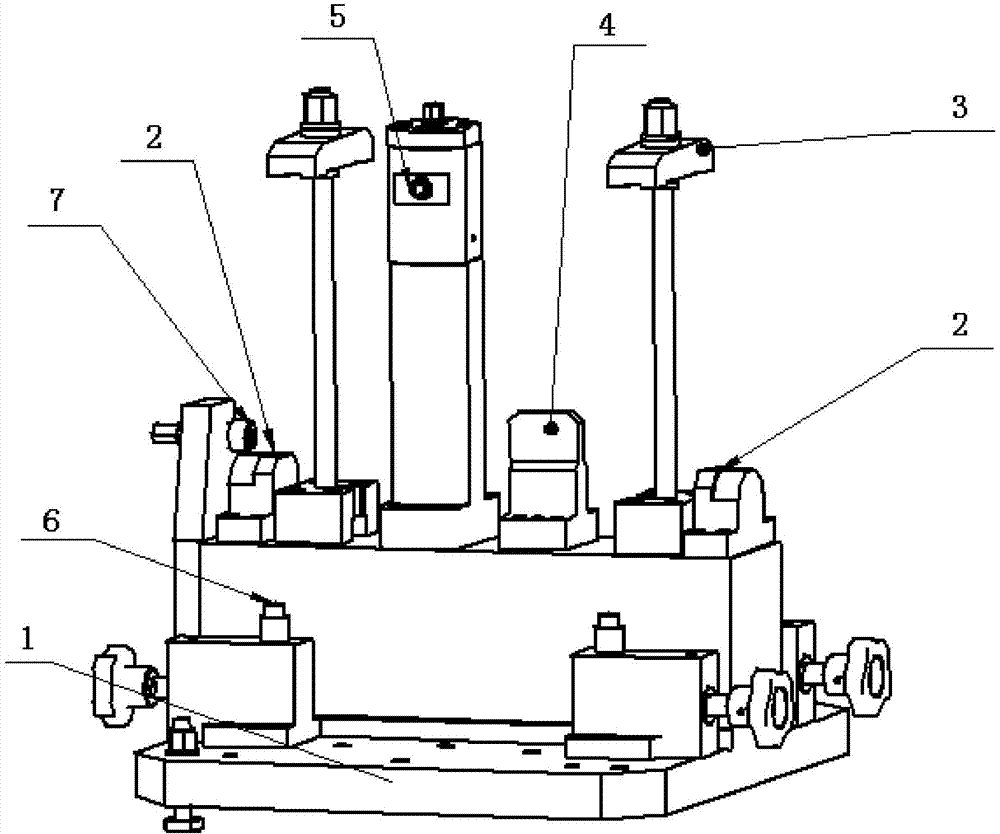

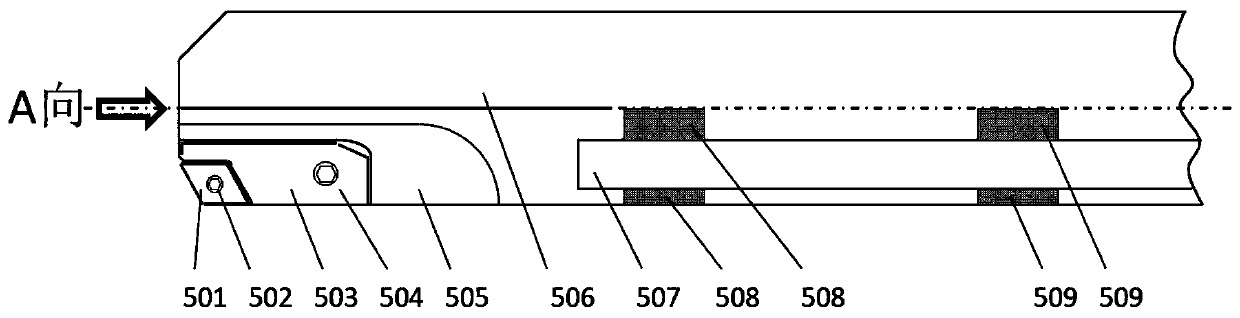

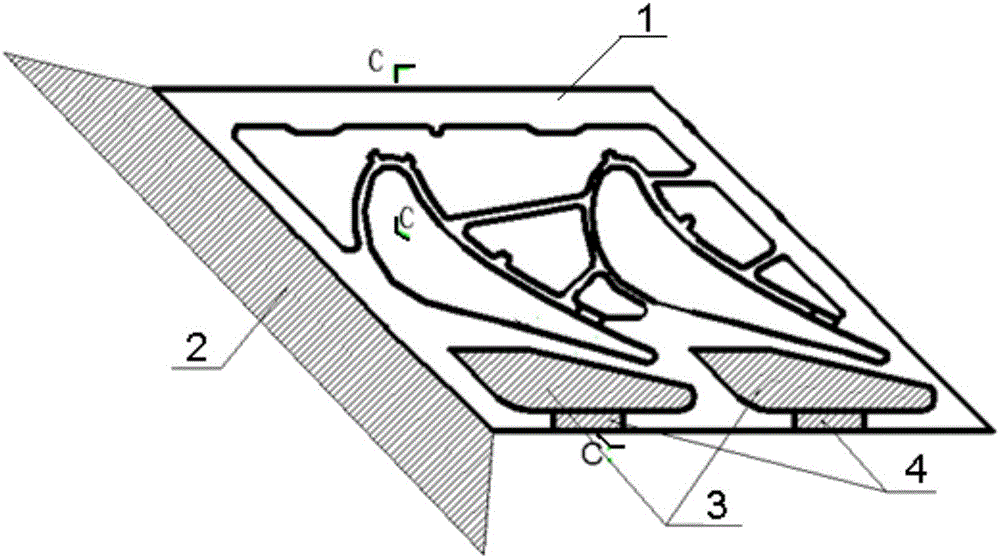

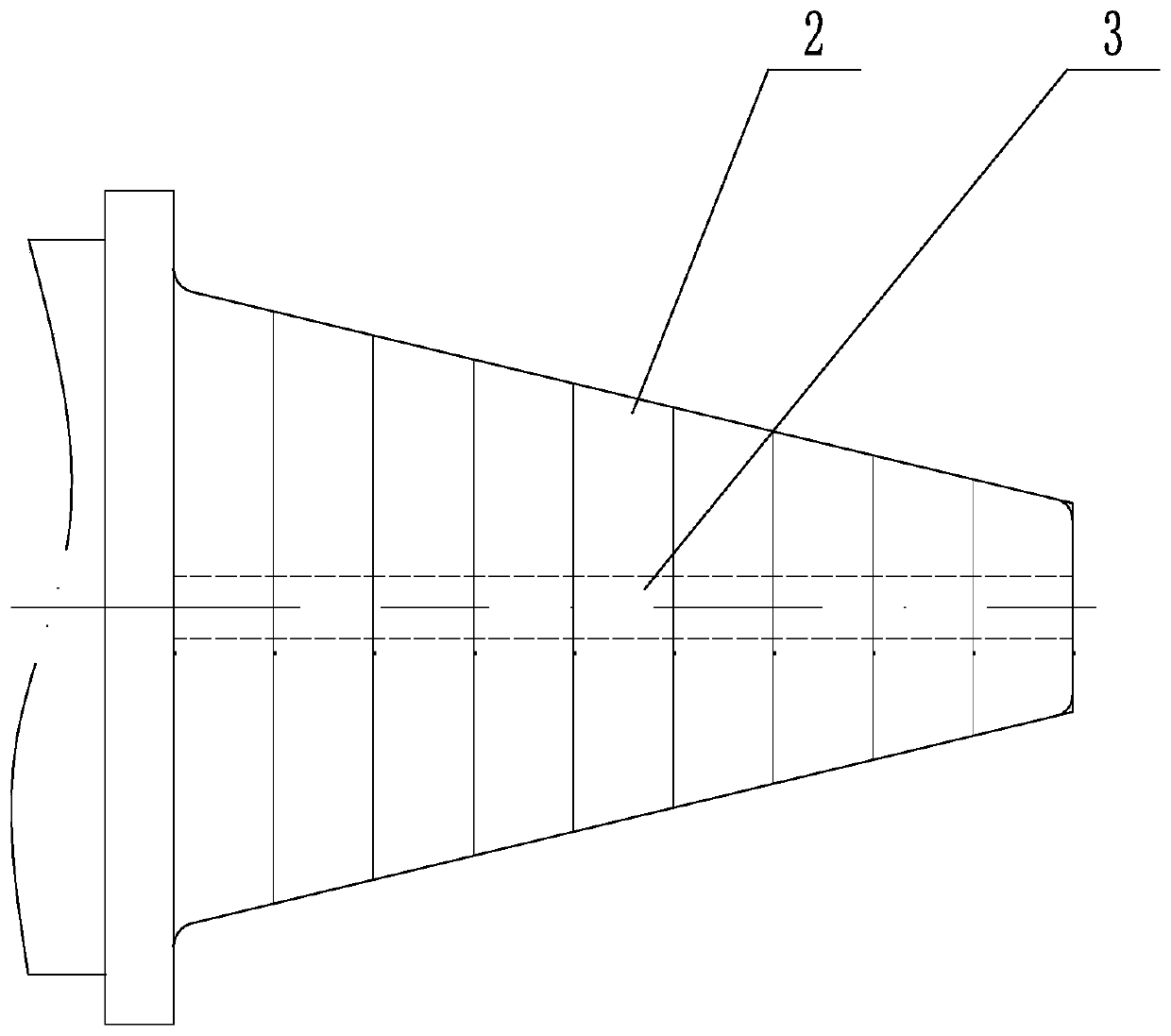

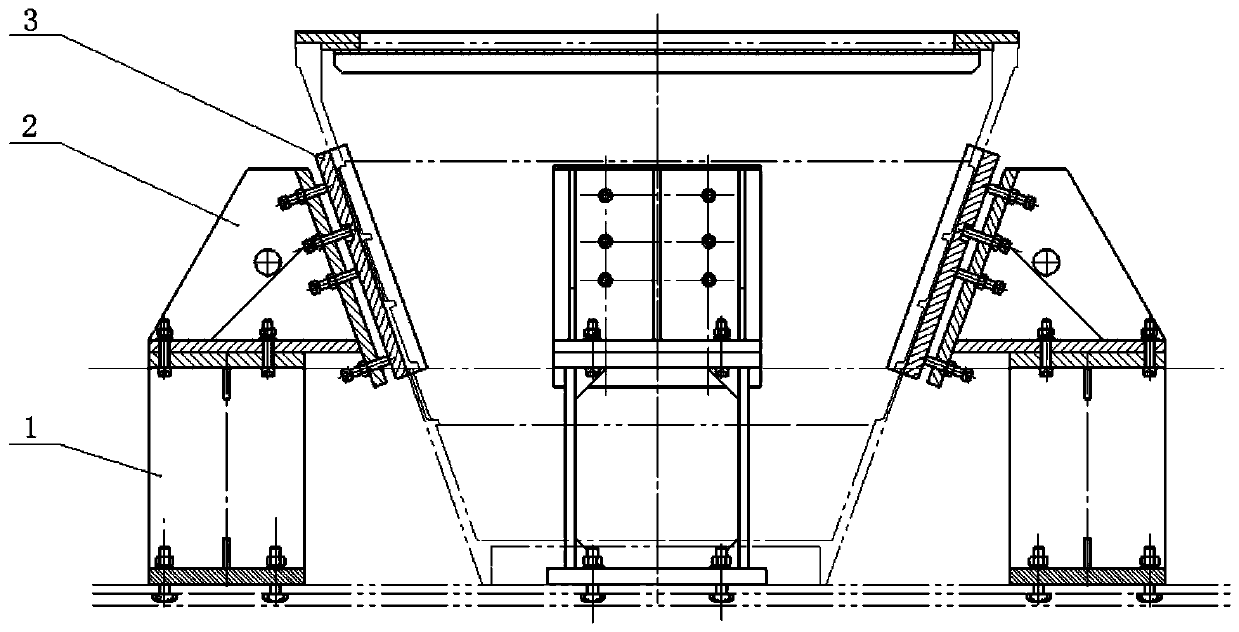

Processing method of large-scale thin-wall cabin shell body and clamp

ActiveCN106425303AFeature Margin UniformQuick fixPositioning apparatusMetal-working holdersEngineeringProcess efficiency

The invention relates to a processing method of a large-scale thin-wall cabin shell body. The processing method comprises the steps of 1, reserving a criterion boss on the shape of the shell body when casting the shell body, conducting rough machining on the lineation criterion, leveling a front and back end surfaces of the shell body, and conducting rough machining on the front and back end surfaces of the shell body; 2, conducting rough machining on shape and an inner cavity of the shell body according to the processing criterion in the step 1, conducting aging treatment after the rough machining, and detecting form and location tolerance deformation quantities of the shell body before and after the aging treatment; 3, analyzing remaining quantities of various parts of specially shaped end of the shell body according to a deformation rule of the shell body, judging whether there is a need to borrow quantity, finishing semi-finishing on the shape and the inner cavity of the shell body, and conducting aging treatment after the semi-finishing; 4, detecting the form and location tolerance deformation quantities before and after the aging treatment of the shell body in the step 4, further figuring out the deformation rule of the shell body, and finishing finish machining of the shell body; 5, finally detecting all the sizes of the shell body and storing the shell body into a storage after the shell body is qualified. The invention also relates to a clamp used according to the method. The processing method can improve sharply processing efficiency, guarantee the quality of a product, causes a small processing deformation, and can guarantee the homogeneity of shell wall thickness.

Owner:航天科工哈尔滨风华有限公司

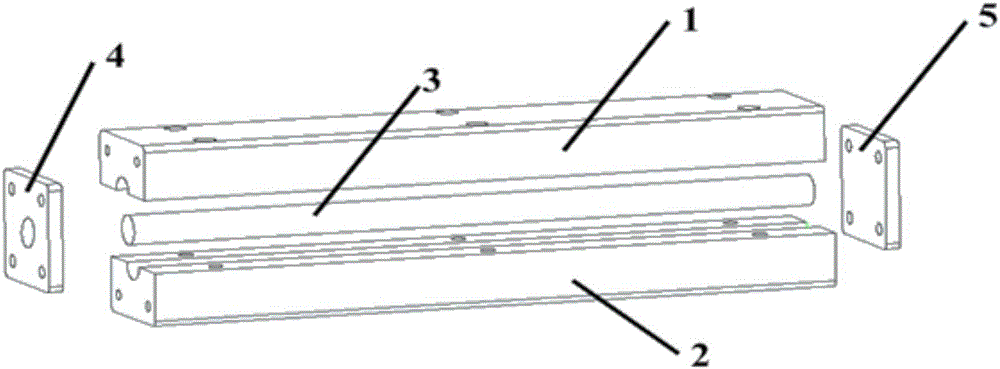

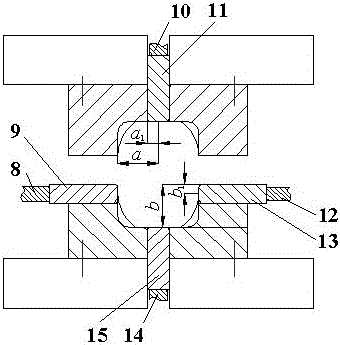

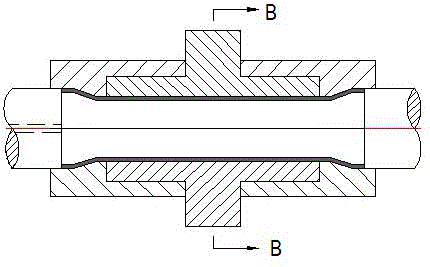

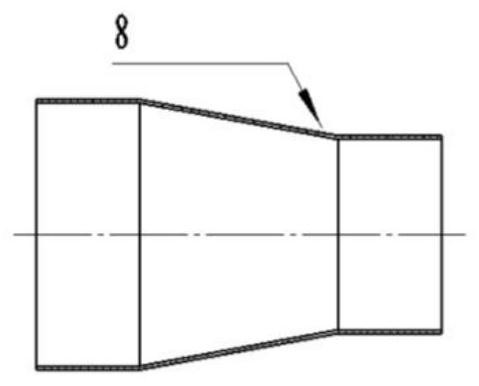

Forming mold and method for composite material pipe fitting

InactiveCN106182804AGuaranteed wall thickness uniformityGood internal qualityTubular articlesMetalProduct design

The invention provides a molding die and a molding method for composite material pipe fittings. The molding die includes a metal outer mold, a core mold and a connection structure arranged at both ends of the metal outer mold; a through hole is arranged in the middle of the metal outer mold, and the core The mold is arranged in the through hole; the metal outer mold is composed of an upper metal outer mold and a lower metal outer mold; the core mold includes a core material layer and a nylon bag film layer sleeved on the outer surface of the core material layer. Composite material pipe fittings prepared by the molding method of the present invention have lower production cost, higher internal quality, and better product thickness uniformity compared with traditional molding techniques, and can shape pipe fittings of various shapes according to product design drawings.

Owner:SHANGHAI COMPOSITES SCI & TECH CO LTD

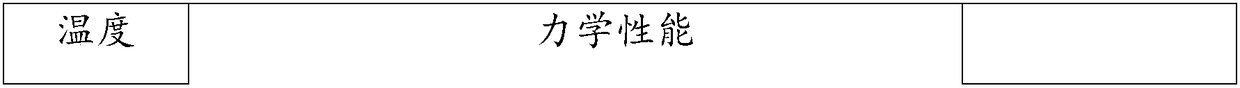

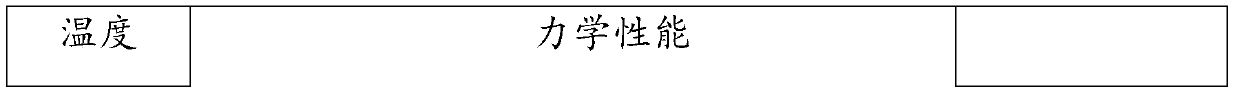

Precision casting forming technology for high-strength aluminum alloy of large thin-walled wing body fusion special-shaped cabin shell

PendingCN111230068AQuality assuranceTroubleshoot less intense technical issuesNumerical controlMachining deformation

The embodiment of the invention discloses a precision casting forming technology for a high-strength aluminum alloy of a large thin-walled wing body fusion special-shaped cabin shell. The technology comprises the following steps of casting a ZL205A high-strength aluminum alloy large thin-walled mesh rib wing body fusion cabin shell through an integral precision sand casting molding process; performing heat treatment on a large thin-walled aluminum alloy special-shaped cabin shell and controlling a deformation amount by adjusting parameters in a heat treatment process to form a high-performancecasting after the heat treatment; and performing numerical control machining on the casting which is subjected to the heat treatment, and controlling the deformation amount through integral surrounding layered cutting cycle machining, three-dimensional photographing scanning, datum transforming and the like in a numerical control machining process, so that precision machining deformation controlof a large thin-walled weakly rigid special-shaped complex cabin product is completed. Through the technology, series of key technical problems that the conventional aluminum alloy casting forming process cannot realize ZL205A high-strength aluminum alloy precision casting and the heat treatment of a large thin-walled weakly rigid mesh rib special-shaped cabin body, and the machining deformation is difficult to control are solved.

Owner:HUBEI SANJIANG AEROSPACE GRP HONGYANG ELECTROMECHANICAL

Manufacturing method for ultra-long thin-wall aluminum alloy sandwich grid rib double-skin integral tail fin

ActiveCN109332998AQuality assuranceGuaranteed wall thickness uniformityNumerical controlHeat treated

The invention belongs to the technical field of machining and manufacturing, and discloses a manufacturing method for an ultra-long thin-wall aluminum alloy sandwich grid rib double-skin integral tailfin. The manufacturing method includes the steps that a ZL205AA high-strength aluminum alloy is used for pouring and molding the integral tail fin; heat treatment is carried out on the integral tailfin; and numerical control machining is carried out on the integral tail fin after heat treatment. According to the manufacturing method for the ultra-long thin-wall aluminum alloy sandwich grid rib double-skin integral tail fin, the overall quality of precision molding, machining and manufacturing can be improved, and the manufacturing cycle is shortened while the manufacturing cost is lowered.

