Spring thrust down clamp of direct tensile test

A tensile test, support technology, applied in the direction of applying stable tension/pressure to test the strength of materials, measuring devices, instruments, etc., can solve the problem of ineffective support, and achieve simple structure, convenient use and easy assembly. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

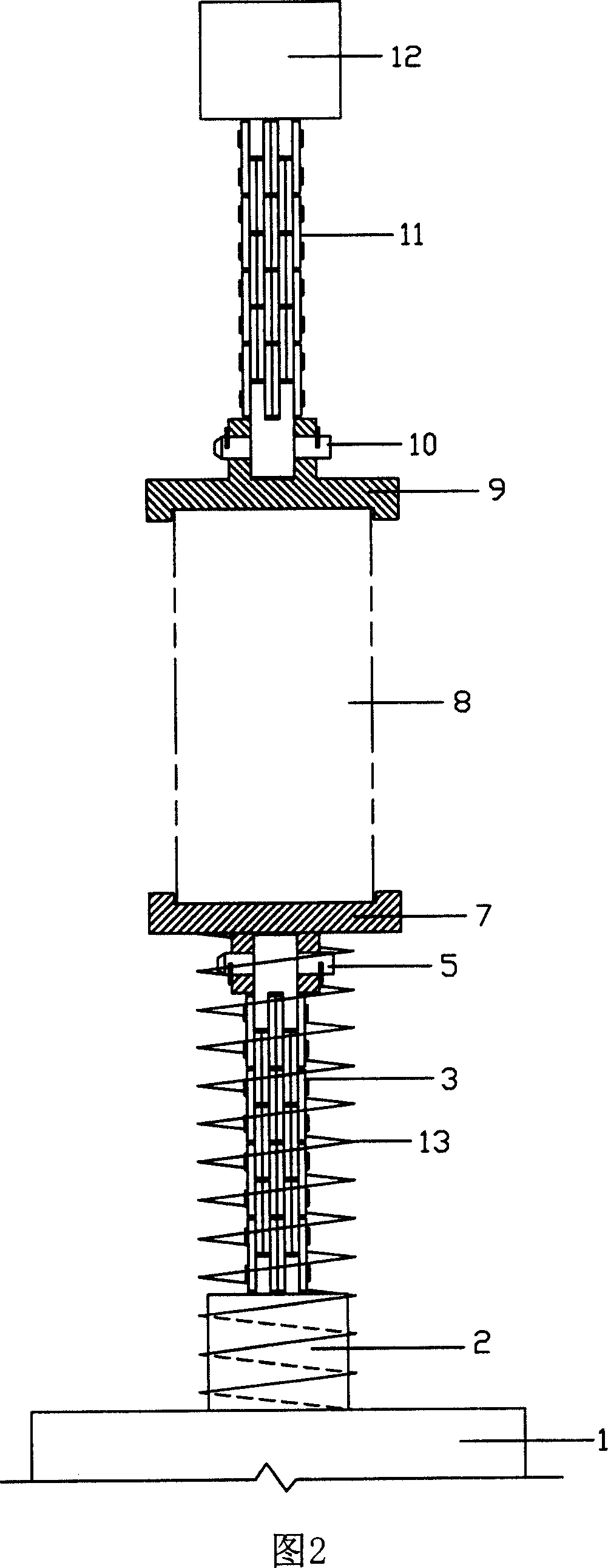

Embodiment 1

[0018] In this embodiment, the structure of the spring-supported lower fixture for the direct tensile test is shown in Figure 2, including the lower joint 2 connected to the base of the testing machine, the lower end cap 7 for fixing the sample, and the lower end cap for connecting the lower joint and the lower end cap. Chain 3. A supporting member for the sample and the lower end cap damaged by the tensile test. The supporting member is a cylindrical compression coil spring 13, and the free height H of the cylindrical compression coil spring is 0 It is greater than the sum of the height of the lower end cap, the lower chain and the lower joint by 3cm to 6cm, and the initial compression amount (the compression amount when the cylindrical compression coil spring is set) is its free height H 0 15% to 25% of the weight, the maximum load is not less than the sum of the weight of the sample, the lower end cap and the lower chain. The lower end cap 7 is composed of a sample fixing ...

