Rotor assembly and electric driving pump

A rotor and component technology, applied in the field of centrifugal pumps, can solve the problems of high mold cost, long cycle time, waste of magnetic materials, etc., and achieve the effect of reducing mold opening costs, improving hydraulic performance, and reducing manufacturing material costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The present invention will be further described below in conjunction with accompanying drawing and specific embodiment:

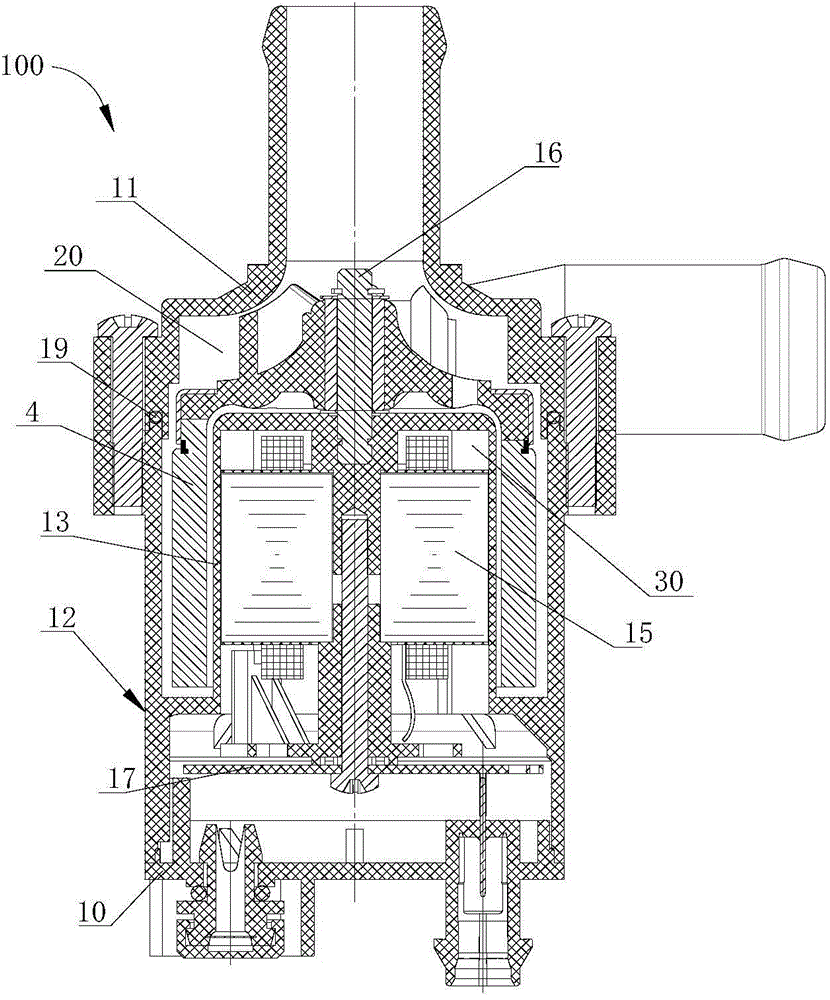

[0044] see figure 1 , the electric drive pump 100 includes a first housing 11, a second housing 12, an end cover 10, a rotor assembly 4, a stator assembly 15, a pump shaft 16, and a circuit board 17; the inner cavity of the pump includes the first housing 11, the second The space between the housing 12 and the end pipe 10, in this embodiment, the connecting part of the first housing 11 and the second housing 12 is provided with an annular sealing ring 19; the electric drive pump 100 has a spacer 13, the spacer 13 Divide the inner chamber of the pump into a flow chamber 20 and a housing chamber 30. The working medium can flow through the circulation chamber 20. The rotor assembly 4 is arranged in the circulation chamber 20. The housing chamber 30 has no working medium passing through. The stator assembly 15 and the circuit board 17 Set in the housing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com