Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

233 results about "In-circuit test" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

In-circuit test (ICT) is an example of white box testing where an electrical probe tests a populated printed circuit board (PCB), checking for shorts, opens, resistance, capacitance, and other basic quantities which will show whether the assembly was correctly fabricated. It may be performed with a bed of nails type test fixture and specialist test equipment, or with a fixtureless in-circuit test setup.

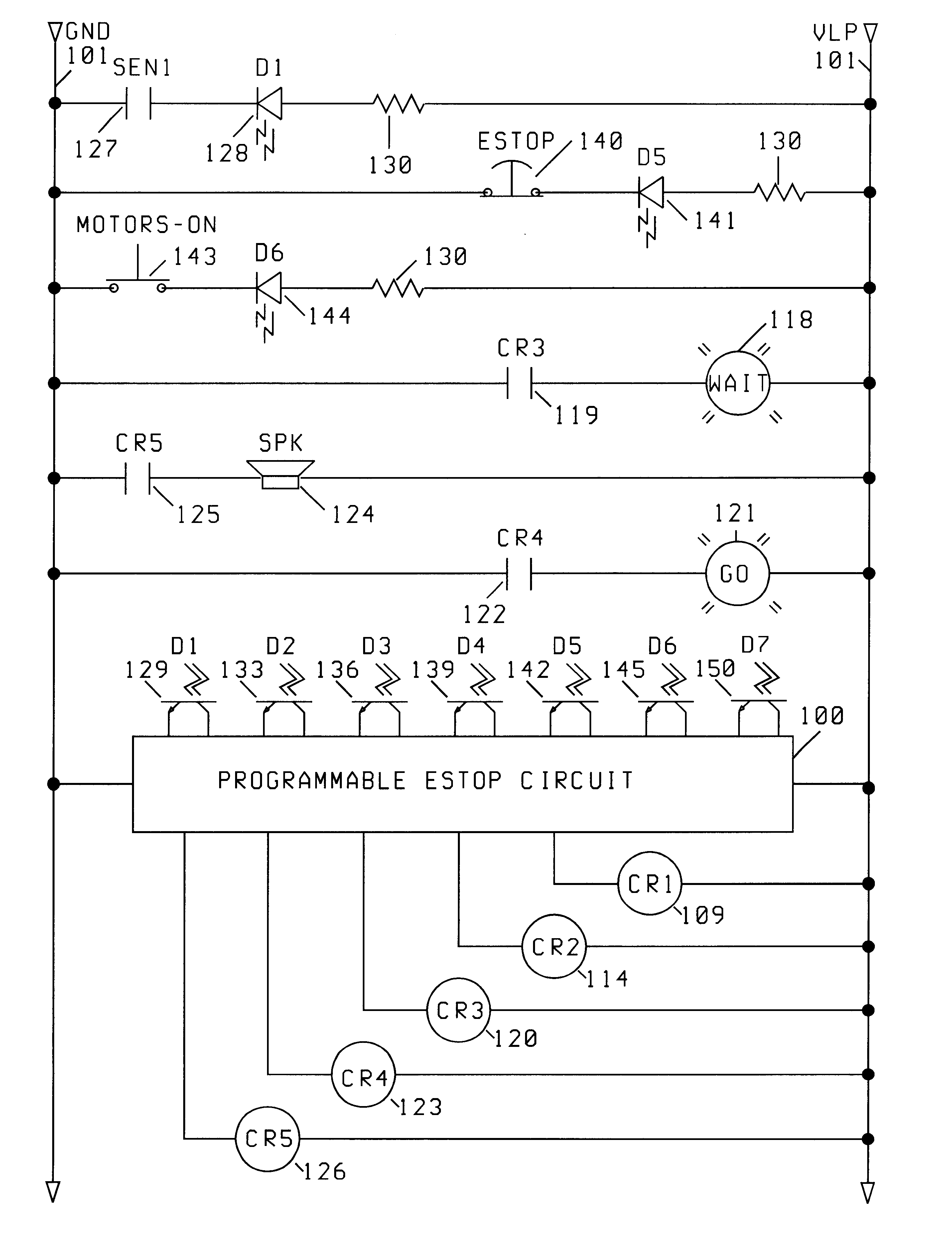

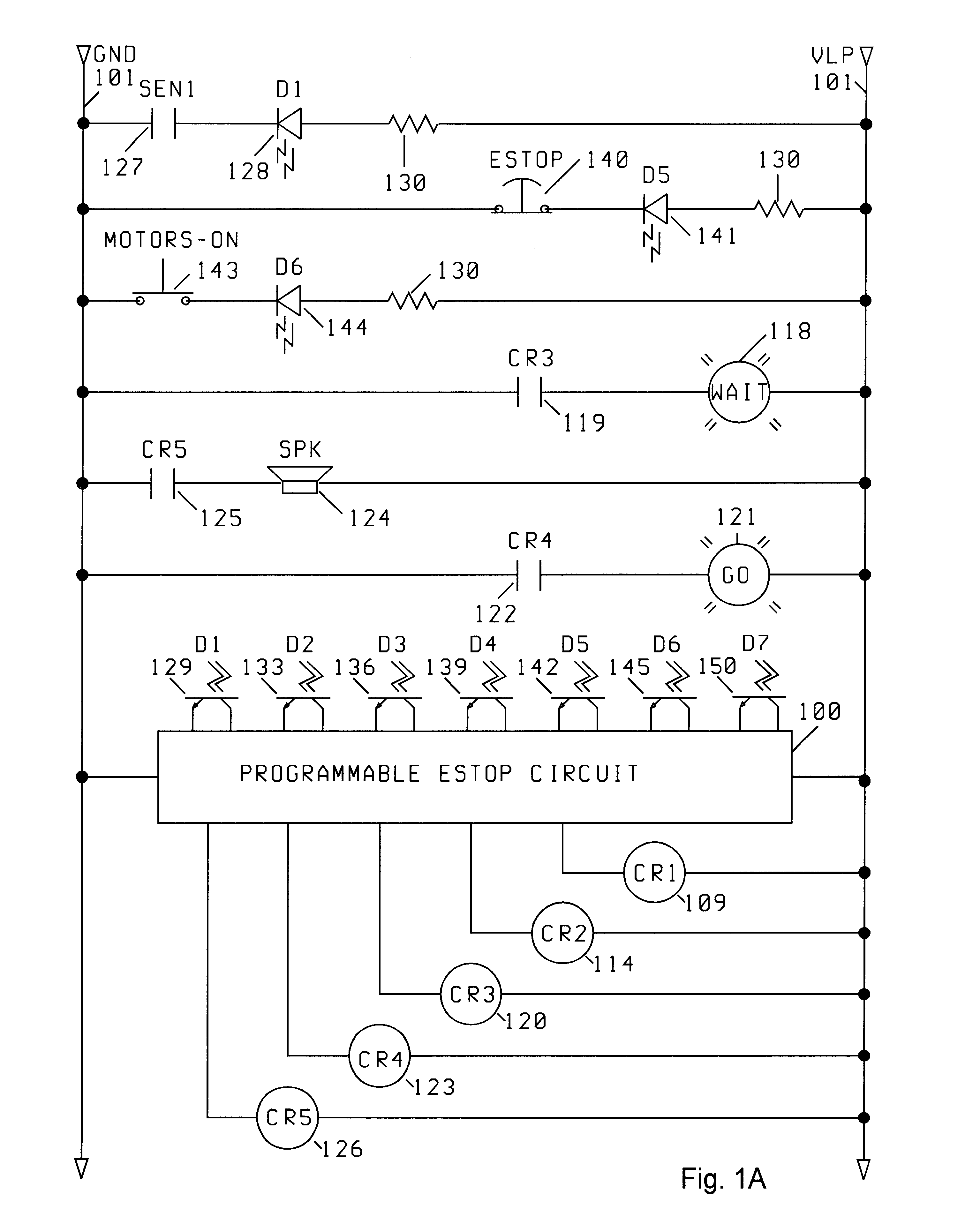

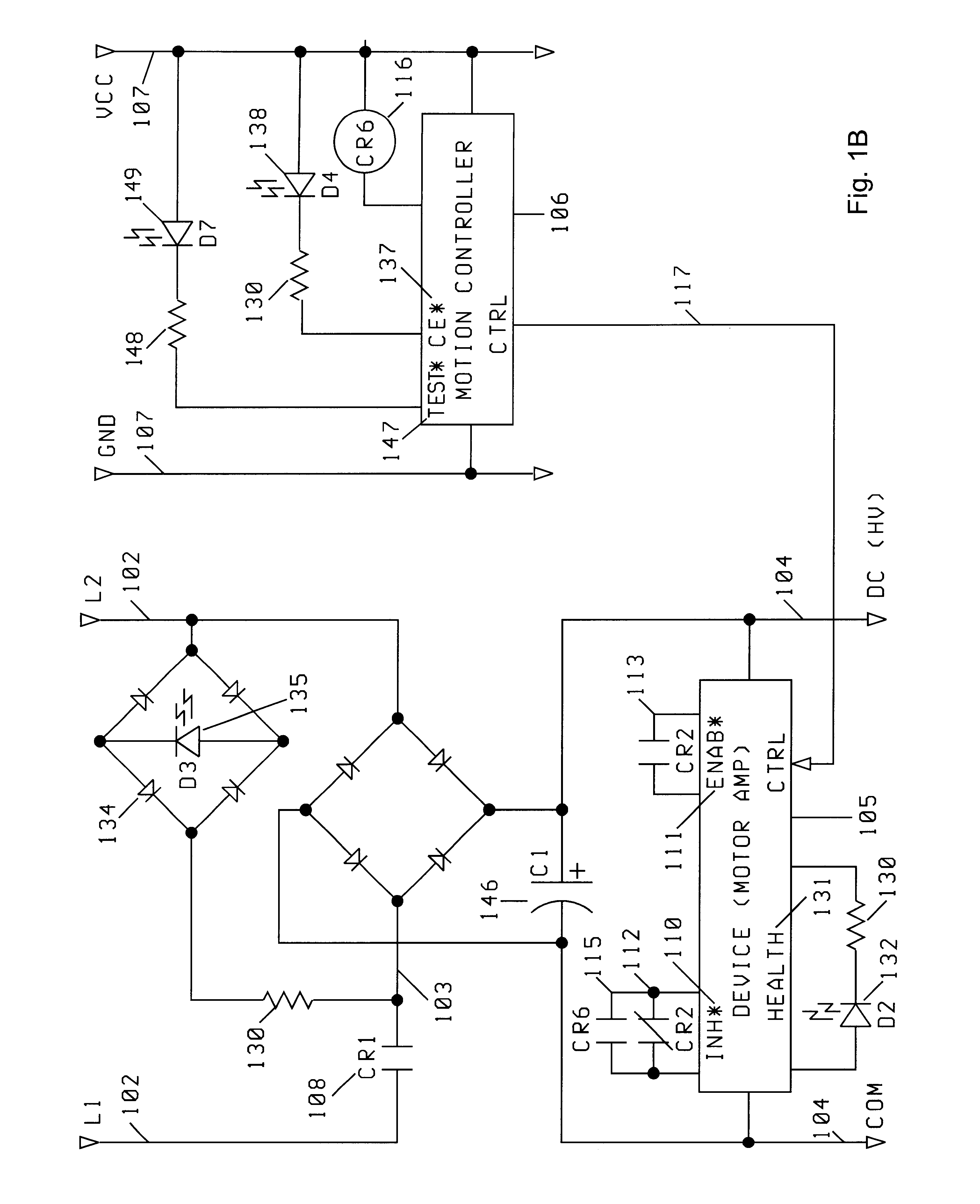

Programmable emergency-stop circuit with testing

InactiveUS6734581B1Safely incorporatedReduce sensitivityBatteries circuit arrangementsEmergency protective circuit arrangementsTest inputKill switch

The invention includes a programmable emergency-stop circuit apparatus and method that provides advanced function not found in other systems. The circuit centralizes the control of high voltage motor power into one place, by providing connections for, in its minimum configuration, several different kill switches, a motors-on button, and an AC motor power relay coil. In the present invention, kill switches, test inputs, emergency-stop and motors-on buttons, computer ready and watchdog signals are all conveniently connected in one location, alongside the AC motor power relay coil driver. Programmable options exist for testing kill inputs online, while the emergency stop is energized.

