On-line detection device and process method of air foam flooding produced gas

An air foam and detection device technology, applied in the field of oil extraction, can solve problems such as hidden safety hazards, different levels of proficiency in instruments, and heavy labor, so as to ensure smooth production, improve research level and application effects, and ensure safe production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

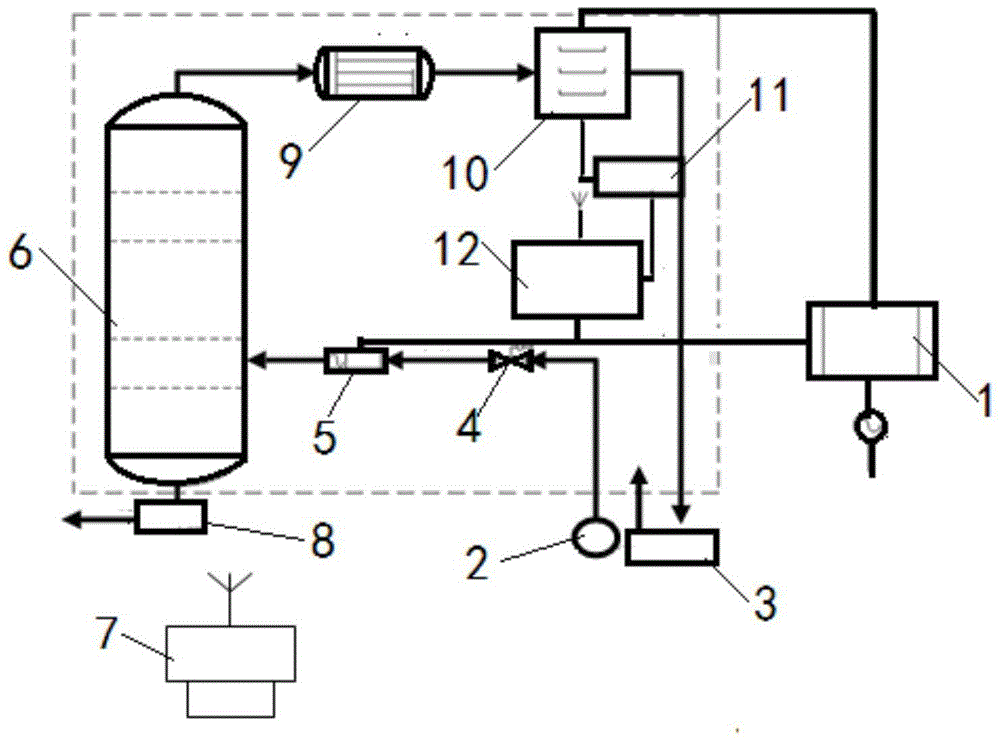

[0026] Embodiment 1: as figure 1 As shown, an air foam flooding produced gas online detection device,

[0027] 1. Gas detection device:

[0028] Mainly by O with data display function 2 , CO, CO 2 It is composed of a combustible gas detection transmitter 10, a solenoid valve 8, a GPRS data acquisition and control module, an industrial control computer, and the like.

[0029] 2. Gas collection and processing device:

[0030] A gas collection, control and processing device consisting of a flow controller 4, a solenoid valve 8, a gas-liquid separator (with pressure control function), and a filter. Provide the clean produced gas to the gas detector with the allowable flow rate and pressure to avoid damage to the detector and connecting pipelines, and ensure the safe and smooth operation of the detection device.

[0031] 3. GPRS network and software data acquisition, processing, analysis and control device:

[0032] Collect and display the parameters of gas components produce...

Embodiment 2

[0050] Embodiment 2: as figure 1 As shown, an air foam flooding produced gas online detection device,

[0051] (1) The linear distance between the gas detection cabinet and the oil-gas separator is 20-30m;

[0052] (2) The straight-line distance between the gas detection cabinet and the vent point is 5m, and the vent end is raised by 3m (protected by a rainproof cap);

[0053] (3) Gas sampling pipelines and venting pipelines are made of galvanized pipes, and the connections with the cabinets are connected by threads (the materials and joints in the cabinets are stainless steel);

[0054] (4) The gas transmitter has dual modes of remote transmission and display;

[0055] (5) Sampling pipelines and venting pipelines are used for thermal insulation treatment, and DN15 galvanized pipes and DN25 galvanized pipes are used respectively;

[0056] (6) 220VAC adopts aviation plug connection mode, if it is not equipped with a heating belt, the power is 220V / 10A; otherwise, 220V / 50A po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com