Air test system used for service test of cooling device

A cooling device and testing system technology, applied in the direction of measuring devices, instruments, etc., can solve the problems of not being able to accurately determine the heat transfer capacity of the cooling device, not being able to simulate air pressure loss, etc., to save raw materials, ensure safe and reliable operation, and reduce costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

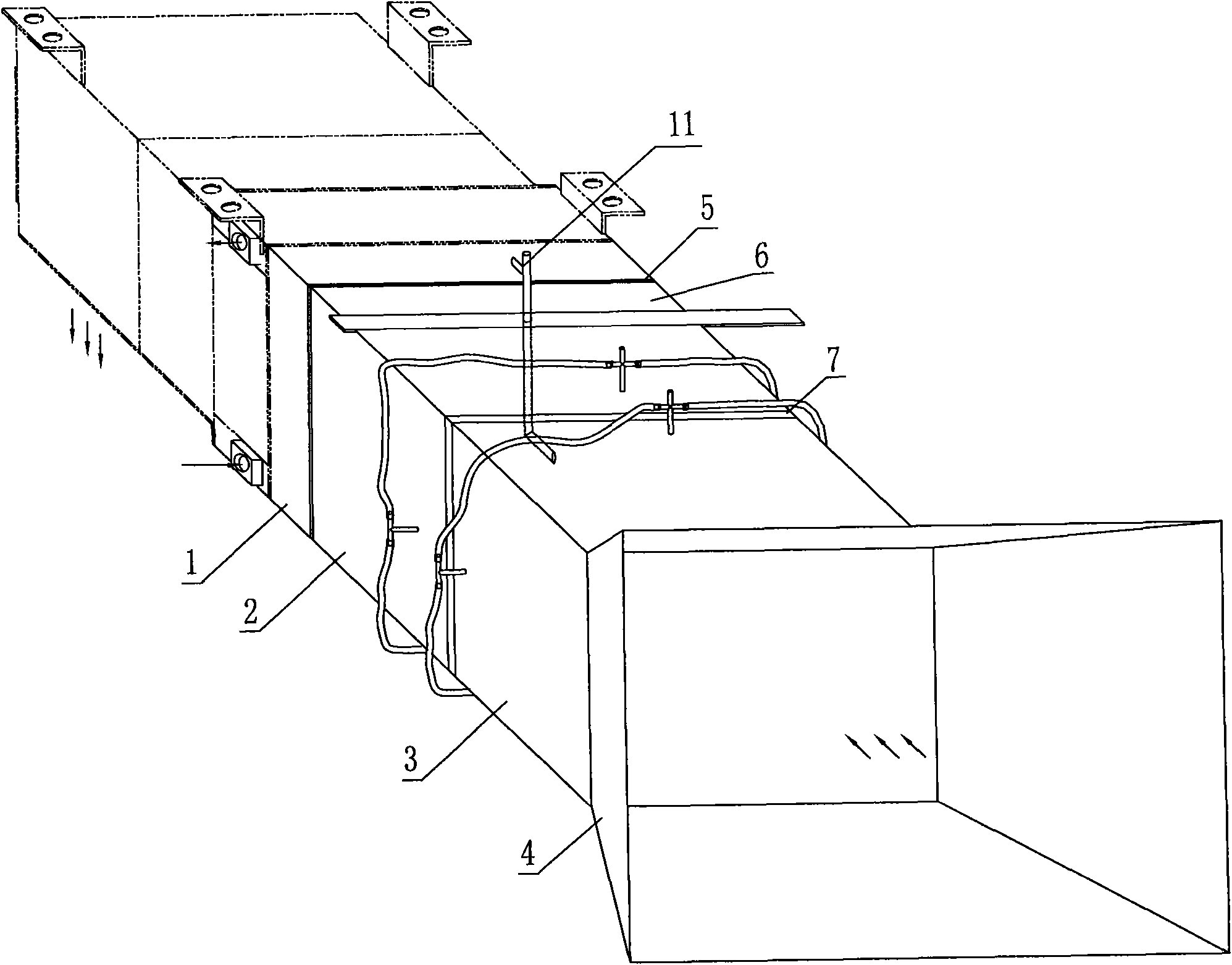

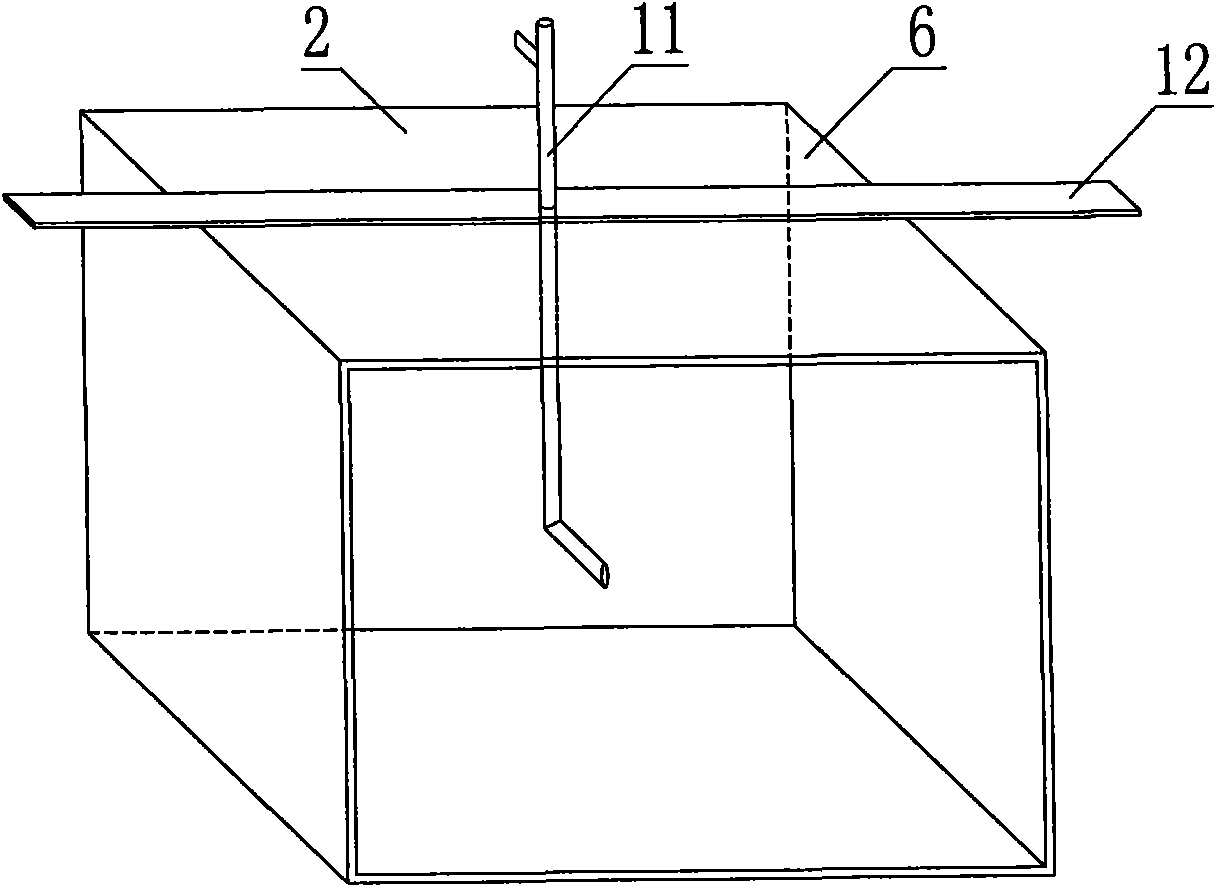

[0025] Now in conjunction with accompanying drawing, the present invention will be further described: figure 1 In the cooling device, the air intake side of the cooling device radiator is arranged in sequence from the main air cylinder 1, the main air cylinder 2, the