Owner:HUBEI SANJIANG AEROSPACE GRP HONGYANG ELECTROMECHANICAL

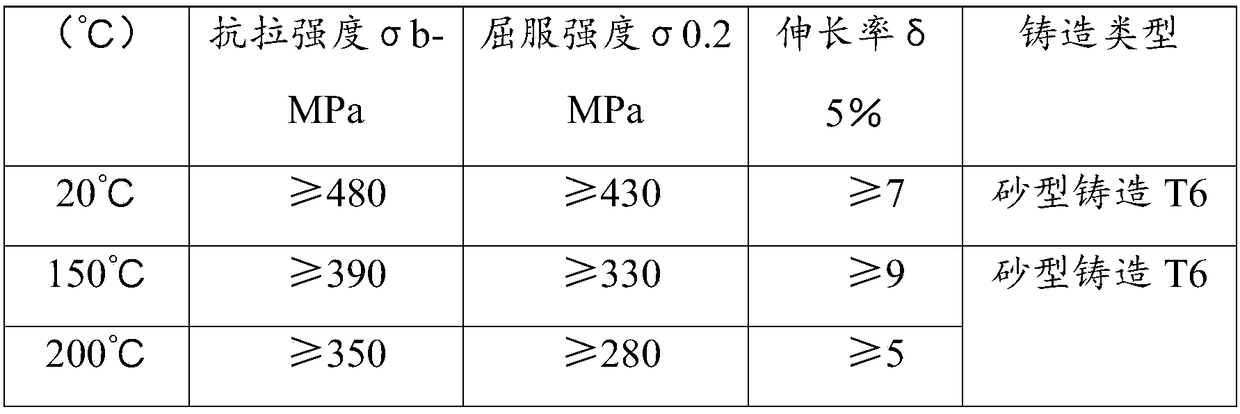

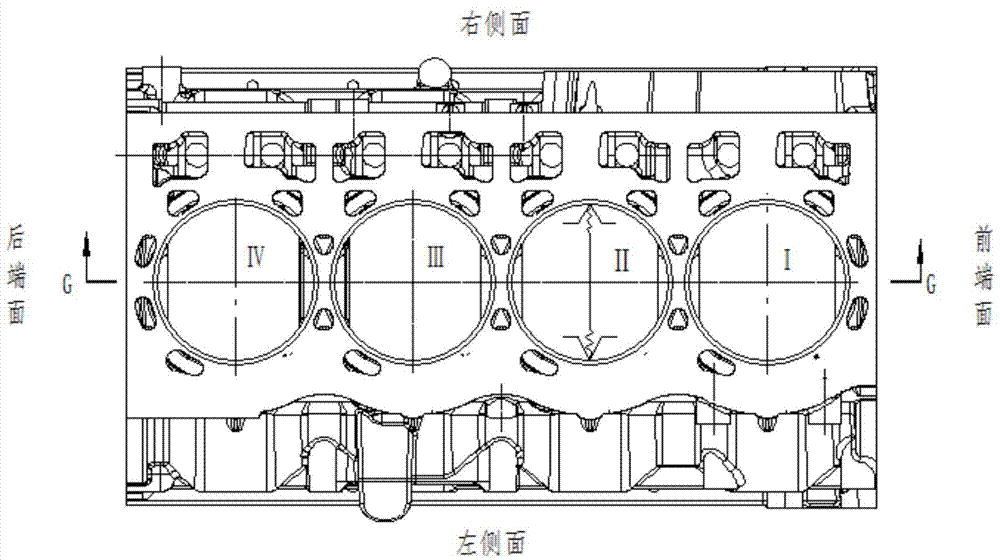

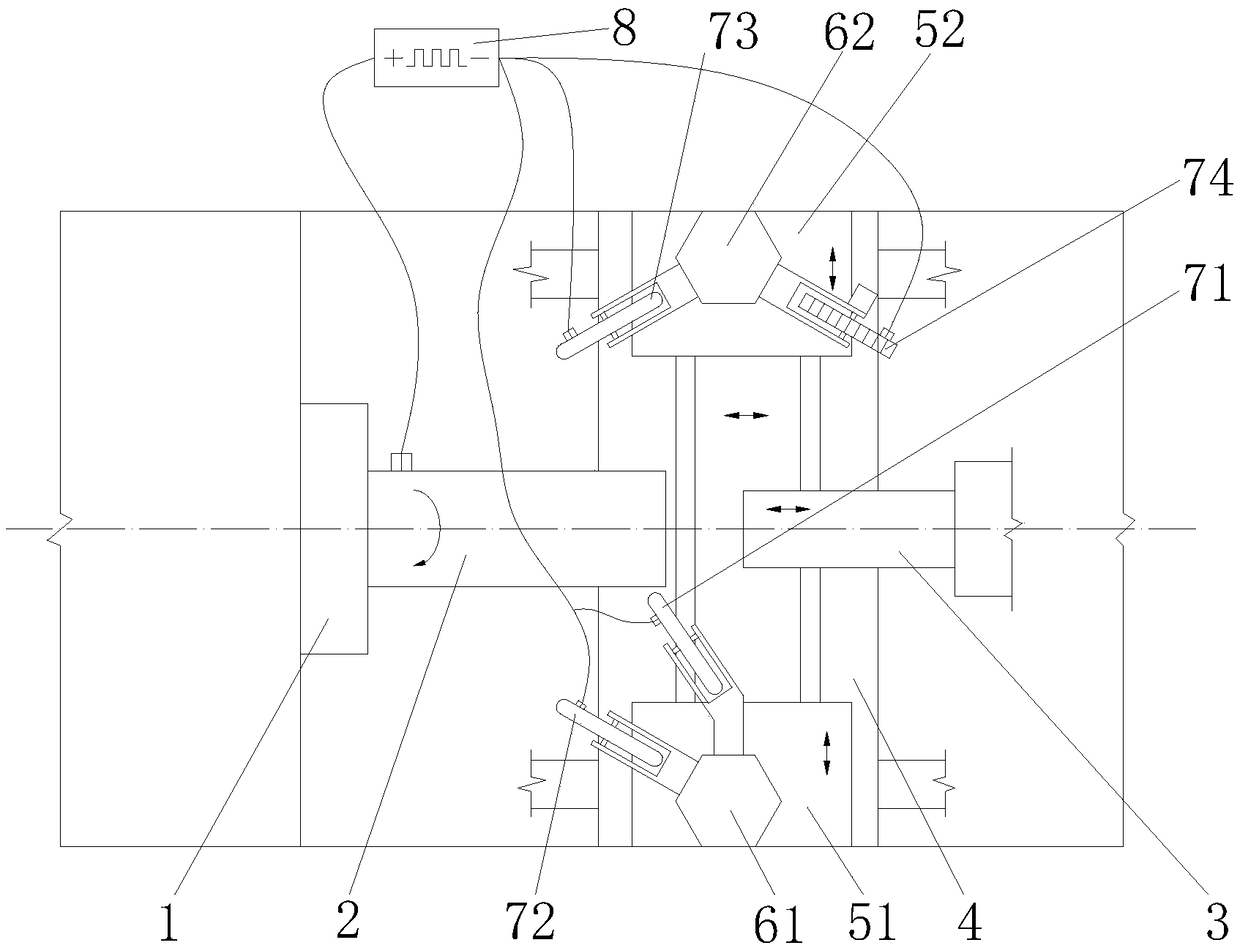

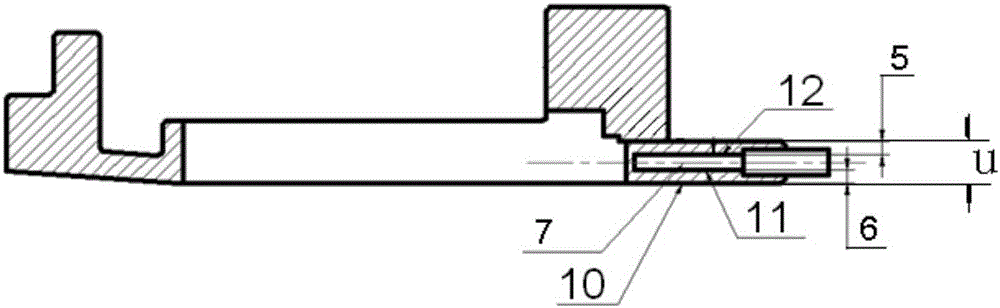

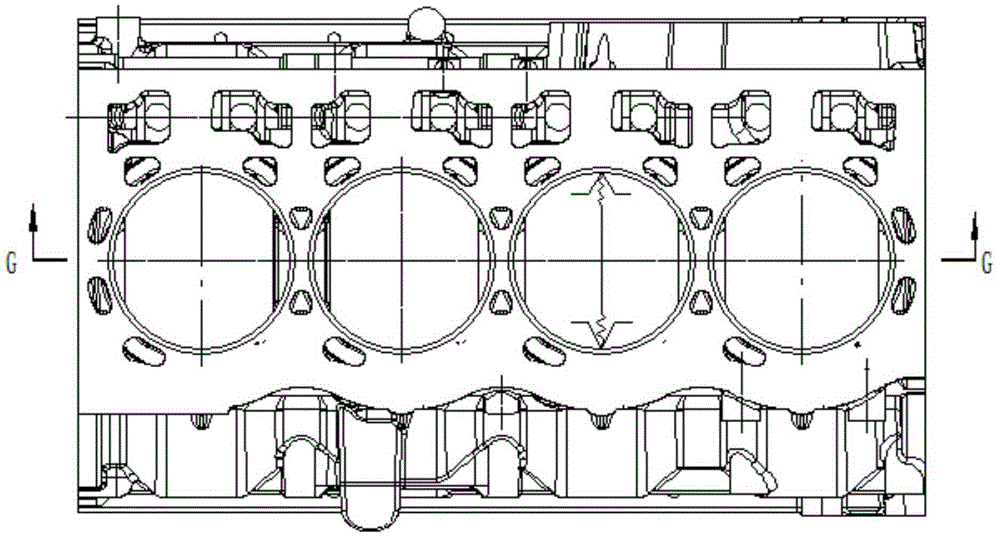

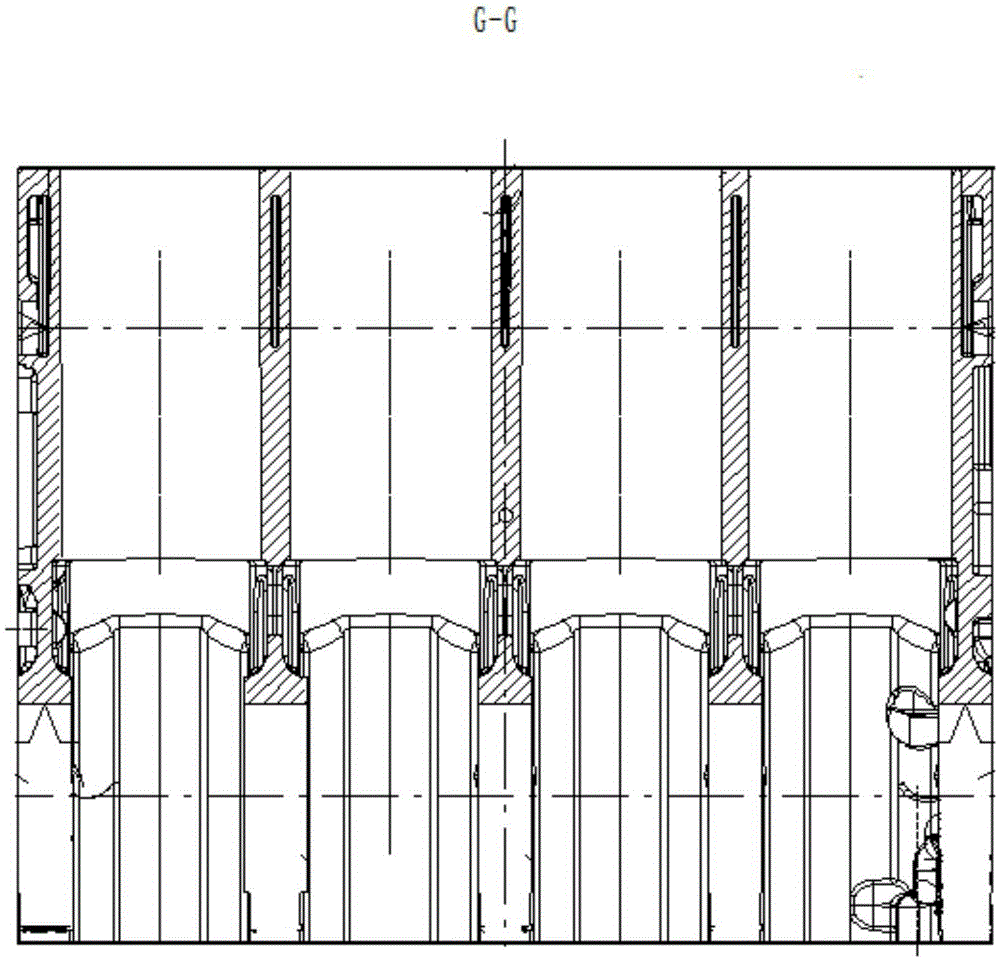

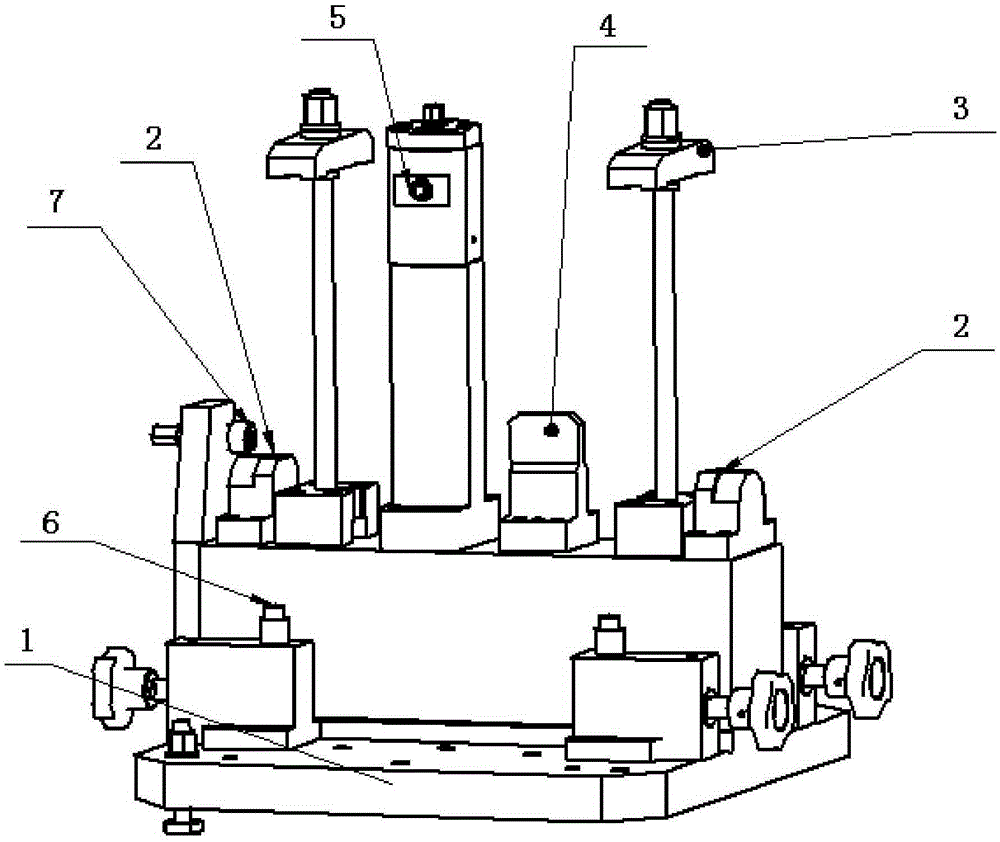

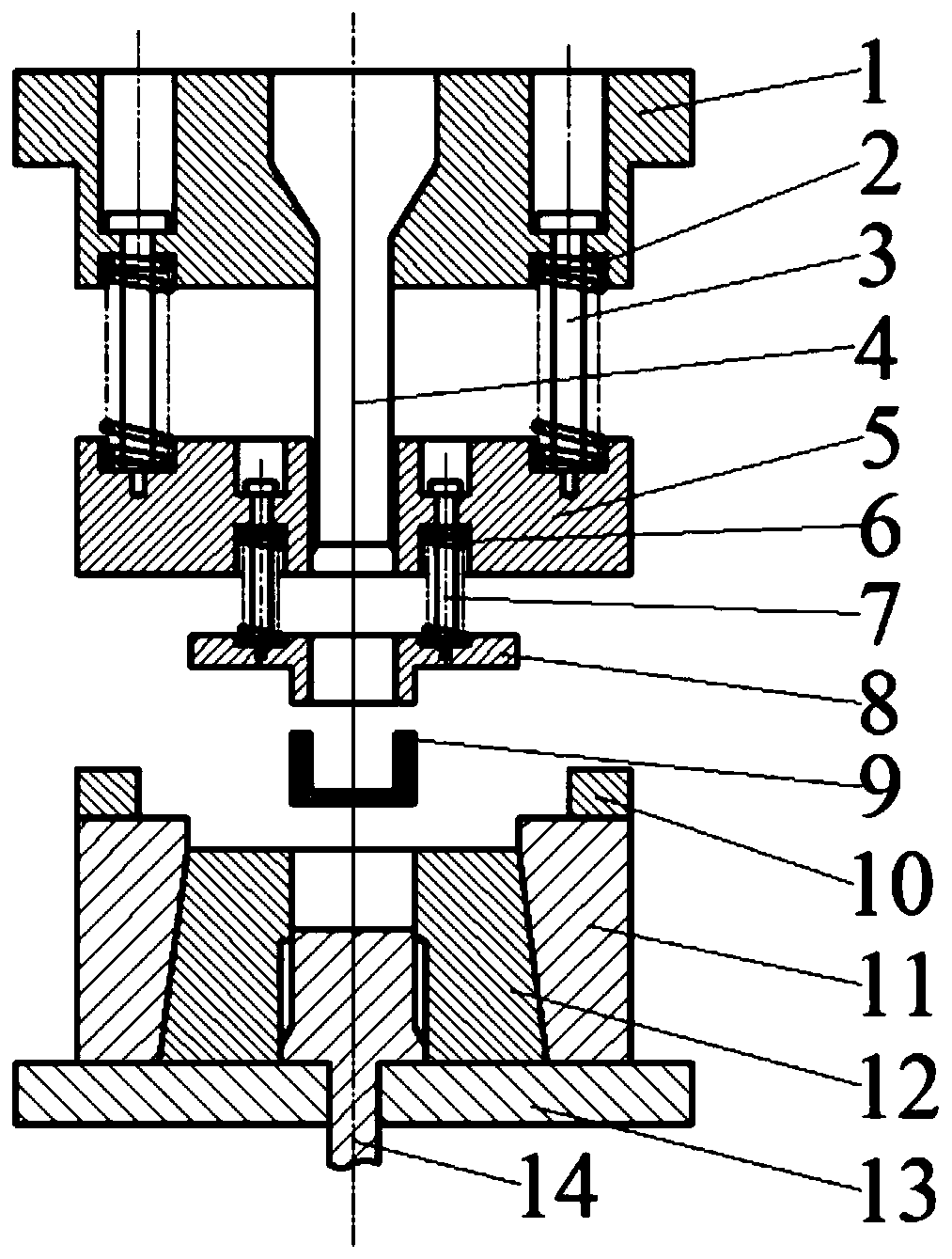

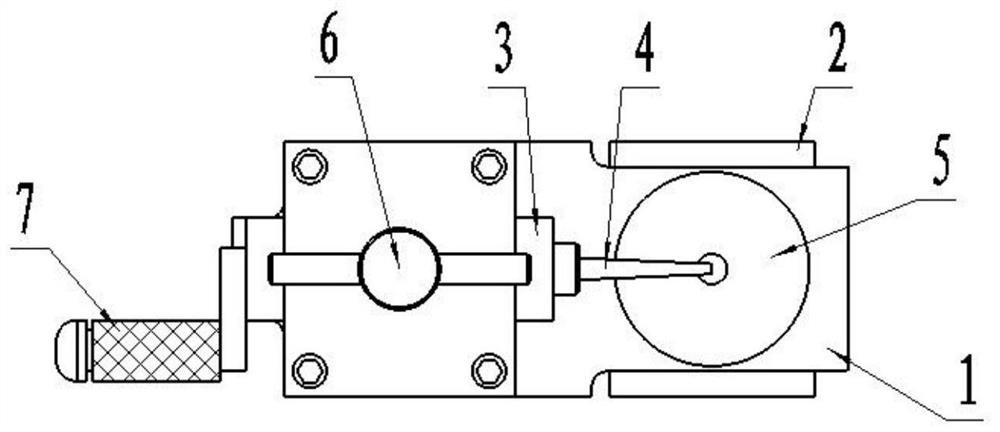

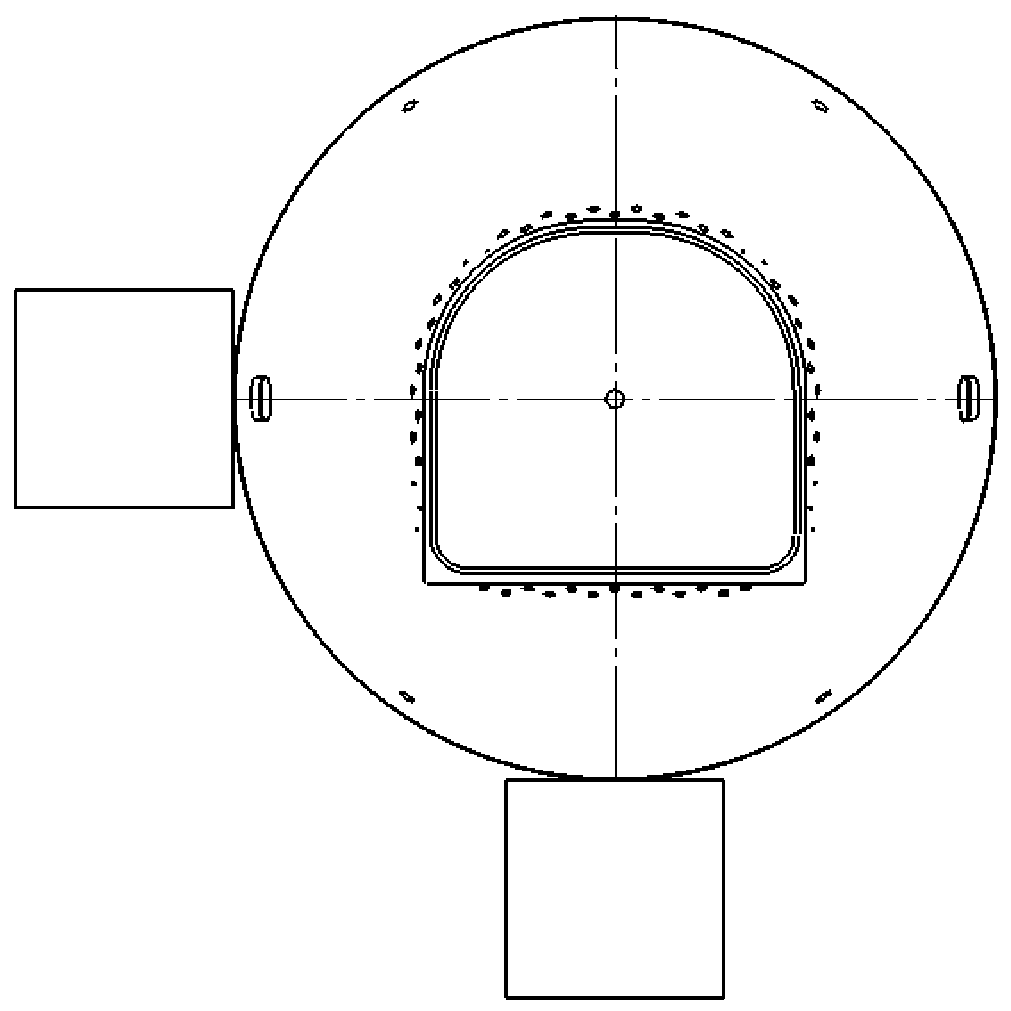

Air cylinder clamp

ActiveCN103753271ASimple structureRealize precise machiningPositioning apparatusMetal-working holdersPulp and paper industryMachining

The invention discloses an air cylinder clamp. The air cylinder clamp comprises a base, spindle hole semicircular location blocks, clamping units and a cylinder hole slider linkage opening unit. Location end surface matched with to-be-located air cylinder front and rear stop spindle semicircular holes are arranged on the spindle hole semicircular location blocks. The clamping units are arranged on base location bosses on the inner sides of the spindle hole semicircular location blocks and comprise clamping supports, T-shaped screw pairs and clamping pressing blocks. A middle block bearing stop location block is provided with air cylinder bearing block location sides. The cylinder hole slider linkage opening unit comprises a base column and a cylinder hole slider component arranged at the top end of the base column. The air cylinder clamps clamp the air cylinder from the end and the sides, the measurement probe spot measurement function of a machining center spindle is used for finding reference coordinate values of machining of air cylinder process location pin holes, and accordingly, accurate machining of air cylinder process location pin holes is achieved, and the air cylinder hole wall thickness uniformity is guaranteed finally.

