System and method for measuring direct tensile strength and deformation of rock

A measurement system and tensile strength technology, applied in the direction of electric/magnetic solid deformation measurement, measurement device, strength characteristics, etc., can solve problems such as bending or torsional stress, easy to generate bending moment, easy to generate stress concentration effect at the end, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

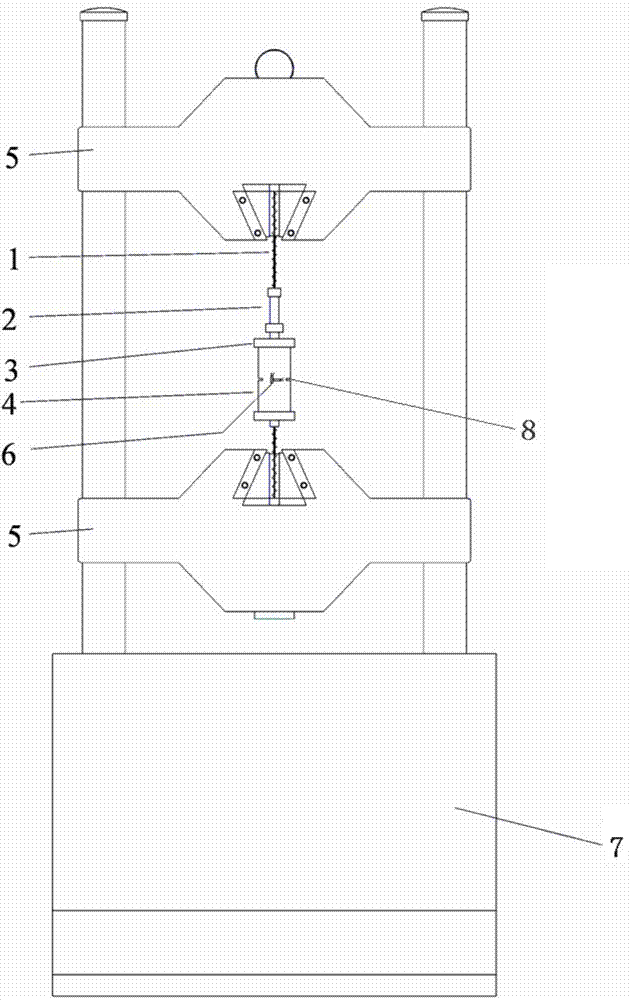

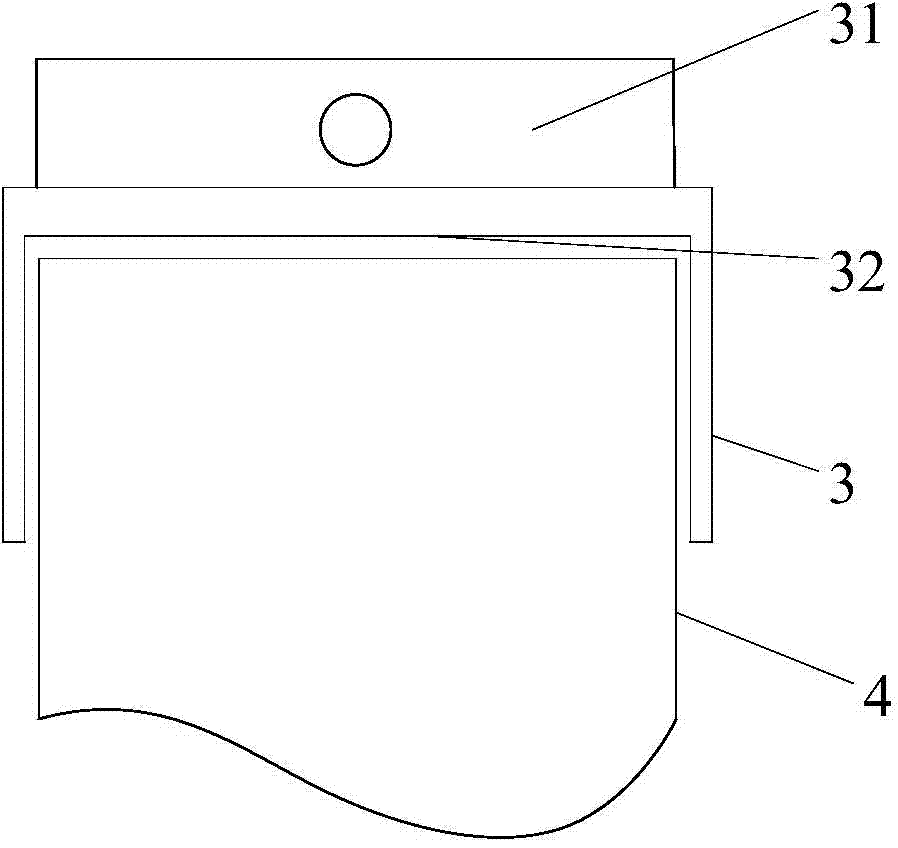

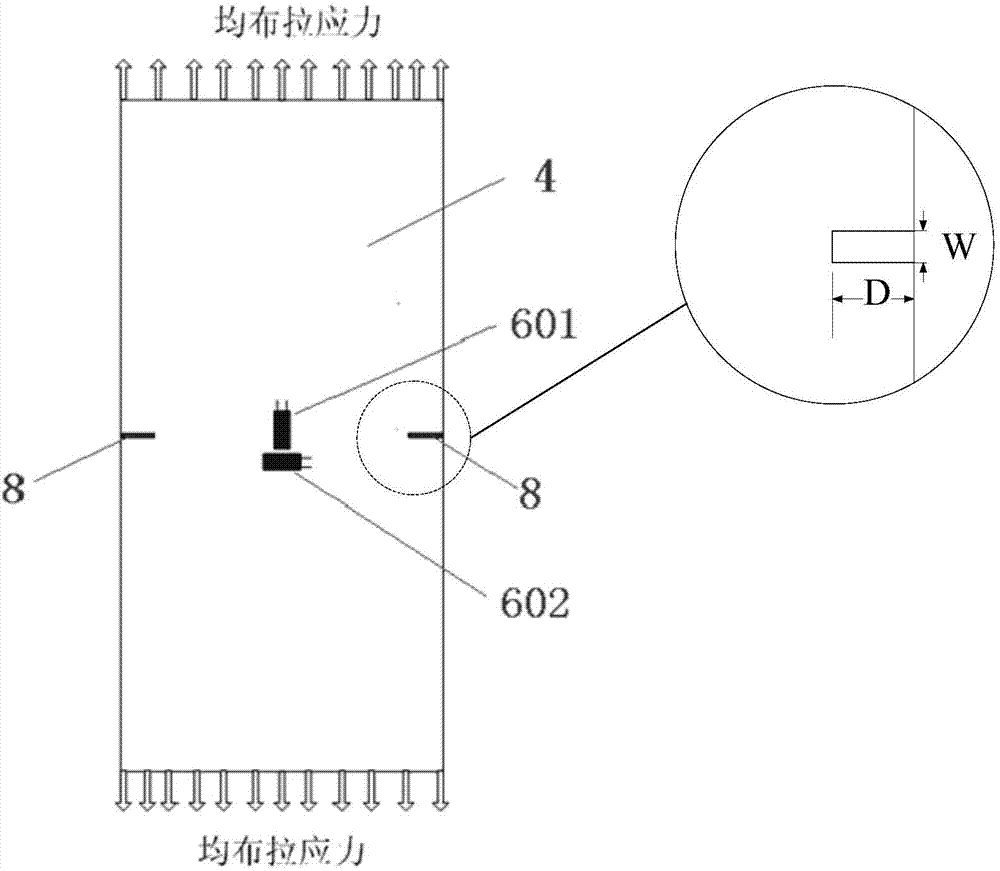

[0040] Technical effects of embodiments of the present invention will be apparent with reference to the following description and accompanying drawings. In these descriptions and drawings, some specific implementations of the embodiments of the present invention are specifically disclosed to represent some ways of implementing the principles of the embodiments of the present invention, but it should be understood that the scope of the embodiments of the present invention is not limited by this limit. On the contrary, the embodiments of the present invention include all changes, modifications and equivalents coming within the spirit and scope of the appended claims.

[0041] The measurement system for direct tensile and deformation measurement of rocks using artificial incisions according to the present invention will be described below with reference to the accompanying drawings.

[0042] Such as figure 1 As shown, the structure of the measuring system for rock direct stretc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com