Owner:EIGENPOINT

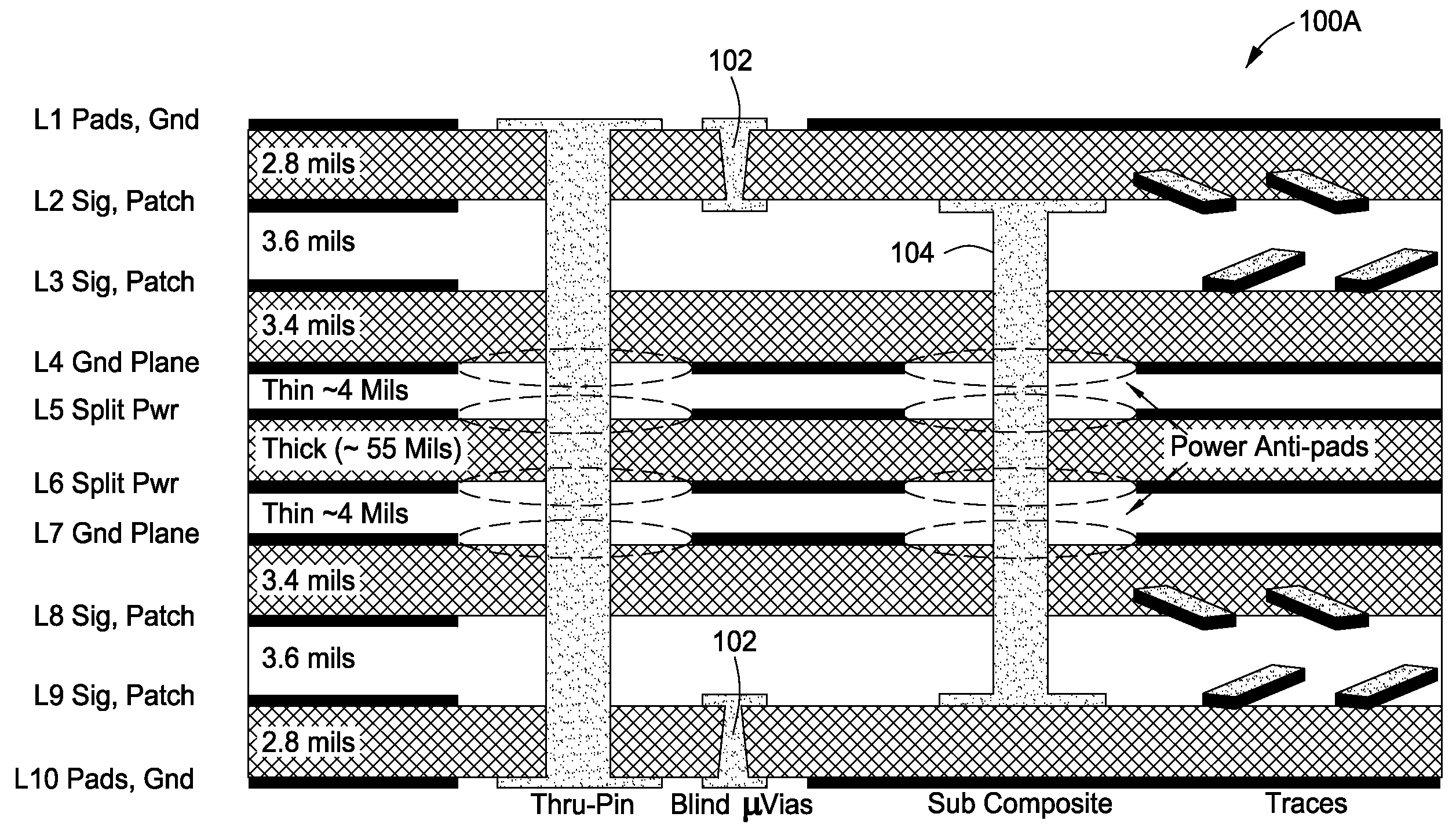

Conductive dome probes for measuring system level multi-ghz signals

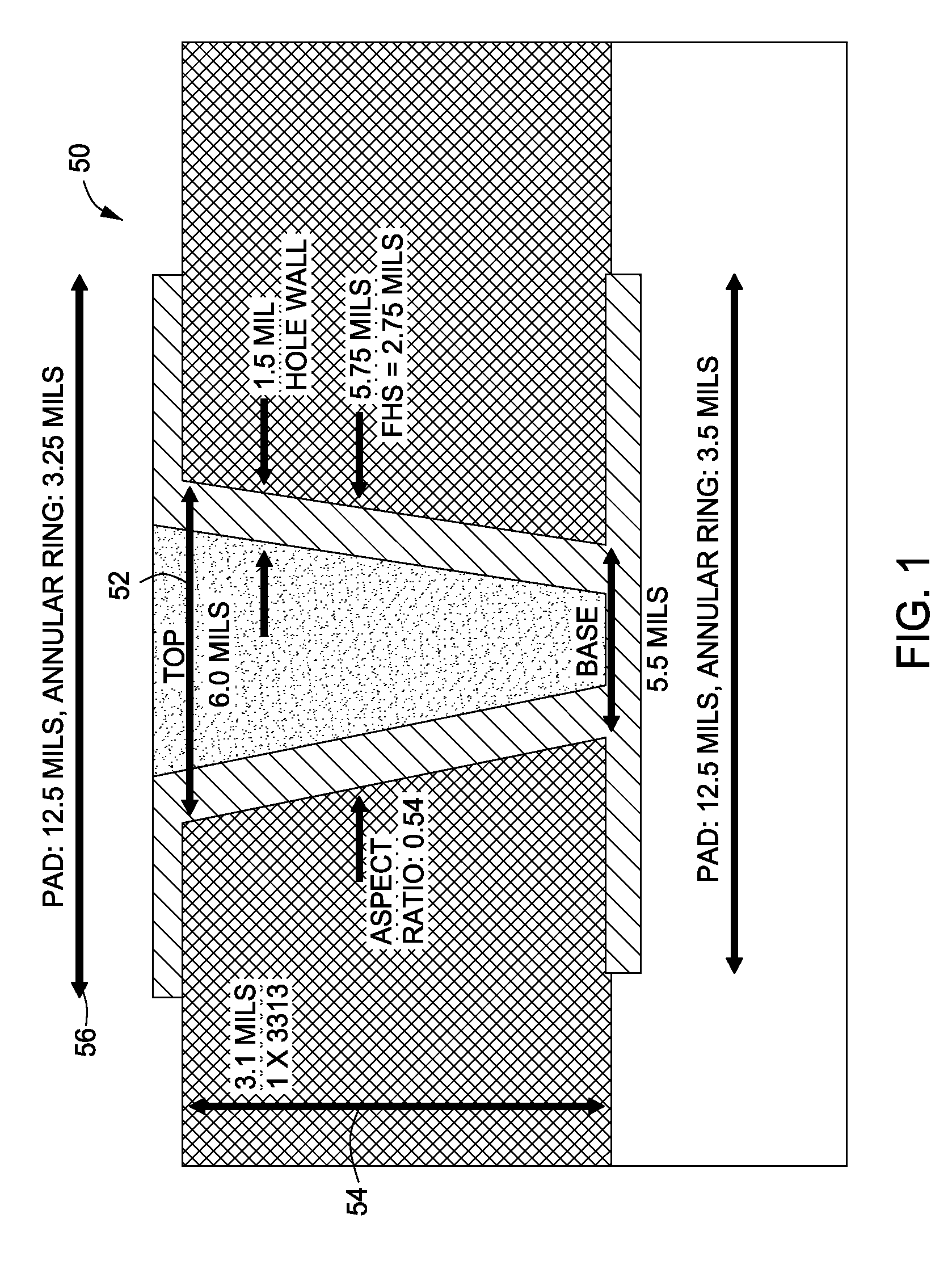

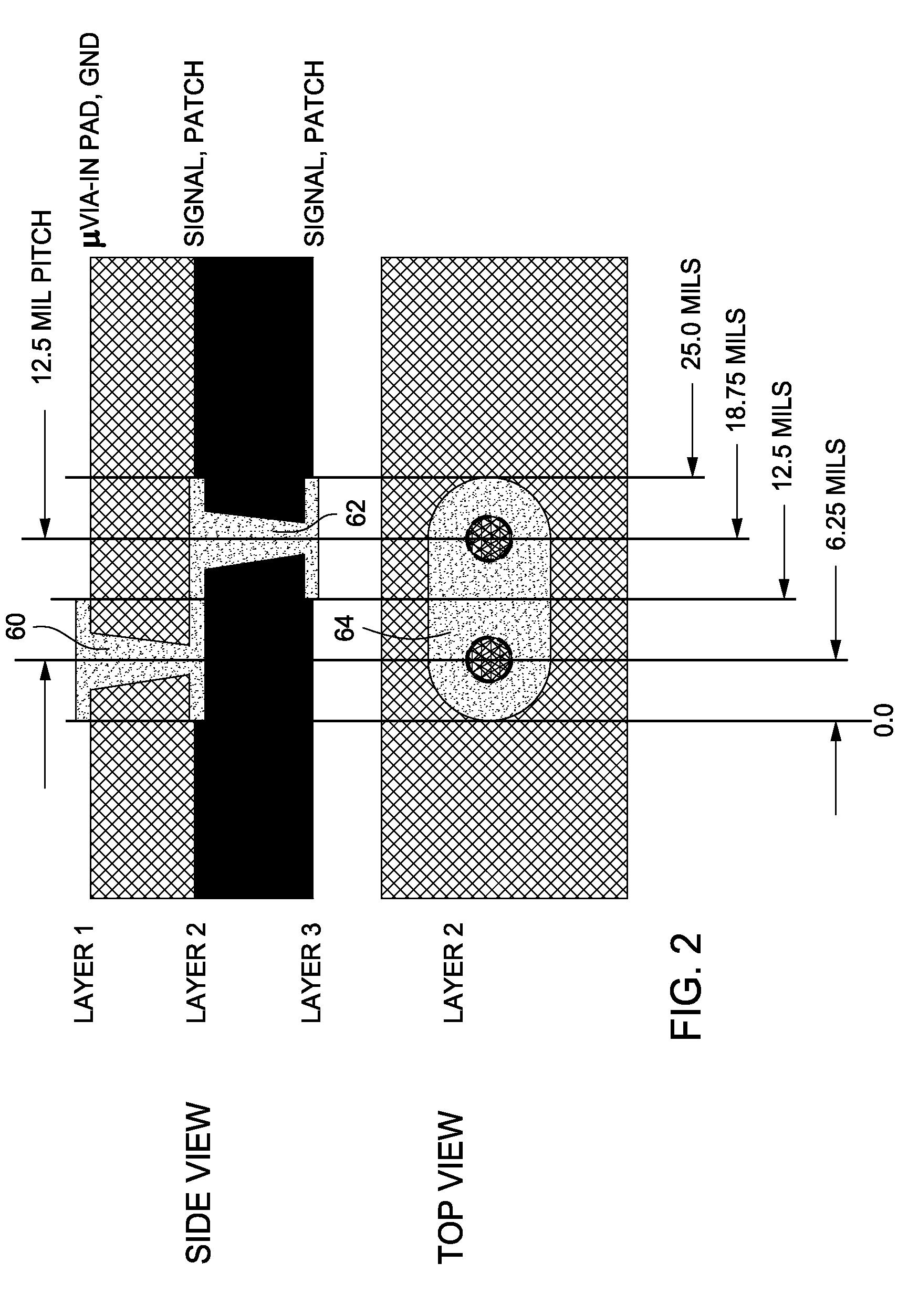

ActiveUS20080250377A1Final product manufactureCross-talk/noise/interference reductionHigh densityReflection loss

Methods and apparatus for accessing a high speed signal routed on a conductive trace on an internal layer of a printed circuit board (PCB) using high density interconnect (HDI technology) are provided. The conductive trace may be coupled to a microvia (μVia) having a conductive dome disposed above the outer layer pad of the μVia. In-circuit test (ICT) fixtures or high speed test probes may interface with the conductive dome to test the high speed signal with decreased reflection loss and other parasitic effects when compared to conventional test points utilizing plated through-hole (PTH) technology.