Owner:GUANGXI YUCHAI MASCH CO LTD

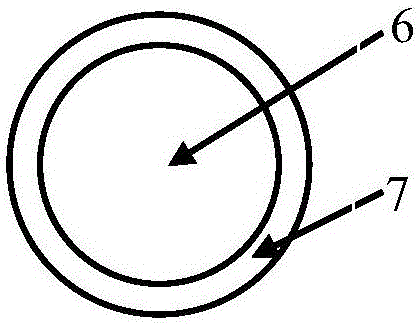

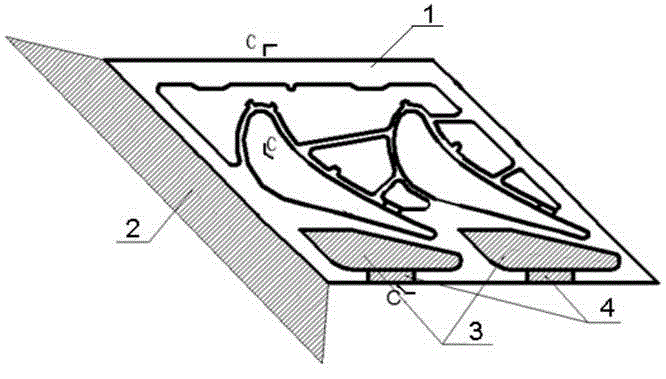

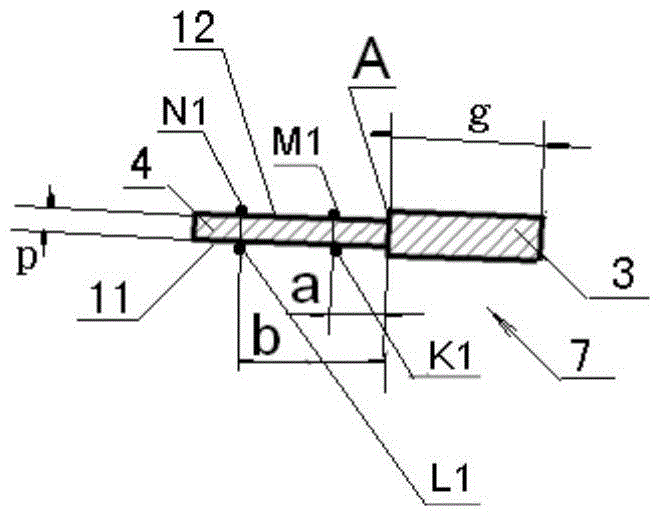

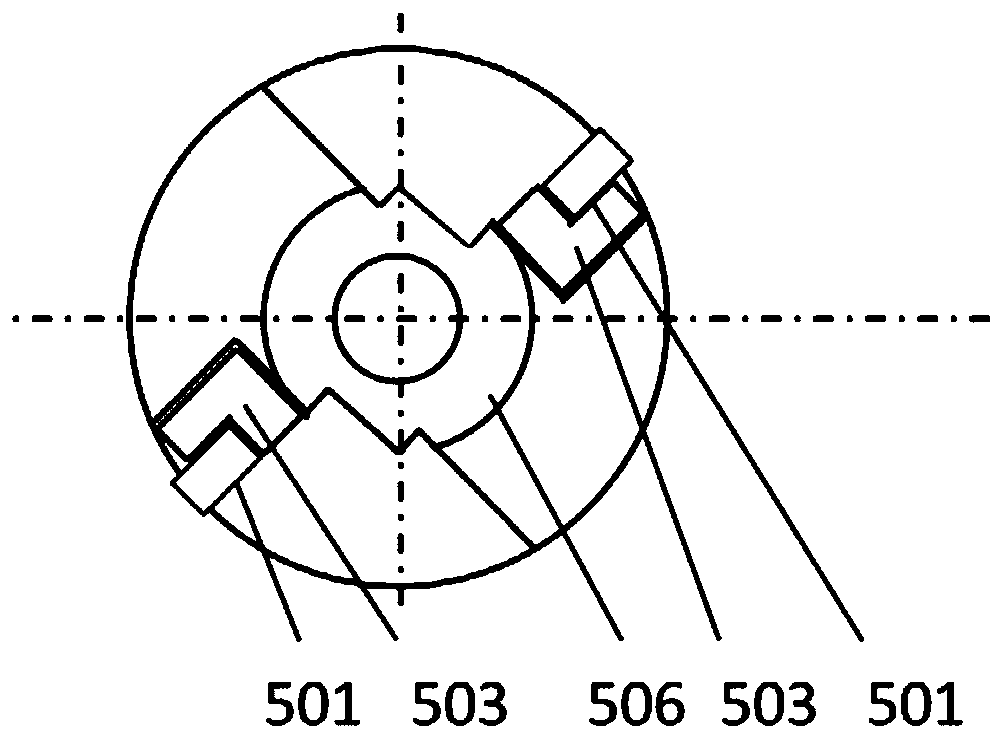

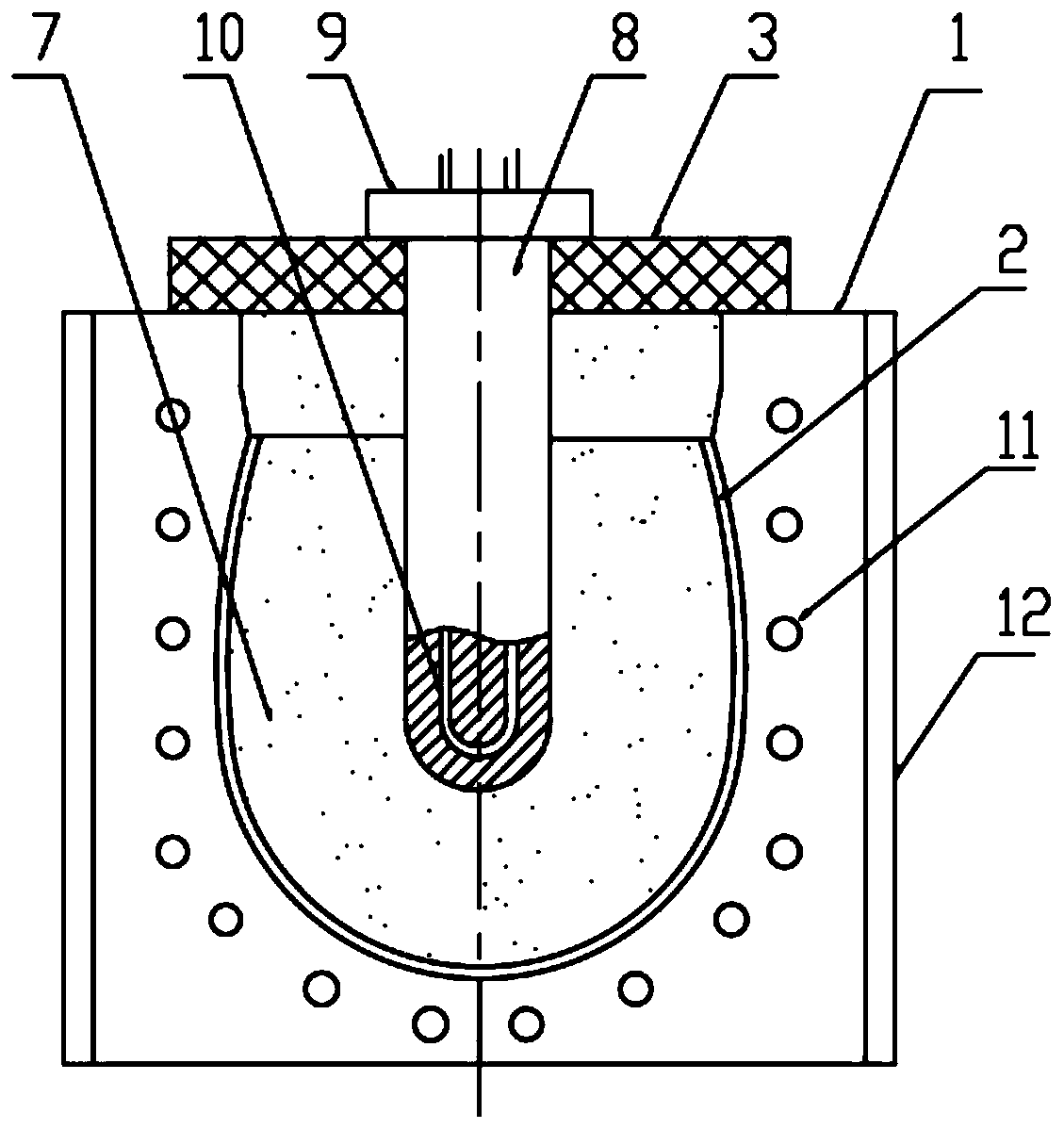

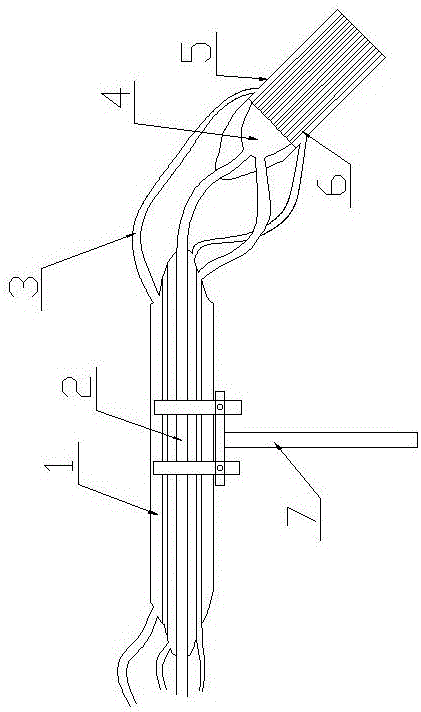

Method for controlling hollow guide blade upper edge plate cavity wall thickness

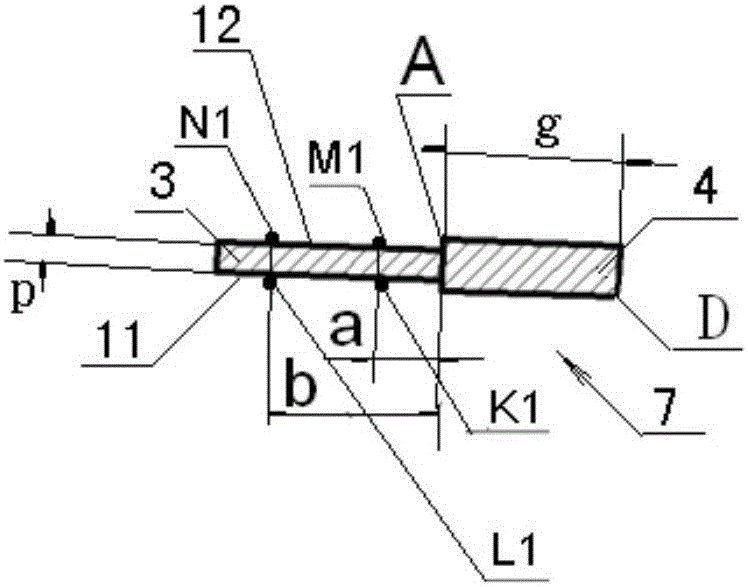

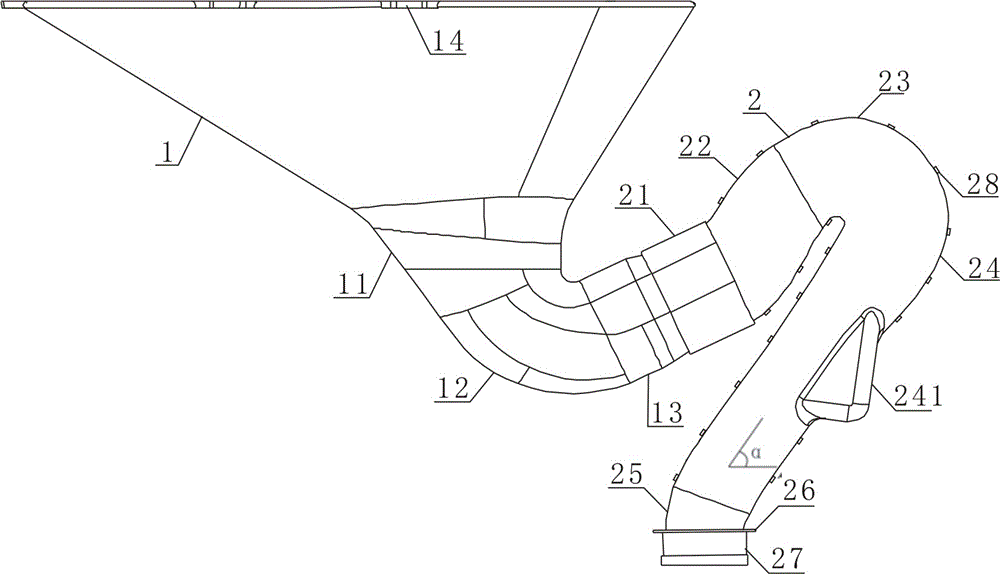

ActiveCN104923722AGuaranteed wall thickness uniformityMeet the requirements of design drawingsFoundry mouldsFoundry coresWaxInvestment casting

The invention belongs to the precise investment casting technology and relates to a method for controlling aero-engine hollow guide blade upper edge plate cavity wall thickness. The method is characterized in that the hollow guide blade upper edge plate wax pattern cavity wall thickness is changed to control casting cavity wall thickness, the front edge of the core body (3) of a ceramic core (7) is allowed to tilt towards a non-runner face, and the included angle alpha of the lower surface (11) of the core body (3) and the runner face (10) of a hollow guide blade upper edge plate wax pattern is allowed to range from 0 degree 30 minutes to 1 degree. By the method, hollow guide blade upper edge plate casting wall thickness evenness at hollow parts is guaranteed, design drawing requirements are satisfied, oversize and scrap are avoided, production yield is increased, and production cost is lowered.

