Forming mold and method for composite material pipe fitting

A composite material and molding die technology, which is applied to household appliances, tubular items, other household appliances, etc., can solve the problems of high mold processing cost, high product production cost, complex molding process, etc., to ensure the uniformity of wall thickness, reduce Equipment investment, good product quality and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

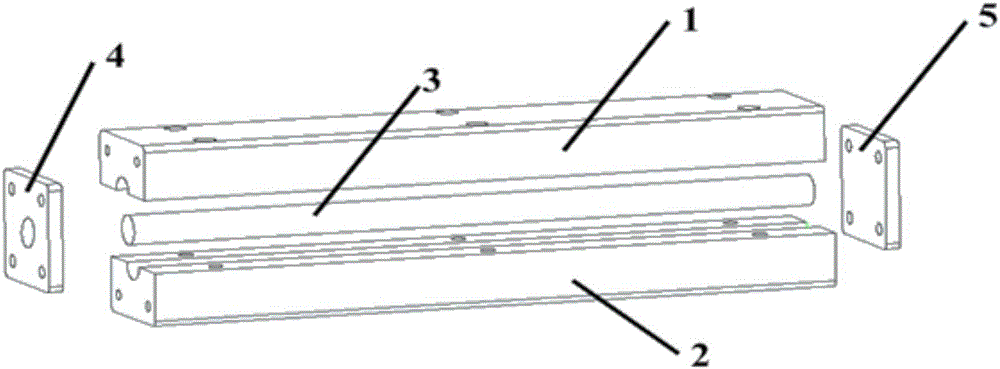

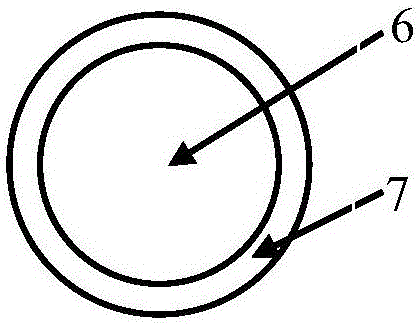

[0036] This embodiment provides a molding die for composite pipe fittings, such as figure 1 and figure 2 As shown, it includes a metal outer mold, a core mold 3 and a connection structure arranged at two ends of the metal outer mold; a through hole is arranged in the middle of the metal outer mold, and the core mold is arranged in the through hole; the metal outer mold is composed of an upper metal outer mold. The mold 1 and the lower metal outer mold 2 are composed; the core mold includes a core material layer 6 and a nylon bag film layer 7 sleeved on the outer surface of the core material layer.

[0037] The nylon bag film layer 7 is a bag film with a tubular structure, one end is sealed, and the other end is connected to an inflation nozzle.

[0038] The thickness of the bag film is 0.03mm-0.15mm, the elongation rate is not lower than 150%, the temperature resistance is not lower than 80°C, and the pressure resistance is not lower than 5MPa.

[0039] The core material la...

Embodiment 2

[0058] This embodiment provides a molding die and molding method for a composite material pipe fitting. The difference from Example 1 is that the cross-sectional shape of the prepared composite material pipe fitting is pentagonal, and the prepared polystyrene foam core material layer The cross-sectional shape is also pentagonal, and other mold structures, mold forming steps and parameters are the same as in Example 1. The wall thickness of the obtained composite pentagonal pipe fitting is 2mm (0mm, -0.05mm), and the flaw detection meets the requirements of Class A in GB2895.

[0059] To sum up, in order to meet the high-quality and low-cost application requirements of composite pipe fittings in high-tech fields such as aerospace, national defense, industry, and high-end sports, the present invention has gone through a lot of experiments and used nylon bag film to cover polystyrene foam The core mold 3 is formed, and the prepreg layer is placed on the surface of the core mold 3...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Heat resistant | aaaaa | aaaaa |

| Withstand voltage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com