Biaxial tension test device for testing performance of sheet metal

A test device and biaxial stretching technology, applied in the direction of measuring devices, optical devices, and analyzing materials, can solve the problems of inability to realize the strain state, complex structure of the device, and limited application, and achieve simple structure, wide application range, and ease of use. The effect of maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

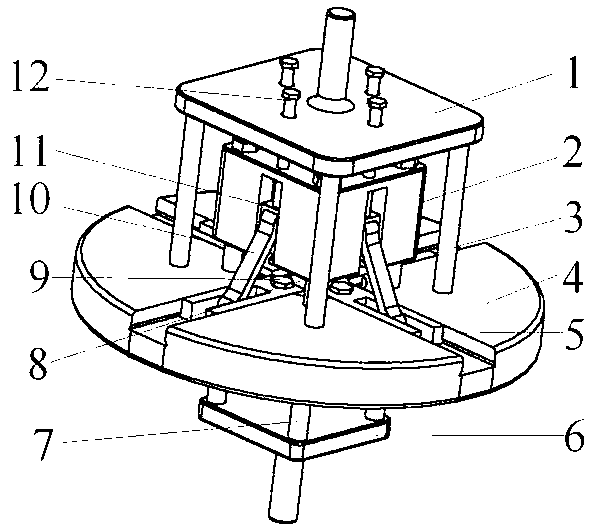

[0023] Such as figure 1 As shown, the bidirectional tensile test device for testing the properties of sheet metal provided by the present invention is composed of an upper connection structure, a lower connection structure, a proportional adjustment mechanism, a clamp slider mechanism and a connecting rod; the upper connection mechanism From top to bottom is an upper plate 1, four upper plate connection studs 3 and a chassis 4, the four upper plate connection studs 3 are fixedly connected to the chassis 4 and the upper plate 1; the lower connection From bottom to top, the mechanism is composed of four lower plate connecting studs 7 fixed on the lower plate 6 by the lower plate 6, the lower plate 6 is located below the chassis 4, and the four lower plate connecting studs 7 are fixed through the chassis 6 Connect the proportional adjustment mechanism, the proportional adjustment mechanism is located between the upper plate 1 and the chassis 4, and the rods of the four lower plat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com