Processing method of large-scale thin-wall cabin shell body and clamp

A processing method and shell technology, applied in the direction of manufacturing tools, metal processing equipment, metal processing machinery parts, etc., can solve the problems of long zero setting time, affecting product stability, and difficulty in clamping and aligning, to ensure wall thickness. The effect of uniformity, small processing deformation and improved processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in detail below in conjunction with the accompanying drawings.

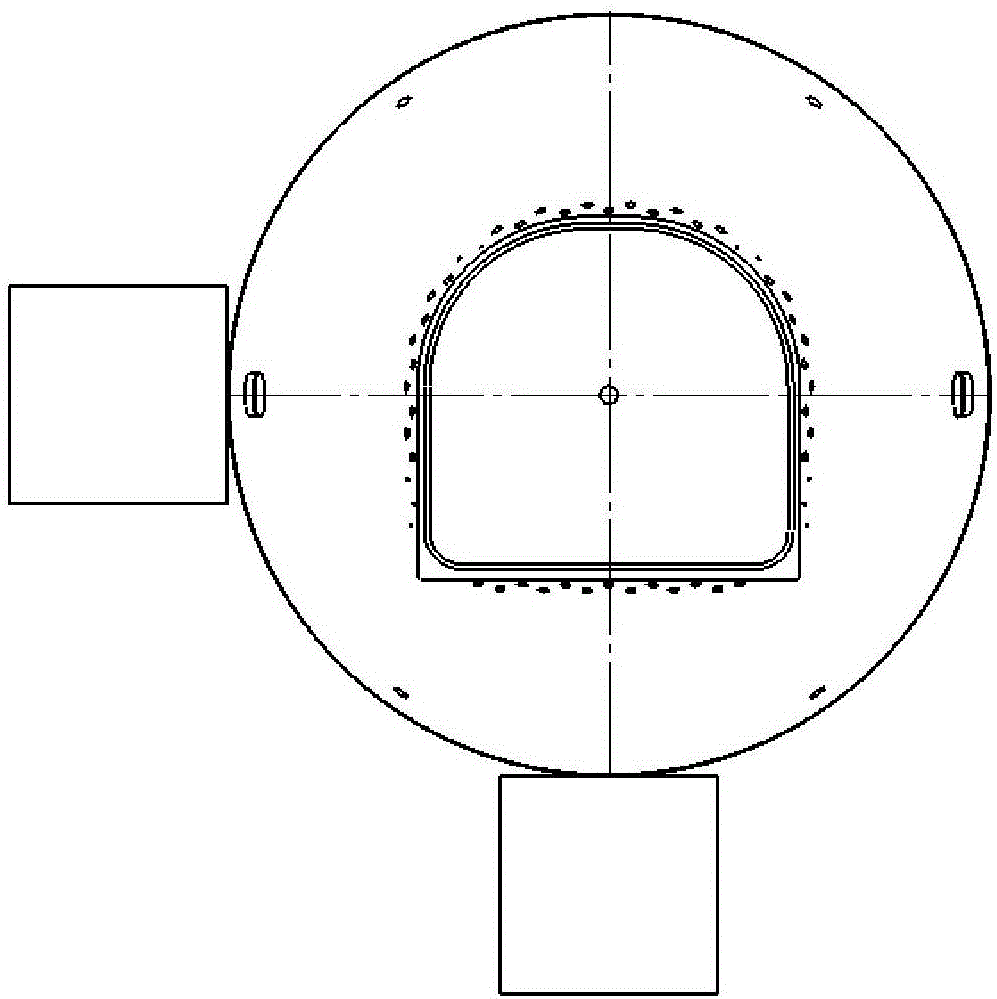

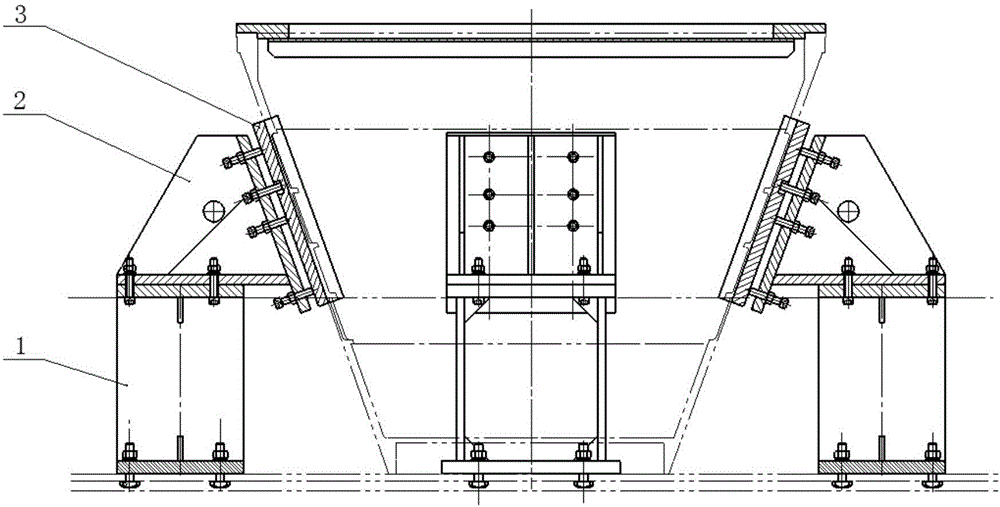

[0028] combine figure 1 As shown, the large thin-walled special-shaped casting cabin shell disclosed in this embodiment is an important product on a certain type of missile, and is the key to ensure reliable connection and separation of the missile during ground lifting, transportation, and booster flight. The front end of the shell is a non-circular special-shaped section, the outer diameter of the outline is 600mm-700mm, and the rear end is a circular end frame with a diameter of φ1400mm. The taper is about 20°, and the typical wall thickness is 3mm.

[0029] The processing method of the above-mentioned large thin-walled special-shaped cabin shell comprises the following steps:

[0030] The first step is to reserve a reference boss on the shape of the shell when casting the shell, rough machining the marking benchmark, level the front and rear end faces of the she...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com