Owner:AECC AVIATION POWER CO LTD

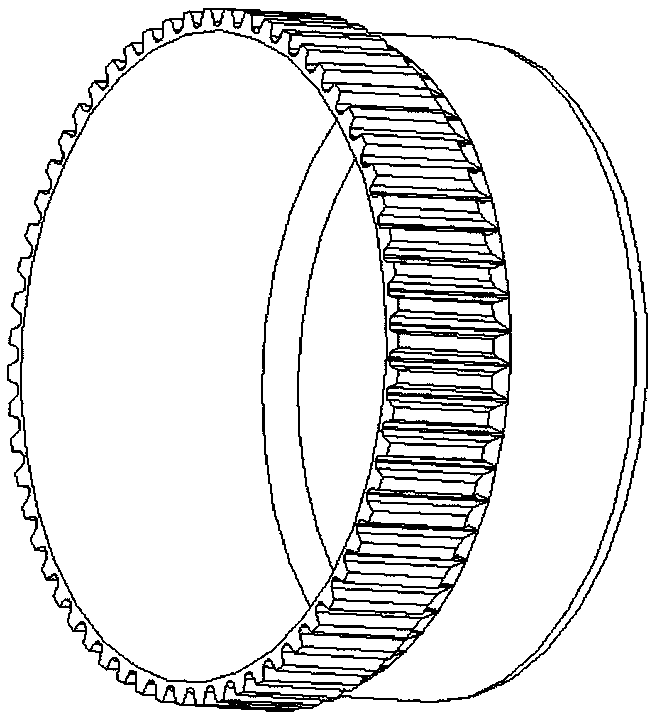

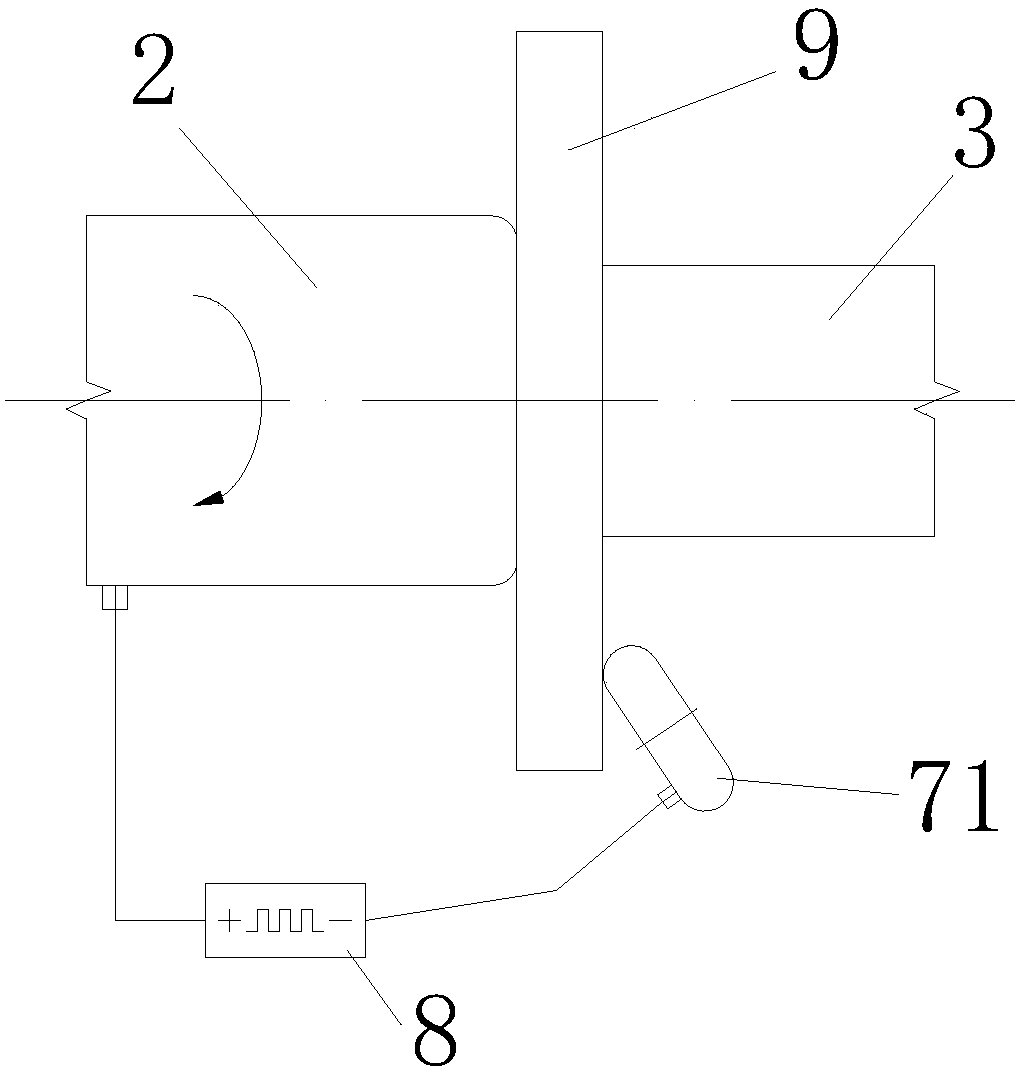

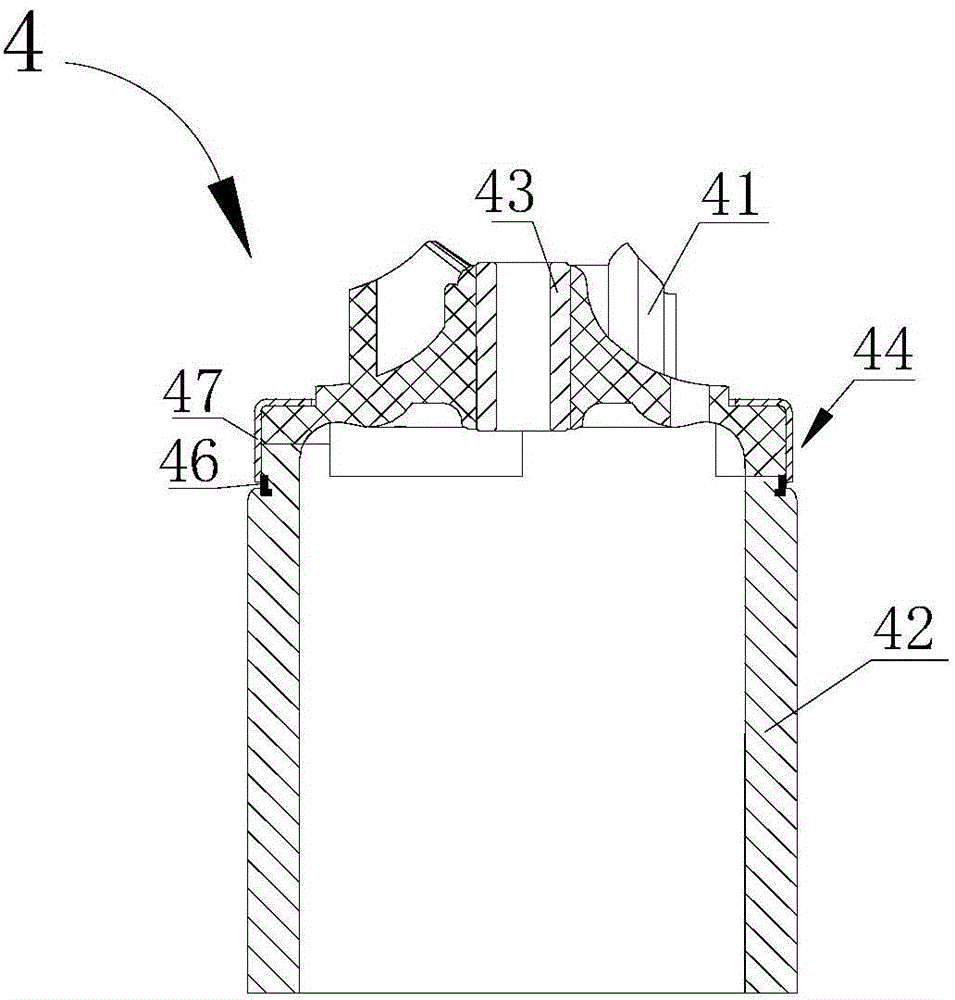

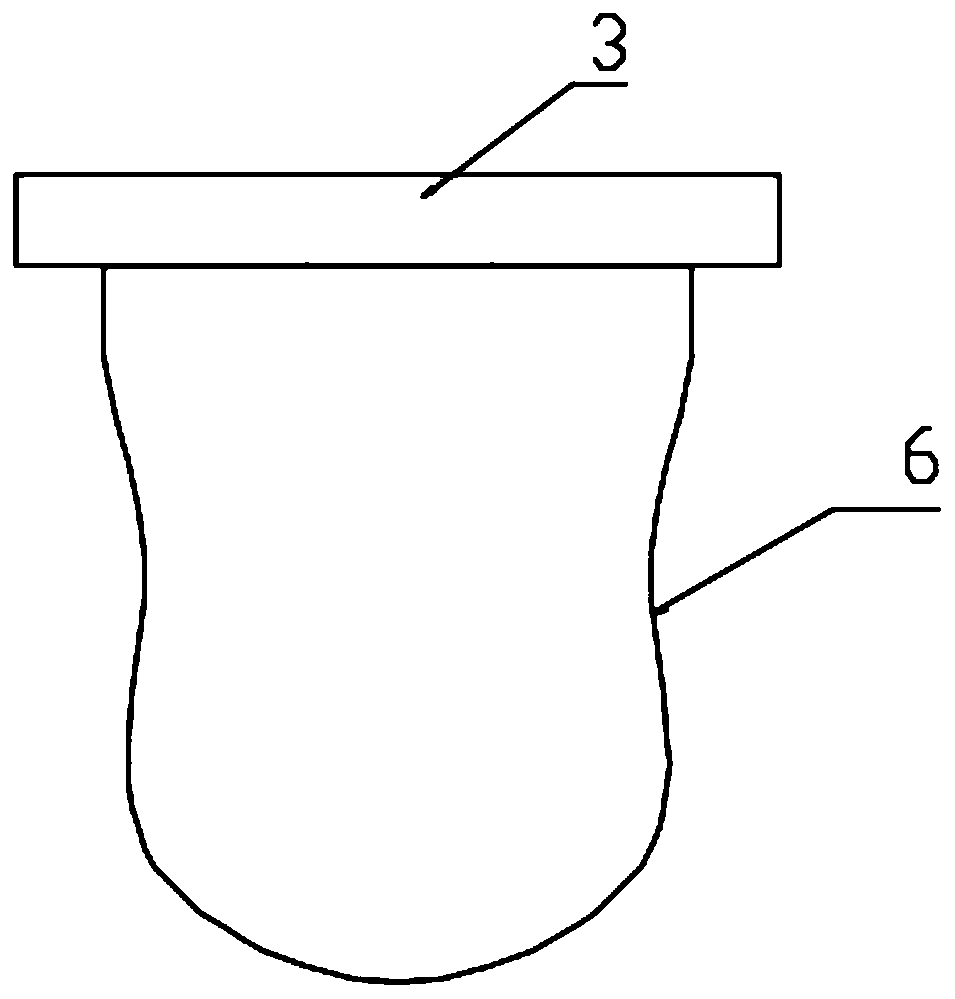

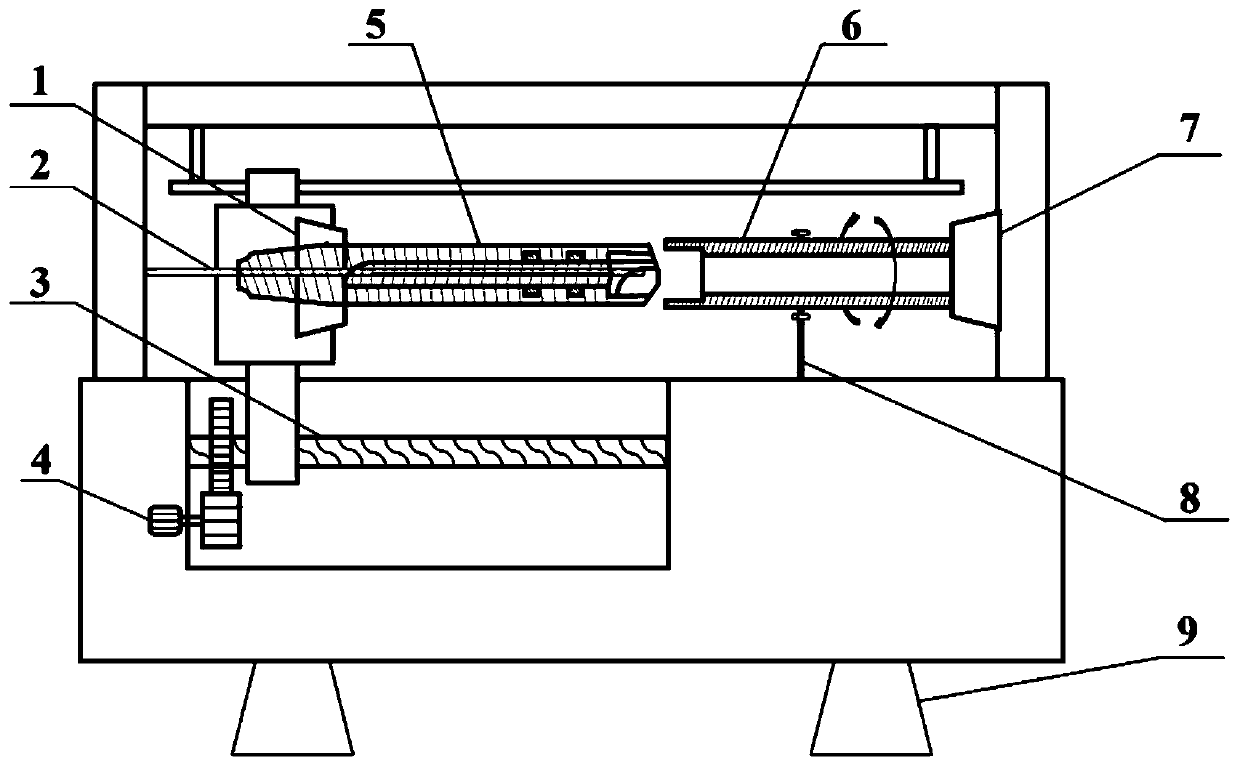

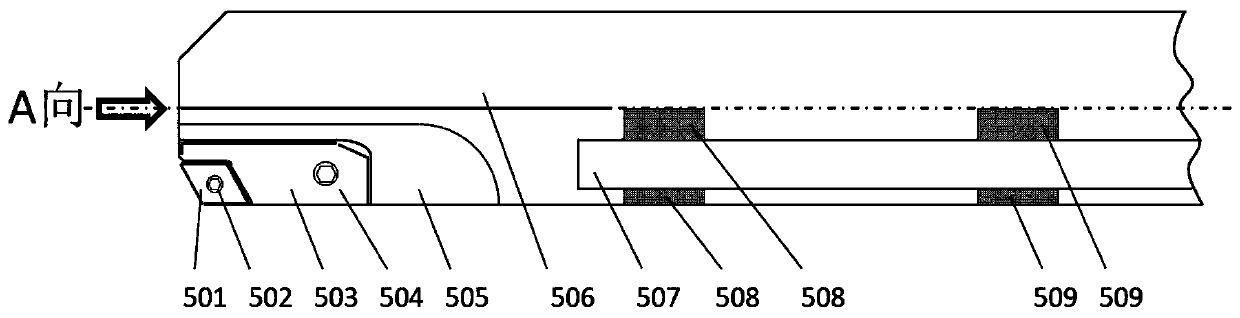

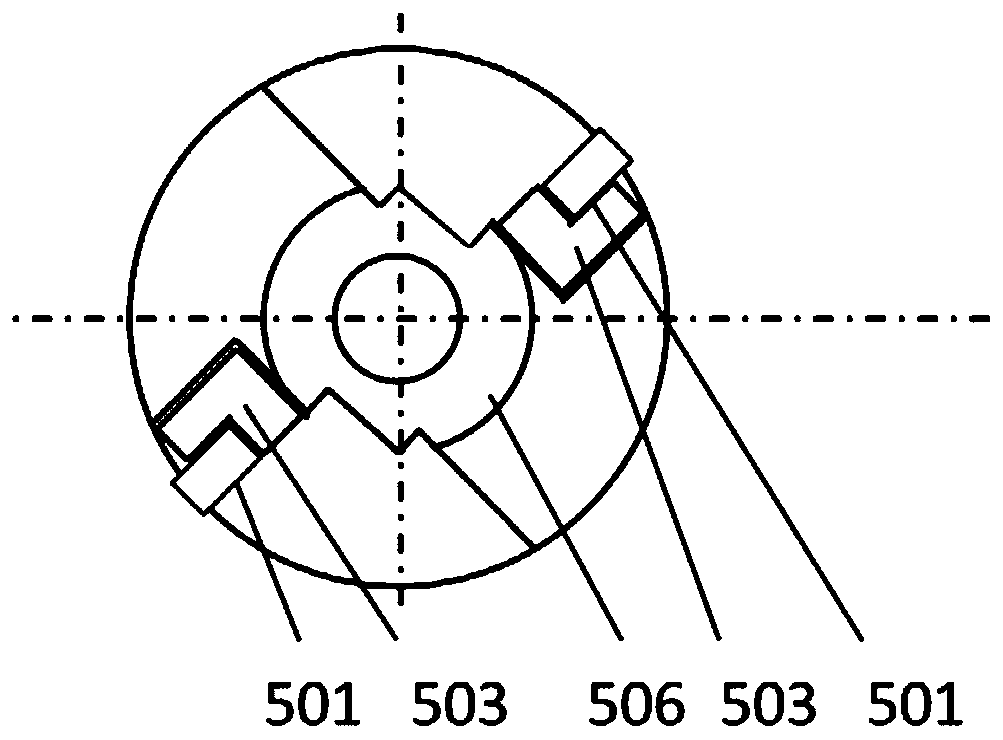

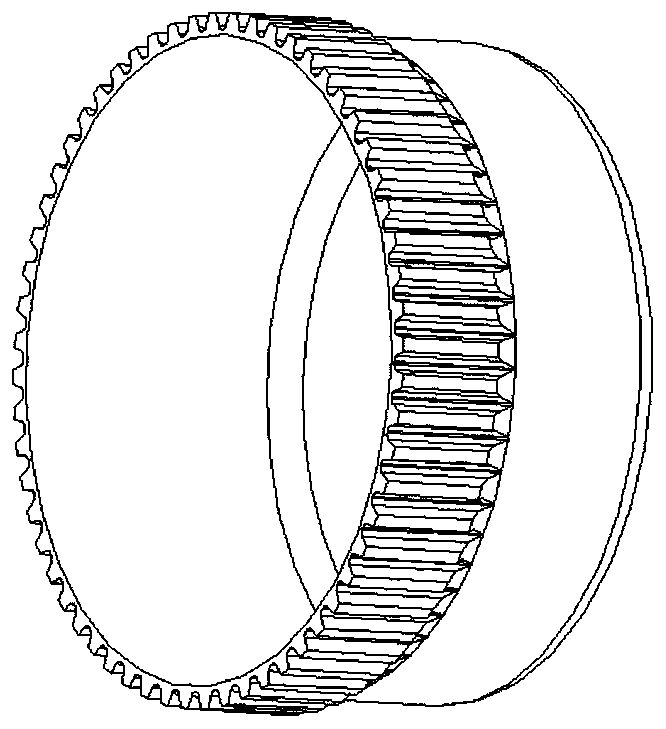

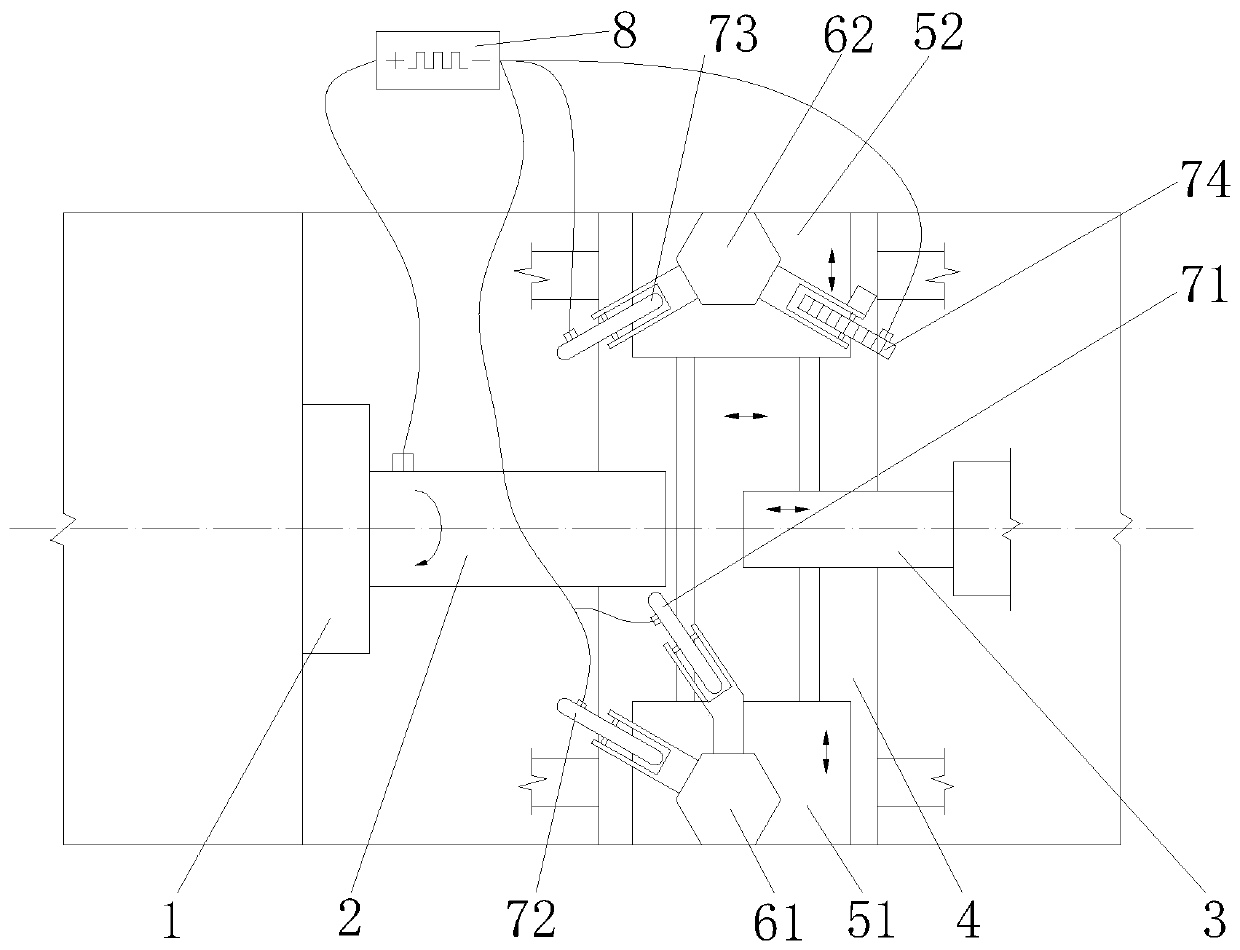

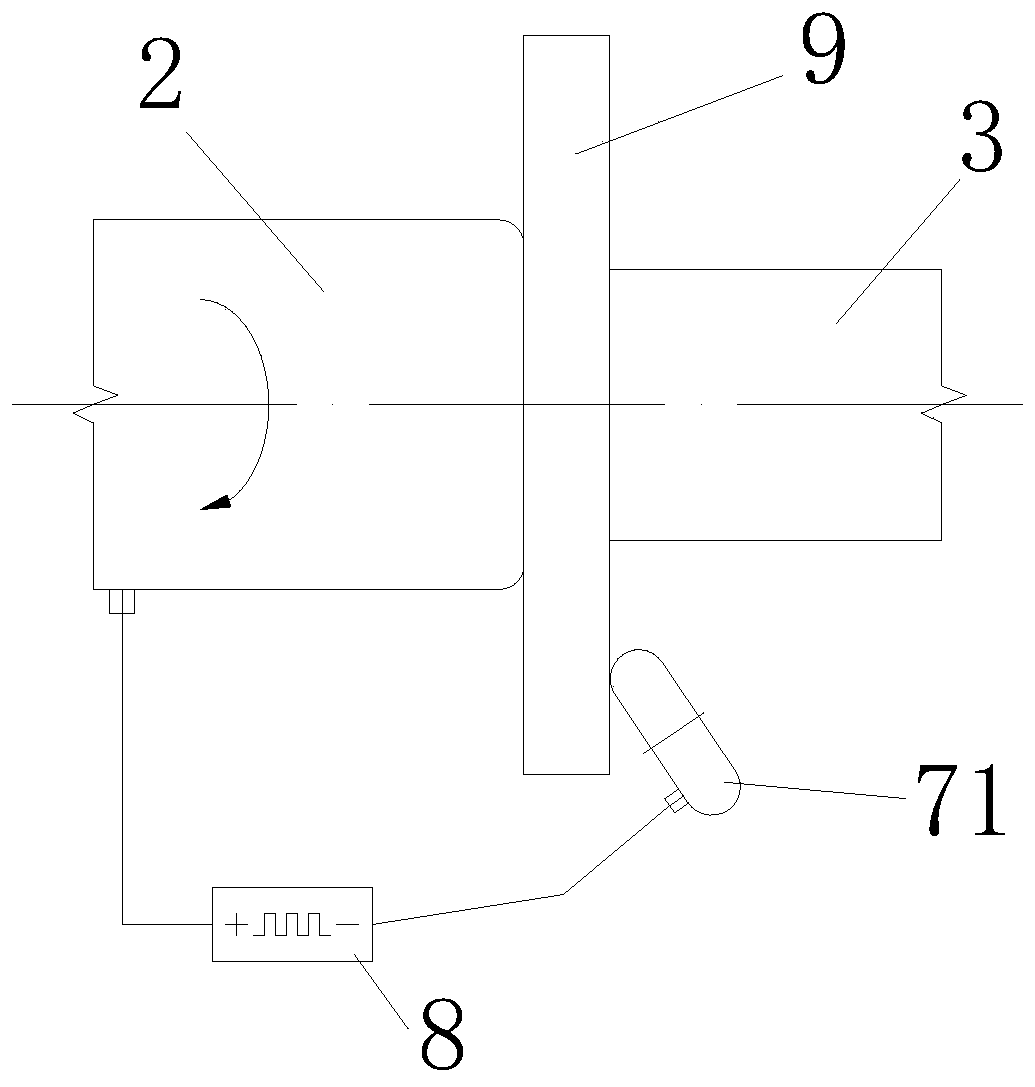

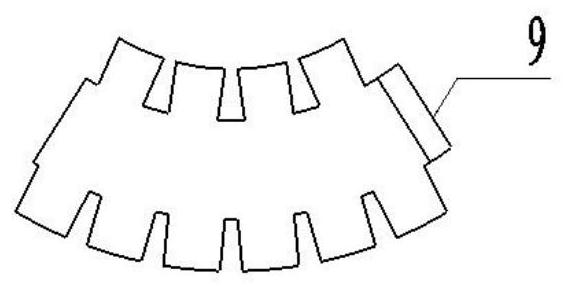

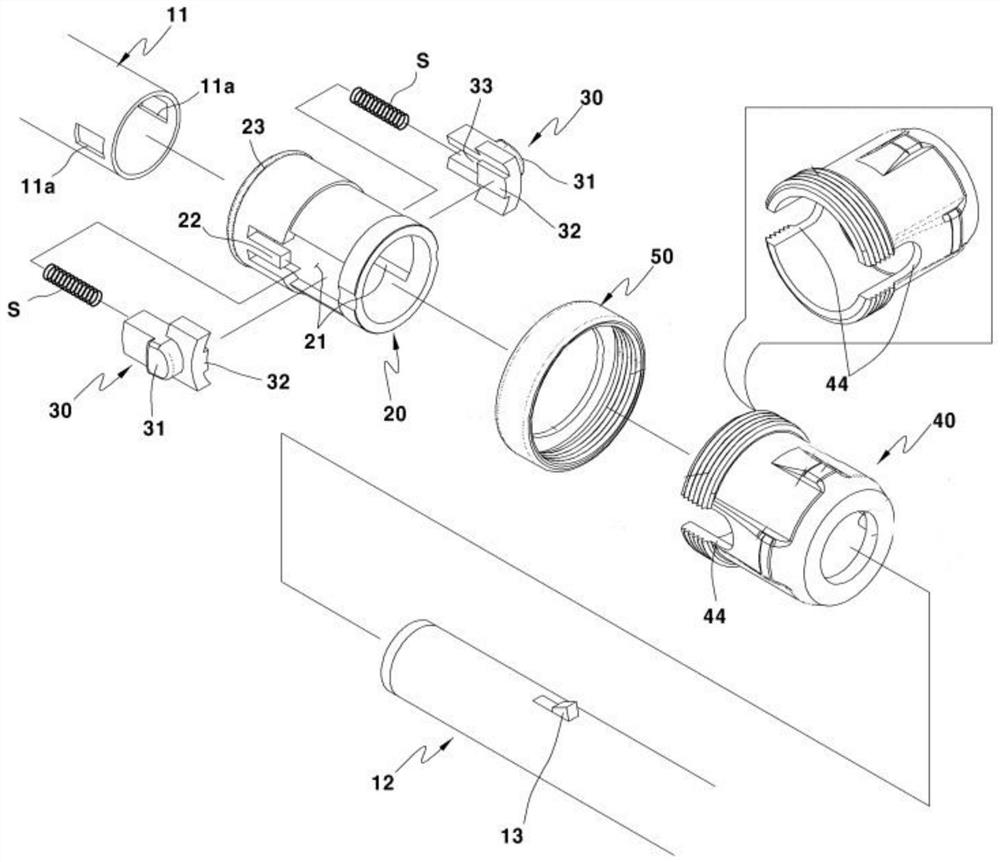

Preparation method of cup-shaped flexible wheel and device thereof

ActiveCN109351836AReduce intensityReduced fatigue lifeShaping toolsEngineeringMechanical engineering

The invention discloses a preparation method of a cup-shaped flexible wheel and a device thereof. A circular slab is tightened at the end of a core die by a tail top. A positive wire of a pulse powersupply is connected with the core die, and a negative wire is directly connected with each rotary wheel of a rotary wheel assembly. The circular slab is first spun and deformed into a cup-shaped workpiece with both inner and outer walls being straight walls by one rotary wheel. Then the cup-shaped workpiece is spun and deformed into two thickened cup-shaped workpieces with different straight wallthickness by another two rotary wheels, and a thicker smooth section is used as a tooth profile reserved section. Finally, the tooth profile reserved section is spun by one toothed rotary wheel to form a circle tooth profile around the outer circumference. At last, a small amount of cutting process is carried out to complete the processing process from the circular slab to the cup-shaped flexiblewheel workpiece. According to the cup - shaped flexible wheel manufacturing process based on plastic forming, streamline formed in the process of deformation can be completely retained, and the service life of parts is prolonged advantageously. The advantage of the method is more obvious for flexible wheels with an extremely small thickness.

