Method for machining circumferential taper holes in irregular spraying pipe casing and composite clamp thereof

A tapered hole processing method and shell technology, applied in the direction of manufacturing tools, metal processing equipment, metal processing machinery parts, etc., can solve the problem of inaccurate alignment of the small end tapered hole 801, which affects the processing quality of the nozzle shell, and the cone surface Problems such as poor apparent quality, to achieve the effect of excellent apparent quality, meeting product design precision requirements, and high processing precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

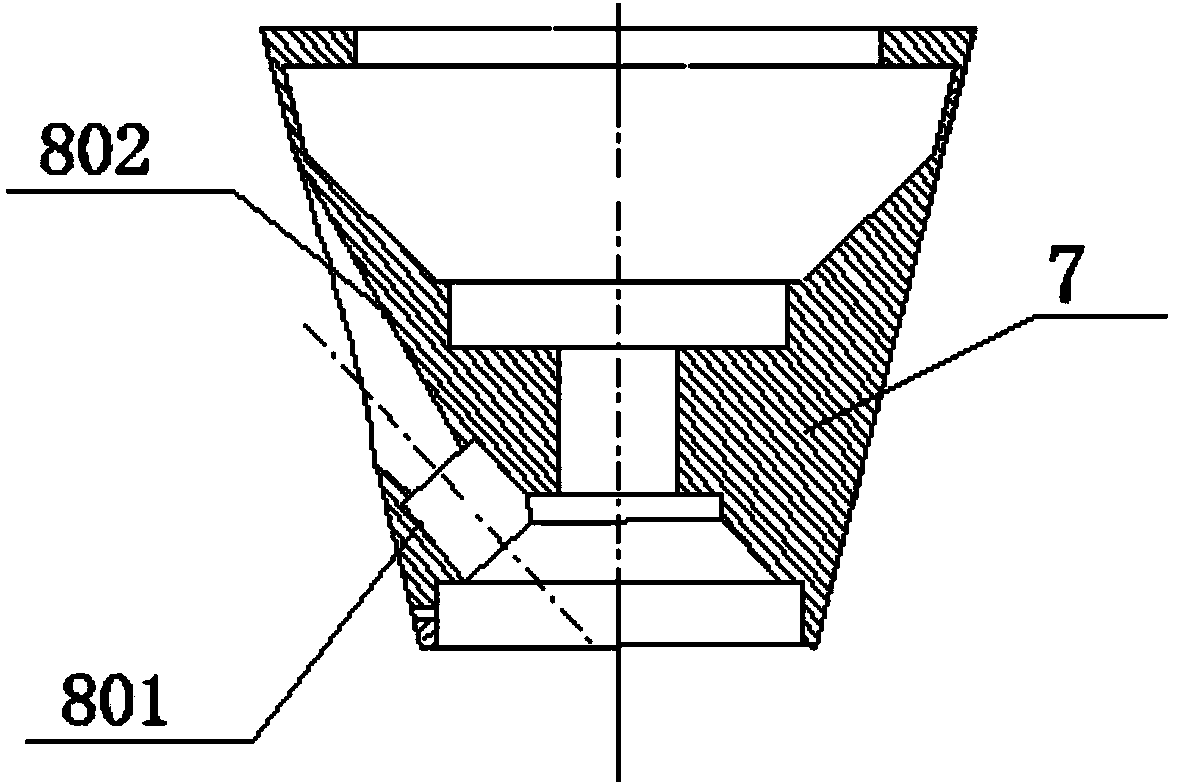

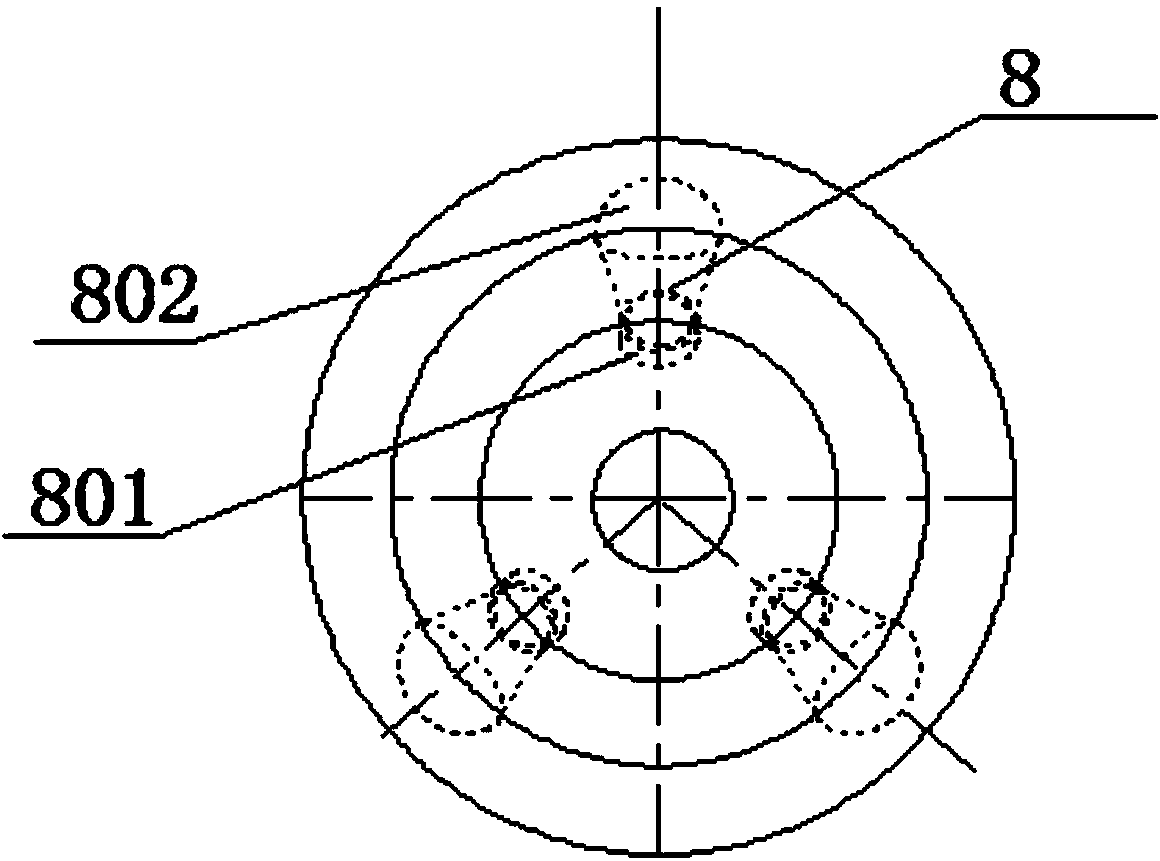

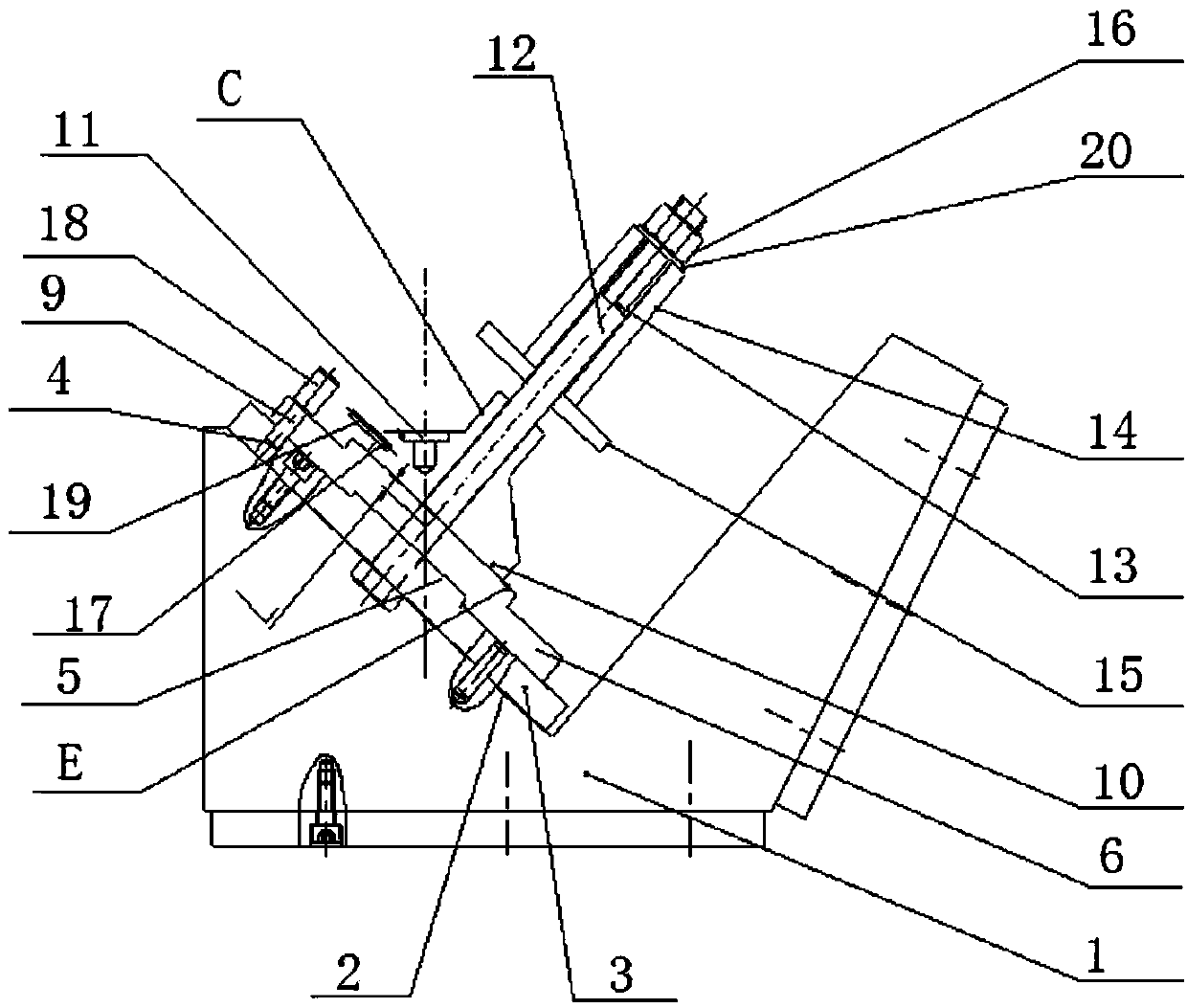

[0040] For the special-shaped nozzle shell, three cone holes are distributed in the circumferential direction. The cone holes are composed of a coaxial small