Dynamic measuring device for worm helix error and pitch error

A tooth pitch error and dynamic measurement technology, applied in the direction of measuring devices, optical devices, instruments, etc., can solve problems such as difficult to achieve high-precision measurement of precision worms, affect the detection accuracy of precision worms, and stepping motor synchronization errors. Lightweight, strong self-resetting ability, and the effect of reducing errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

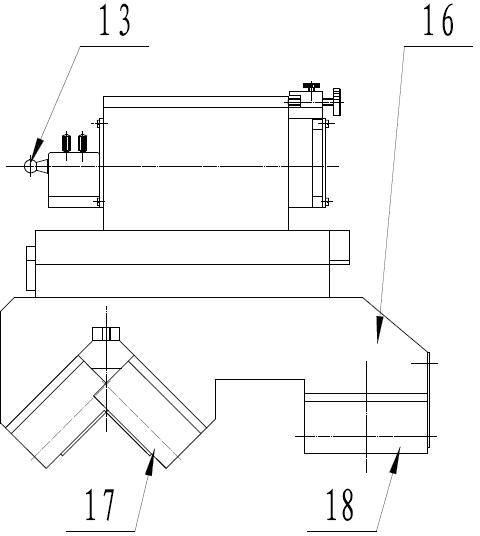

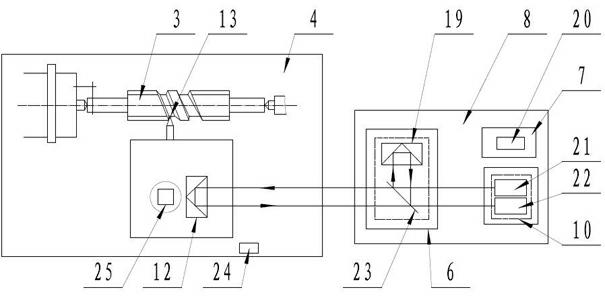

[0010] The dynamic measurement device for the helical error and pitch error of the worm screw of the present invention includes a support assembly, a feed guide module, a measurement assembly, and a computer processing system 9 for data processing and control; the support assembly mainly includes a bed 4 and a head frame 1 , tailstock 5, laser bracket 8; the feed guide module mainly includes the axial feed transmission assembly 15 and the guide rail 11; the measurement assembly mainly includes the measuring table 2, the measuring head 13, the circular grating system 14 and the laser length measuring system; the guide rail 11 The headstock 1 is fixed on the bed 4; the measuring table 2 and the tailstock 5 are placed on the guide rail 11; the circular grating system 14 in the headstock 1 and the worm 3 to be tested are driven by the axial feed transmission assembly 15 to achieve synchronization Rotation; when the worm to be measured 3 rotates, the measuring head 13 drags the meas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com