Owner:SOUTH CHINA UNIV OF TECH

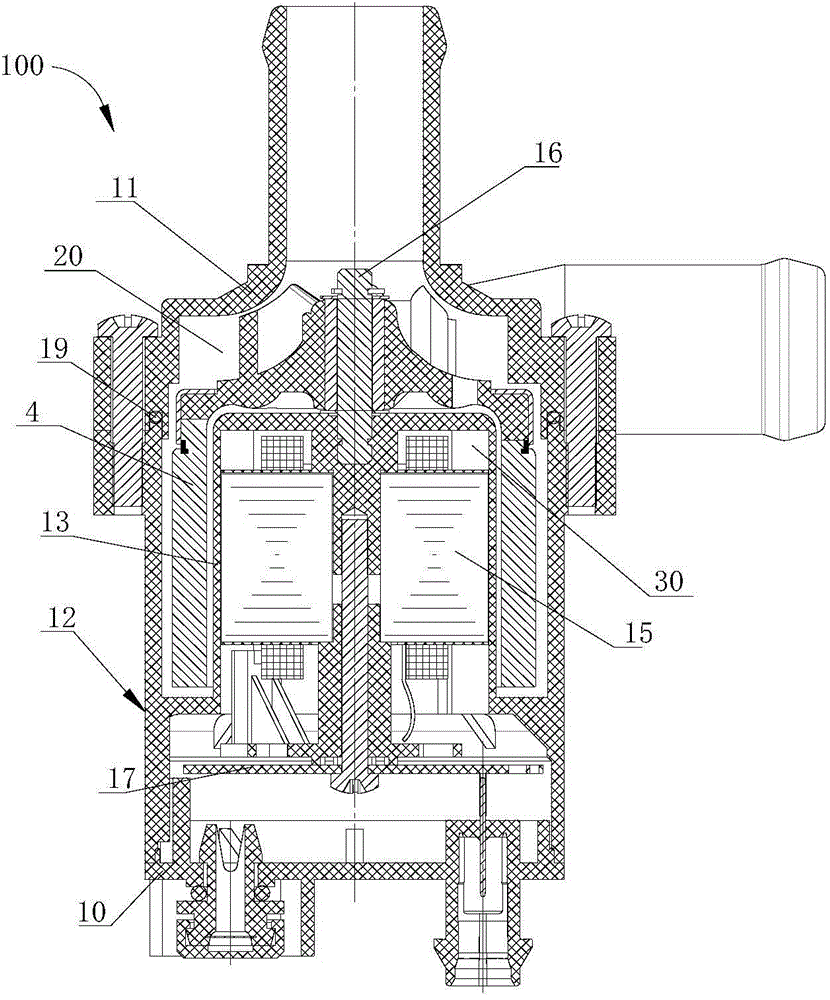

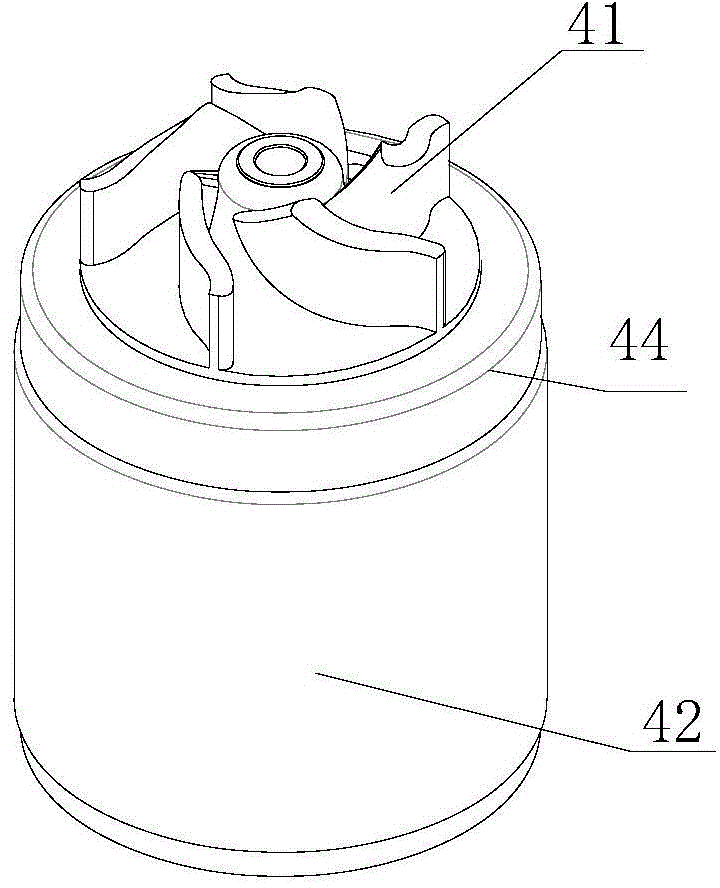

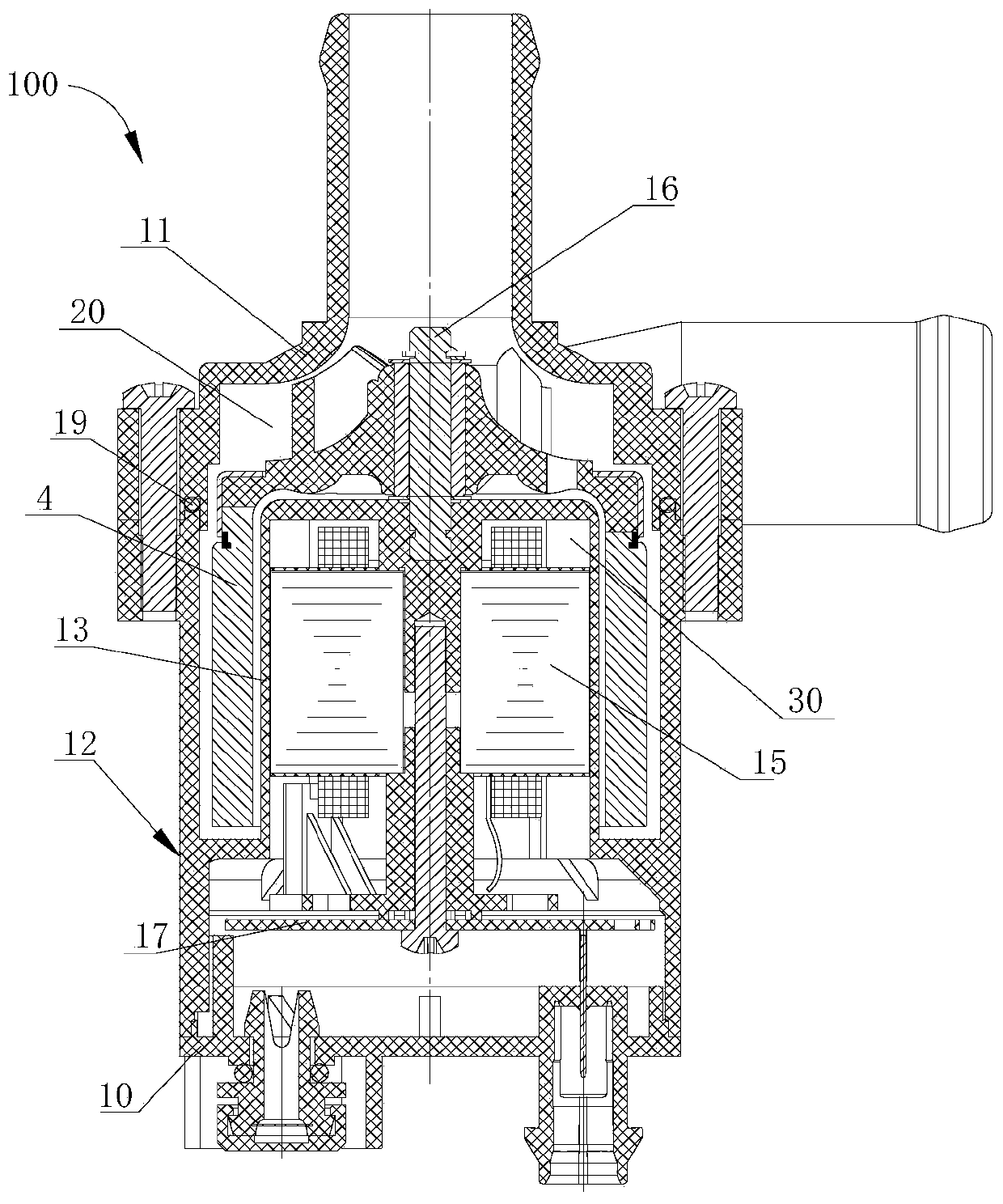

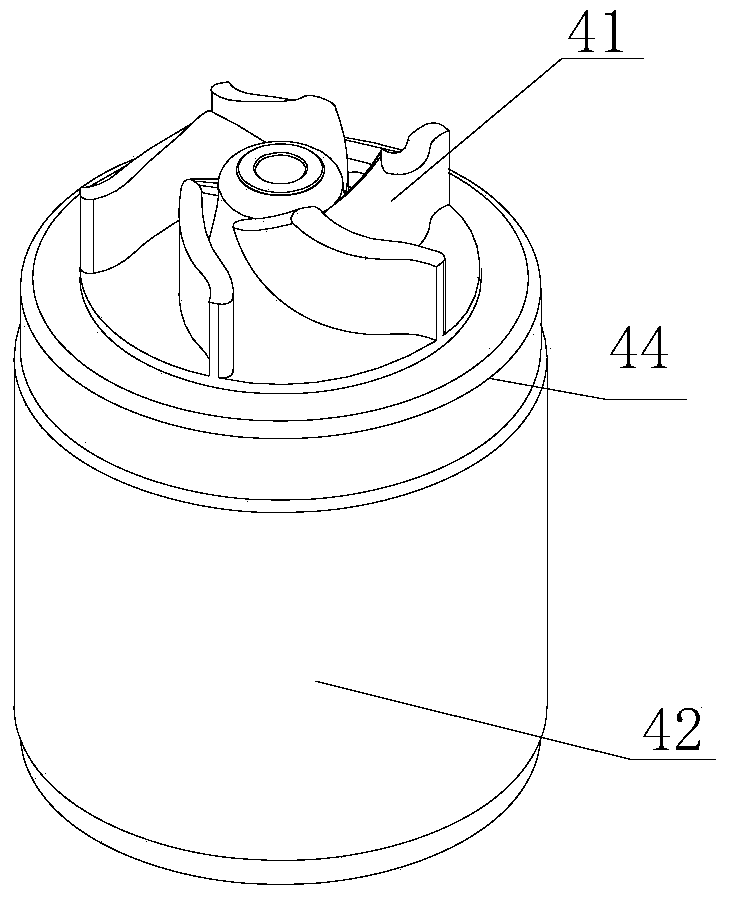

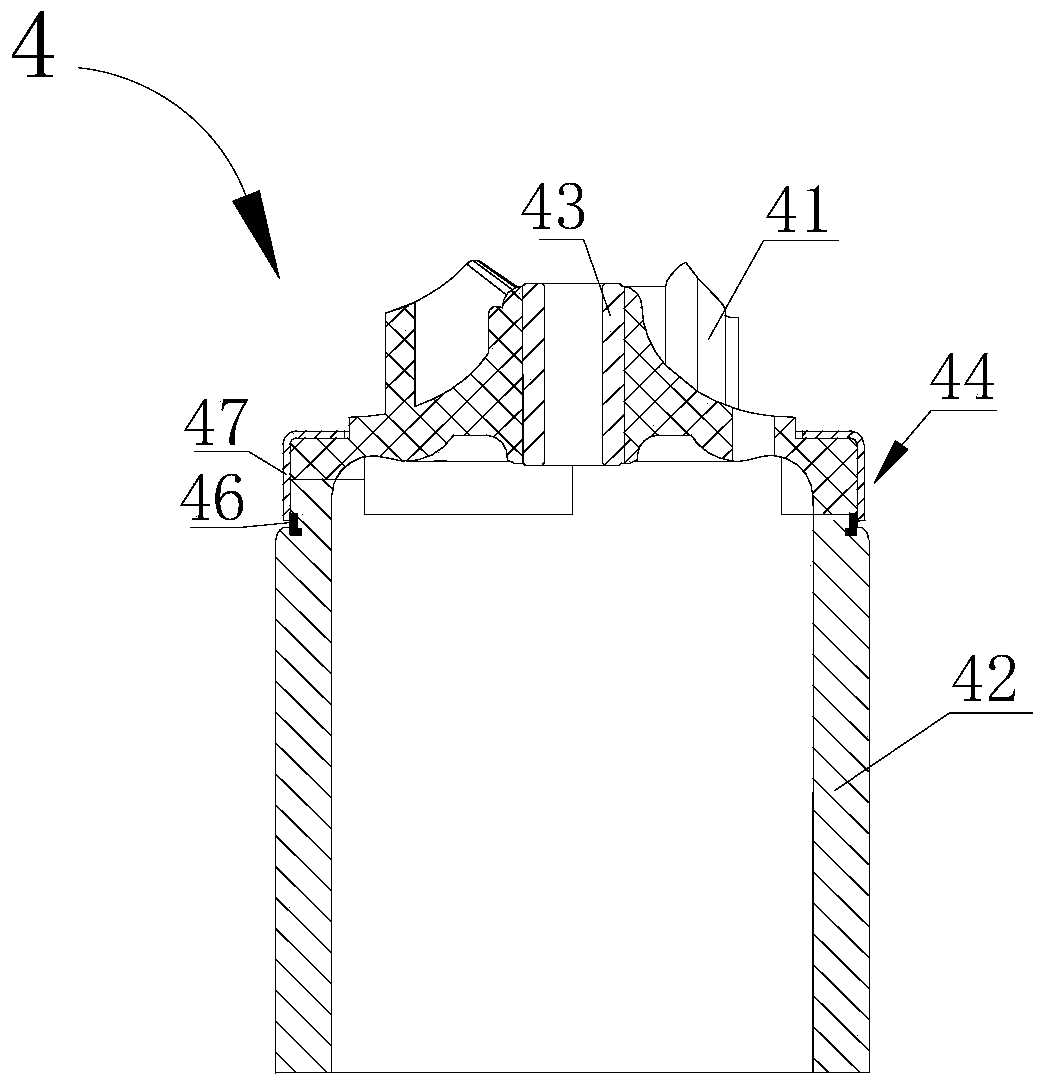

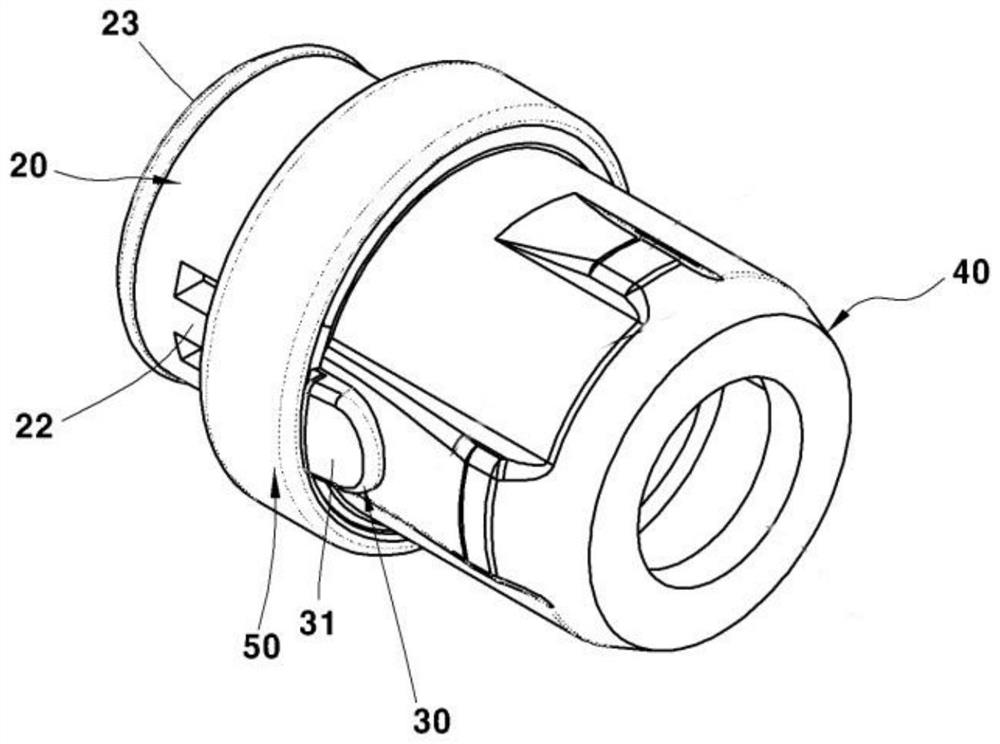

Rotor assembly and electric driving pump

ActiveCN106208516AImprove versatilityGuaranteed cylindricityPump componentsEngine fuctionsImpellerPlastic materials

A rotor assembly is disclosed and comprises an impeller and a rotor that are respectively and separately formed via injection mold operation; injection molding material of the rotor comprises magnetic material, injection molding material of the impeller does not comprise the magnetic material, the impeller comprises a first matching part while the rotor comprises a second matching part, the impeller and the rotor are arranged in a matched manner via the first matching part and the second matching part and are fixed relative to each other via a fixing device, and therefore the impeller and the rotor can be respectively made of different material; the impeller can be made of common plastic material, and manufacture material cost of the rotor assembly can be lowered.

Owner:ZHEJIANG SANHUA AUTOMOTIVE COMPONENTS CO LTD

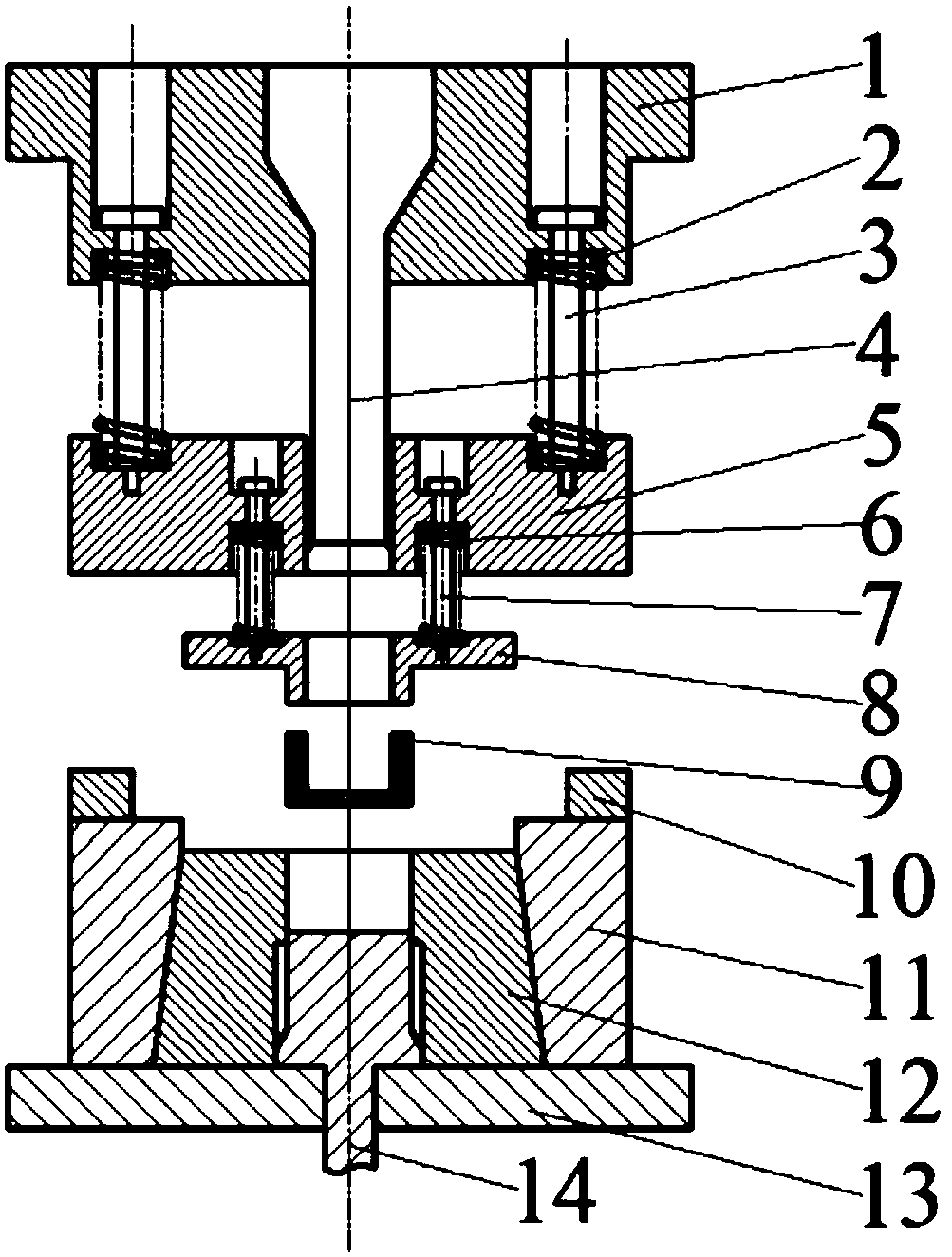

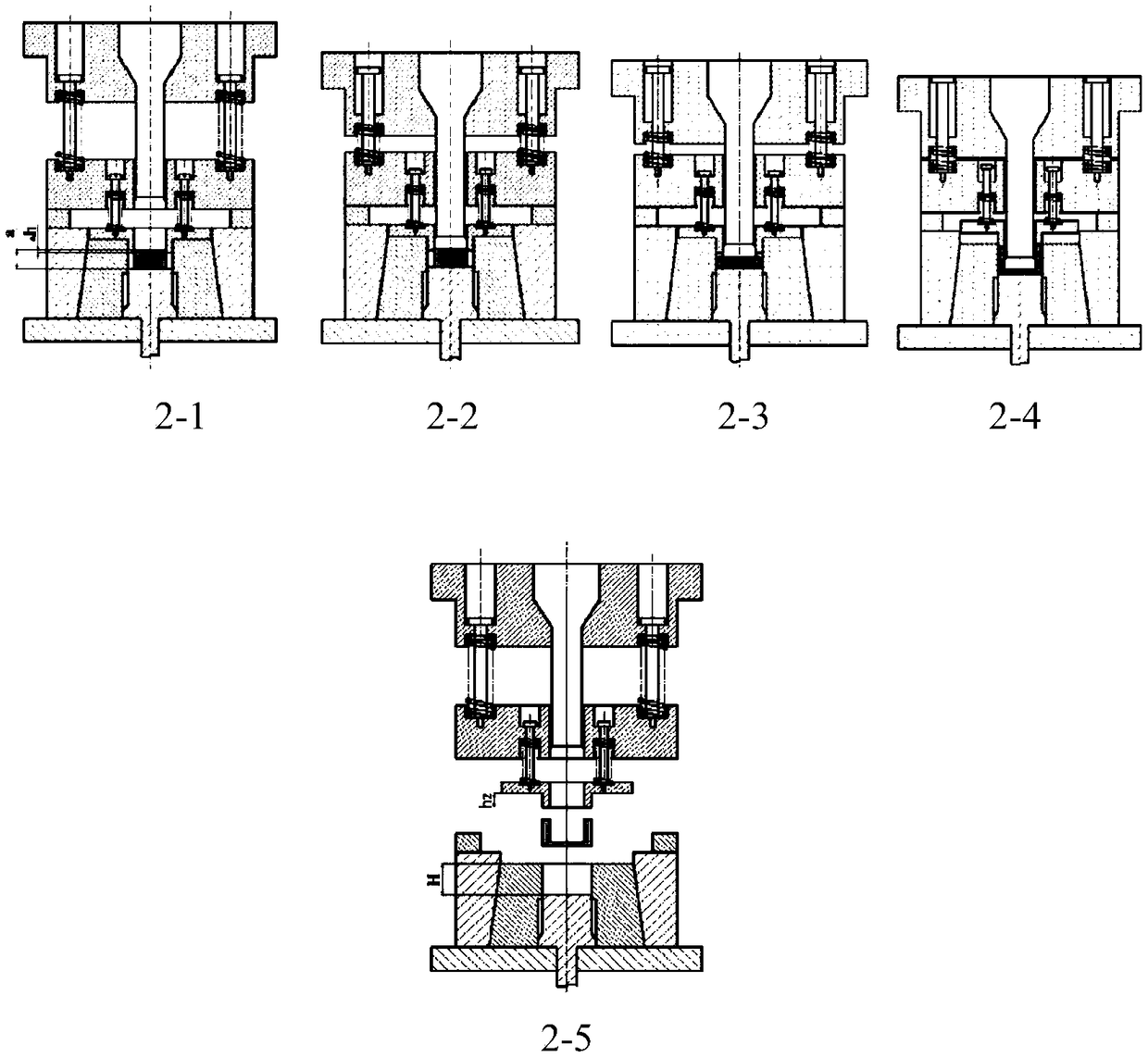

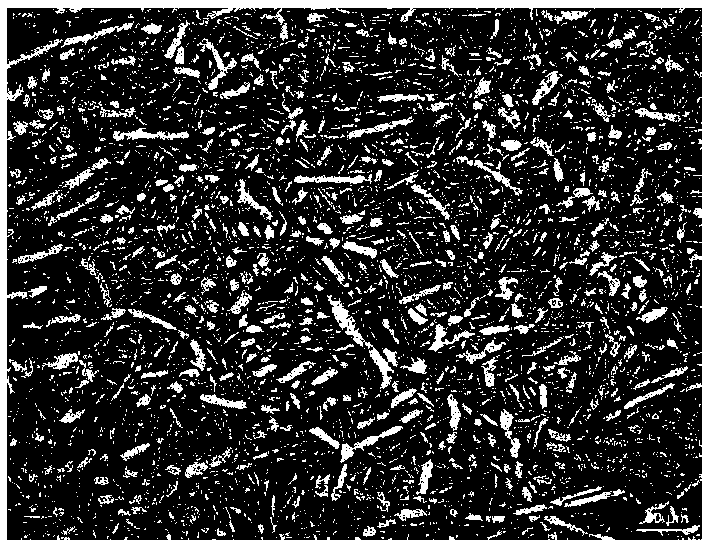

Hot reverse extrusion forming method for titanium alloy cup-shaped part

ActiveCN108838226AIncreased self-directionGuaranteed wall thickness uniformityExtrusion diesEconomic benefitsTitanium alloy

The invention relates to a hot reverse extrusion forming method for a titanium alloy cup-shaped part, and belongs to the technical field of hot reverse extrusion forming technologies. The machining method comprises the steps of placing a heated blank into an extrusion container to be subjected to reverse extrusion one-time forming by utilizing the guide positioning action of a material pressing insert, and the roughing blank making step in the forming process of the cup-shaped part is omitted. The material pressing insert guarantees that lugs of the cup-shaped part are flush through the tension action of a back pressure spring; and meanwhile, because a floating male die is in linkage with the back pressure spring with higher back pressure tension, it is achieved that the cup-shaped part can be demolded smoothly after being formed. With the hot reverse extrusion forming method for the titanium alloy cup-shaped part, the phenomenon that in the traditional reverse extrusion process, because one single unloading spring is overhigh in back pressure, the material of a wall of a cup-shaped part flows inwards sharply to tightly hold a male die, and demolding is difficult to carry out is avoided, and meanwhile the reverse extrusion forming force is reduced, and the requirement on equipment tonnage is lowered; and additionally, because a titanium alloy cup-shaped force piece is formed atone time by adopting reverse extrusion in the preparation process, the step of roughing blank prefabrication in the existing technology is omitted, the production period is shortened, the manufacturing cost is reduced, and the economic benefit is greatly improved.

