Numerical control vibration deep-hole drilling and boring machining equipment and method

A technology of processing equipment and processing methods, applied in metal processing equipment, drilling/drilling equipment, boring/drilling, etc., can solve the problems of low machining accuracy, unstable chip breaking and removal, and reduce the chip volume , The effect of realizing automation and solving the problem of chip breaking and removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

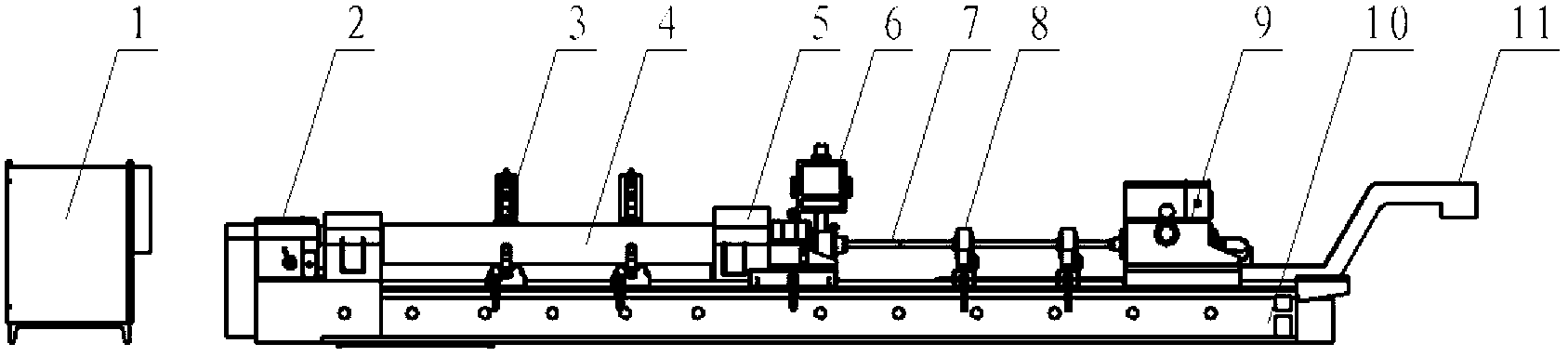

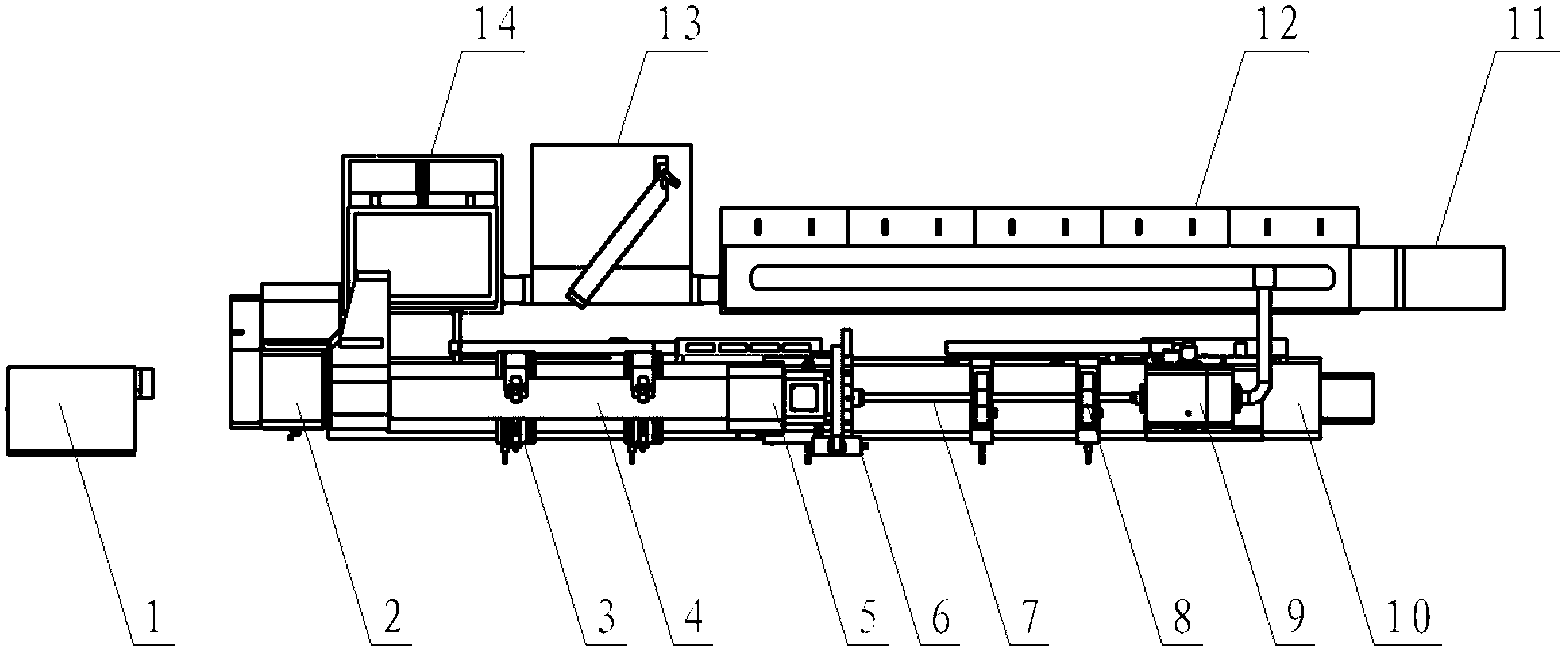

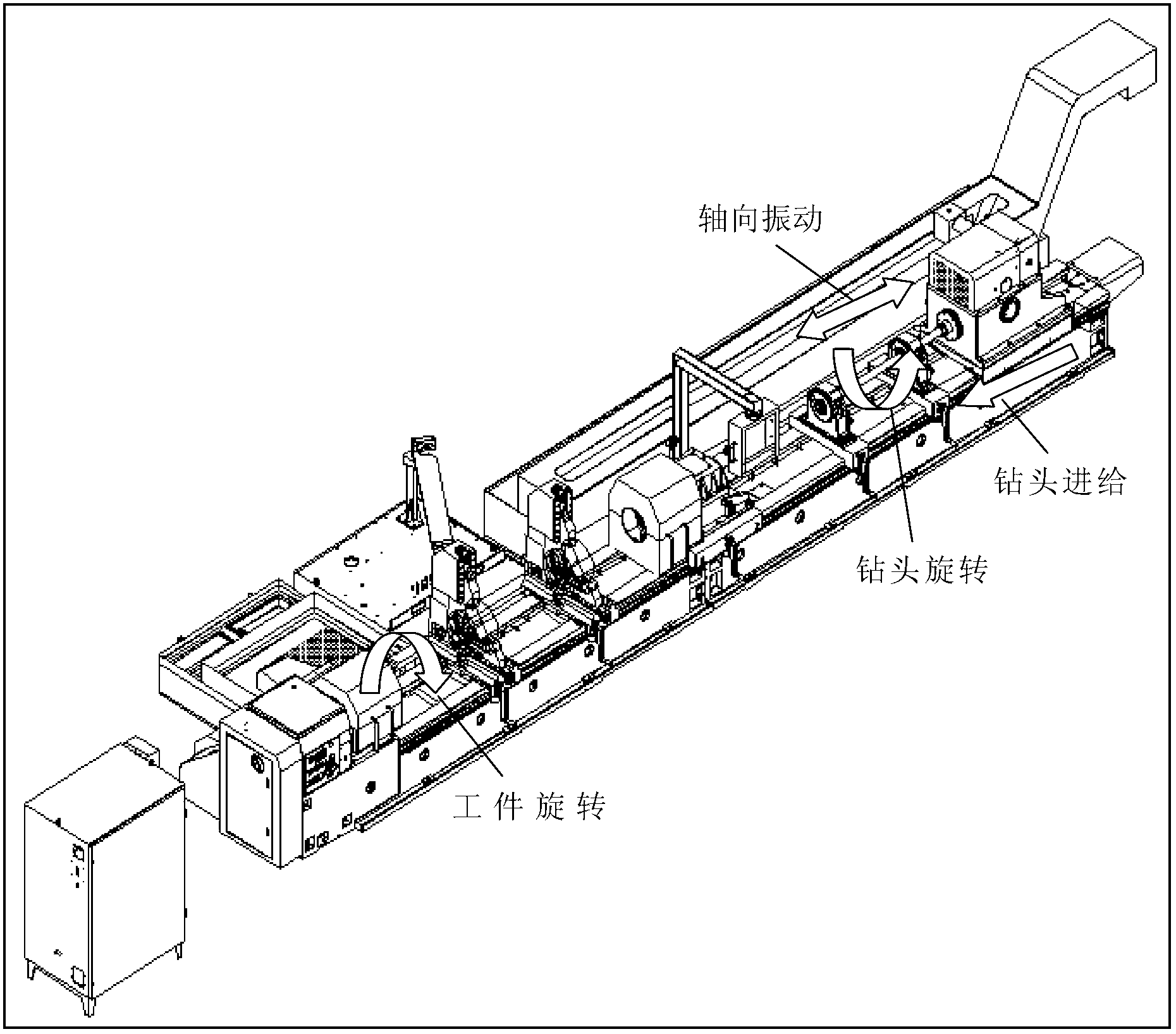

[0024] Embodiment, a kind of CNC vibration deep hole drilling and boring processing equipment, see figure 1 , figure 2 , including the bed 10, the chip conveyor 11, the crude oil tank 12 at the end of the bed, the essential oil tank 13, the crude oil tank 14 at the head of the bed, the pump station and the spindle box 2 arranged on the bed 10, the oil receiver 5, the vibration box 9, the workpiece 4. The drill bit and drill pipe 7, the workpiece 4 is set between the spindle box 2 and the oiler 5 through the workpiece support 3; the drill pipe support 8 is arranged between the oiler 5 and the vibration box 9, and the drill bit and the drill pipe 7 are installed In the guide support holes of the vibrating box 9, the drill pipe support 8 and the oil receiver 5. It adopts low-frequency axial vibration drilling method for two-way rotary BTA internal chip removal deep hole processing. The drill bit is connected with the vibrating box 9 through the drill rod, and rotates under the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com