Owner:CISCO TECH INC

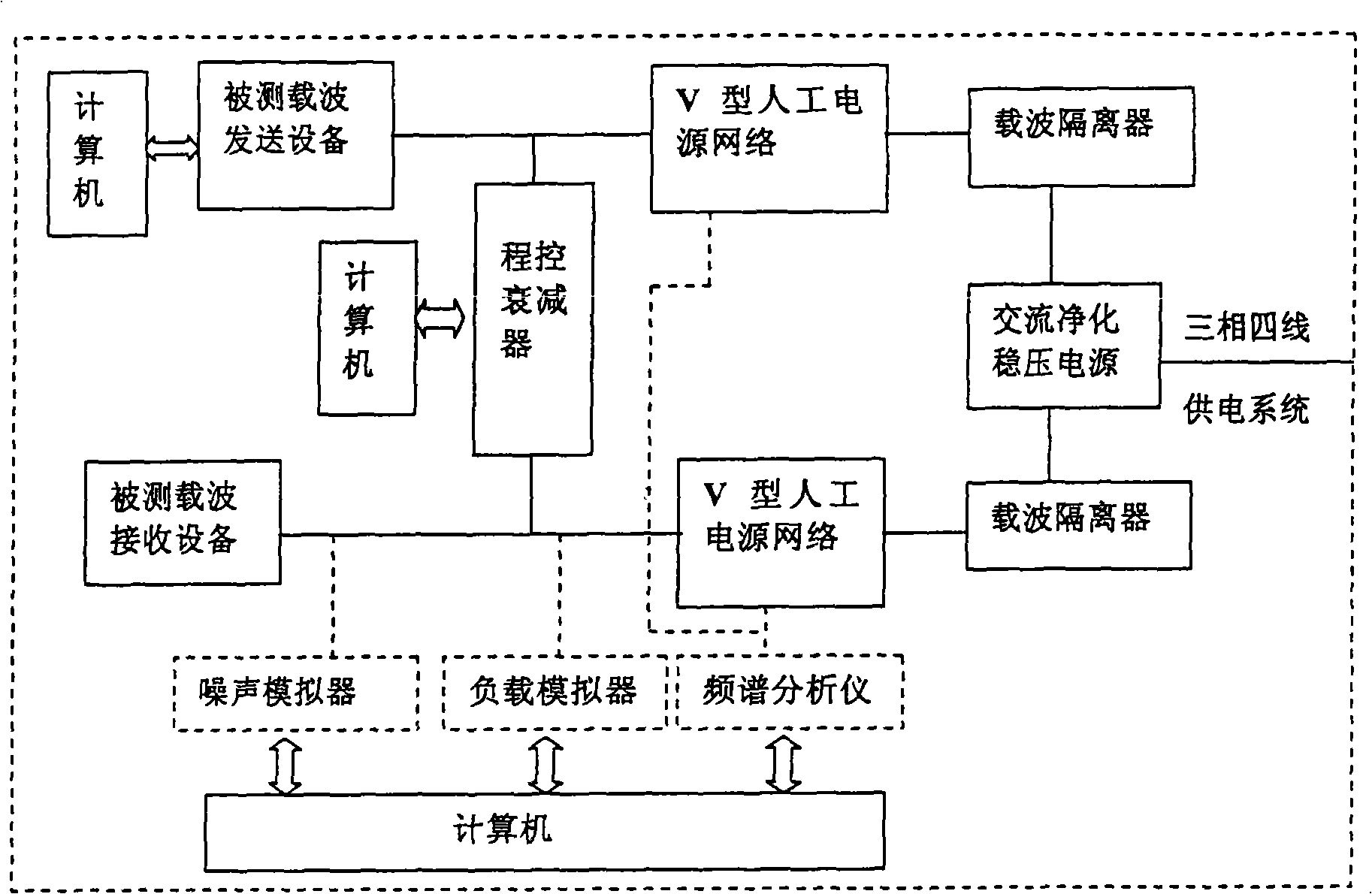

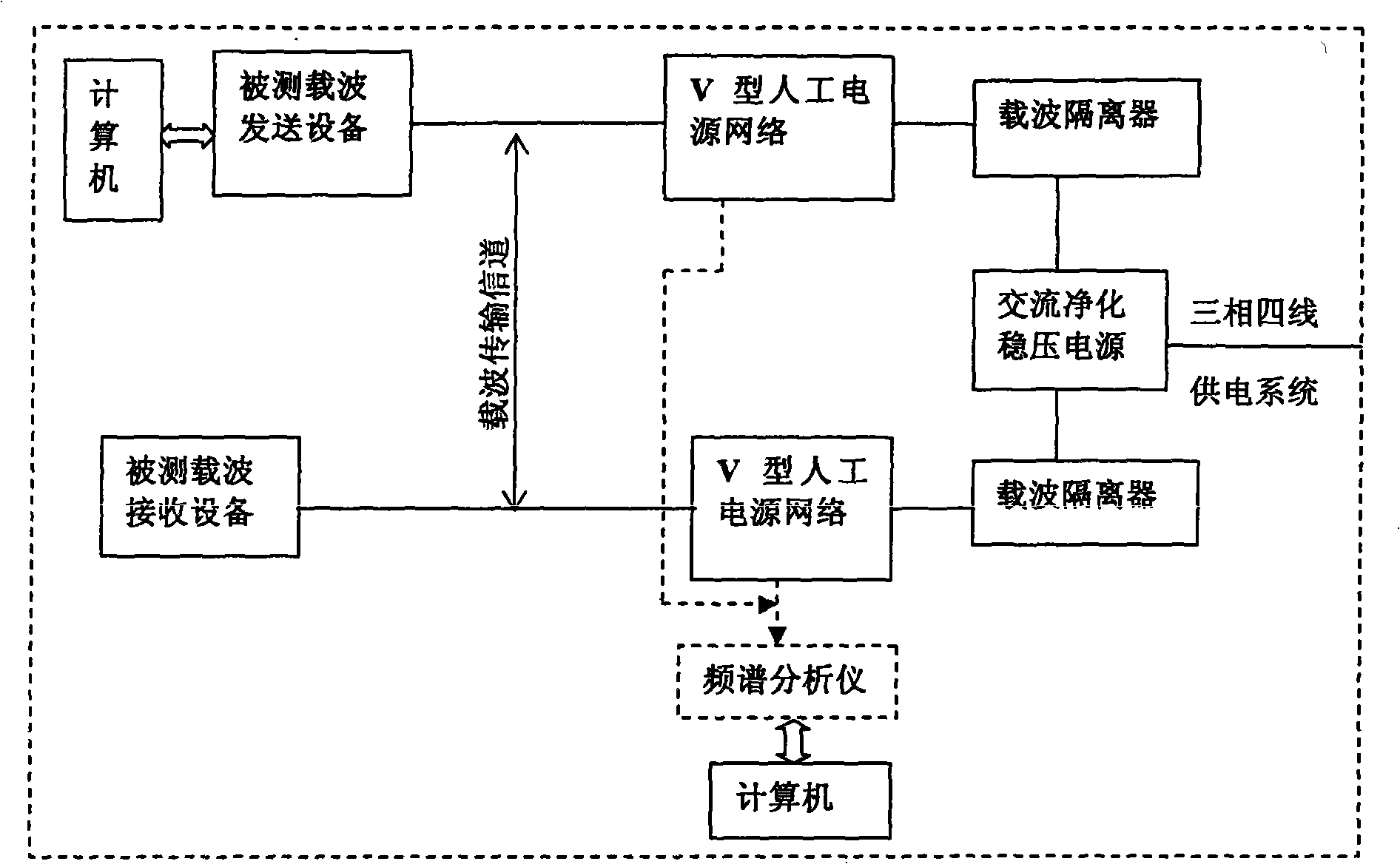

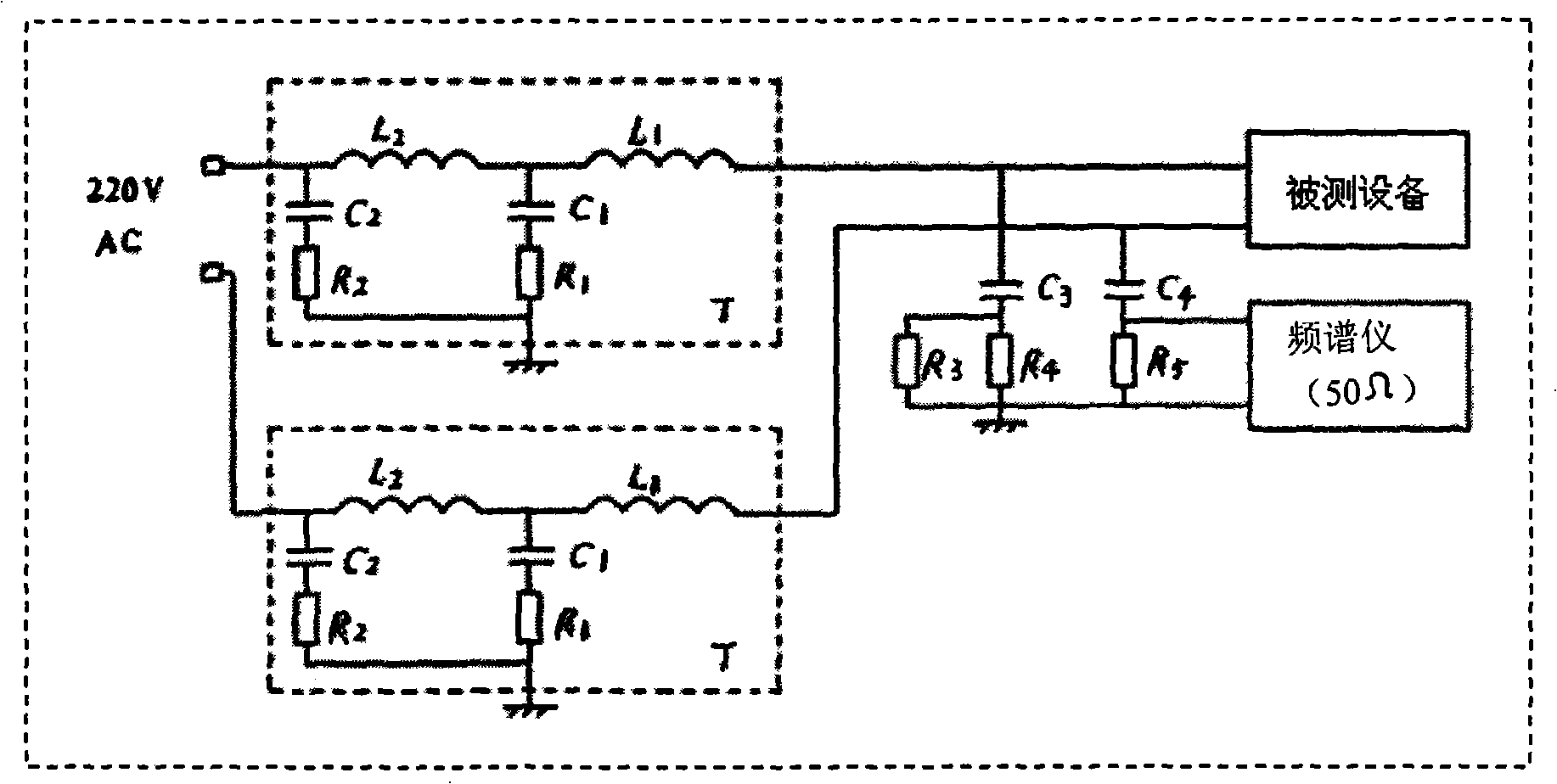

Low-voltage powerline carrier communication experiment method and its experiment system

ActiveCN101404523AComparableRealize online sensitivity testPower distribution line transmissionLine-transmission monitoring/testingLow voltage circuitsPilot system

The invention relates to a low-voltage electric wire carrier communication test method and a testing system thereof. The testing method comprises the following testing methods: I, a carrier transmitting PWL online testing method; II, a carrier receiving sensitivity online testing method; III, a carrier communication anti-interference online testing method; IV, a low-voltage circuit impedance change online testing method. The testing system comprises a carrier transmitting device, a program control attenuating device, a tested carrier receiving device, a manual power network, a frequency spectrograph receiver, a computer, a frequency spectrograph, a noise simulator, an impedance simulator and a purifying power. The invention has the advantages of adopting a manual power network parameter model regulated in GB / T 6113 F2, thus having a high standardization degree and comparable testing data; avoiding the testing problems brought by adopting different carrier communication schemes; realizing the online sensitivity testing; carrying out the test at any time and being not affected by the external environment factors like the weather; besides, the invention can simulate the impedance change environment of a real circuit, thus leading the analyzing of the carrier communication on the impedance change of the circuit to be feasible.

Owner:NANJING XINLIAN ELECTRONICS

System and method for online testing of radiation effect of modular digital integrated circuit

ActiveCN105911454AImprove standardizationImprove scalabilityElectronic circuit testingComputer moduleModularity

The invention relates to a system and method for the online testing of a radiation effect of a modular digital integrated circuit, and the system enables all needed function circuits in the effect testing to be divided into relatively independent modules on the basis of summarizing the similarities and differences of conventional digital integrated circuit radiation effect online testing systems. The electrical and mechanical connection among the modules, the design in the modules and the mechanical structure of a system board respectively employ conventional industrial standards, thereby achieving a purpose that a system can employ a commercial module or an independently developed modular for quick connection, enabling the system to be better in expandability, and saving the design time and cost of hardware. The method can be used for the majority of the online testing of the radiation effect of digital integrated circuits of bullets and satellites. The system plays an important role in standardizing a national radiation effect online testing system.

Owner:NORTHWEST INST OF NUCLEAR TECH

Socket connection test modules and methods of using the same

InactiveUS6956387B2Resistance/reactance/impedenceElectronic circuit testingCapacitancePin grid array

Test modules, systems, and methods employing capacitors for the testing of the solder joint connections between a printed circuit board (PCB) and a socket of a device are presented in embodiments of the current invention. A test module having capacitors in parallel, and in particular embedded capacitors, can be used to test tied traces and their solder joint connections by measuring the total capacitance of the capacitors. Embodiments of the current invention present no-power tests that can be used with a variety of testing platforms and test fixtures, such as in-circuit testing (ICT) and manufacturing defect analysis (MDA.) Additionally, the test module can be used with a variety of sockets, such as a ball grid array, a pinned grid array, and a land grid array.

Owner:INTEL CORP

Non-contact vibration detecting method of tower crane structure

InactiveCN103033253AFast extractionLarge amount of informationSubsonic/sonic/ultrasonic wave measurementUsing wave/particle radiation meansVibration measurementOutlier

The invention relates to a non-contact vibration detecting method of a tower crane structure and belongs to the technical field of detecting. The method is non-contact measurement. A multipoint and on-line test can be achieved by arranging a plurality of cameras without arranging a sensor on a detected object. The non-contact vibration detecting method of the tower crane structure has no load effect and is easy to implement. Image information is directly digitalized to form a full-automation and full-digitalization vibration measurement disposing and recording system. Amount of information is larger than that of a traditional method. Regions of interest (ROI)technology is used in the method to reduce an image tracking area and calculated amount. Speeded-up robust features (SURF) method is used to accelerate extraction rate of feature points. The PauTa criterion is used to reject'outlier' and improve accuracy of the SURF method. Reliability of a crane safety monitoring system in prior art is improved.

Owner:TAIYUAN UNIVERSITY OF SCIENCE AND TECHNOLOGY

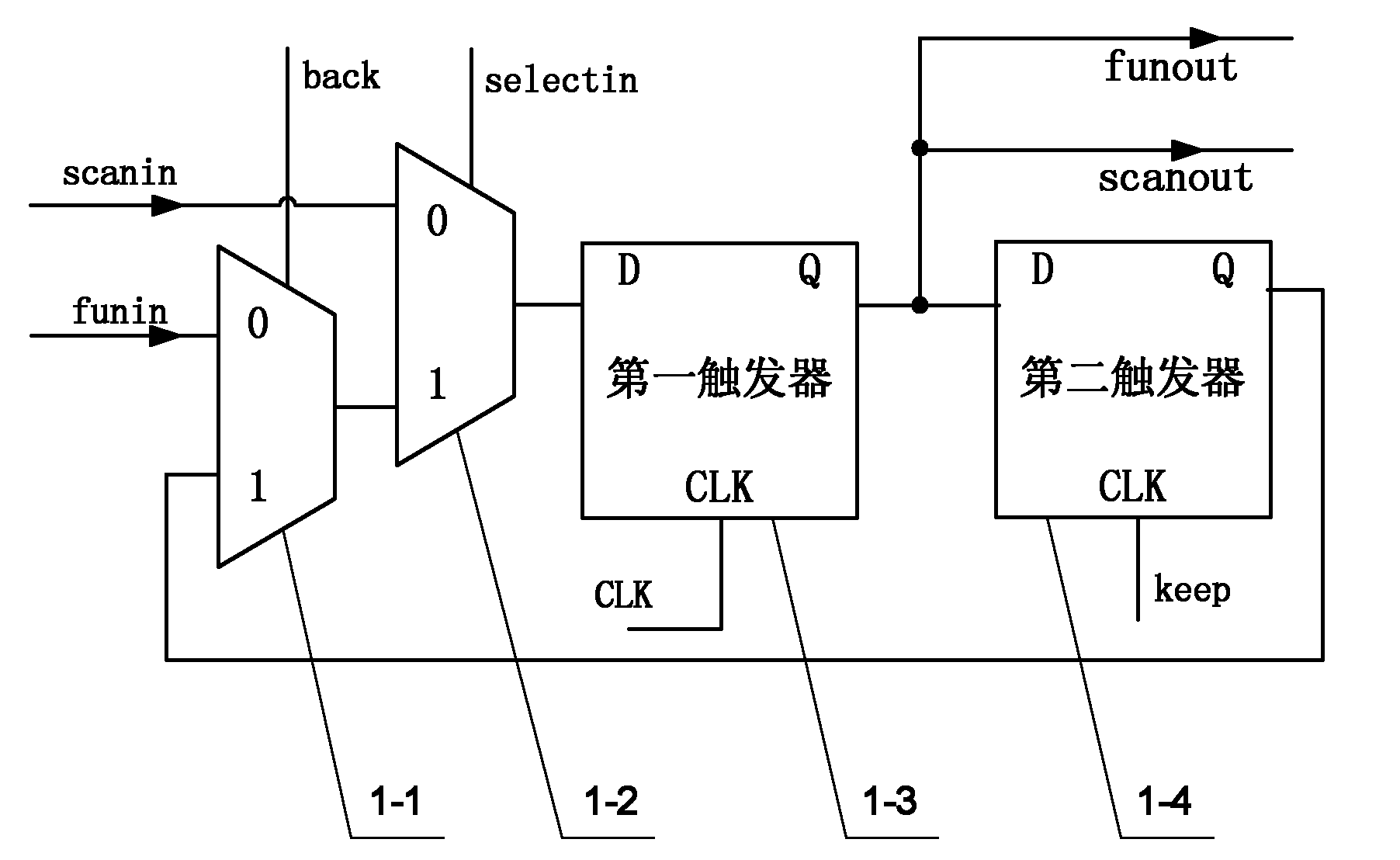

Improved scan chain unit and non-concurrent testing method based on same

InactiveCN102043122ASimple timing controlImprove test efficiencyDigital circuit testingSystem testingMultiplexer

The invention relates to an improved scan chain unit and a non-concurrent testing method based on the same, which belongs to the filed of on-chip system testing and aims at solving the problems that the existing scan chain-based non-concurrent on-line testing method has strict requirements for time sequences, is difficult to control and can not realize the one-step import of multiple groups of test vectors. The improved scan chain unit is used for replacing a D trigger in an on-chip system, and the unit contains two triggers and two selectors, wherein a first trigger is a basic unit which composes the original circuit scan chain and is used for realizing the function same with that of the original D trigger, and a second trigger is introduced for saving data in the testing process; and the two data selectors control the flow direction of data by means of enable ends, a first selector is used for controlling whether data in the second trigger can be transmitted to the first trigger, and a second selector is used for controlling the working state or the scanning state of the first trigger. Thus, multiple groups of test vectors can be input to the unit for continuous testing, and therunning state of the circuit is not changed before and after the test.