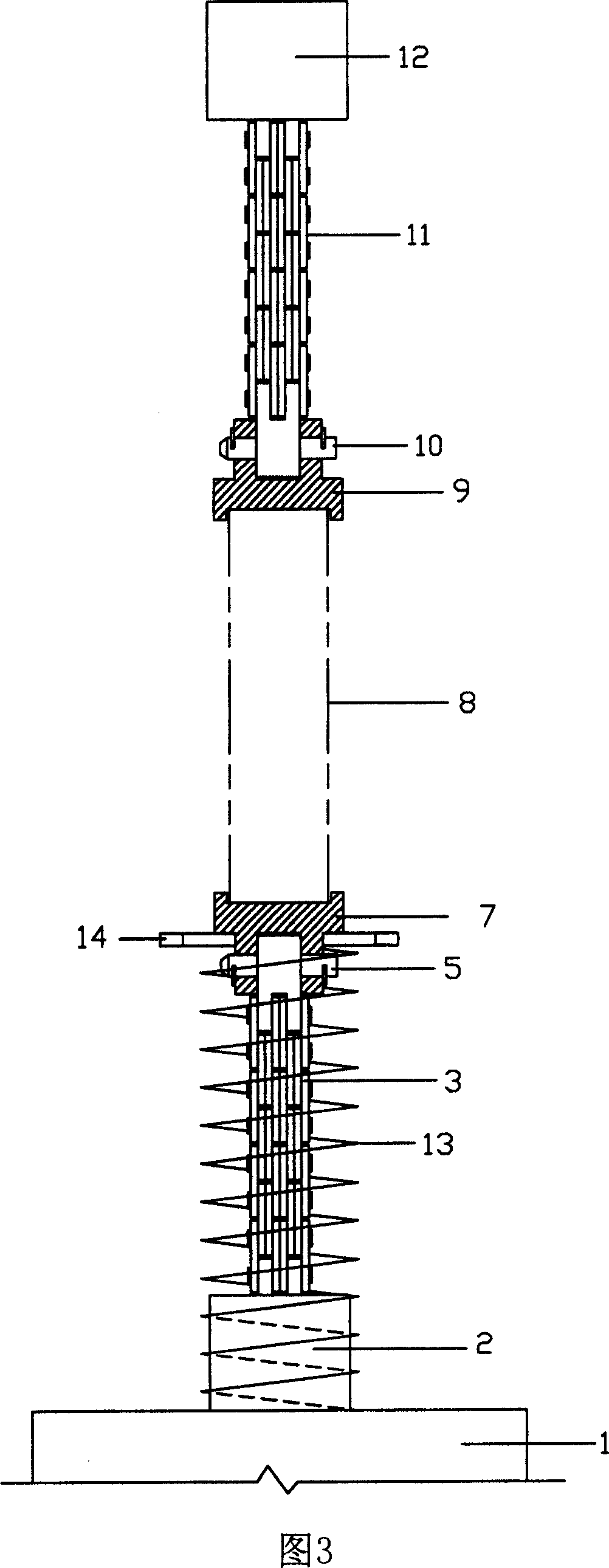

Embodiment 2

[0022] In this embodiment, the structure of the spring-supported lower clamp for the direct tensile test is shown in Figure 3, including the lower joint 2 connected to the base of the testing machine, the lower end cap 7 for fixing the sample, and the lower end cap for connecting the lower joint and the lower end cap. Chain 3. A supporting member for the sample and the lower end cap damaged by the tensile test. The lower end cap 7 is composed of a sample fixing groove and a connecting section. The supporting member is composed of a cylindrical compression coil spring 13 and a supporting plate 14. The outer diameters of the lower end cap sample fixing groove and the connecting section are smaller than that of the cylindrical compression coil spring. the inside diameter of. The free height H of the cylindrical compression coil spring 13 0 It is greater than the sum of the height of the lower end cap, the lower chain and the lower joint by 3cm to 6cm, and the initial compression...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com