main air cylinder 3 and the air intake rectifying air cylinder 4, and the air temperature is set between the main air cylinder 1 and the main air cylinder 2. Measuring device 5, an air flow measuring device is set on the main air duct 2

[0026] 6. An air pressure loss simulator 7 is installed between the main air cylinder 2 and the main air cylinder 3, and an air pressure loss measuring device is installed before and after the air pressure loss simulator 7. exist figure 1 Among them, the air intake rectifying air cylinder 4 is from large to small, and its transition shape line is an arc line.

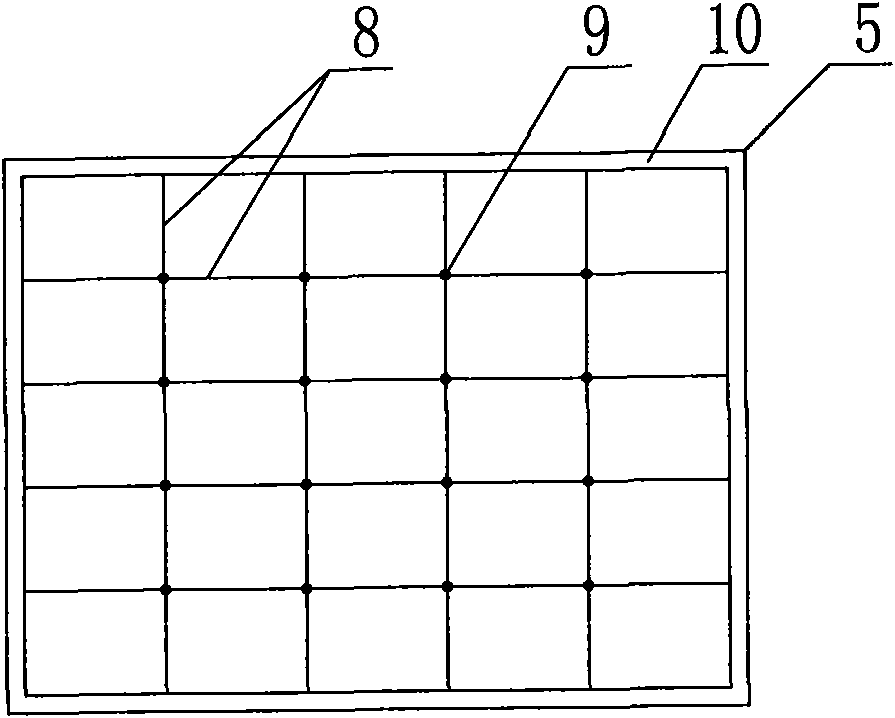

[0027] exist figure 2 Among them, the structure of the air temperature measuring device 5 is that the frame 10 is co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com