Owner:HARBIN INST OF TECH

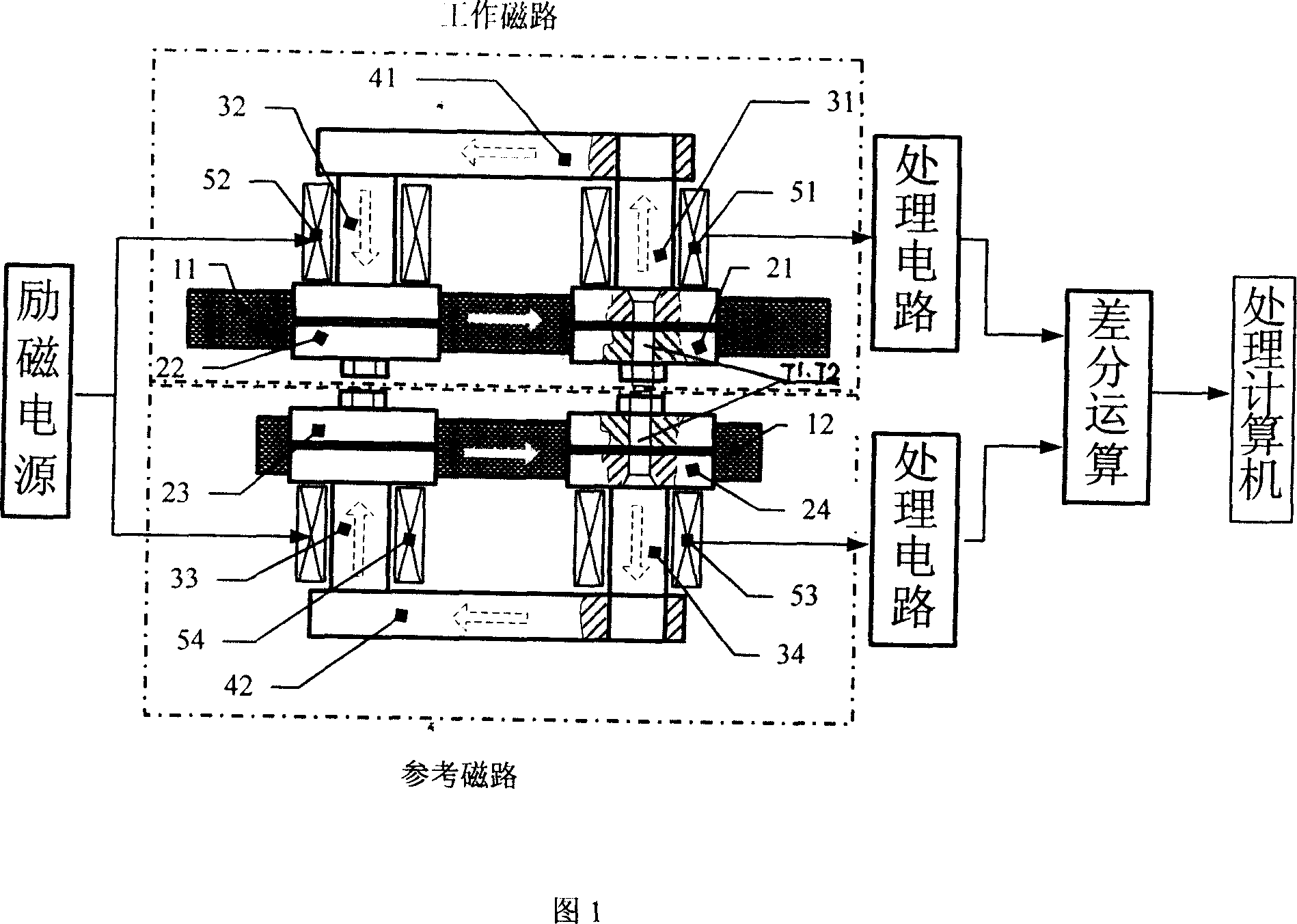

Differential and temperature compensating type on-line testing method and system for bridge cable force

InactiveCN1952635AGood dynamic responseEasy to install and debugForce measurement by measuring magnetic property varationTension measurementStress conditionsEngineering

An on line test method and test system of differential type temperature-compensating bridge rope force based on the magnetoelasticity is disclosed. The bridge rope is the ferromagnetic material and placed in the specific magnetic field, the bridge rope will be magnetized; the magnetic conductivity of bridge rope will change with the variety of stress condition and temperature. The sensor comprises operating magnetic circuit and reference magnetic circuit, in every designing of the magnetic circuit, the bridge rope is just a part of the magnetic circuit and not as the iron core of the actuating coil and the measuring coil. The reference magnetic circuit of sensor just feels the changes of temperature, but the operating magnetic circuit feels the changes of temperature and rope force, the output signal of the operating magnetic circuit and the reference magnetic circuit is differential to eliminate the temperature effect, the value of rope force can be tested with the corresponding relationship between the change of magnetic conductivity and rope force. The test method of rope force in the invention characterized in high accuracy, well dynamic response, low price of sensor, convenience of mounting and conditioning, long service life, strong overcurrent protection power, fitting for static and dynamic measurement, sampling just in time in all-weather, the testing results are free of effects of anticorrosive coating and protective plastic casing which is in surface of bridge.

Owner:CHONGQING YA PAI BRIDGE ENG QUALITY TESTING CO LTD

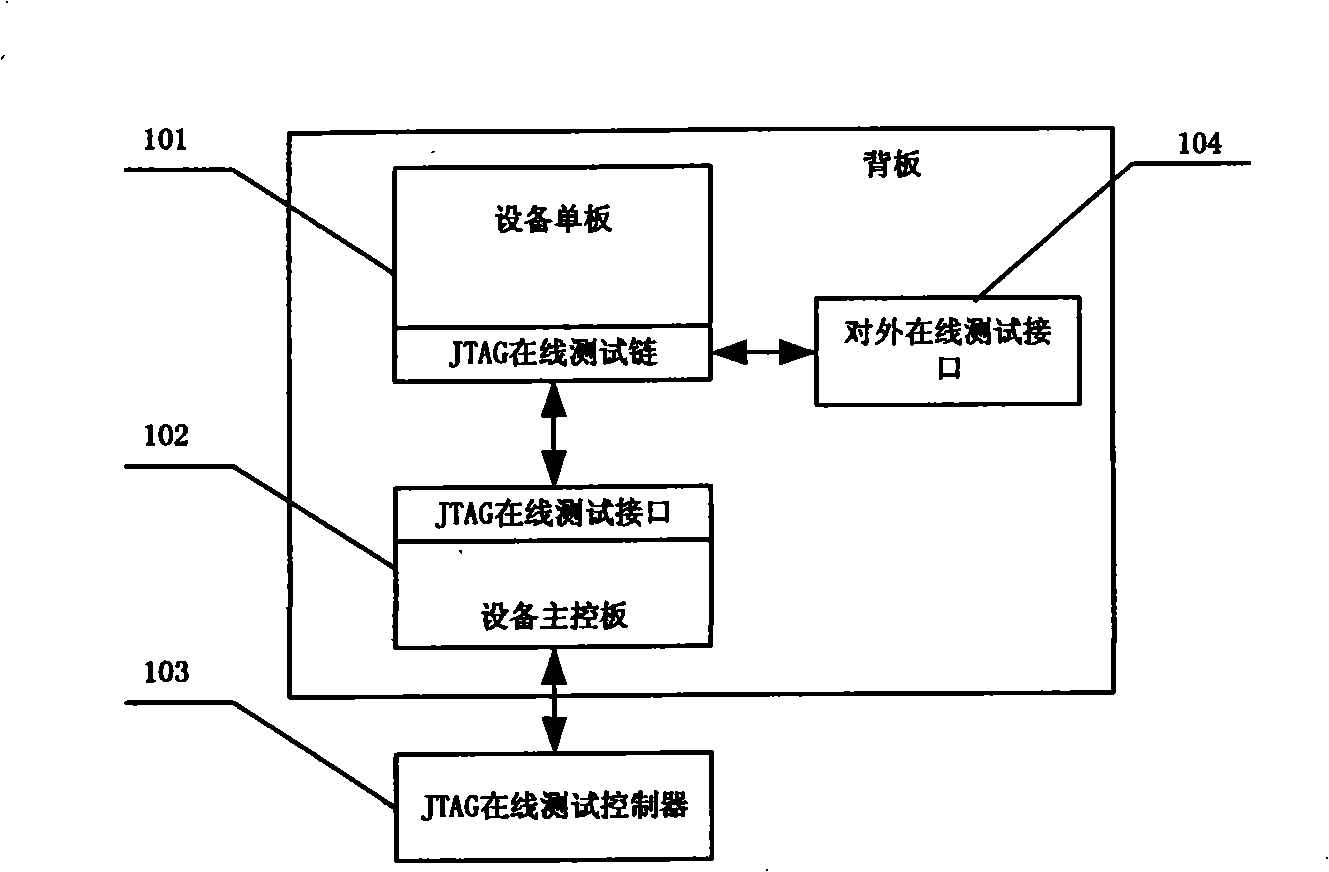

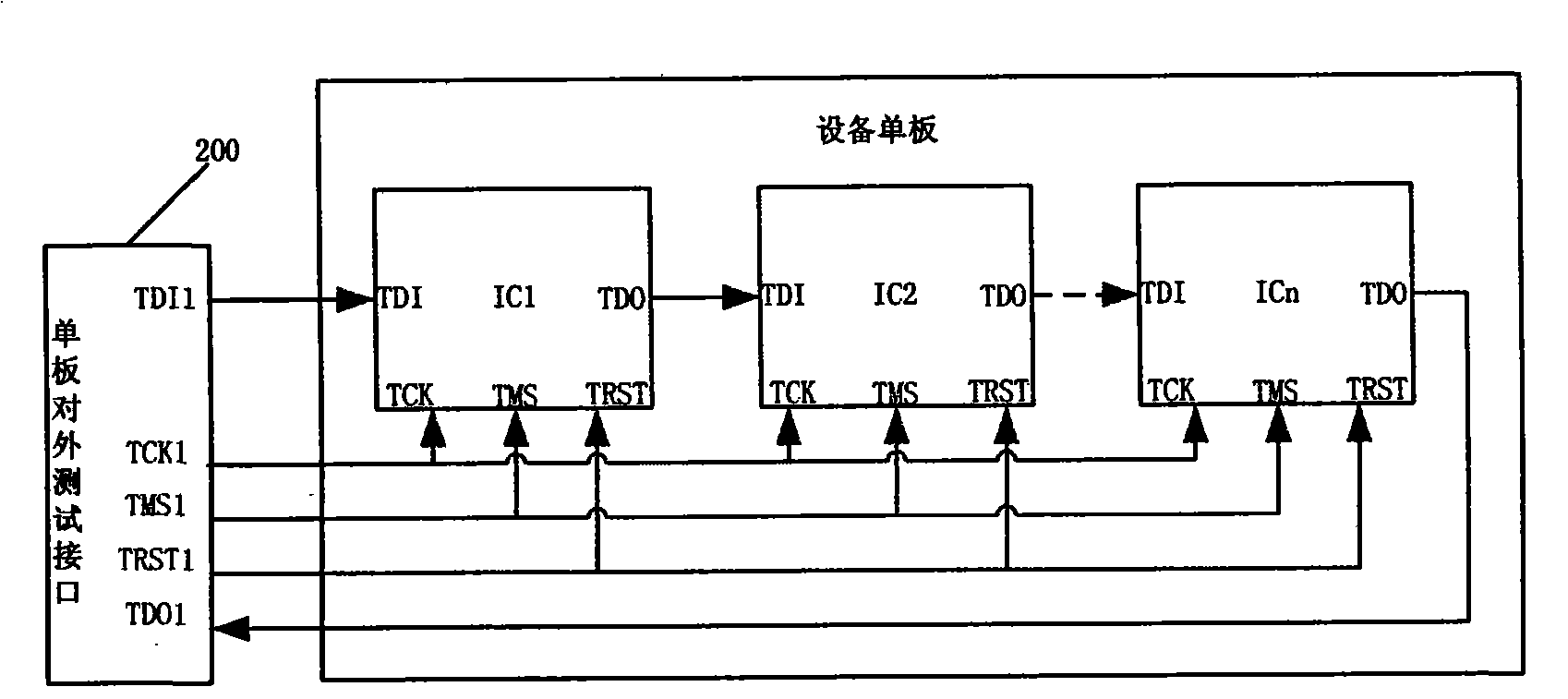

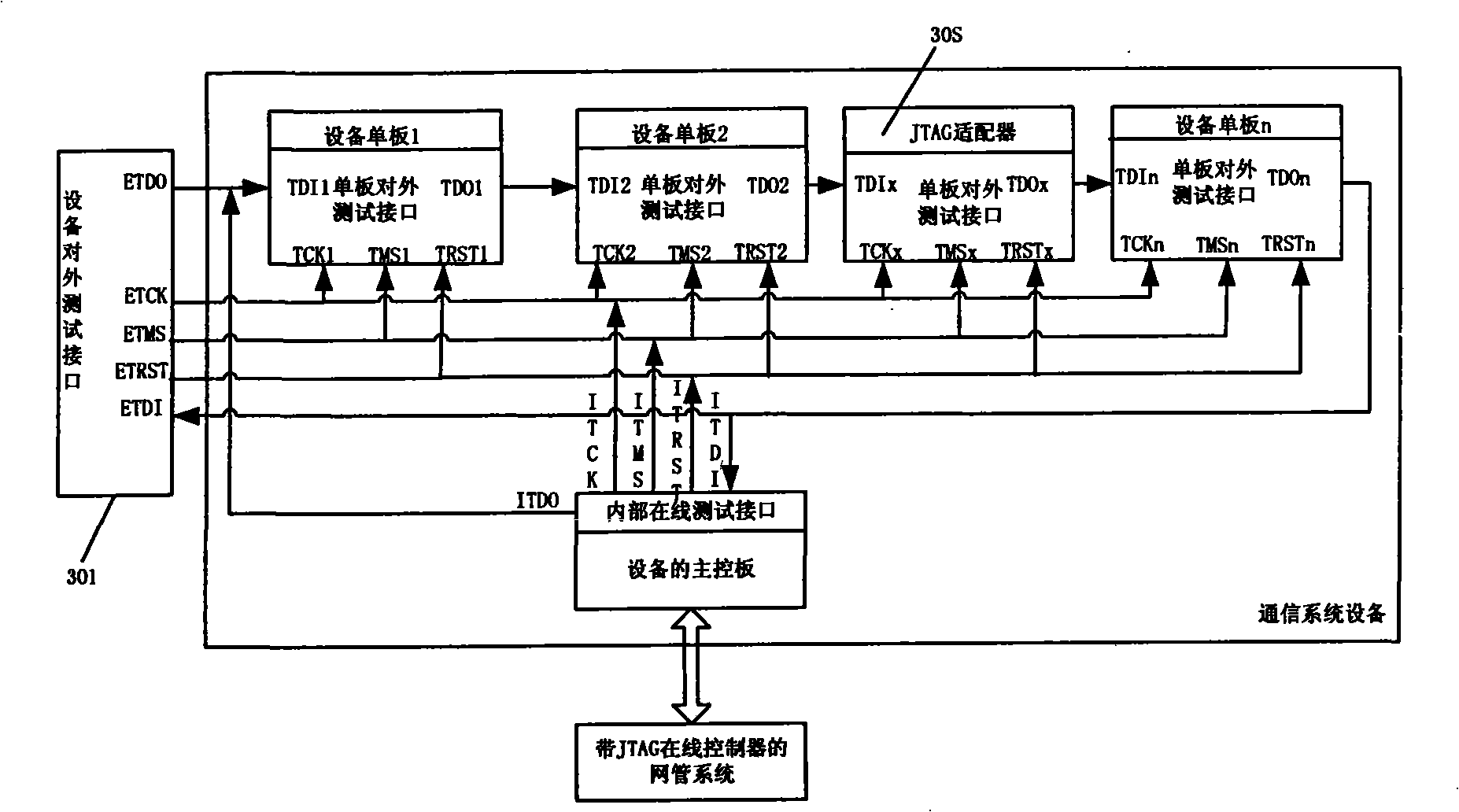

Communication system equipment and detection method thereof

InactiveCN101325517ARealize online automationRealize manual regular inspectionSupervisory/monitoring/testing arrangementsRadio/inductive link selection arrangementsComputer hardwareCommunications system

