Calibration method and data measurement device for finite element thermal-mechanical coupling model of high energy beam additive manufacturing

An additive manufacturing and thermal coupling technology, applied in the field of additive manufacturing, can solve problems such as cracking, substrate deformation, and inability to monitor the evolution of the thermal field in the entire field, and achieve the effect of comprehensive information and various types of measurement data.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described in detail below in conjunction with specific embodiments, which are explanations of the present invention rather than limitations.

[0036] The invention relates to a method for verifying a finite element thermomechanical coupling model of high-energy beam additive manufacturing. The finite element thermomechanical coupling model is verified by using the heat-deformation-strain field measurement results obtained through real-time measurement by a data measuring device.

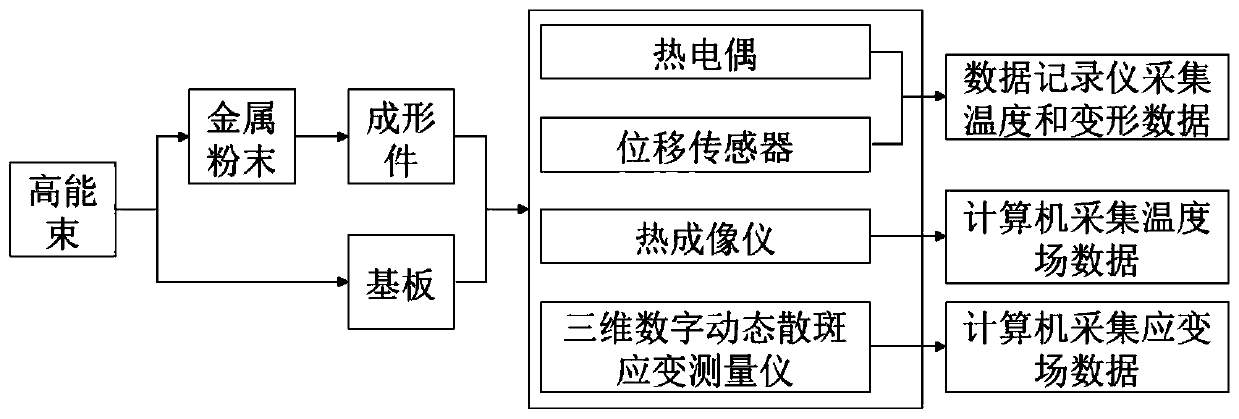

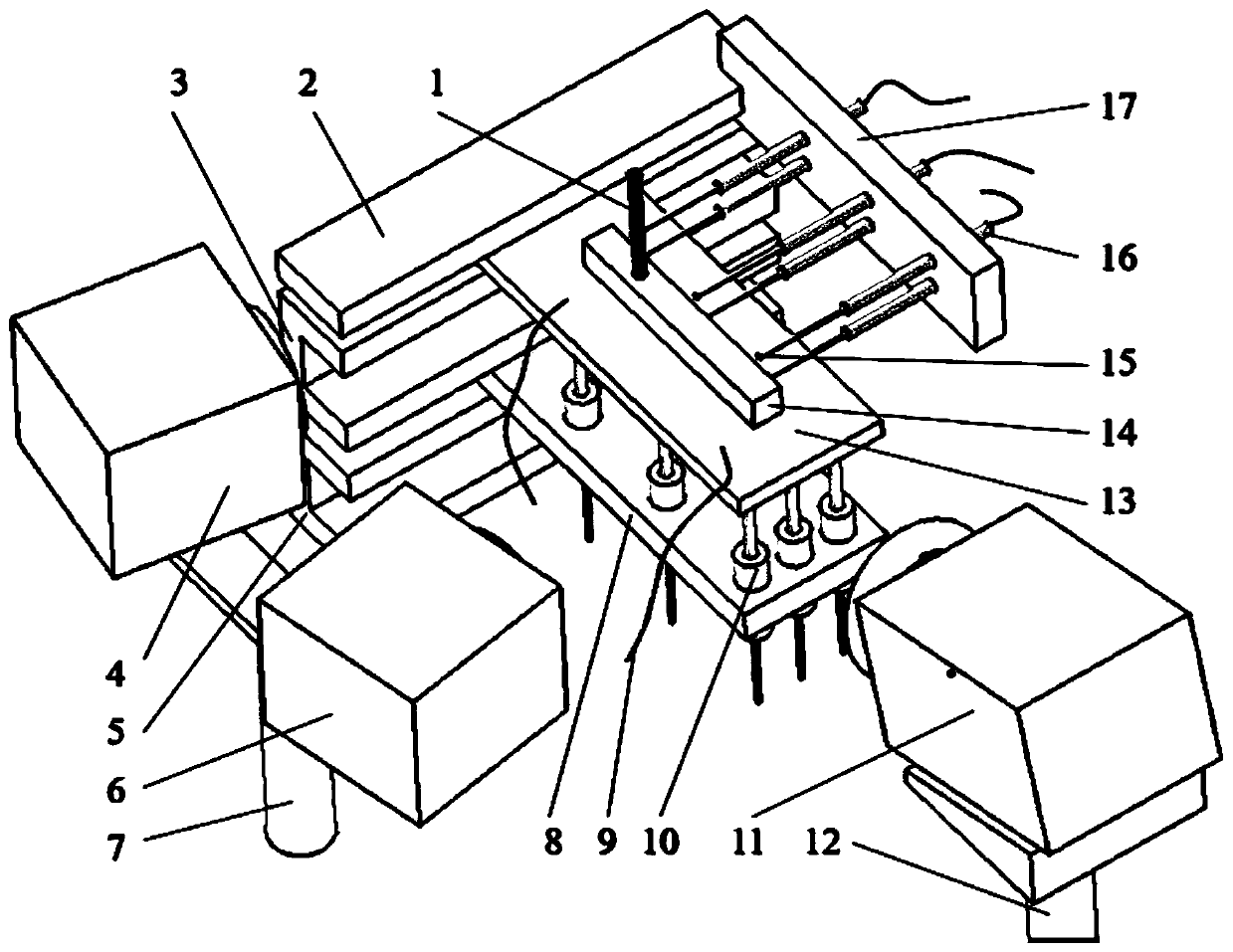

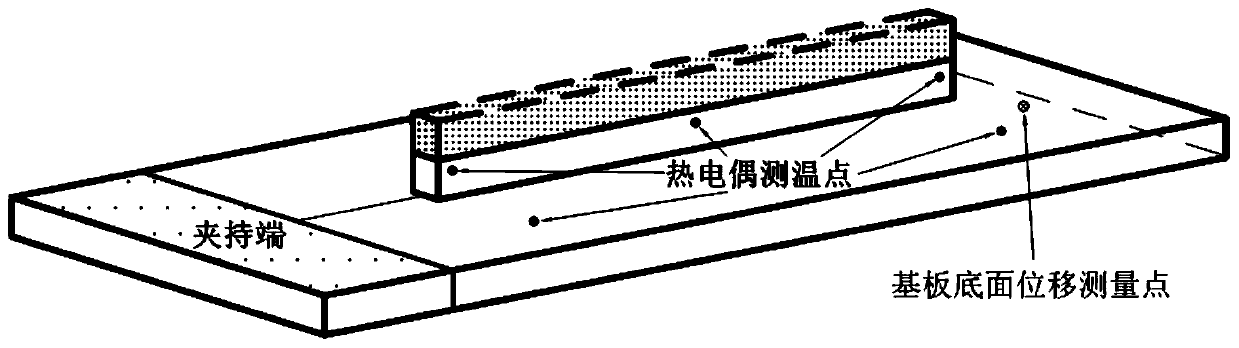

[0037] The following embodiments take the laser beam in the high-energy beam as a representative to illustrate how the present invention realizes the in-situ real-time accurate measurement of the heat-deformation-strain field by using the data measuring device in the high-energy beam additive manufacturing process and applies it to thermal-mechanical coupling Model validation. Such as figure 1 As shown, in the high energy beam processing process, the ther...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com