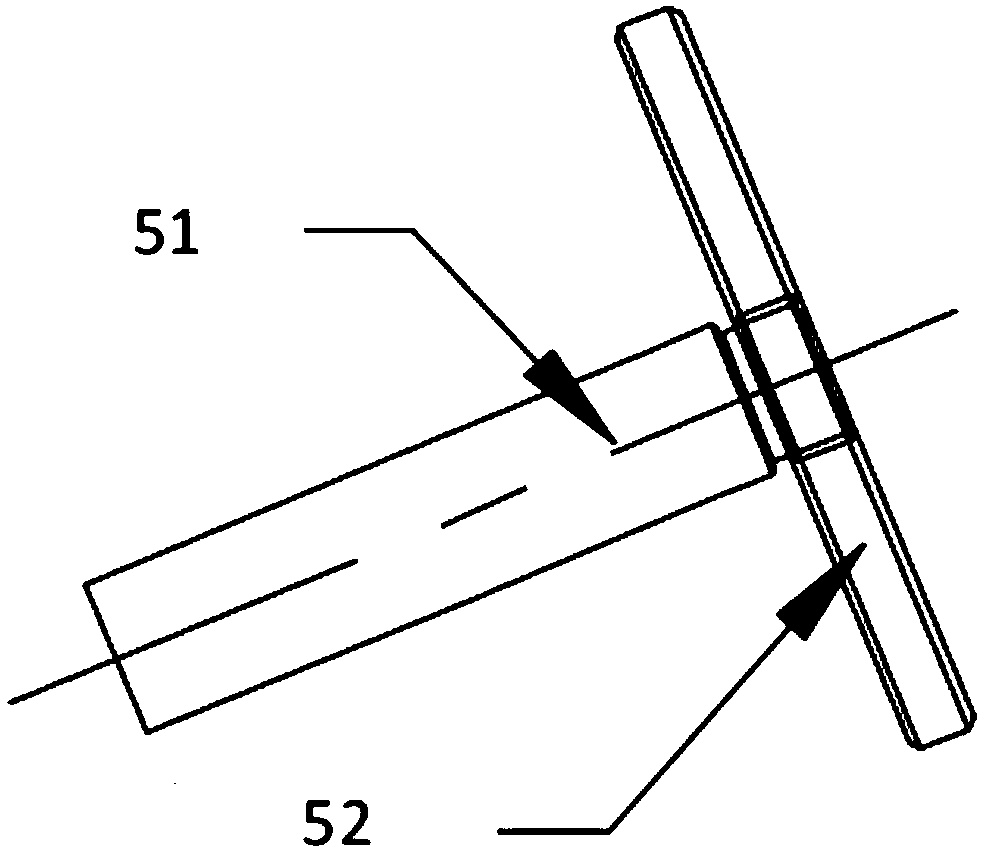

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

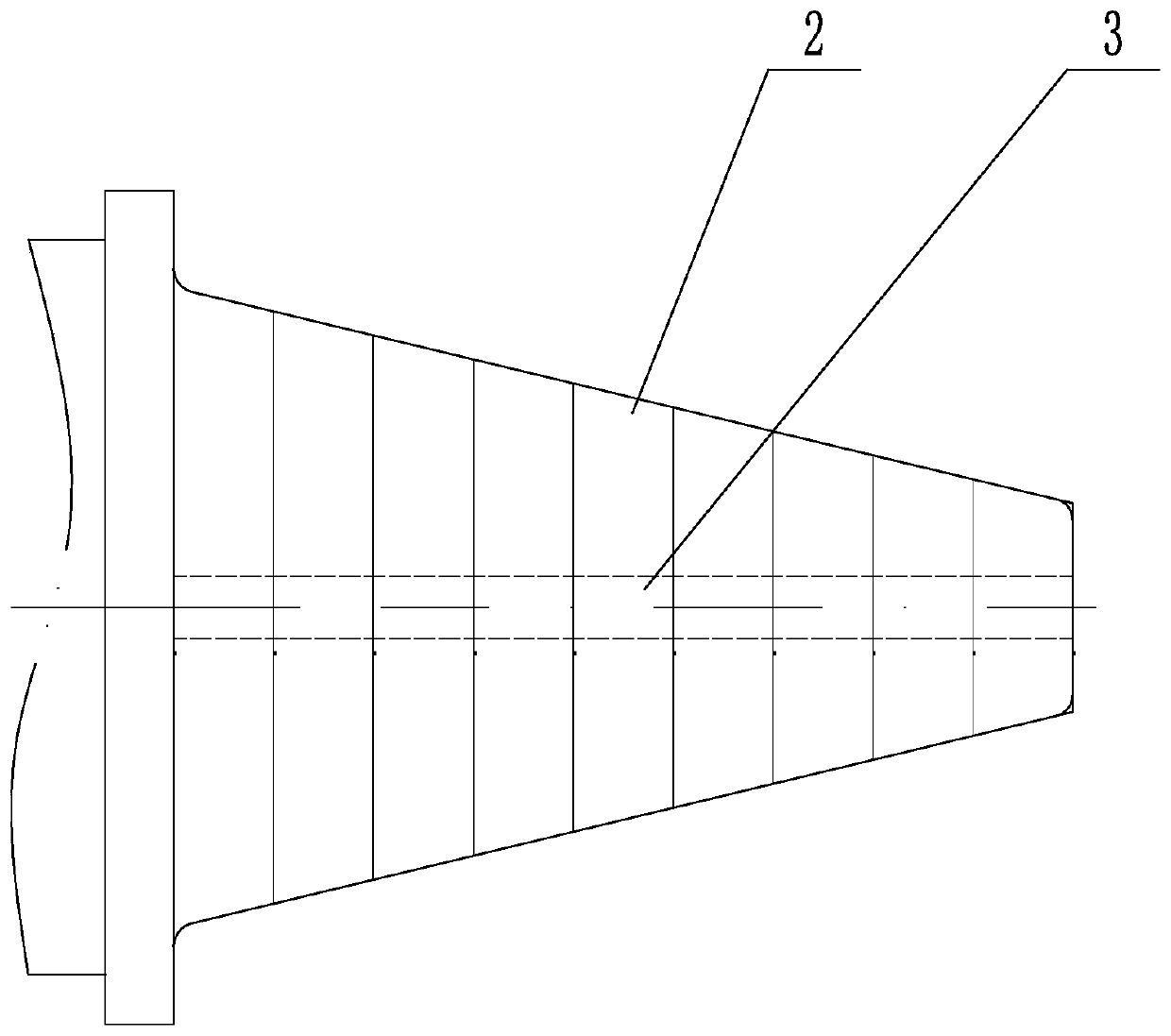

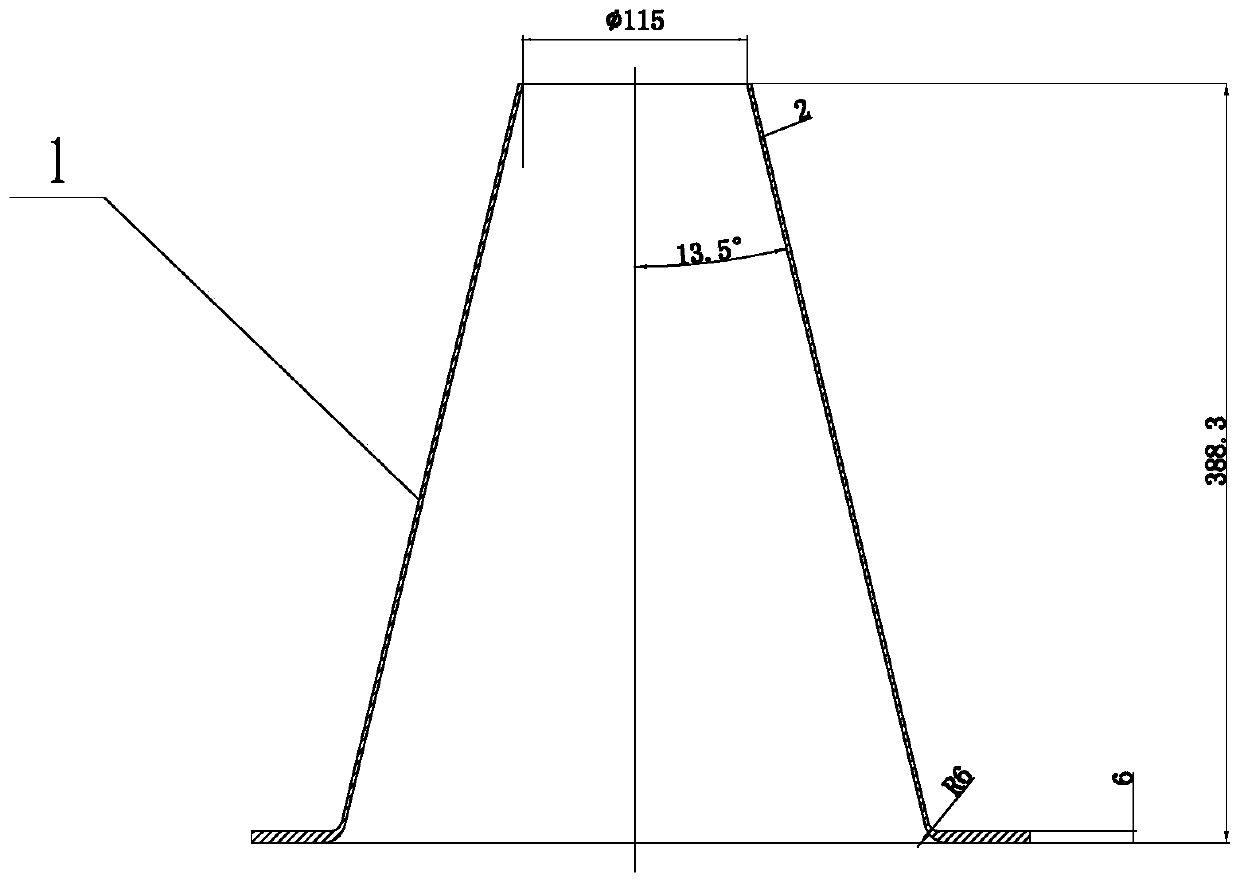

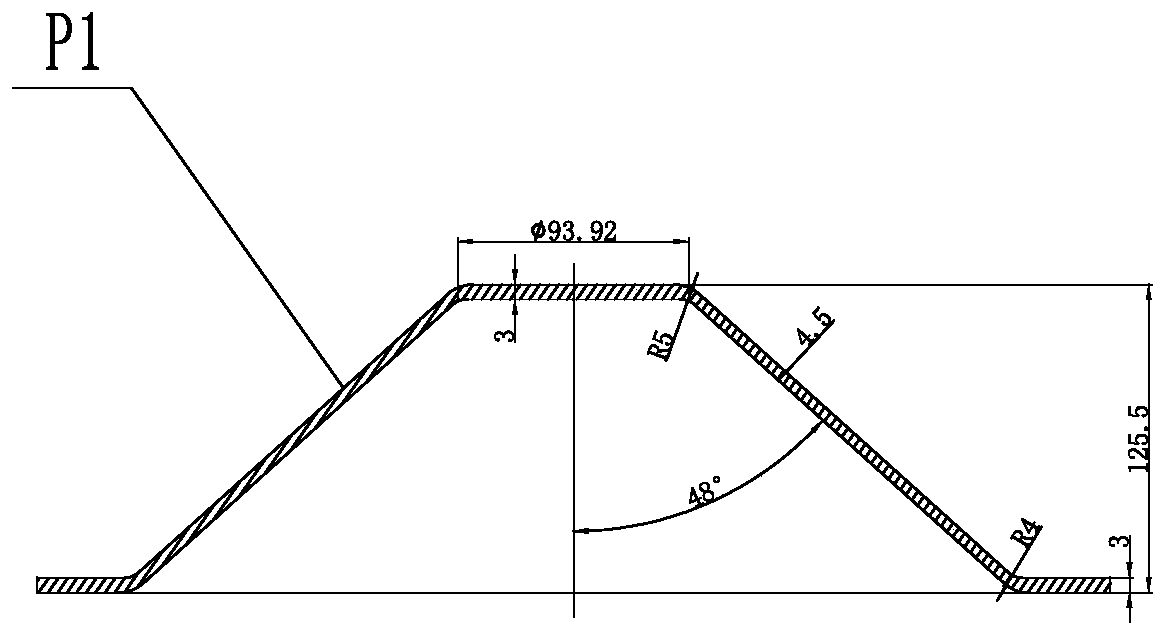

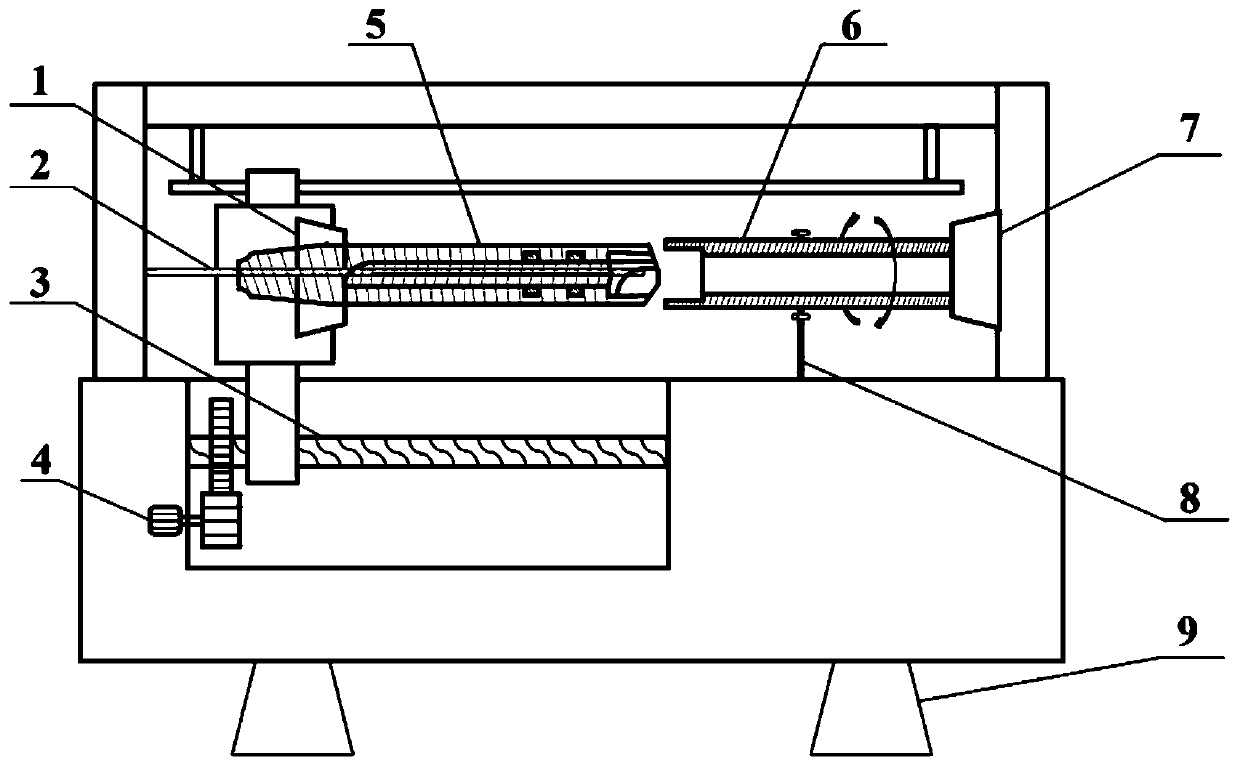

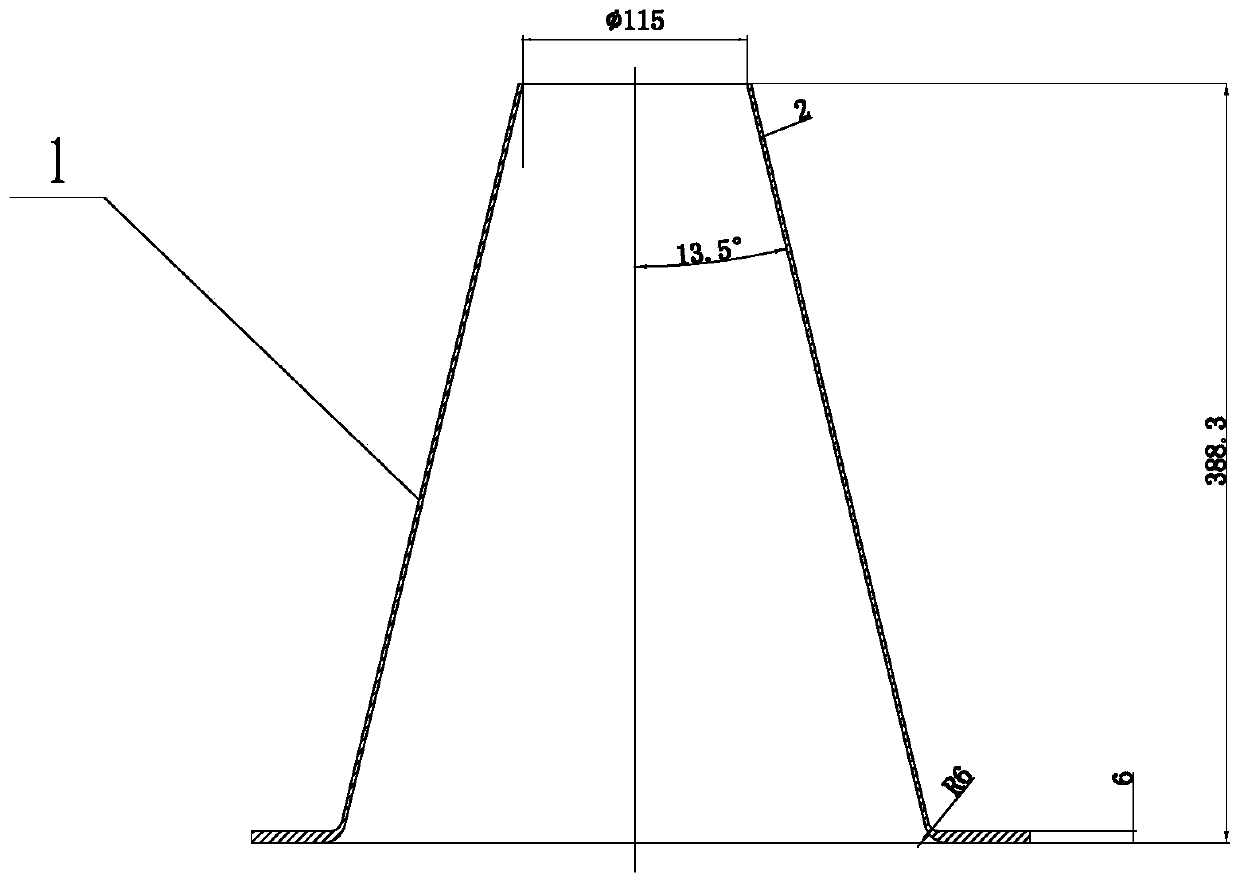

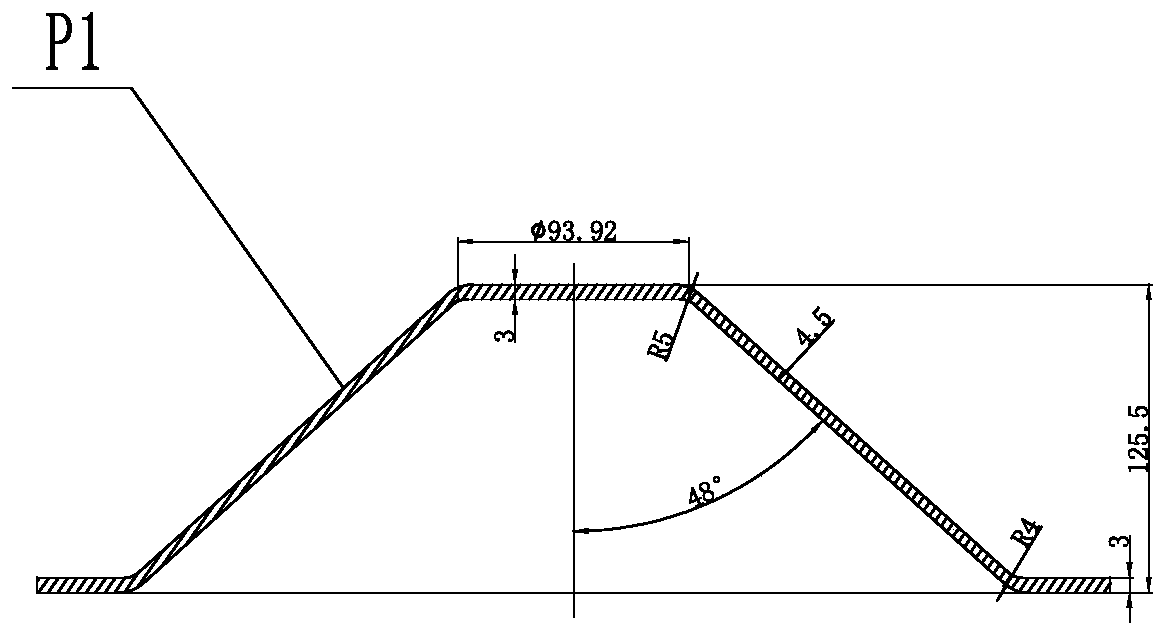

Spinning pressing forming method of deep conical thin-walled rotary part with flange

The invention relates to the technical field of spinning pressing forming, in particular to a spinning pressing forming method of a deep conical thin-walled rotary part with a flange. The method comprises the following steps of determining the number of times of spinning pressing, and working out the sizes of a circular flat plate blank according to the volume, turning allowance and spinning pressing forming allowance of the blank which is already subjected to the last time of spinning pressing forming and the equal volume principle; determining the process parameters of a spinning wheel and multi-section core dies during each time of spinning pressing according to the wall thickness and half taper angle of the blank during each time of spinning pressing forming, wherein the rotating speeds of the core dies are sequentially reduced from the small-diameter end of the core dies to the large-diameter end of the core dies; carrying out spinning pressing on the corresponding core dies withthe number of times of spinning pressing starting from 1 to n to gradually reduce the wall thickness or half taper angle of the blank until the blank formed after the last time of spinning pressing forming is obtained; and carrying out turning on the blank which is formed after the last time of spinning pressing forming. The spinning pressing forming method of the deep conical thin-walled rotary part with the flange is suitable for alloy materials, and the sectional and different rotating speeds of the core die are designed to ensure the wall thickness forming uniformity of the part.

Owner:NINGBO UNIV

Machining method of elongated thin-wall aluminum-based composite material pipe with uniform wall thickness

ActiveCN109702488AAdvantages of machining methodsImprove straightnessOther manufacturing equipments/toolsMaintainance and safety accessoriesDiameter ratioMachining

The invention provides a machining method of an elongated thin-wall aluminum-based composite material pipe with uniform wall thickness. The machining method comprises the following steps that firstly,rough turning is carried out on an outer circle of the aluminum-based composite material pipe; secondly, destressing heat treatment is carried out, then an inner hole is roughly bored by using a special tool, then destressing heat treatment is carried out again, then destressing heat treatment is carried out after the outer circle of the aluminum-based composite material pipe is subjected to semi-finish turning, then a special tool is used for finely boring the inner hole, and finally finish turning is carried out on the outer circle. According to the machining method of the elongated thin-wall aluminum-based composite material pipe with the uniform wall thickness, the large length-diameter ratio thin-wall pipe can be produced, and the wall thickness uniformity, straightness and coaxiality can be guaranteed.