Owner:ZTE CORP

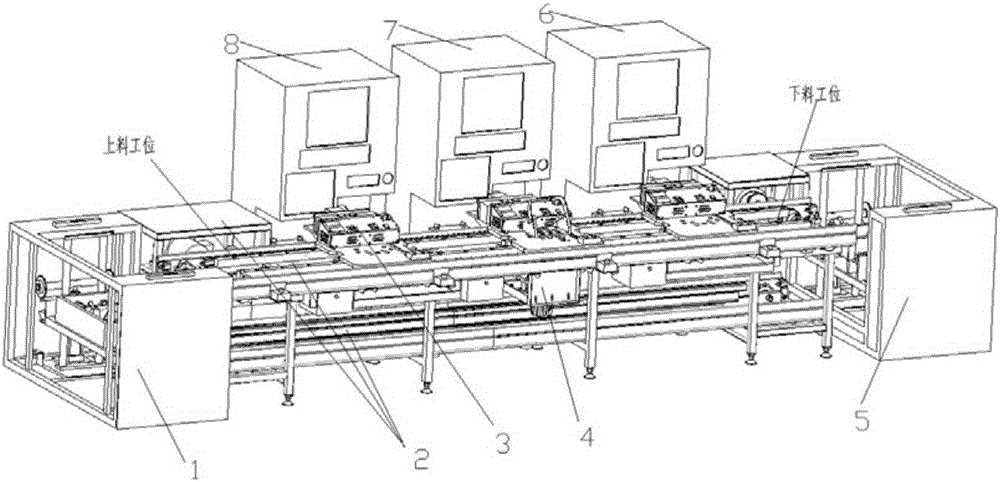

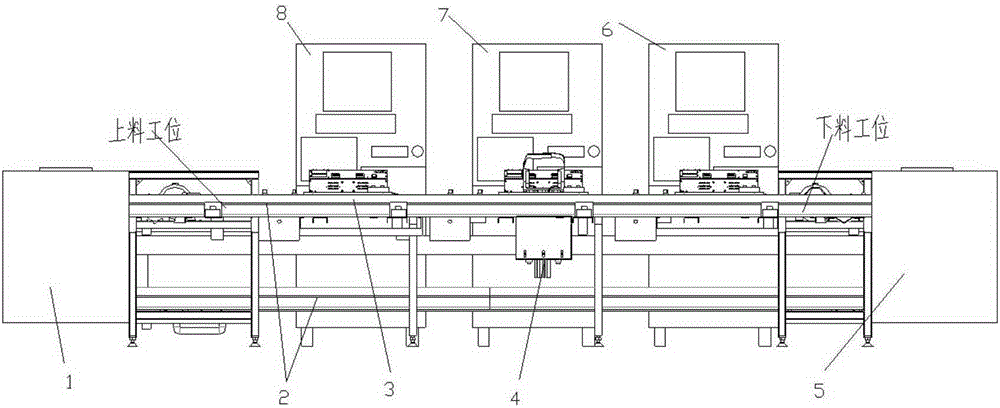

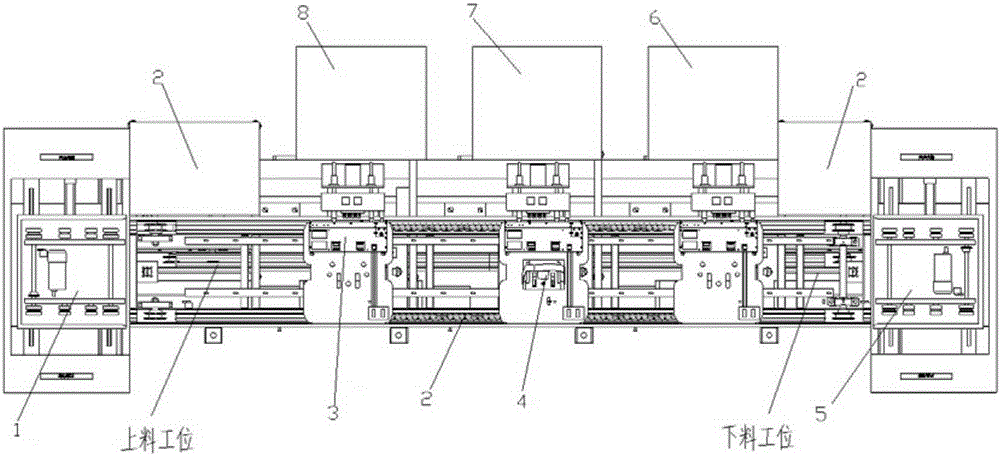

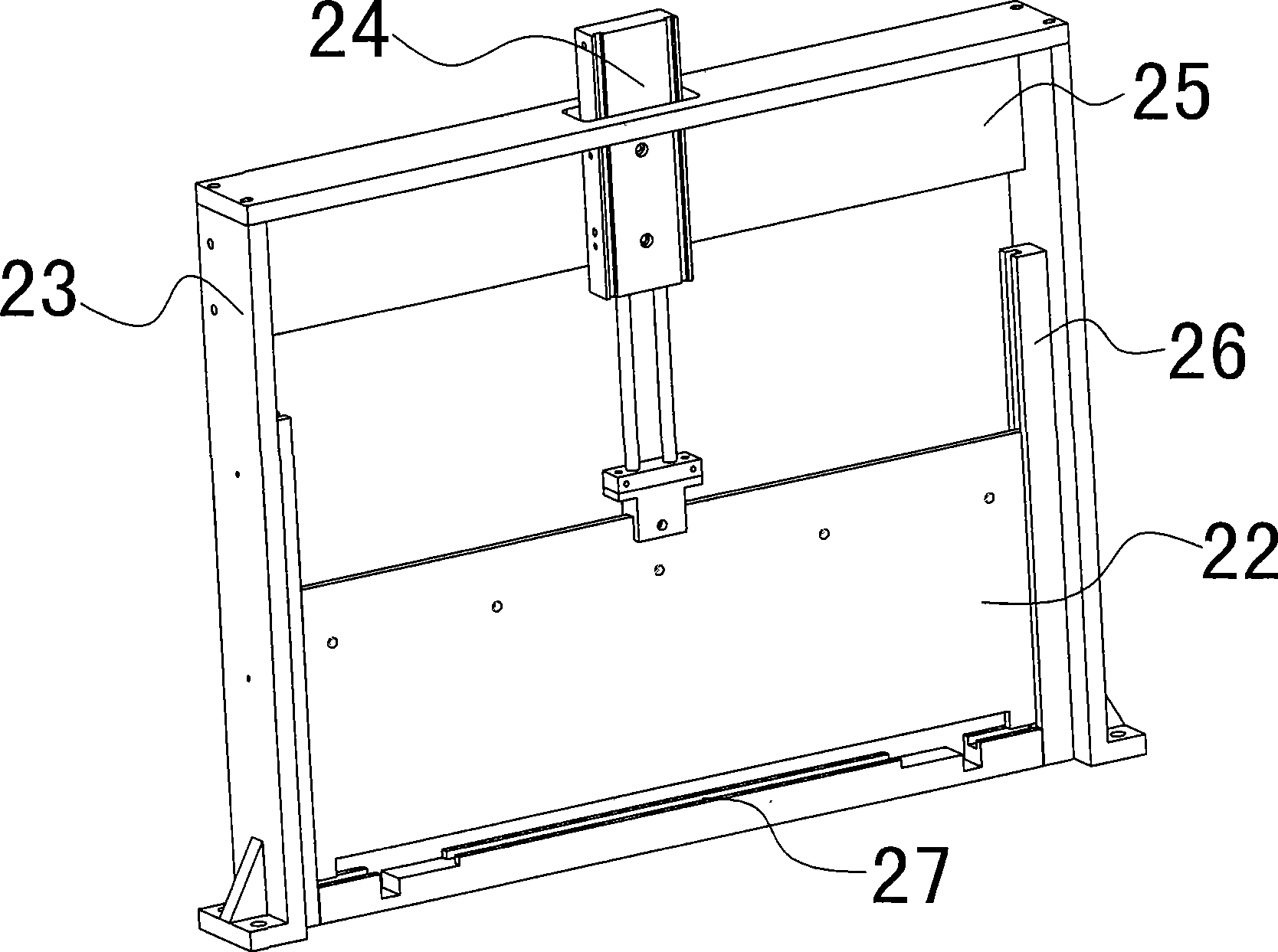

Instrument vibration testing system and application thereof

ActiveCN105352687ASimulated vibration realOnline test data is reliableVibration testingElectric machineryEngineering

The invention discloses an instrument vibration testing system and the application thereof. The system comprises an instrument vibration testing device, a tool plate assembly device which is used for fixing an instrument and transmitting performance parameters of the instrument under the vibration condition, a conveying positioning device which is used for conveying the tool plate assembly device with the instrument to each work position, lifting devices which are located at two sides of the conveying positioning device and are used for lifting the tool plate assembly device with the instrument, and a testing electrical cabinet which is used for detecting and recording the state performance parameters of the instrument before vibration, in vibration and after vibration. The system is used for the vibration testing of a vehicle-mounted instrument. The system can be used for the vibration testing of various types of instruments, especially for the testing of the vehicle-mounted instrument. The system can integrate the conveying, vibration and testing of the instrument into one body for continuous execution, and can control and adjust the vibration frequency through a motor regulator. The system has the remarkable characteristics of on-line vibration testing, is true in vibration simulation of the instrument, is reliable in on-line testing data, is high in production efficiency, and is low in labor intensity.

