Multifunction friction wear testing machine

A friction and wear, multi-functional technology, applied in the direction of using mechanical devices, machine/structural components testing, measuring devices, etc., can solve the problems of no quantitative indicators, performance testing of synthetic diamond products, etc., to achieve simple structure, stable and reliable control. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

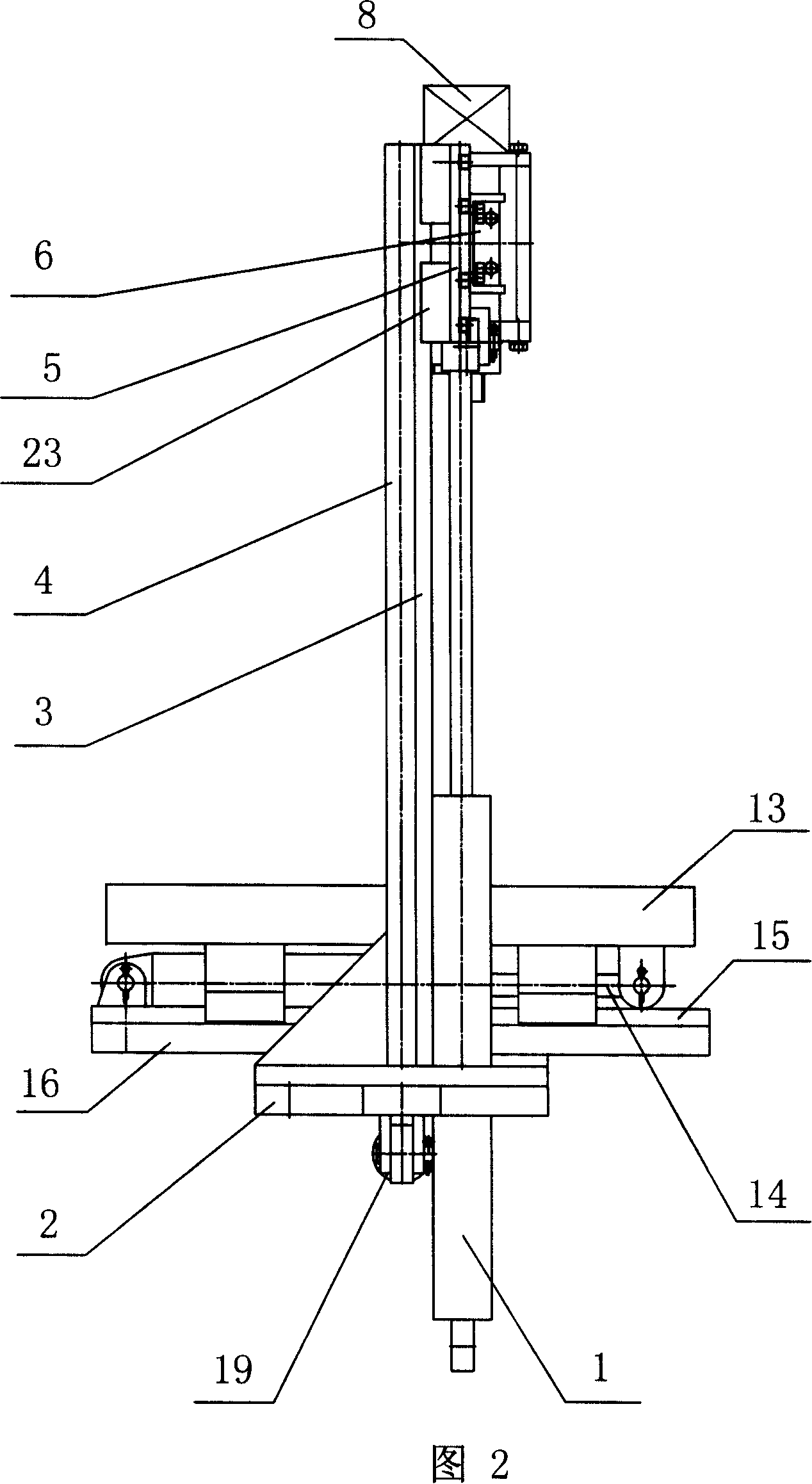

[0054]As shown in Fig. 1, Fig. 2, Fig. 3, Fig. 4, Fig. 5, Fig. 6, Fig. 7, Fig. 8, Fig. 9, Fig. 10, Fig. 11, Fig. 12, Fig. 13, Fig. 14, Fig. l5, Fig. 16, Fig. 17. As shown in Figure 18, Figure 19, Figure 20, Figure 21, Figure 22, Figure 23, Figure 24, Figure 25, Figure 26, Figure 27, Figure 28, and Figure 29, the multifunctional friction and wear testing machine includes the first A hydraulic cylinder 1, base plate 2, first guide rail 3, column 4, slider connecting plate 5, beam 6, torque sensor 7, hydraulic motor 8, main shaft housing 9, main shaft 10, speed sensor 11, water inlet connecting plate 12 , workbench 13, third hydraulic cylinder 14, third guide rail 15, slide plate 16, second guide rail 17, second pressure sensor 18, second hydraulic cylinder 19, first pressure sensor 20, the lower end of column 4 and base plate 2 The left end is fixedly connected (by bolts), the column 4 is provided with a first guide rail 3 along the Z direction, and the first guide rail 3 is pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com