Owner:HARBIN INST OF TECH +1

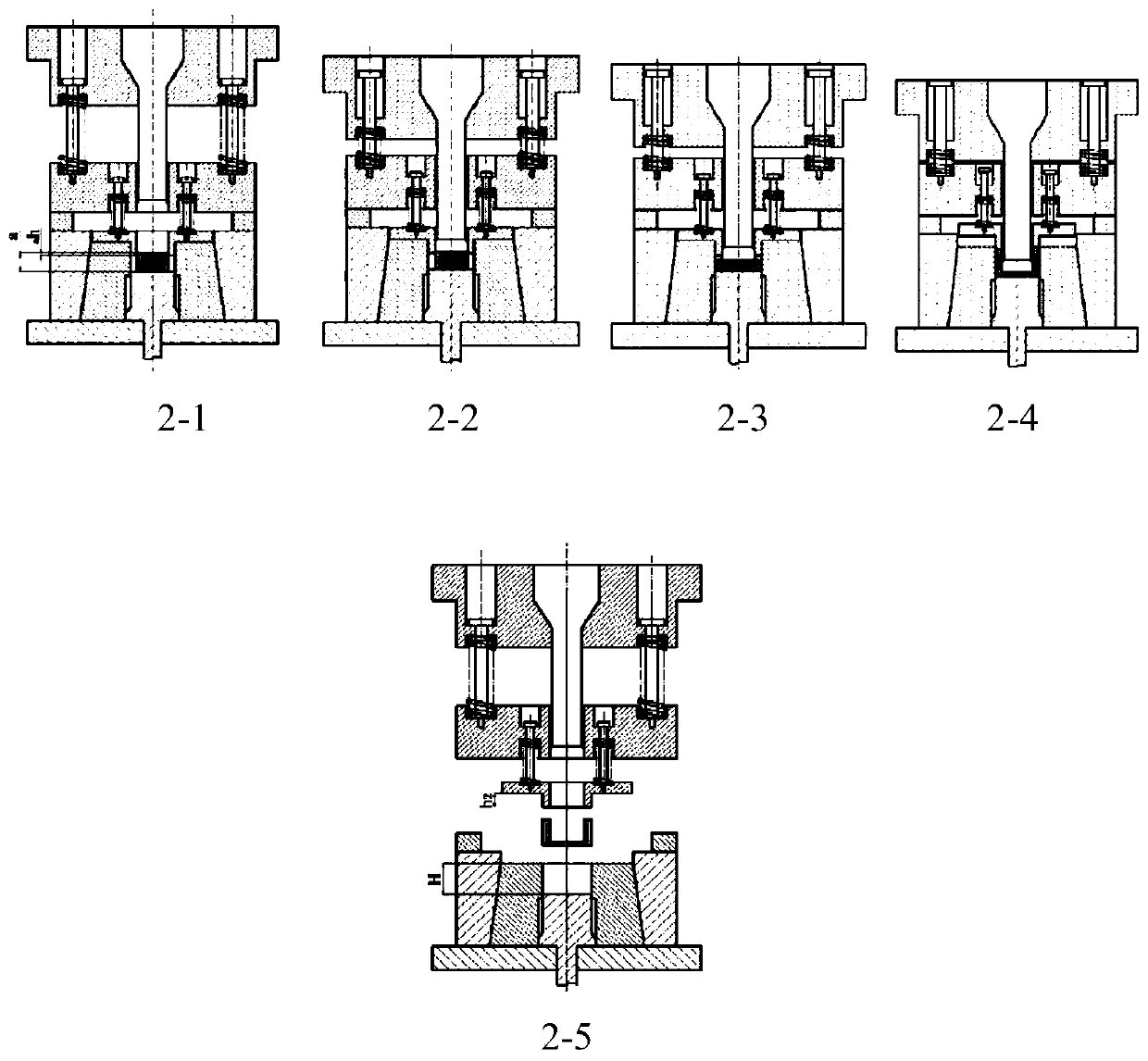

Forming method of hollow component

The invention relates to a forming method of a hollow component. According to the technical scheme, the forming method of the hollow component comprises the following steps: step one, preparing a die, adding four anti-deformation structures on the die, and mounting a one-way valve on a punch; step two, placing an initial tube blank in a cavity of the die, closing the die and sealing ends; step three, filling a fluid medium inside the tube blank; step four, enabling the anti-deformation structures to move oppositely; and step five, retracting the anti-deformation structures to initial positions, repeating the step four and the step five to form a component in the required shape, relieving internal fluid pressure, opening the die, and taking out a part. The anti-deformation structures are arranged in the die, so that a petal shape is repeatedly and accumulatively used, while the rolling effect of friction is eliminated, forming pressure is reduced, the breakage defect is avoided, and uniformity of the wall thickness is improved.

Owner:李明

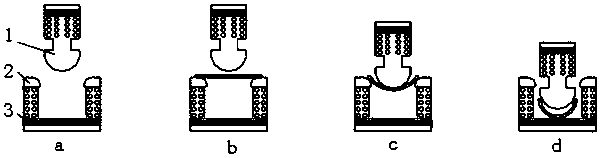

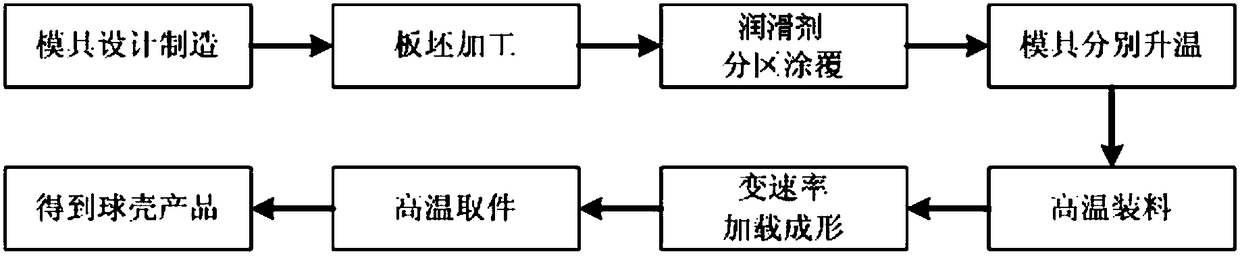

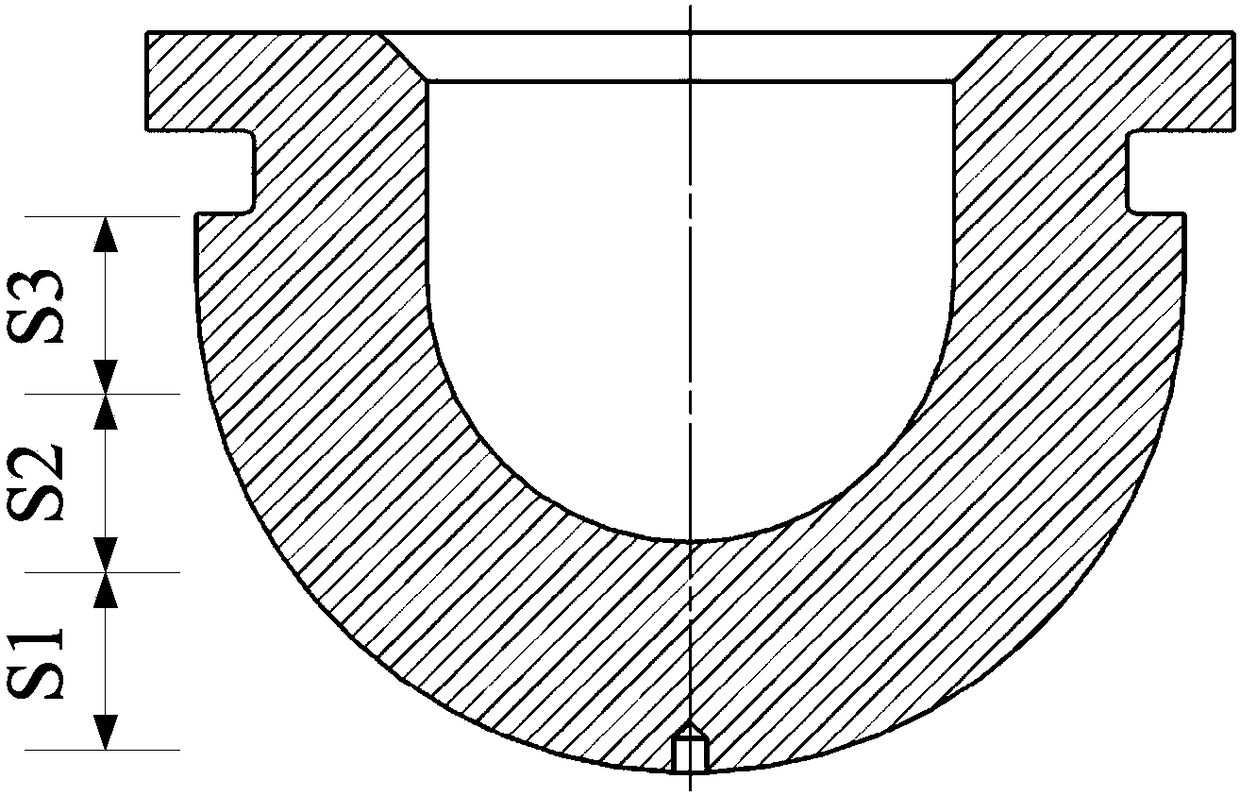

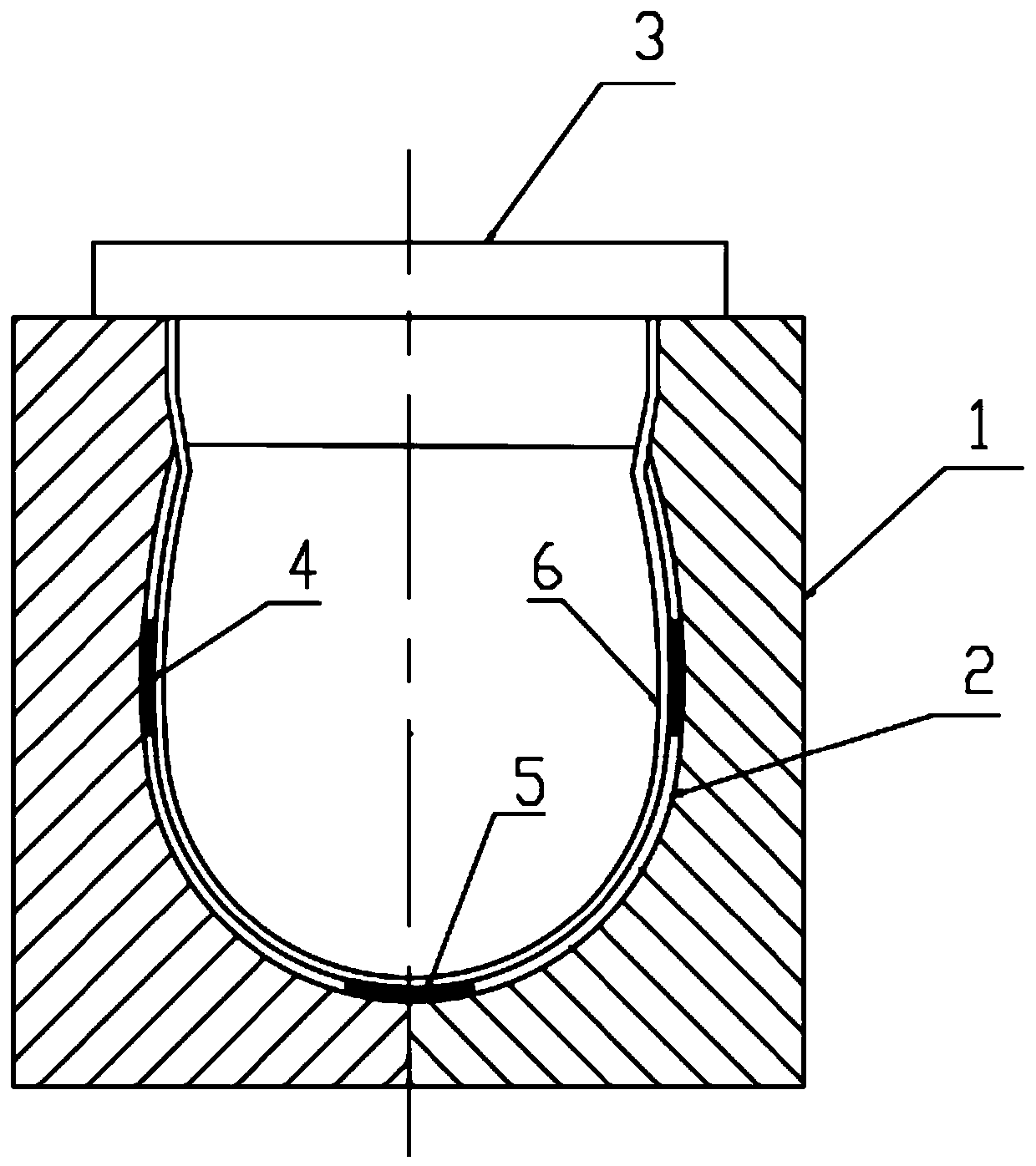

Wall thickness homogenization method adopting isothermal stamping for titanium alloy thick-wall spherical shell

ActiveCN108145000ADimensionally stableReduced loss of mechanical propertiesShaping toolsHollow articlesReduction rateTitanium

The invention discloses a wall thickness homogenization method adopting isothermal stamping for a titanium alloy thick-wall spherical shell. Through divisional design on friction coefficients of a male die and a to-be-formed plate, the male die and pull rings are heated separately so that a temperature gradient is formed, the wall thickness homogenization of the titanium alloy thick-wall sphericalshell is ensured, the spherical bottom reduction rate is reduced from 50% in conventional forming to below 15%, the overall wall thickness fluctuation of a housing does not exceeds 30% of the wall thickness of a blank and the size is stable. Since the reduction of the spherical bottom is inhibited effectively, the extent of damage of the mechanical property at the spherical bottom is reduced substantially, the overall mechanical property of the titanium alloy thick-wall spherical shell is better, the titanium alloy thick-wall spherical shell is particularly applicable to development and production of a TA7 low-temperature titanium alloy gas cylinder product for a carrier rocket, and is also applicable to the development and production of titanium alloys in other fields and other trademarks and the like products, and the wall thickness homogenization method is very practical.

Owner:AEROSPACE RES INST OF MATERIAL & PROCESSING TECH +1

Thin-wall shell forming die device with rigid insertion type solid core male die

PendingCN110014672AHigh positioning accuracyReduce the probability of driftDomestic articlesEngineeringSilica gel

The invention discloses a thin-wall shell forming die device with a rigid insertion type solid core male die. The thin-wall shell forming die device comprises a female die which is divided into at least two oppositely-arranged parts, and the male die is arranged in the female die; a cavity for forming a shell is formed between the outer wall of the male die and the inner wall of the female die; the male mold is of a solid-core silica gel structure; a core shaft hole which is used for being inserted into by a core shaft and is matched with the core shaft in shape is formed in the male mold; anda core shaft hole port is located at the tail end of the male mold. The thin-wall shell forming die device with the rigid insertion type solid core male die can eliminate glue accumulation, ensure uniform wall thickness of the formed shell, and is more convenient and fast to operate.

Owner:厦门宇诠复材科技有限公司

Control Method of Wall Thickness of Upper Edge Plate of Hollow Guide Vane

ActiveCN104923722BGuaranteed wall thickness uniformityMeet the requirements of design drawingsFoundry mouldsFoundry coresWaxInvestment casting

The invention belongs to the precise investment casting technology and relates to a method for controlling aero-engine hollow guide blade upper edge plate cavity wall thickness. The method is characterized in that the hollow guide blade upper edge plate wax pattern cavity wall thickness is changed to control casting cavity wall thickness, the front edge of the core body (3) of a ceramic core (7) is allowed to tilt towards a non-runner face, and the included angle alpha of the lower surface (11) of the core body (3) and the runner face (10) of a hollow guide blade upper edge plate wax pattern is allowed to range from 0 degree 30 minutes to 1 degree. By the method, hollow guide blade upper edge plate casting wall thickness evenness at hollow parts is guaranteed, design drawing requirements are satisfied, oversize and scrap are avoided, production yield is increased, and production cost is lowered.

Owner:AECC AVIATION POWER CO LTD

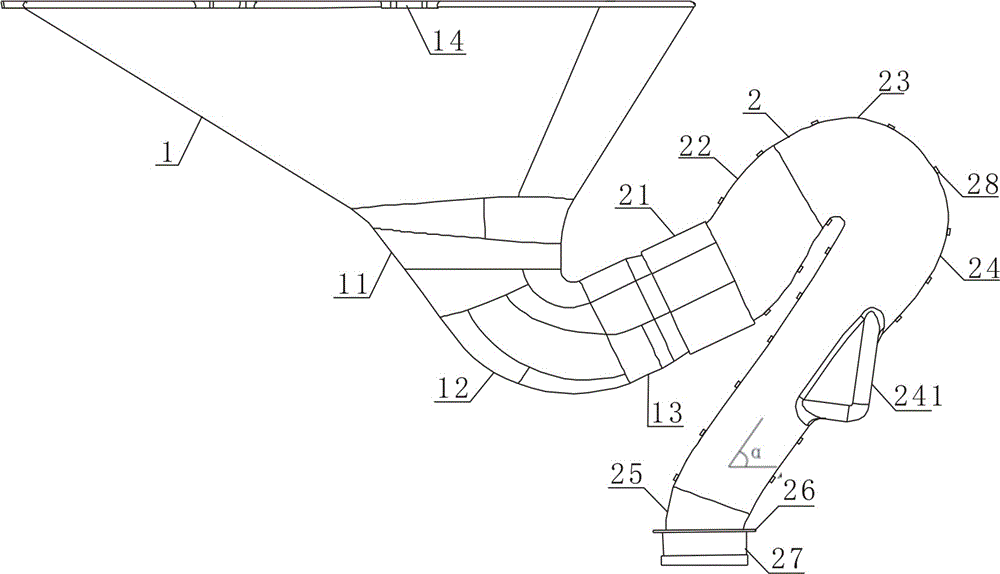

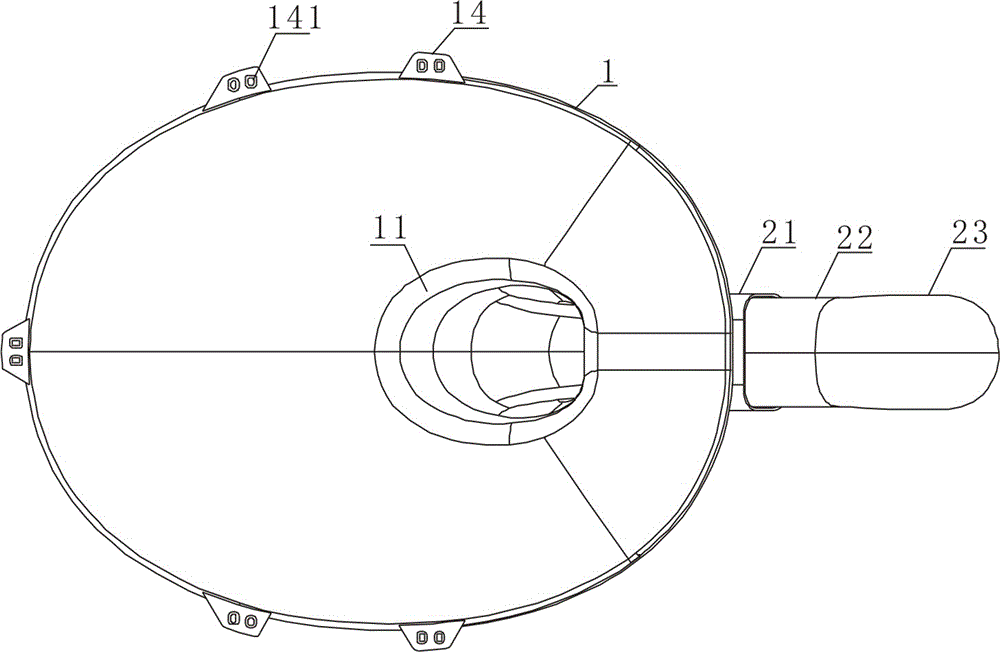

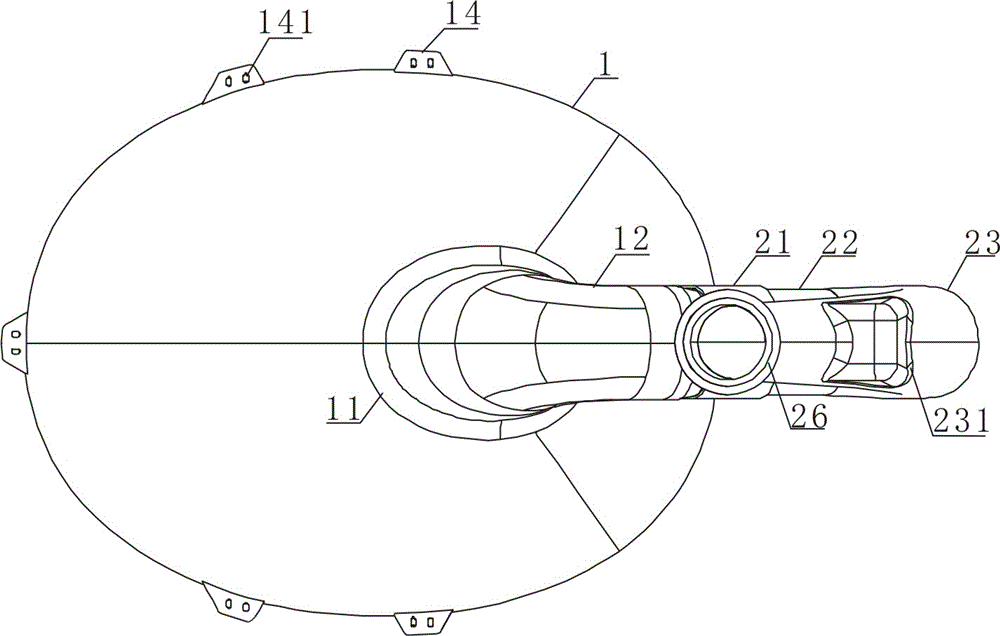

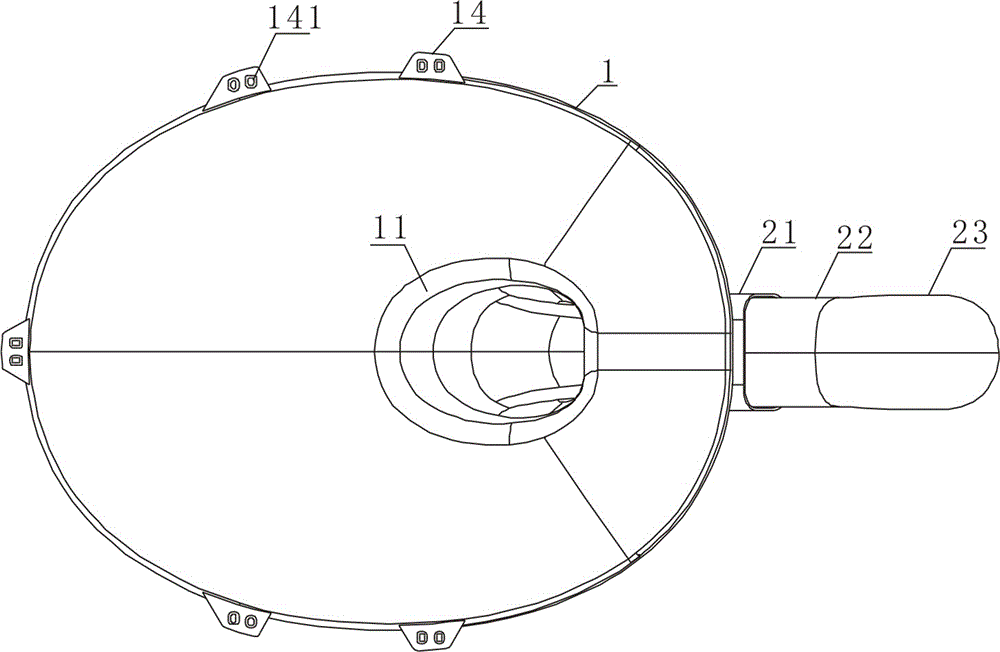

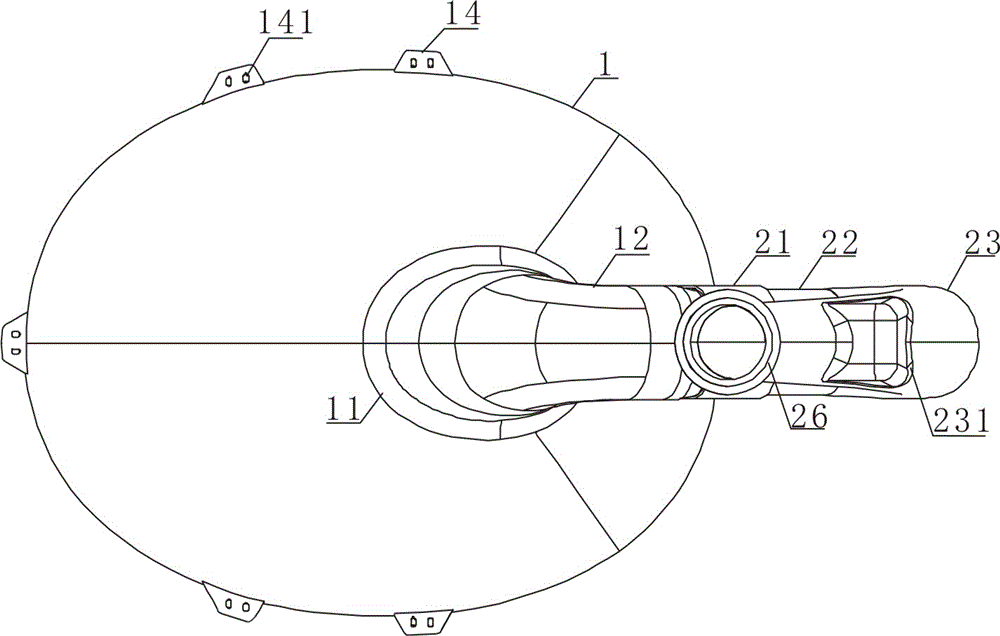

Toilet sewage discharging structure

The invention discloses a toilet sewage discharging structure. The toilet sewage discharging structure comprises a tank and a trap which is communicated with the tank; the tank comprises a funnel-shaped tank main body and a water storage connecting pipe which is communicated with the bottom of the tank main body; the trap comprises a water inlet pipe, a trap main body and a second water outlet pipe which are connected in turn. The toilet sewage discharging structure had the advantages of being high in sewage discharging capability and convenient to maintain.