Owner:深圳格芯集成电路装备有限公司

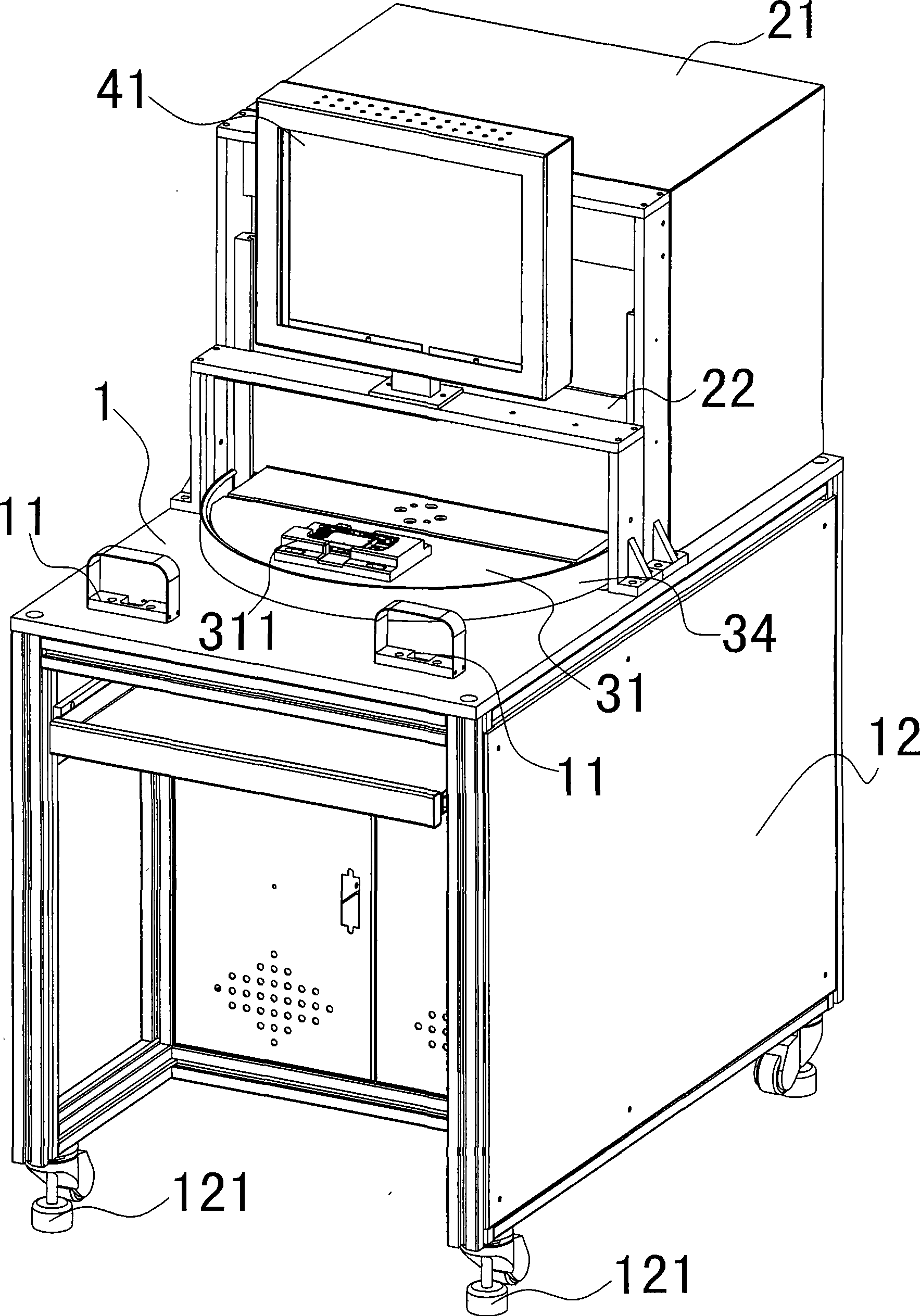

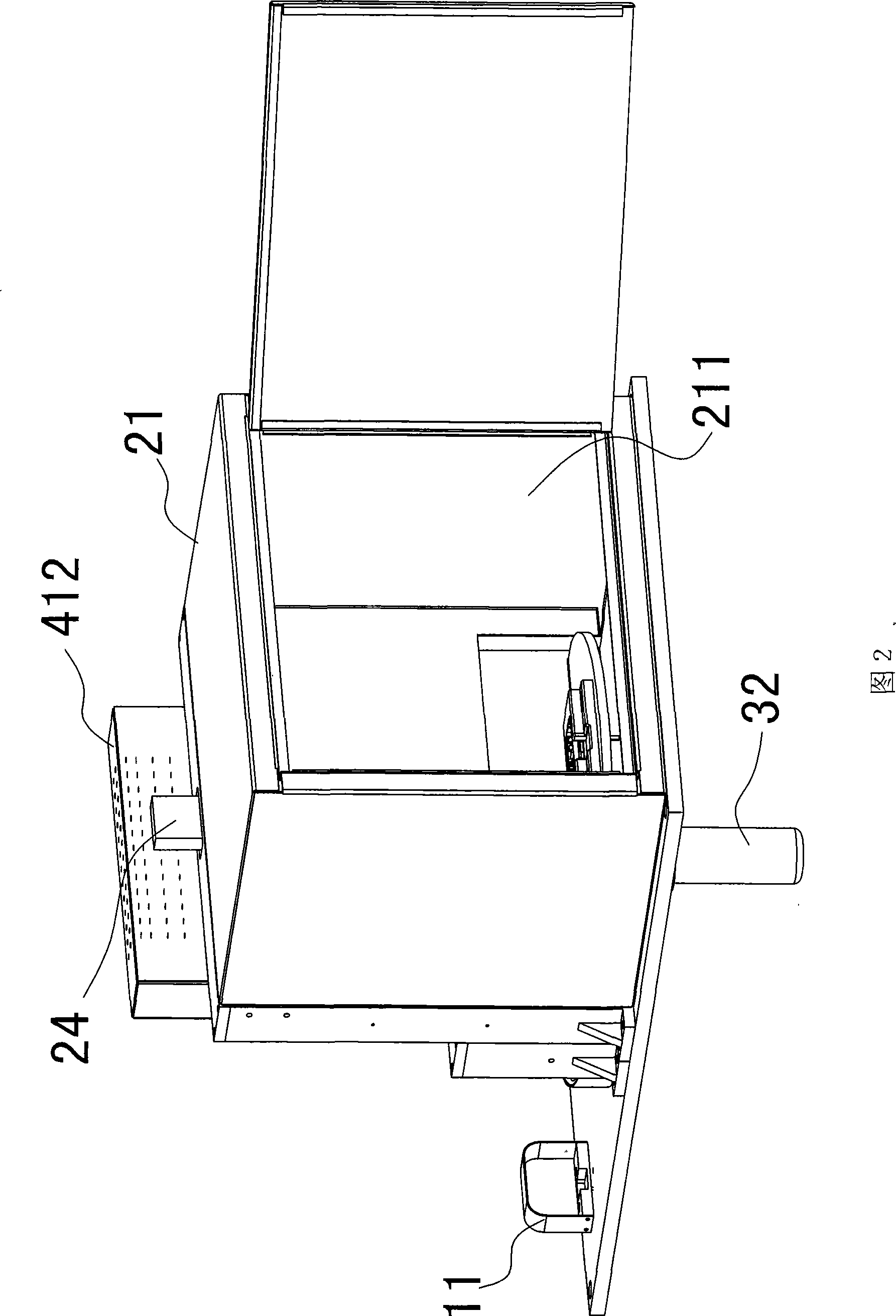

Automatic test equipment for mobile phone component

InactiveCN101431553ARapid online detection workSupervisory/monitoring/testing arrangementsSubstation equipmentAutomatic test equipmentDisplay device

The invention belongs to mobile phone testing technology field, especially relating to test equipment for audio frequency and vibration function of components of mobile phone. The test equipment comprises working platform, sound insulation chamber, rotary disc and test device. The sound insulation chamber structure comprises box body and box door; the rotary disc structure comprises drive device, rotary disc connected with the drive device and positioning tool. The test device comprises audio frequency analysis processor, vibration signal collector, data processor and processing result display. The sound insulation chamber structure and rotary disc structure are both provided at the working platform; the box body cover is provided at the rotary disc; the box door is provided upper of the rotary disc; the processing result display is fixed outside of box door. On-line quick test for audio frequency and vibration function can be implemented to satisfy quick production demand for large quantities of components.

Owner:BYD CO LTD

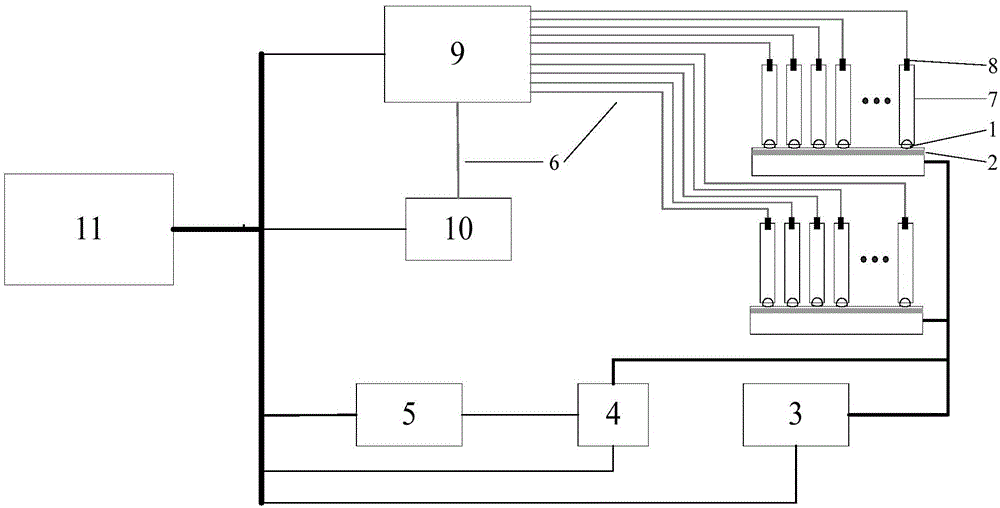

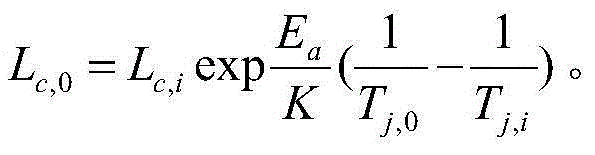

Accelerated on-line test system for service life of LED

ActiveCN105021968AAccurate and stable temperature controlSave energyIndividual semiconductor device testingThermal insulationMathematical model

The invention discloses an accelerated on-line test system for the service life of an LED, and relates to an LED test system. The system comprises an aging device, a spectrum collection device, an electric test device, and a computer control processing module. The aging device is provided with a constant temperature controller and an aging constant current source. The spectrum collection device is provided with at least one optical path, a cosine collector, a testing sampling clamping tool, a sixteen-way optical multiplexer, and a spectrometer. The electric test device is provided with an electric matrix switch and a testing source meter. The computer control processing module comprises a computer control part and a computer processing part. A PID heater is employed for the direct temperature control of an LED heat sink, thereby not only enabling the system to achieve miniaturization and temperature control to be more accurate and stable, but also saving a large amount of energy. Moreover, the heater is provided with a thermal insulation device, thereby preventing high temperature from affecting testing equipment. An on-line testing result is more continuous, and an error caused by the inconsistence of testing conditions is avoided. Testing parameters are complete. The service life can be predicted more accurately in a short time through the combination of a physical model and a mathematic model.

Owner:XIAMEN LONGSTAR LIGHTING

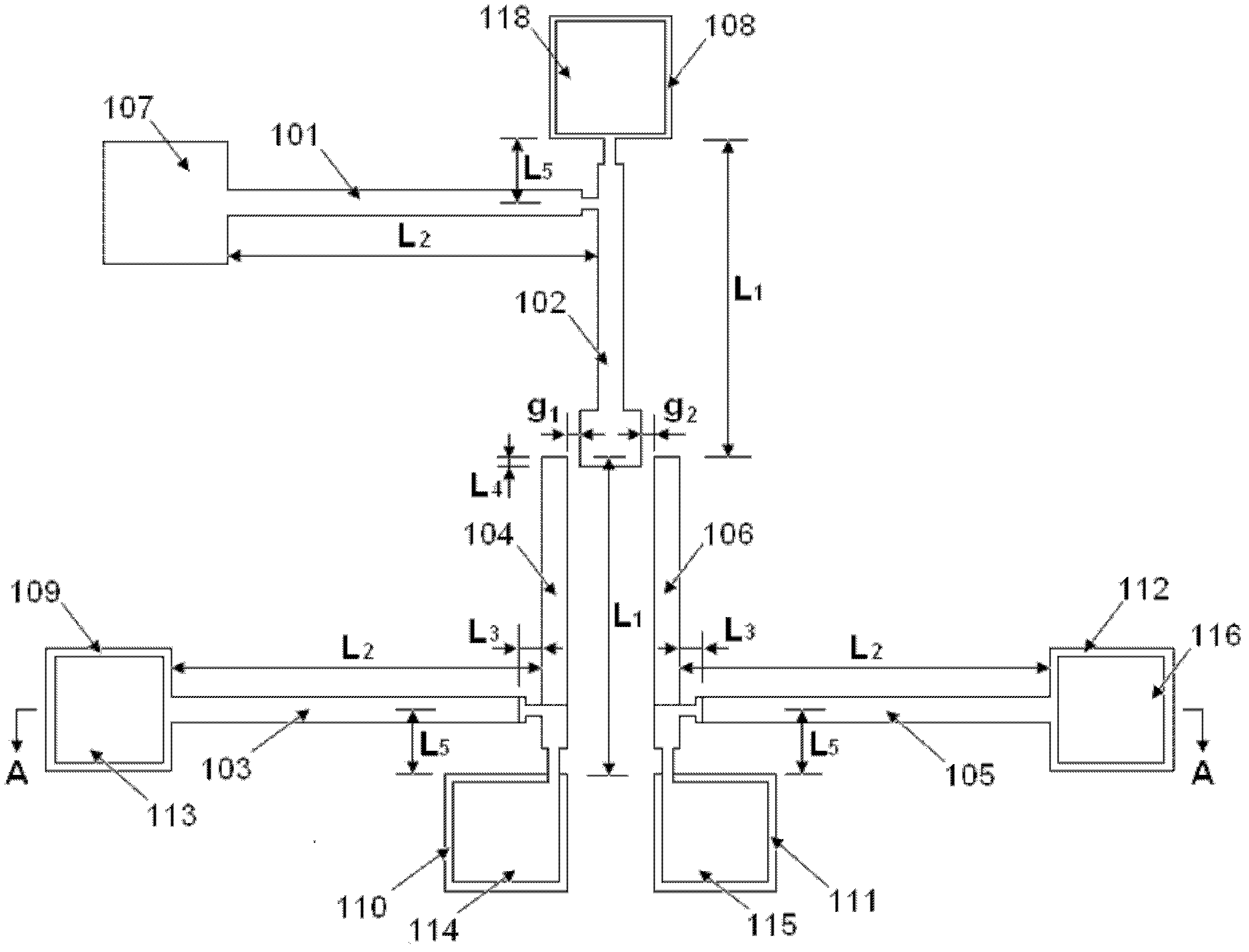

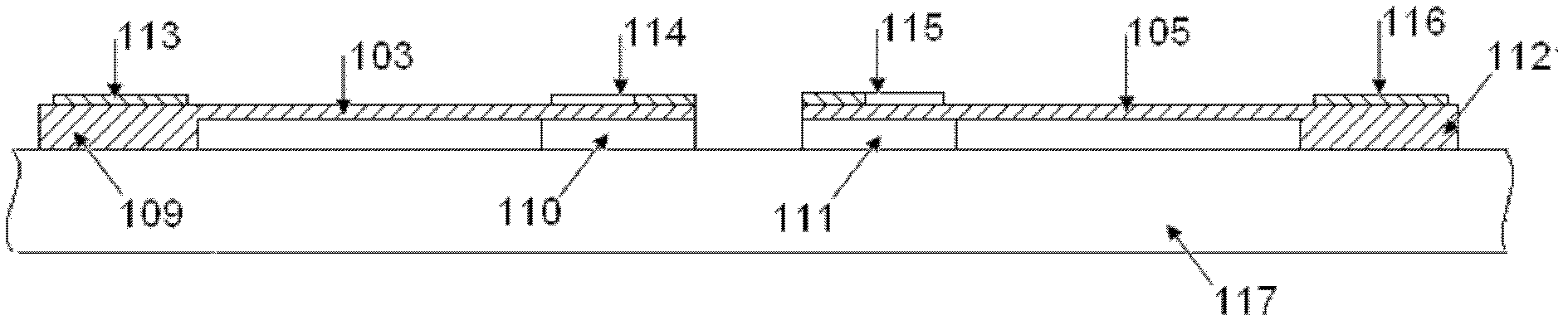

On-line testing structure for polycrystalline silicon material residual stress

InactiveCN102565143AImpact meetsAvoid influenceSemiconductor/solid-state device testing/measurementForce measurementElectrical resistance and conductanceManufacturing technology

The invention discloses an on-line testing structure for polycrystalline silicon material residual stress, which includes three polycrystalline silicon deflecting pointers with identical basic structures, wherein the three polycrystalline silicon deflecting pointers are arranged in a triangular way with the pointers pointed to the center, and the initial deflection directions of the pointers under the residual stress action are controlled so as to enable the interval retaining and interval variation to effectively reflect the size and quality of the residual stress; the manufacturing technology of the testing structure is simple without any special machining requirements; and thermal drive is adopted during the testing, and the testing parameters are the resistances of the drive beam before and after the thermal driving. Even though the thermal expansion principle is adopted during the use, the measuring instrument doesn't need the coefficient of thermal expansion, so that the measurement result is free from the error caused by on-line testing the coefficient of thermal expansion. The invention has the advantages that the testing structure is simple, the electric signal loading and measuring are convenient, and the calculating method is stable.

