Efficient heat dissipation type middle gear motor with centrifugal overrunning double-clutch system

A deceleration motor and overrunning clutch technology, which is applied in chain/belt transmission devices, motor vehicles, electromechanical devices, etc., can solve the problems of insufficient output power of the rear hub motor, large main circuit current, and large power consumption, etc., to achieve improvement The effect of riding experience, improving quality and prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

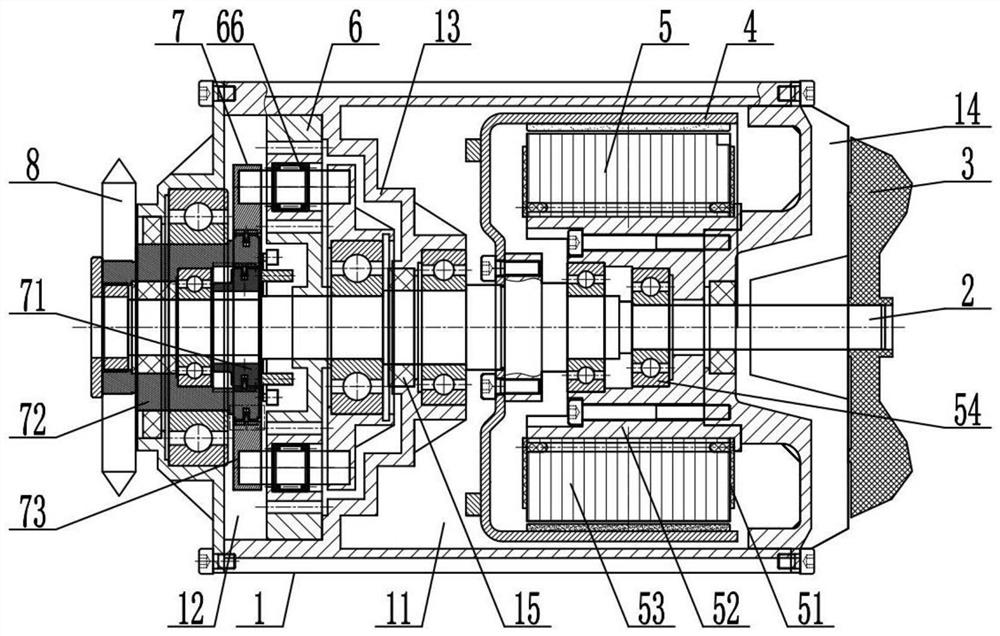

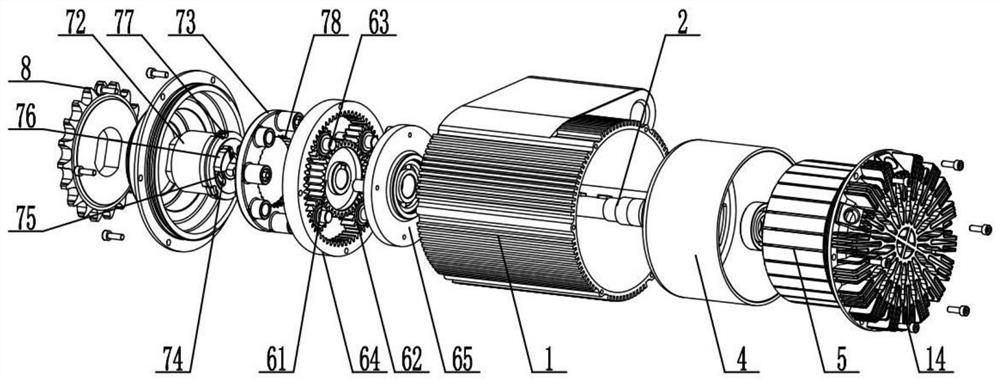

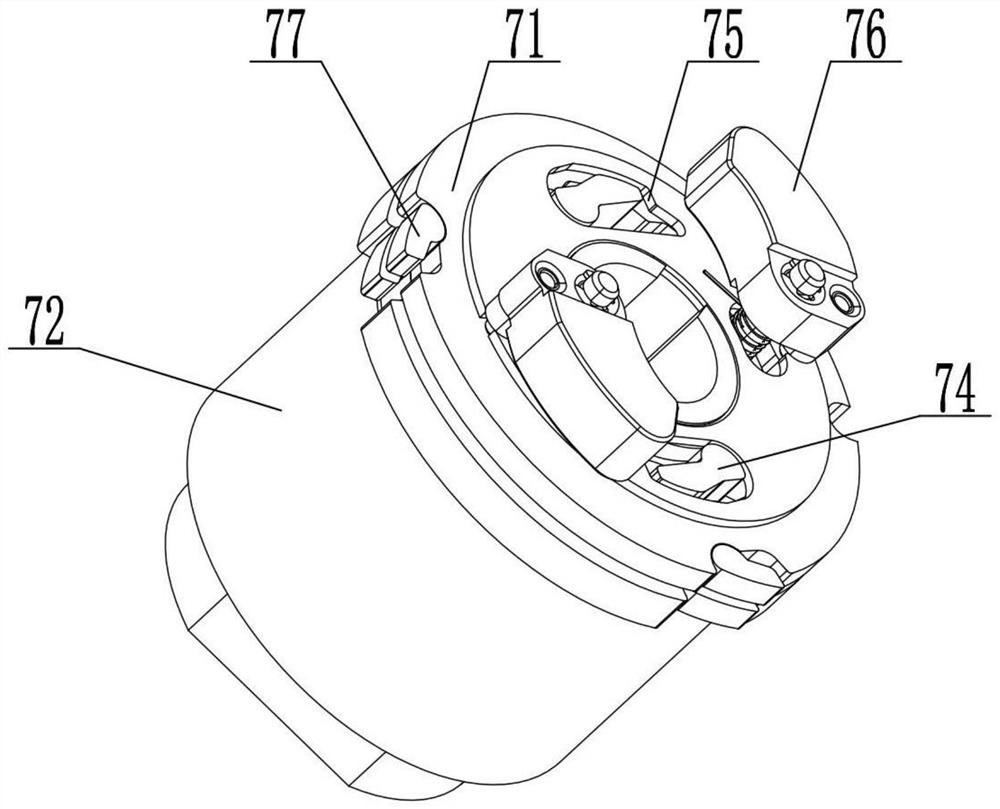

Embodiment 1

[0039] A high-efficiency heat-dissipating mid-mounted geared motor with a centrifugal overrunning dual-clutch system, comprising a housing 1 and a motor shaft 2, the motor shaft 2 runs through the housing 1 and is rotationally connected to the housing 1, and the housing 1 is provided with There is an insulating oil cooling tank 11, and also includes a cooling fan 3, a rotor assembly 4, a stator assembly 5, a planetary reduction mechanism assembly 6, a centrifugal overrunning dual clutch system 7, and a speed change sprocket 8, which are sequentially sleeved on the motor shaft 2, The cooling fan 3 is fixed on the side of the motor shaft 2 close to the insulating oil cooling groove 11, the stator assembly 5 and the rotor assembly 4 are arranged in the insulating oil cooling groove 11, and the stator assembly 5 and the rotor assembly 4 are arranged in the insulating oil cooling groove 11. The assembly 5 is fixed on the casing 1, the rotor assembly 4 is arranged coaxially with the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com