Half-fixed and combined rock strain measuring device

A rock mass and strain testing technology, applied in the direction of mechanical solid deformation measurement, etc., can solve the problems of non-recyclable and repeated use, poor signal quality, complicated installation and debugging, etc., to achieve stable and reliable test signals, reduce test costs, and safe operation and installation convenient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] best practice

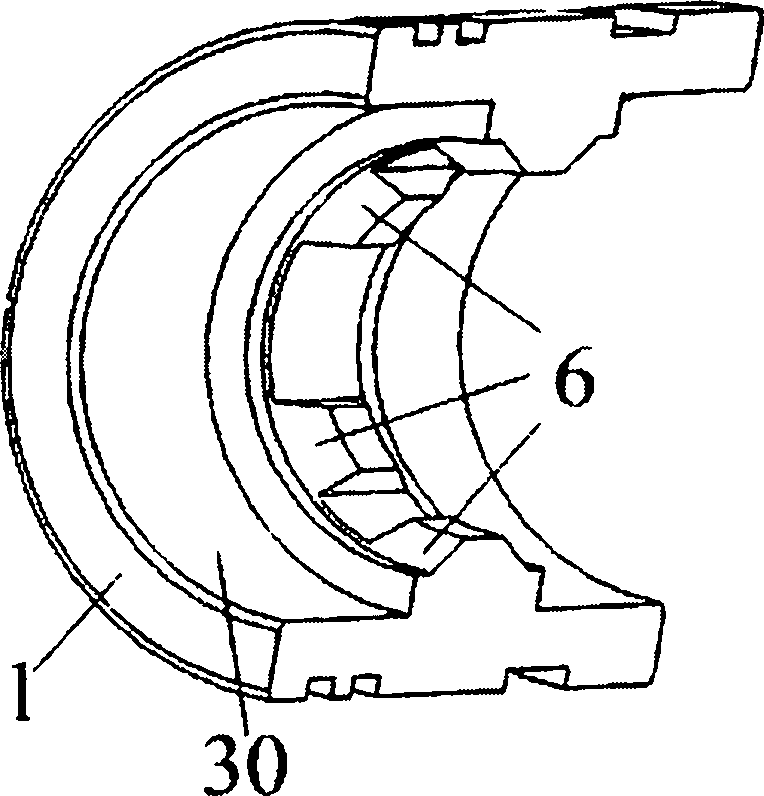

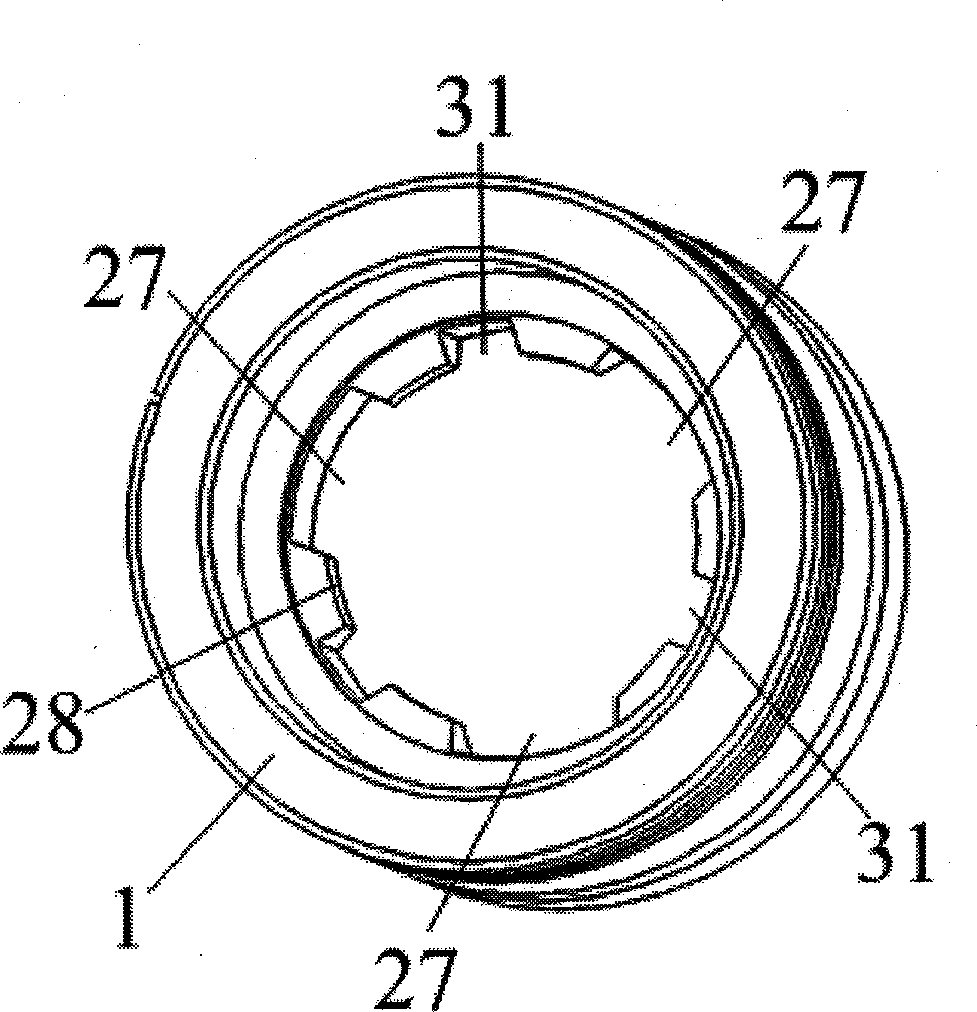

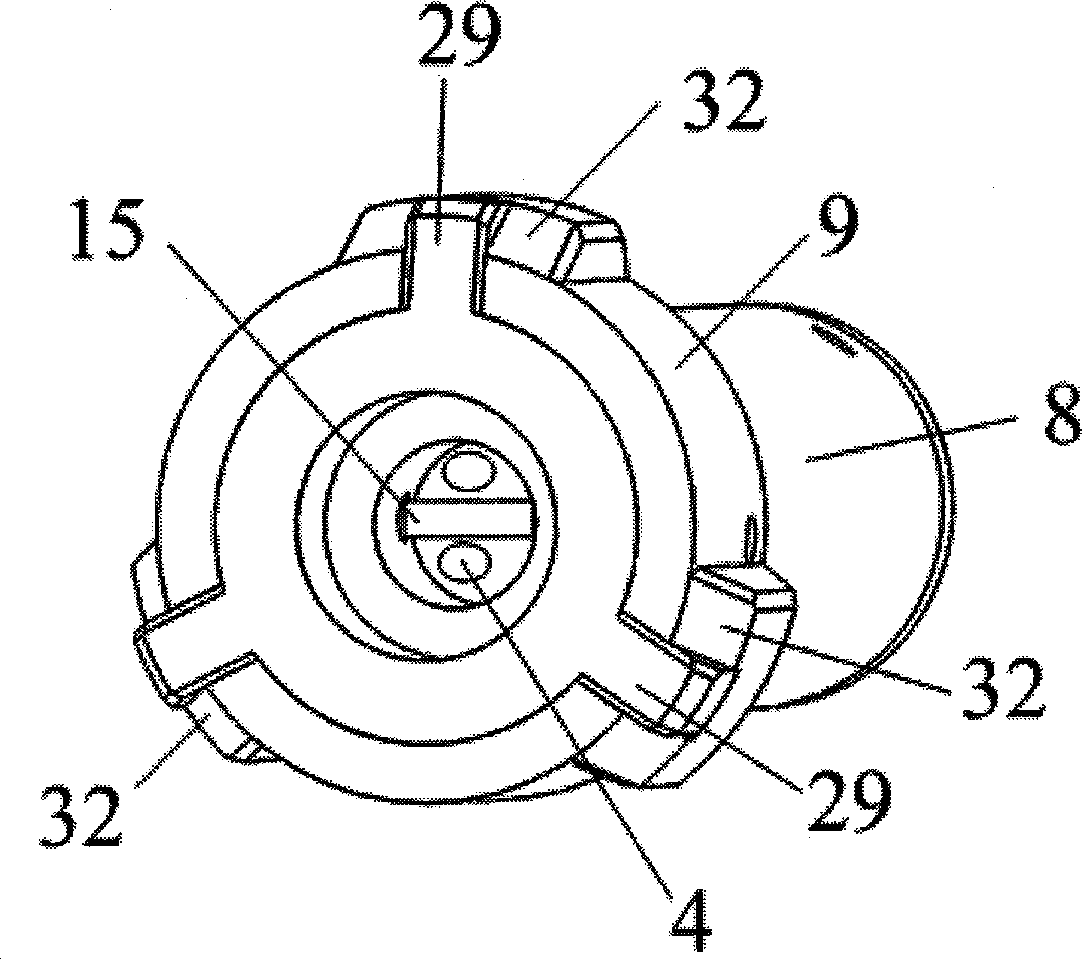

[0024] figure 1 , figure 2 Among them, (1) is the target ring, (2) is the support tube for the distance between the target ring, (3) is the independent strain test unit, (4) is the non-wired data communication transceiver, (5) is the strain reading buffer controller , (6) is in the middle of the axial position of the measuring ring, and its radial surface is equipped with two upper and lower conical seats facing away from each other, (7) is in the rock mass hole, (8) is an independent strain test The unit shell is supported, (9) is a spherical shape contact head at two axial ends of the independent strain test unit, (10) is a wireless communication antenna, and (11) is a strain reading buffer controller shell.

[0025] figure 1 , figure 2 Among them, the strain reading buffer controller (5) is outside the upper part of the rock mass hole, and a plurality of independent strain test units (3) can be arranged in sequence between each marking ring in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com