Owner:SOUTHEAST UNIV

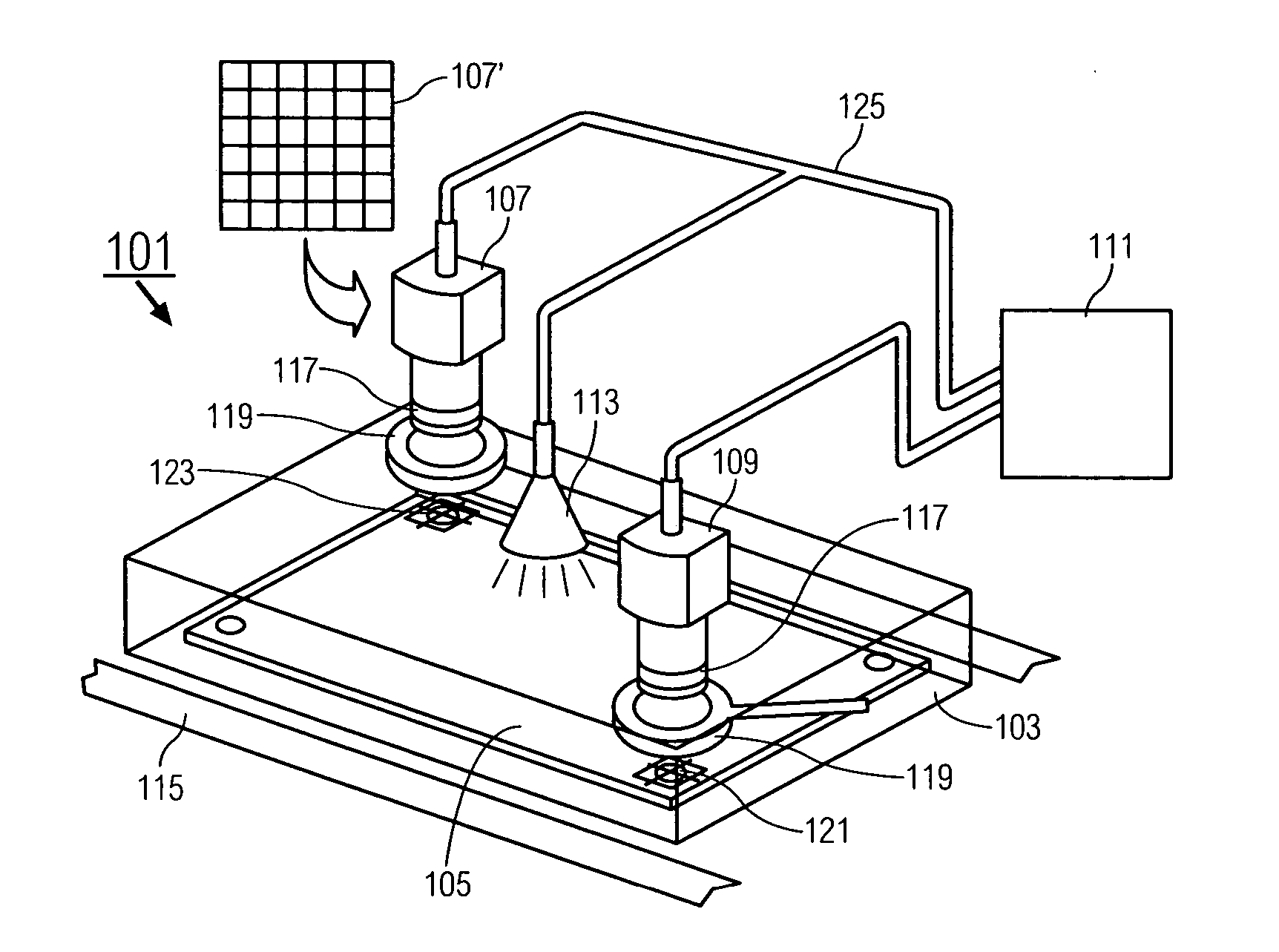

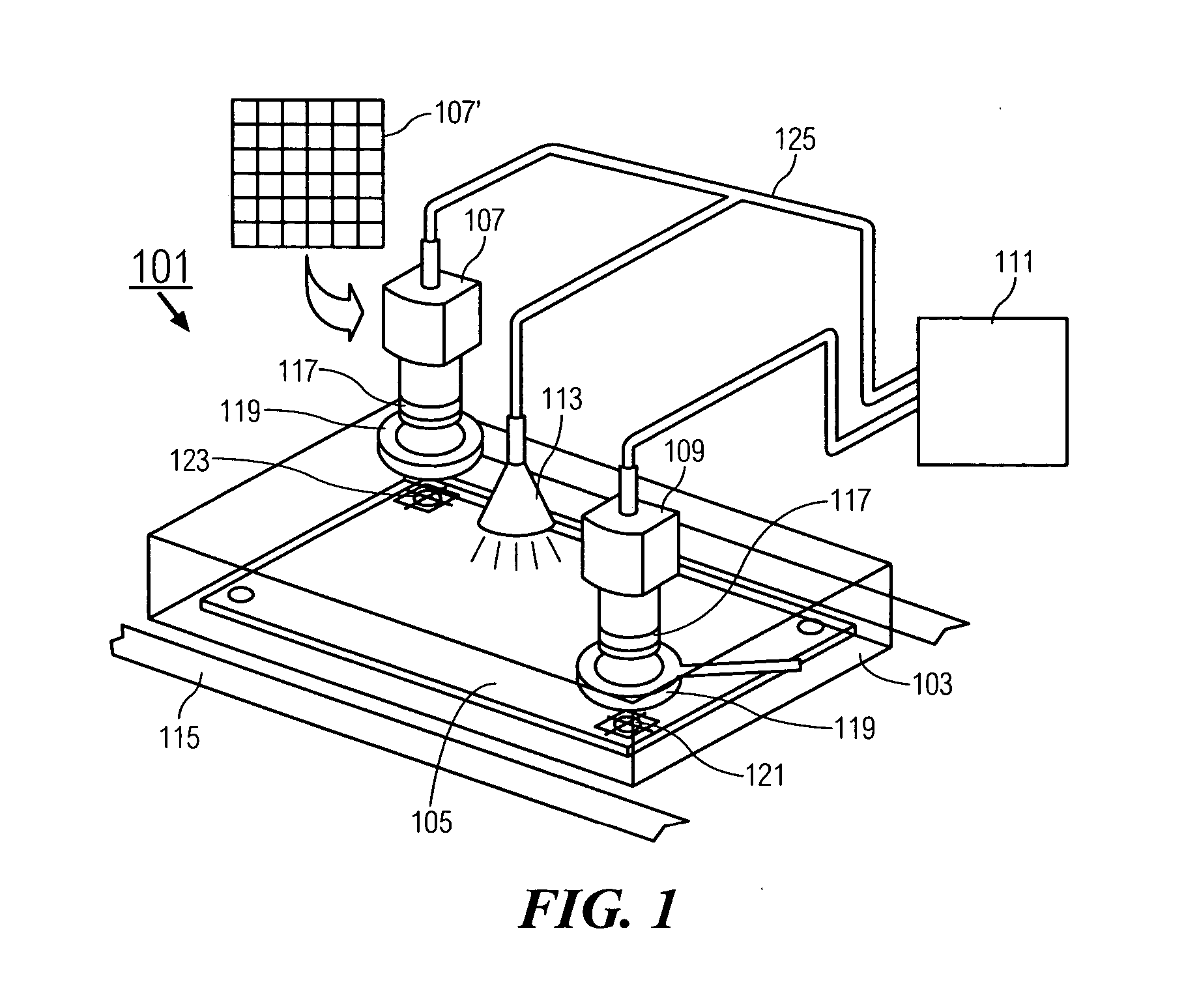

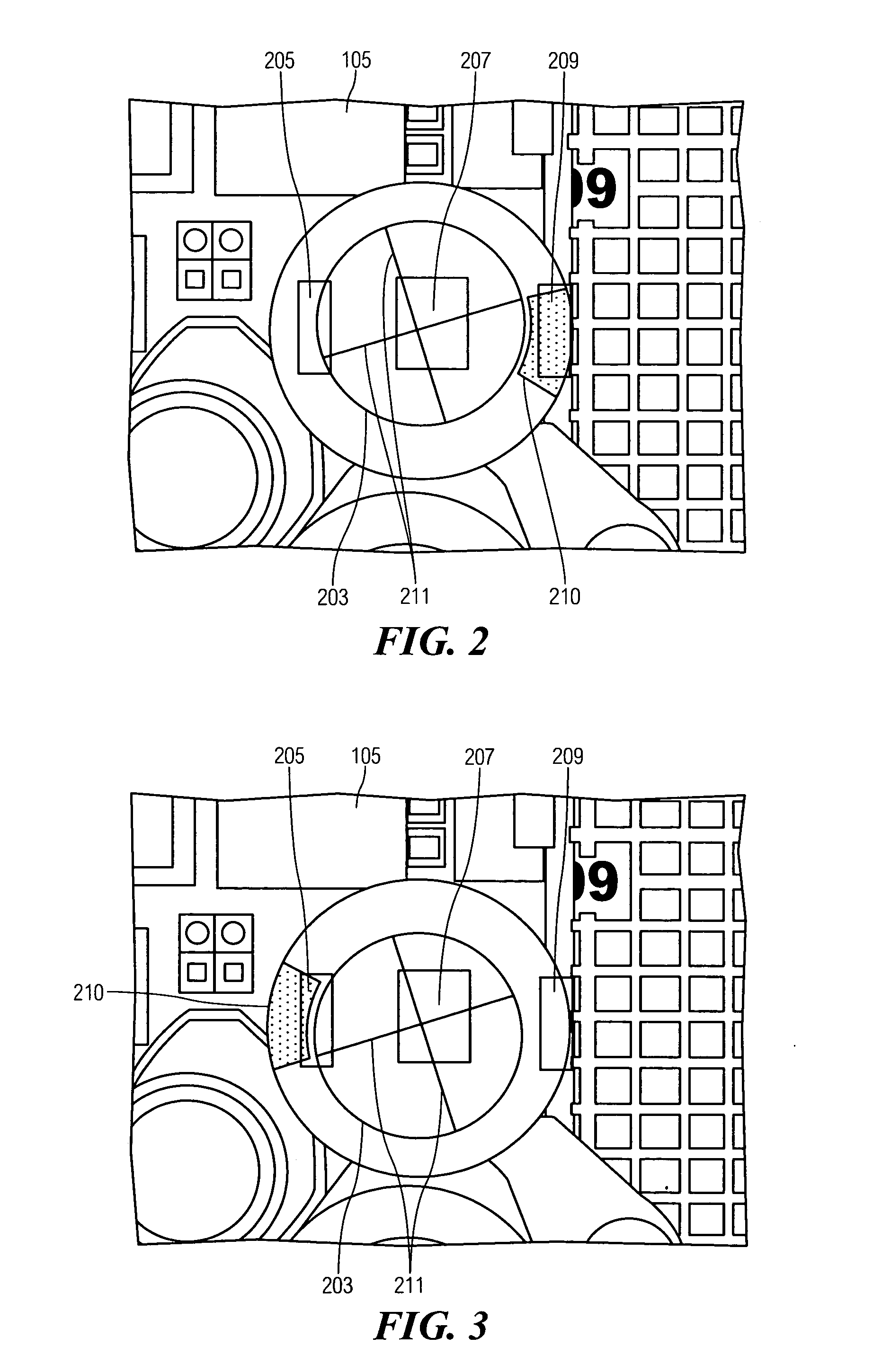

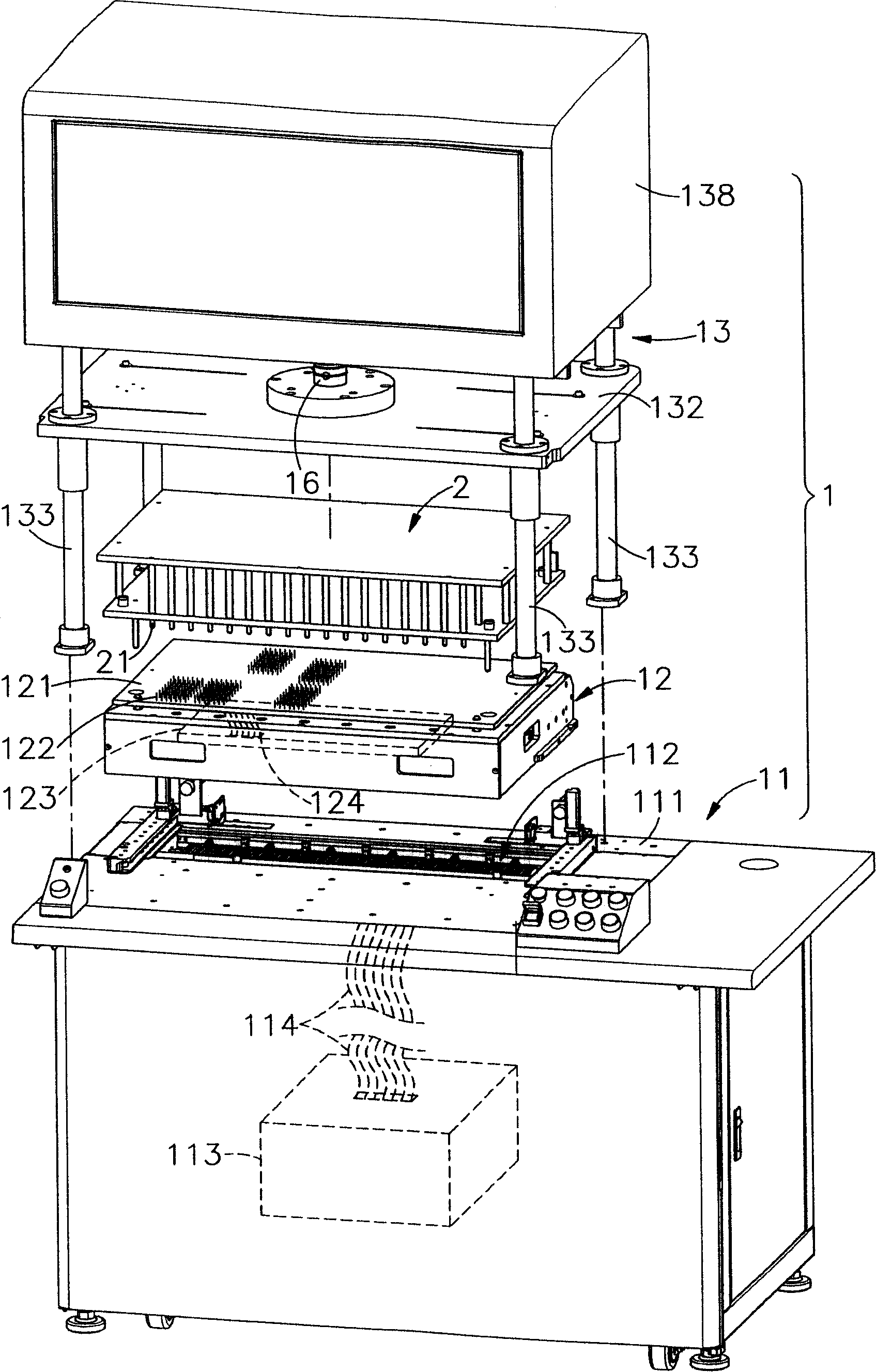

In-circuit test fixture with integral vision inspection system

InactiveUS20070013772A1Material analysis by optical meansSemiconductor/solid-state device manufacturingVision inspectionImaging analysis

An in-circuit test fixture performs both electrical tests on a Printed Circuit Assembly (“PCA”) and reads distinguishing features of a feature of interest of the PCA. The in-circuit test fixture physically supports an image sensor array. A light focusing means has a position relative to the distinguishing features and the image sensor such that a focused real image of the distinguishing features is imaged onto the image sensor. The image sensor outputs image information of the distinguishing features. A processor performs image analysis based on the image information of the distinguishing features to determine if defects exist.

