A kind of closed special-shaped pneumatic component forming and correcting general mold and component forming method

A technology for general molds and formed parts, applied in the field of thermal processing mold design, can solve the problems of low efficiency and high processing costs, and achieve the effects of stable quality, saving manufacturing costs, surface accuracy and high surface quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Further details will be given below in conjunction with the accompanying drawings and embodiments.

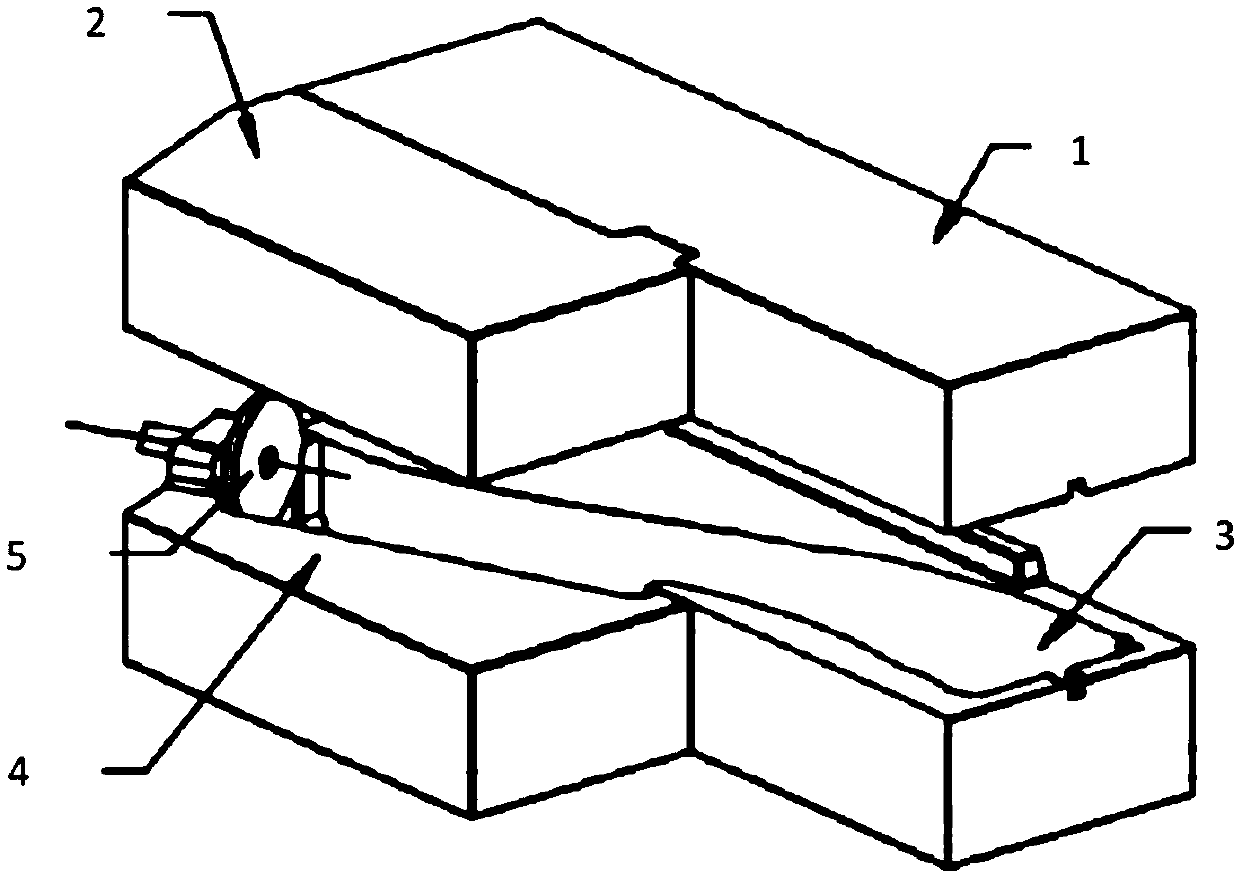

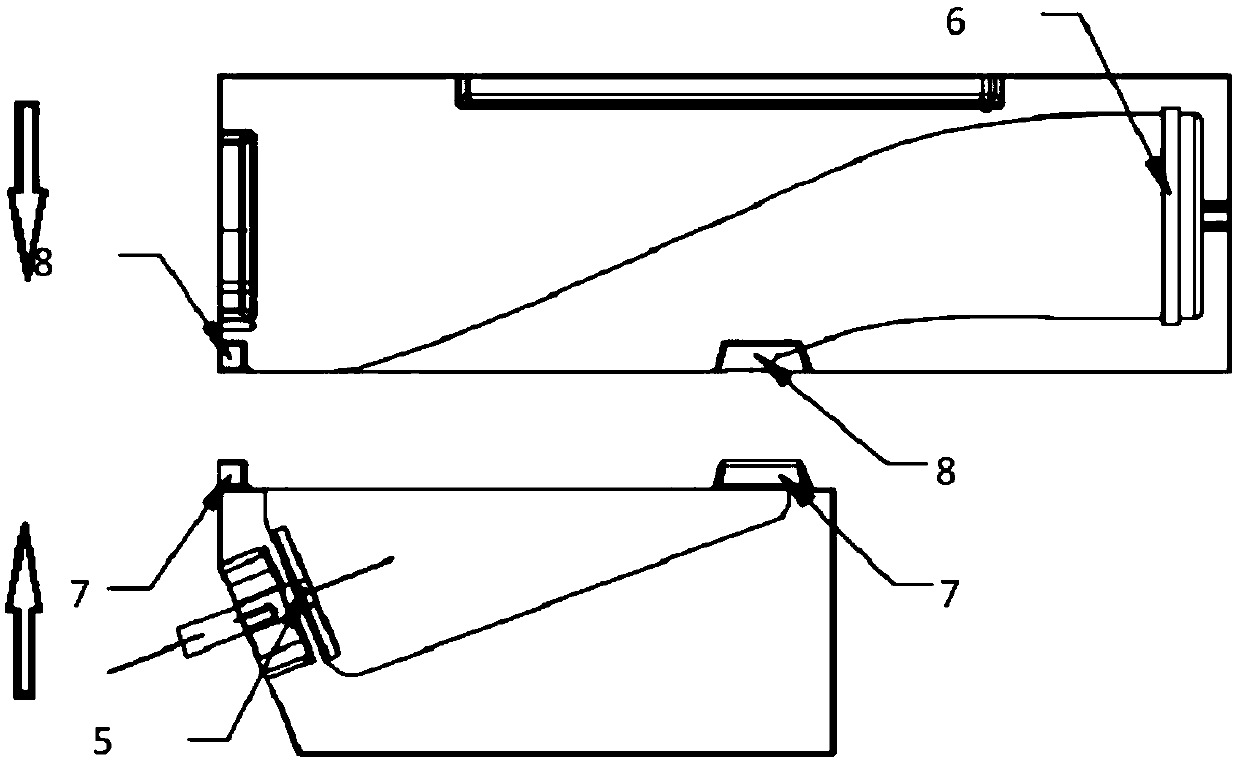

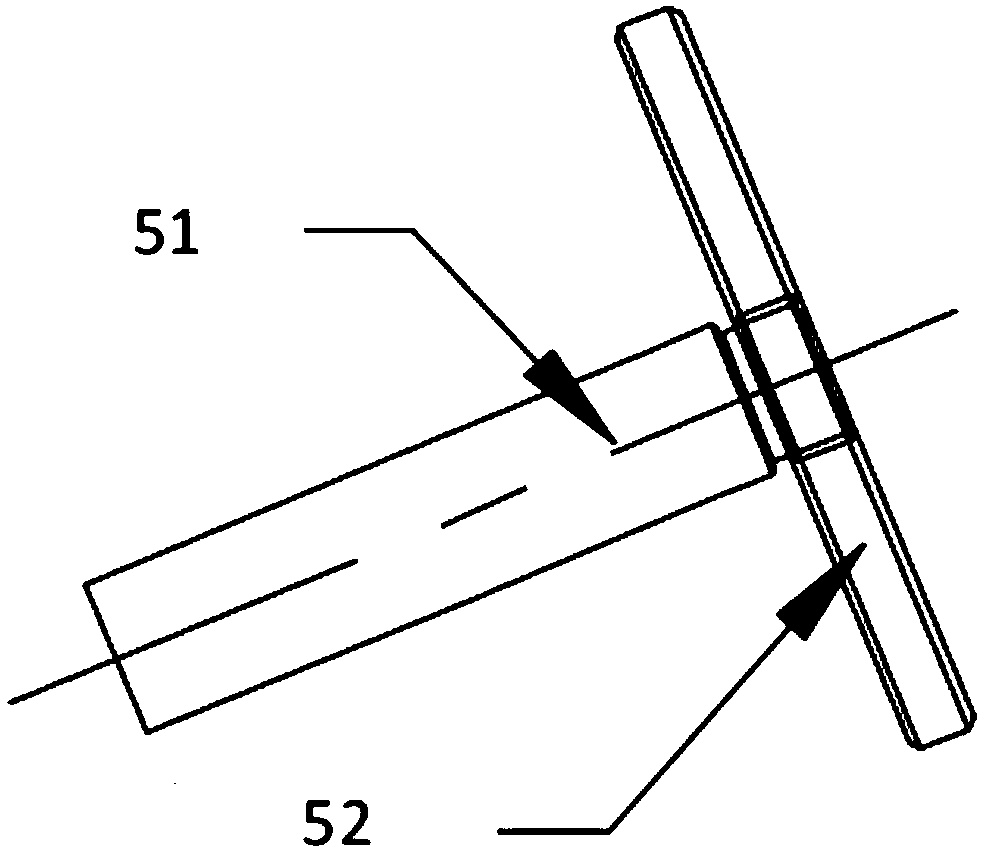

[0029] A general mold for forming and correcting a closed special-shaped pneumatic component, such as figure 1 As shown, it includes: the first upper mold 1, the second upper mold 2, the first lower mold 3, the second lower mold 4, the feeding device 5; the first upper mold 1, the second upper mold 2, the first lower mold 3. Forming grooves are processed in the middle of the second lower mold 4; the first upper mold 1 and the second upper mold 2 are spliced on the side to form the upper mold, and the first lower mold 3 and the second lower mold 4 are spliced to form the lower mold on the side After the upper mold and the lower mold are spliced, the forming grooves of the first upper mold 1, the second upper mold 2, the first lower mold 3, and the second lower mold 4 are consistent with the parts to be processed; the forming of the second lower mold 4 A feeding devic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com