Owner:SICHUAN MONARCH SANITARY WARE +1

A Spinning Forming Method of Deep Conical Thin-wall Rotary Part with Flange

The invention relates to the technical field of spinning pressing forming, in particular to a spinning pressing forming method of a deep conical thin-walled rotary part with a flange. The method comprises the following steps of determining the number of times of spinning pressing, and working out the sizes of a circular flat plate blank according to the volume, turning allowance and spinning pressing forming allowance of the blank which is already subjected to the last time of spinning pressing forming and the equal volume principle; determining the process parameters of a spinning wheel and multi-section core dies during each time of spinning pressing according to the wall thickness and half taper angle of the blank during each time of spinning pressing forming, wherein the rotating speeds of the core dies are sequentially reduced from the small-diameter end of the core dies to the large-diameter end of the core dies; carrying out spinning pressing on the corresponding core dies withthe number of times of spinning pressing starting from 1 to n to gradually reduce the wall thickness or half taper angle of the blank until the blank formed after the last time of spinning pressing forming is obtained; and carrying out turning on the blank which is formed after the last time of spinning pressing forming. The spinning pressing forming method of the deep conical thin-walled rotary part with the flange is suitable for alloy materials, and the sectional and different rotating speeds of the core die are designed to ensure the wall thickness forming uniformity of the part.

Owner:NINGBO UNIV

A method for manufacturing an ultra-long thin-walled aluminum alloy sandwich rib double-skin integral empennage

The invention belongs to the technical field of mechanical processing and manufacturing, and discloses a method for manufacturing a super-long thin-walled aluminum alloy sandwich grid rib double-skin integral tail, comprising: adopting ZL205AA high-strength aluminum alloy to form the integral tail; The integral tail is heat treated; the heat treated integral tail is processed by numerical control. The manufacturing method of the super-long thin-walled aluminum alloy sandwich grid rib double-skin integral empennage provided by the present invention can improve the overall quality of precision molding and manufacturing, reduce the manufacturing cost and shorten the manufacturing cycle.

Owner:HUBEI SANJIANG AEROSPACE GRP HONGYANG ELECTROMECHANICAL

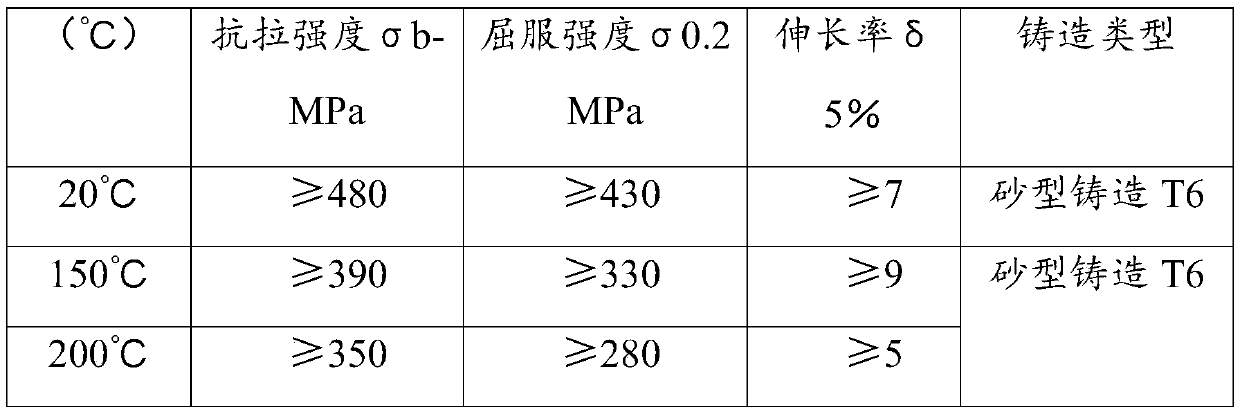

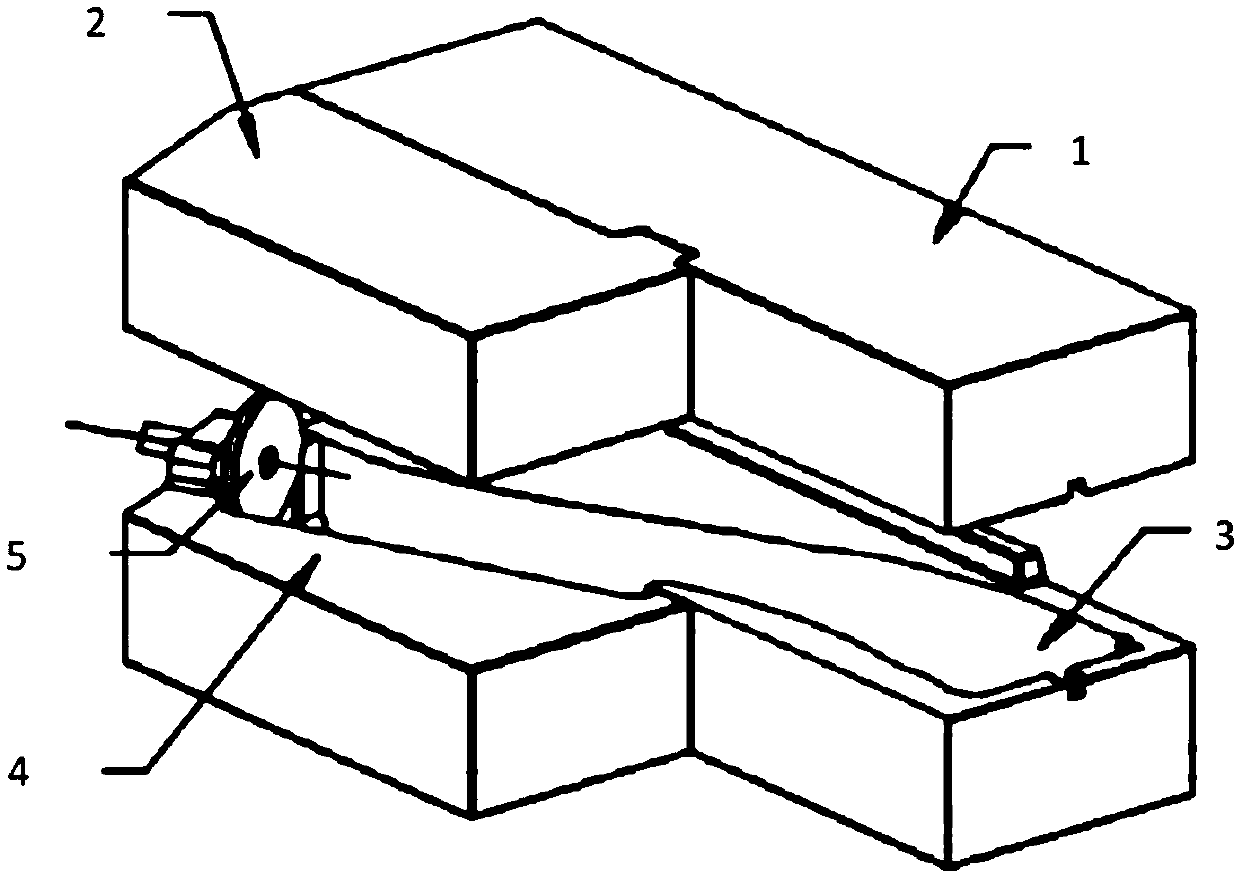

A kind of closed special-shaped pneumatic component forming and correcting general mold and component forming method

ActiveCN107876634BLow processing and manufacturing costsReduce local thinning of wall thicknessShaping toolsGeneral purposeAbnormal shaped

A universal die for closed special-shaped pneumatic component forming and shape correcting comprises a first upper die body (1), a second upper die body (2), a first lower die body (3), a second lowerdie body (4) and a material supplementing device (5). Forming grooves are machined in the middles of the first upper die body (1), the second upper die body (2), the first lower die body (3) and thesecond lower die body (4). The first upper die body (1) and the second upper die body (2) are spliced on the side face to form an upper die. The first lower die body (3) and the second lower die body(4) are mutually spliced on the side face to form a lower die. After the upper die and the lower die are spliced, the forming grooves of the first upper die body (1), the second upper die body (2), the first lower die body (3) and the second lower die body (4) are consistent with a to-be-machined component in appearance. The material supplementing device (5) is installed at the tail end of the forming groove of the second lower die body (4). According to the universal die, precise hot forming and shape correcting of a special-shaped pneumatic component are guaranteed, the formed special-shapedpneumatic component is stable in quality, the size precision, the profile precision and the surface quality are high, and later local shape correcting can be finished.

Owner:BEIJING HANGXING MACHINERY MFG CO LTD

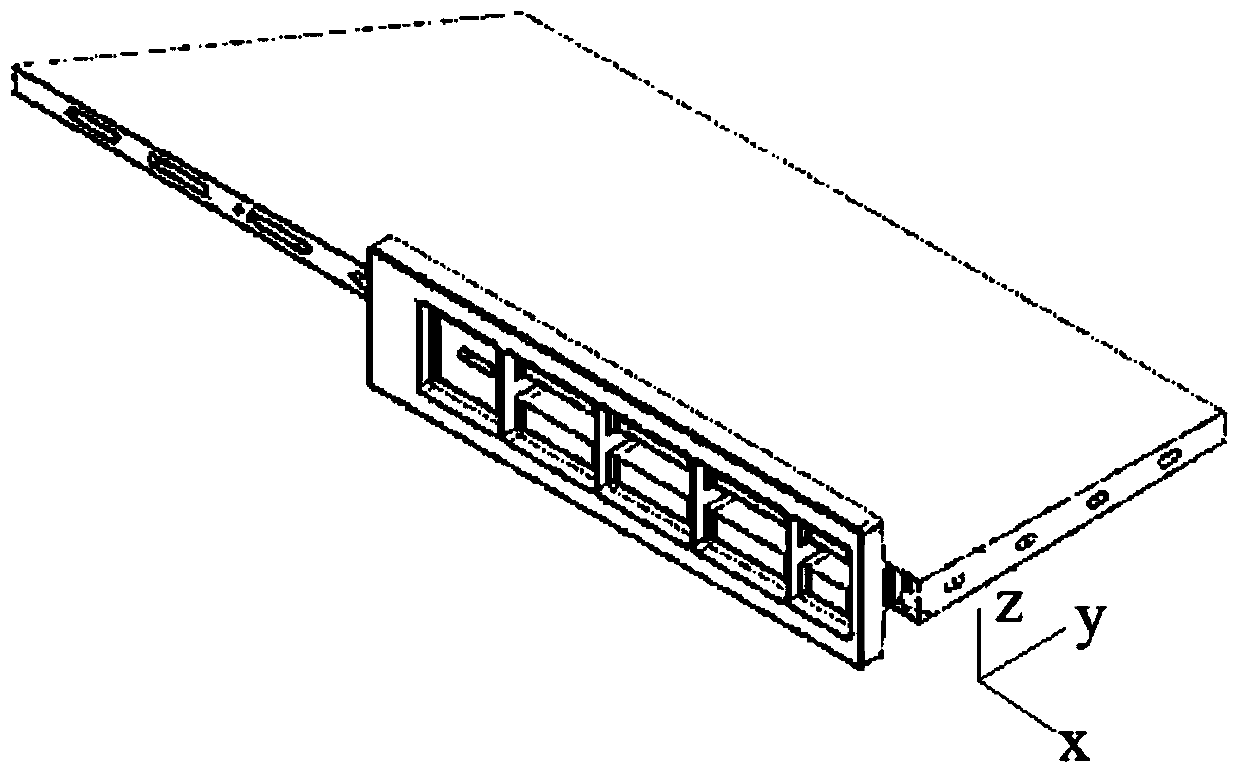

An initial alignment device, processing device and processing method for a special-shaped ceramic radome

ActiveCN109702605BUnified processing standardsReduce machining accuracyRadiating element housingsWorking accessoriesStructural engineeringRadome

The invention provides a special-shaped ceramic antenna cover machining device and method. The device comprises a head cone supporting ring, an inner molded surface aligning ring, end face pressing plates and a plurality of outer supporting mechanisms. Each outer supporting mechanism comprises an outer support and an adjusting screw rod, and the inner molded surface aligning ring comprises an insertion end and a fixed end. According to the device and method, the machining reference of an antenna cover is determined through a primary alignment tool, it is guaranteed that the position of a clamping space of the antenna cover in all working procedures is free of deviation, the machining reference is unified, and the machining precision is effectively controlled.

Owner:AEROSPACE INST OF ADVANCED MATERIALS & PROCESSING TECH

Cylinder block fixture

ActiveCN103753271BSimple structureRealize precise machiningPositioning apparatusMetal-working holdersPulp and paper industryCylinder block

The invention discloses an air cylinder clamp. The air cylinder clamp comprises a base, spindle hole semicircular location blocks, clamping units and a cylinder hole slider linkage opening unit. Location end surface matched with to-be-located air cylinder front and rear stop spindle semicircular holes are arranged on the spindle hole semicircular location blocks. The clamping units are arranged on base location bosses on the inner sides of the spindle hole semicircular location blocks and comprise clamping supports, T-shaped screw pairs and clamping pressing blocks. A middle block bearing stop location block is provided with air cylinder bearing block location sides. The cylinder hole slider linkage opening unit comprises a base column and a cylinder hole slider component arranged at the top end of the base column. The air cylinder clamps clamp the air cylinder from the end and the sides, the measurement probe spot measurement function of a machining center spindle is used for finding reference coordinate values of machining of air cylinder process location pin holes, and accordingly, accurate machining of air cylinder process location pin holes is achieved, and the air cylinder hole wall thickness uniformity is guaranteed finally.

Owner:GUANGXI YUCHAI MASCH CO LTD

Rotor assembly and electric drive pump

ActiveCN106208516BImprove versatilityGuaranteed cylindricityPump componentsMagnetic circuitImpellerManufactured material

A rotor assembly, comprising an impeller and a rotor, the impeller and the rotor are separately injection molded, the injection molding material of the rotor includes a magnetic material, and the injection molding material of the impeller does not include a magnetic material; the impeller includes a first matching part, the The rotor includes a second matching part, the impeller and the rotor are arranged through the first matching part and the second matching part, and are relatively fixed by the fixing device; in this way, the impeller and the rotor can be made of different materials, and the impeller can use common plastic materials, which can Reduced manufacturing material costs for rotor assemblies.

Owner:ZHEJIANG SANHUA AUTOMOTIVE COMPONENTS CO LTD

A method for hot reverse extrusion forming of titanium alloy cup-shaped parts

ActiveCN108838226BQuick and smooth exitExtended service lifeExtrusion diesEconomic benefitsEngineering

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

Machining method for thin and thin-walled aluminum-matrix composite pipe with uniform wall thickness

ActiveCN109702488BImprove straightnessGuaranteed wall thickness uniformityOther manufacturing equipments/toolsMaintainance and safety accessoriesPipeMachining

The invention provides a machining method of an elongated thin-wall aluminum-based composite material pipe with uniform wall thickness. The machining method comprises the following steps that firstly,rough turning is carried out on an outer circle of the aluminum-based composite material pipe; secondly, destressing heat treatment is carried out, then an inner hole is roughly bored by using a special tool, then destressing heat treatment is carried out again, then destressing heat treatment is carried out after the outer circle of the aluminum-based composite material pipe is subjected to semi-finish turning, then a special tool is used for finely boring the inner hole, and finally finish turning is carried out on the outer circle. According to the machining method of the elongated thin-wall aluminum-based composite material pipe with the uniform wall thickness, the large length-diameter ratio thin-wall pipe can be produced, and the wall thickness uniformity, straightness and coaxiality can be guaranteed.

Owner:HARBIN INST OF TECH +1

A kind of preparation method and device of cup-shaped flexspline

ActiveCN109351836BReduce intensityReduced fatigue lifeShaping toolsStructural engineeringPulse power supply

The invention discloses a preparation method of a cup-shaped flexible wheel and a device thereof. A circular slab is tightened at the end of a core die by a tail top. A positive wire of a pulse powersupply is connected with the core die, and a negative wire is directly connected with each rotary wheel of a rotary wheel assembly. The circular slab is first spun and deformed into a cup-shaped workpiece with both inner and outer walls being straight walls by one rotary wheel. Then the cup-shaped workpiece is spun and deformed into two thickened cup-shaped workpieces with different straight wallthickness by another two rotary wheels, and a thicker smooth section is used as a tooth profile reserved section. Finally, the tooth profile reserved section is spun by one toothed rotary wheel to form a circle tooth profile around the outer circumference. At last, a small amount of cutting process is carried out to complete the processing process from the circular slab to the cup-shaped flexiblewheel workpiece. According to the cup - shaped flexible wheel manufacturing process based on plastic forming, streamline formed in the process of deformation can be completely retained, and the service life of parts is prolonged advantageously. The advantage of the method is more obvious for flexible wheels with an extremely small thickness.

Owner:SOUTH CHINA UNIV OF TECH

A method for expanding a quartz tube and a special blowtorch device

ActiveCN103771691BAccurate diameterPrecisely maintain the diameterGlass reforming apparatusCentrifugal forceWaste material

The invention discloses a tube expanding method of a quartz tube. The tube expanding method comprises the following steps that firstly a main quartz tube is arranged on a left clamping head and a right clamping head of a tube expanding machine; a blowlamp device on a middle tray device of the tube expanding machine is started, and simultaneously the left clamping head and the right clamping head rotate synchronously to drive the main quartz tube to rotate; in rotation, the local part of the main quartz tube is heated, the heated part of the main quartz tube is in a semi-melted state, and the main quartz tube in the semi-melted state expands outwards under the action of centrifugal force generated by rotation; under the action of a tube-expanding supporting wheel on the middle tray device, sizing is carried out; after being sized, the tube is transferred to a cutting machine to cut off waste materials clamped at the two ends. The tube expanding method disclosed by the invention has the advantages that since a cold water tank is arranged on the middle tray device, the diameter of the quartz tube after being expanded can be fast and accurately maintained; since the special blowlamp device is arranged in tube expansion, the working efficiency of tube expansion and the tube expanding quality are improved, the gas blowing noise is reduced, the gas inflow is reduced, the air contact opportunity is increased, the use efficiency of gas is improved and the energy is saved.

Owner:江苏宏伟石英科技有限公司

Toilet sewage structure

The invention discloses a toilet sewage discharging structure. The toilet sewage discharging structure comprises a tank and a trap which is communicated with the tank; the tank comprises a funnel-shaped tank main body and a water storage connecting pipe which is communicated with the bottom of the tank main body; the trap comprises a water inlet pipe, a trap main body and a second water outlet pipe which are connected in turn. The toilet sewage discharging structure had the advantages of being high in sewage discharging capability and convenient to maintain.

Owner:SICHUAN MONARCH SANITARY WARE +1

Winding drum device and conical drum preparation method

PendingCN113770241AGuaranteed wall thickness uniformityHigh precisionShaping toolsWelding/cutting auxillary devicesEngineeringFloppy disk

The invention discloses a winding drum device and a conical drum preparation method. The winding drum device comprises a base, a support, a swing table, a mandrel and a floppy disc, the support and the swing table are arranged on the base, the floppy disc is arranged on the swing table, the floppy disc is used for bearing a foil material, the mandrel is rotatably arranged on the support, and the swing table is arranged on the support, the tail end of the mandrel can abut against the floppy disc to enable the floppy disc and the foil to deform, the swing table can drive the floppy disc to swing so as to adjust the angle, and the mandrel rotates to drive the foil and the floppy disc to rotate so as to roll the foil.

Owner:NANJING SANLE GROUP

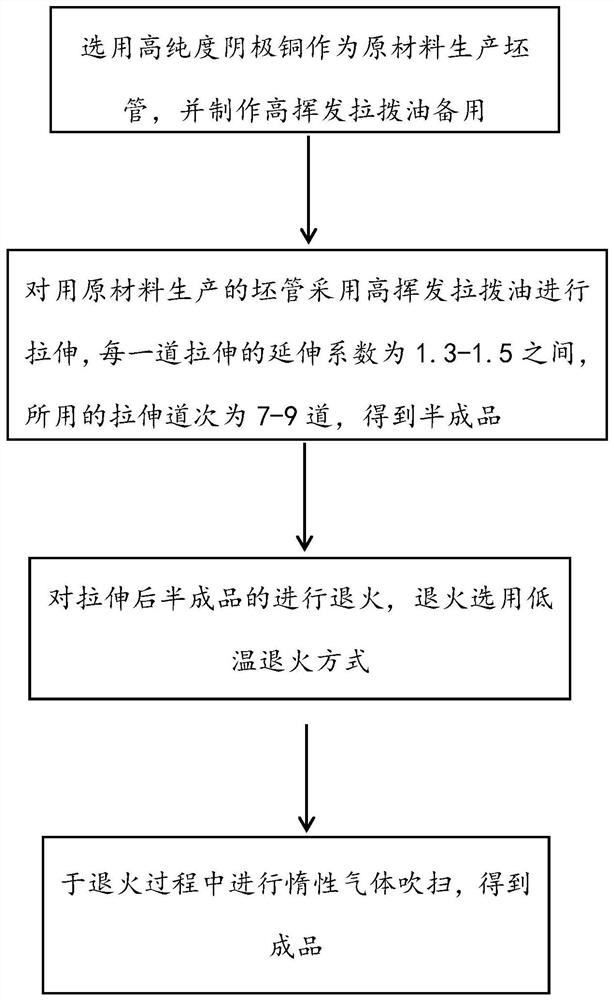

High-precision welding-free special copper coil manufacturing process

ActiveCN113231486BGuaranteed cleanlinessGuaranteed roundnessFurnace typesHeat treatment furnacesGas passingManufactured material

Owner:QINGDAO HONGTAI COPPER IND

A processing method and fixture for a large thin-walled cabin section shell

ActiveCN106425303BFeature Margin UniformQuick fixPositioning apparatusMetal-working holdersEngineeringProcess efficiency

The invention relates to a processing method of a large-scale thin-wall cabin shell body. The processing method comprises the steps of 1, reserving a criterion boss on the shape of the shell body when casting the shell body, conducting rough machining on the lineation criterion, leveling a front and back end surfaces of the shell body, and conducting rough machining on the front and back end surfaces of the shell body; 2, conducting rough machining on shape and an inner cavity of the shell body according to the processing criterion in the step 1, conducting aging treatment after the rough machining, and detecting form and location tolerance deformation quantities of the shell body before and after the aging treatment; 3, analyzing remaining quantities of various parts of specially shaped end of the shell body according to a deformation rule of the shell body, judging whether there is a need to borrow quantity, finishing semi-finishing on the shape and the inner cavity of the shell body, and conducting aging treatment after the semi-finishing; 4, detecting the form and location tolerance deformation quantities before and after the aging treatment of the shell body in the step 4, further figuring out the deformation rule of the shell body, and finishing finish machining of the shell body; 5, finally detecting all the sizes of the shell body and storing the shell body into a storage after the shell body is qualified. The invention also relates to a clamp used according to the method. The processing method can improve sharply processing efficiency, guarantee the quality of a product, causes a small processing deformation, and can guarantee the homogeneity of shell wall thickness.

Owner:航天科工哈尔滨风华有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com