end cone hole and an outer cone hole. The cone angle of the outer cone hole is 10° on one side, and the small end cone hole is The angle is 1.5° on one side, the angle between the centerline of the cone hole and the centerline of the nozzle casing is 38°±5′, and the space dimension L between the intersection point of the centerline of the cone hole and the centerline of the nozzle casing and the end face of the small end is 10.2± 0.05mm, the relative angle of the circumferential tapered hole is two places of 128°±5′, and the total length of the shell is 195±0.2mm.

[0041] The processing steps are as follows:

[0042] 1) Rough machining of the nozzle shell: refer to the final size of the product to rough machine each part of the nozzle shell to remove the allowance, process the total length of the shell to 195.6±0.2, and ...

Embodiment 2

[0050] For a special-shaped nozzle shell, three taper holes are distributed in the circumferential direction. The taper holes are composed of a coaxial small-end taper hole and an outer taper taper hole. The cone angle of the cone hole is 1° on one side, the angle between the centerline of the cone hole and the centerline of the nozzle casing is 36°±5′, and the space dimension L between the intersection point of the centerline of the cone hole and the centerline of the nozzle casing is from the small end is 18.5±0.05mm, the relative angles of three taper holes in the circumferential direction are two 132°±5′, and the total length of the shell is 235±0.3mm.

[0051] The processing steps are as follows:

[0052] 1) Rough machining of the nozzle shell: refer to the final size of the product to carry out rough machining on each part of the nozzle shell to remove the allowance. The rough machining shall leave a margin of 2-3mm on one side according to the maximum size of the nozzle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com