Machining method for thin and thin-walled aluminum-matrix composite pipe with uniform wall thickness

An aluminum-based composite material and machining technology, applied in metal processing equipment, metal processing mechanical parts, manufacturing tools, etc., can solve the problems affecting the service performance of pipes, large aspect ratio, low stiffness, etc., to ensure dimensional stability. , Small surface roughness, high straightness effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] It should be noted that, in the case of no conflict, the embodiments of the present invention and the features in the embodiments can be combined with each other.

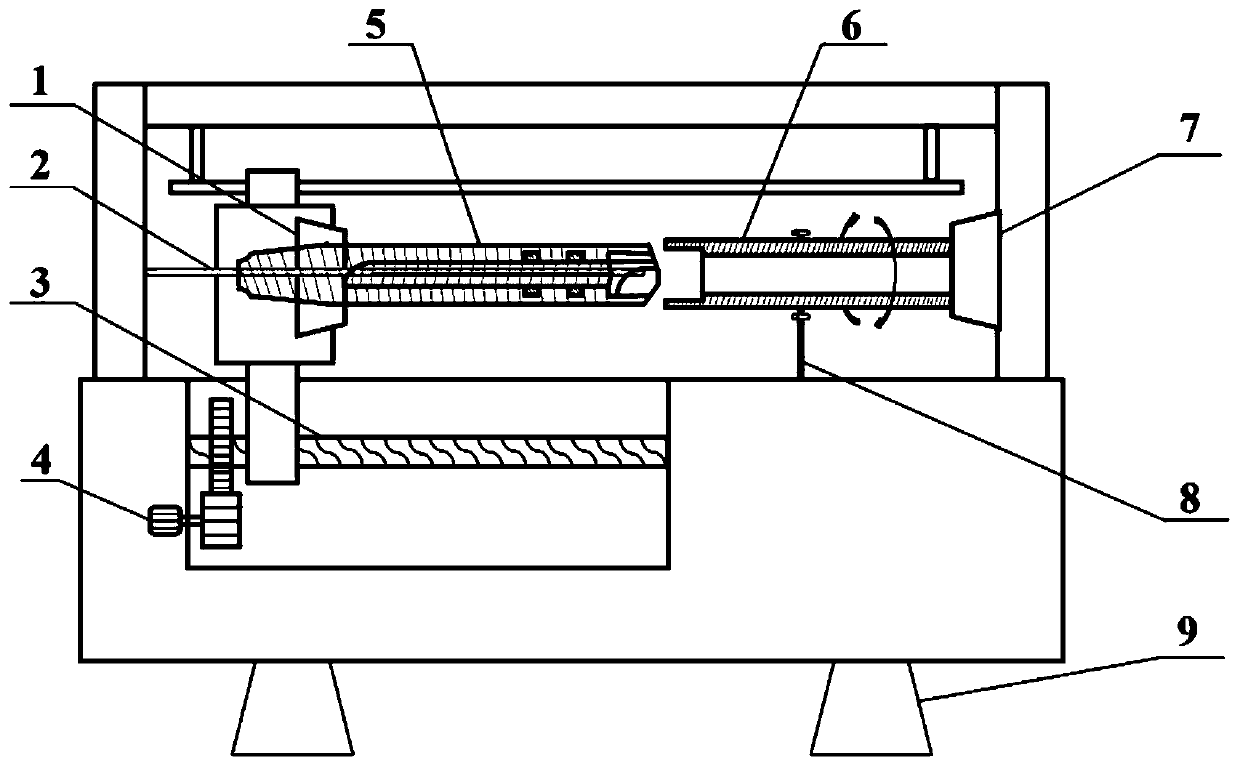

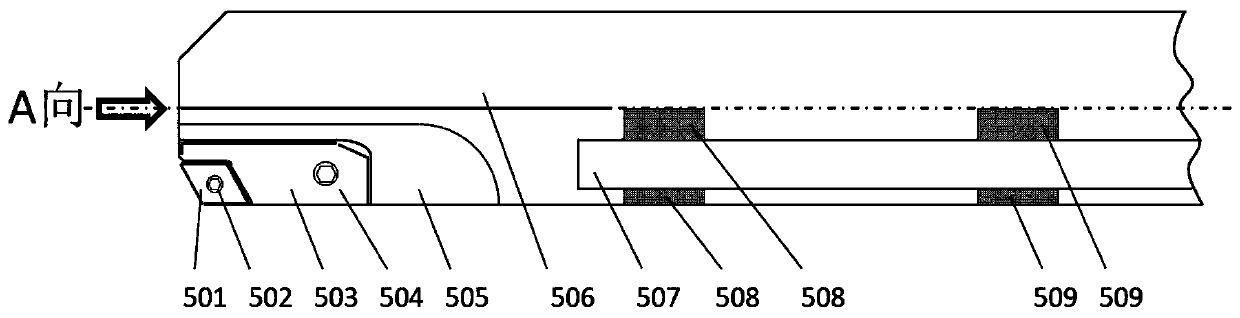

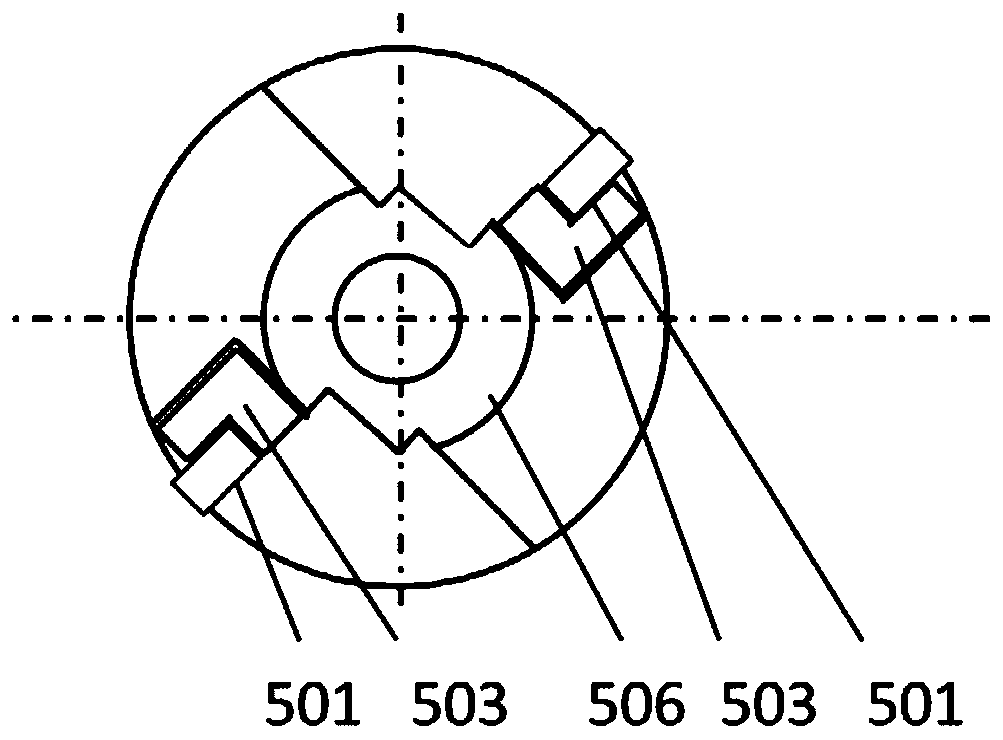

[0041] The present invention will be described in detail below with reference to the accompanying drawings and examples.

[0042] A machining method for a thin and thin-walled aluminum matrix composite pipe with uniform wall thickness,

[0043] 1) Rough turning the outer circle of the aluminum matrix composite pipe. The inner diameter of the aluminum matrix composite pipe to be processed is 40mm-80mm, the inner diameter has a machining allowance of 1.5mm-3mm, the wall thickness is 4mm-7mm, the length is 100mm-1200mm, and the straightness is better than 1.0mm. The volume content of silicon carbide whiskers (SiCw) in the composite material is 15-30 vol.%. Polycrystalline diamond turning tool is used for rough turning the outer circle of the pipe, the feed speed is 30-50mm / min, the cutting depth is 125μm-250μ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com