Owner:AGILENT TECH INC

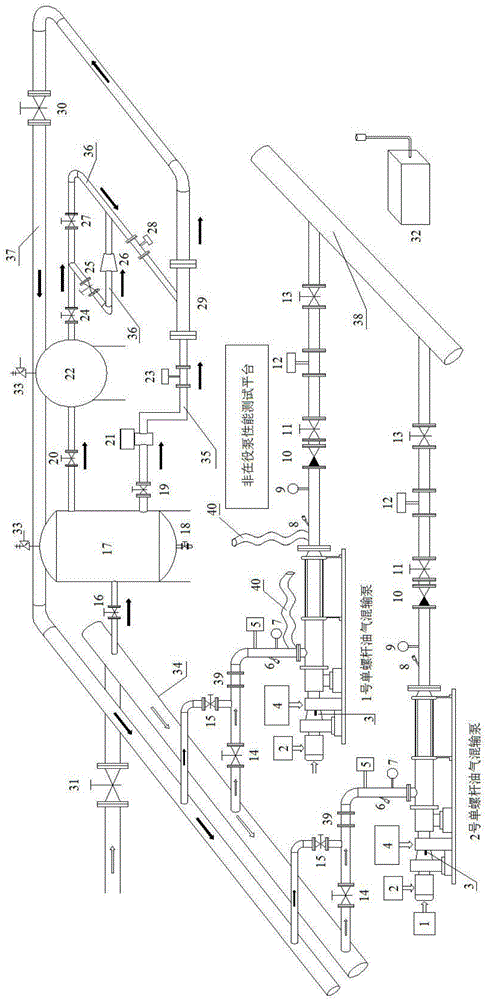

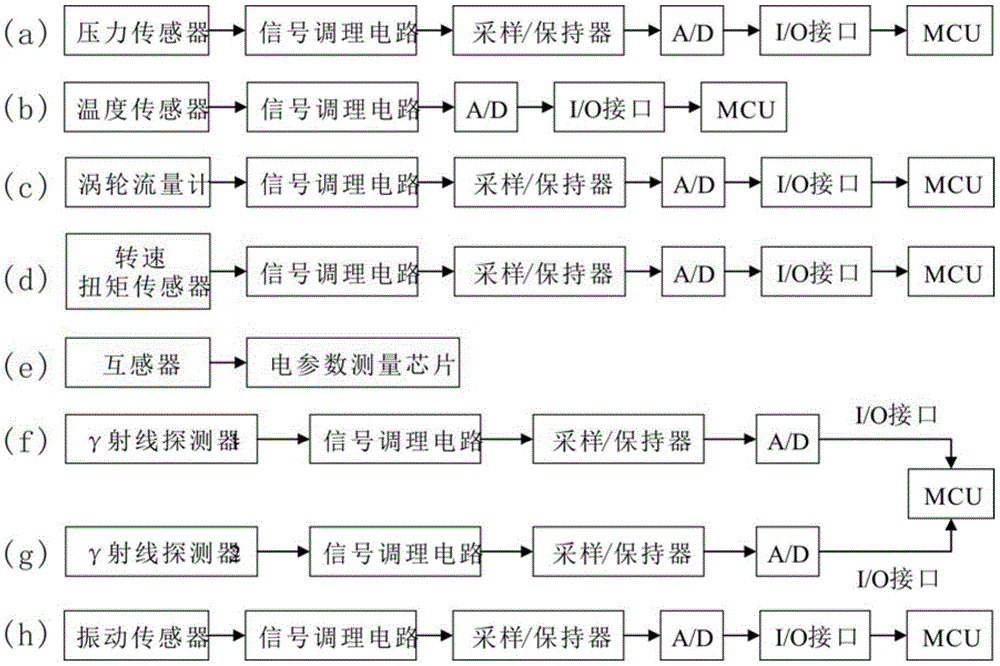

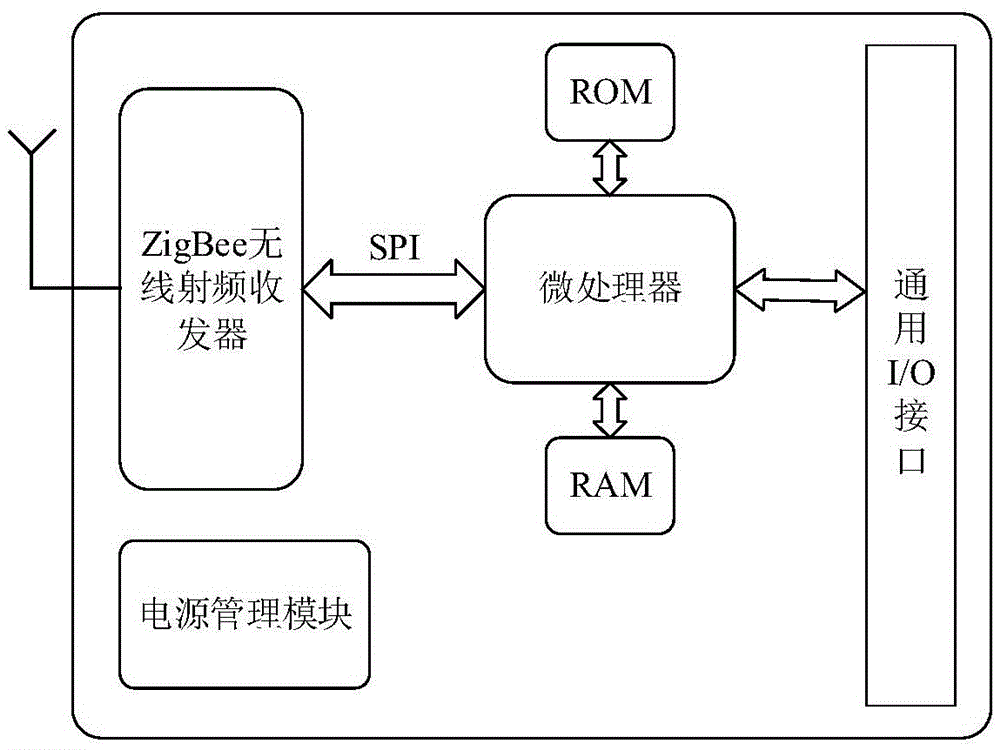

Device and method for diagnosing faults and testing performance of single-screw pump

InactiveCN105649978ARealize online monitoringImplement fault diagnosisPump componentsRotary piston pumpsEngineeringTest fixture

The invention provides a device and method for diagnosing faults and testing performance of a single-screw pump. The operation condition of the single-screw pump can be subjected to online monitoring, fault diagnosis and performance testing. Two work modes, namely, a normal production monitoring mode and a performance online testing mode are provided in the device. In the normal production monitoring mode, based on real-time monitoring on running parameters of the pump in the normal production process, the online monitoring of the operation condition of the pump is achieved; and online diagnosis of common faults of the pump can be completed by means of online detected data, and a maintaining strategy is made on the basis. In the pump performance testing mode, pump performance testing of an in-service single-screw pump / an out-of-service single-screw pump under a common operating condition / extreme operating condition can be achieved, the pump capacity efficiency, the shaft power, the lift, the overall efficiency and other performance parameters can be calculated under different operating conditions, and a performance curve is drawn and stored on the basis.

Owner:SOUTHWEST PETROLEUM UNIV

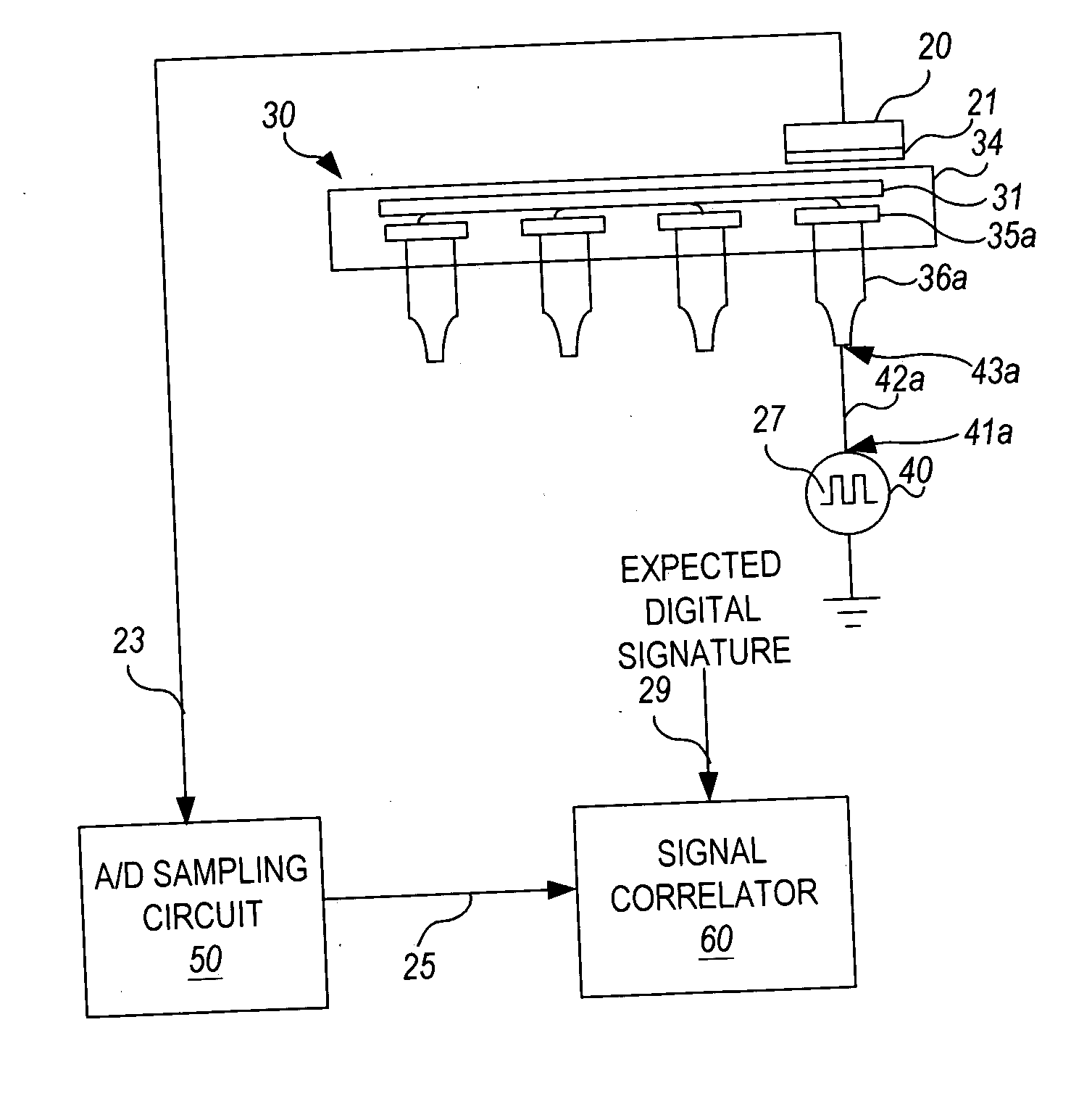

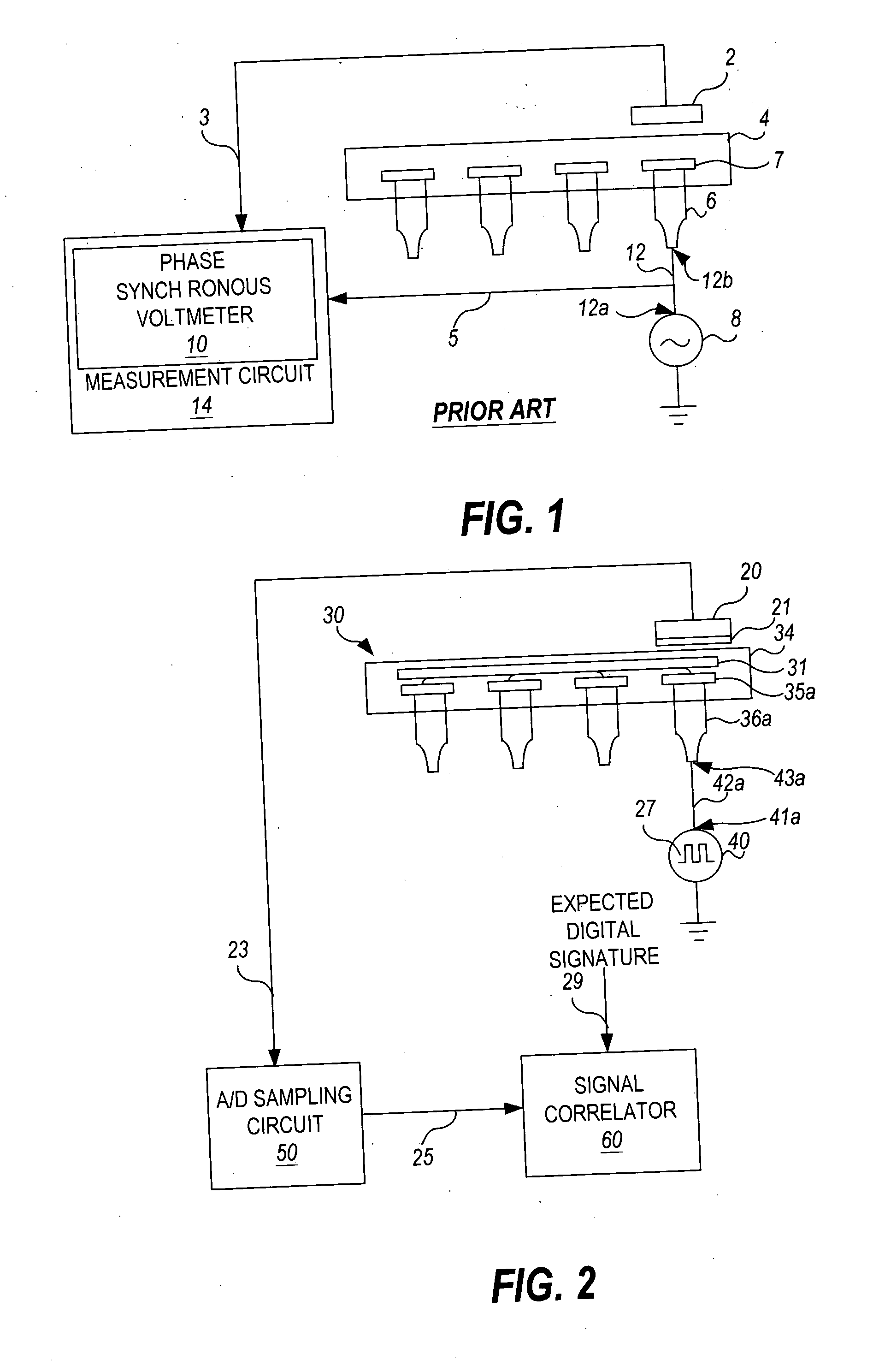

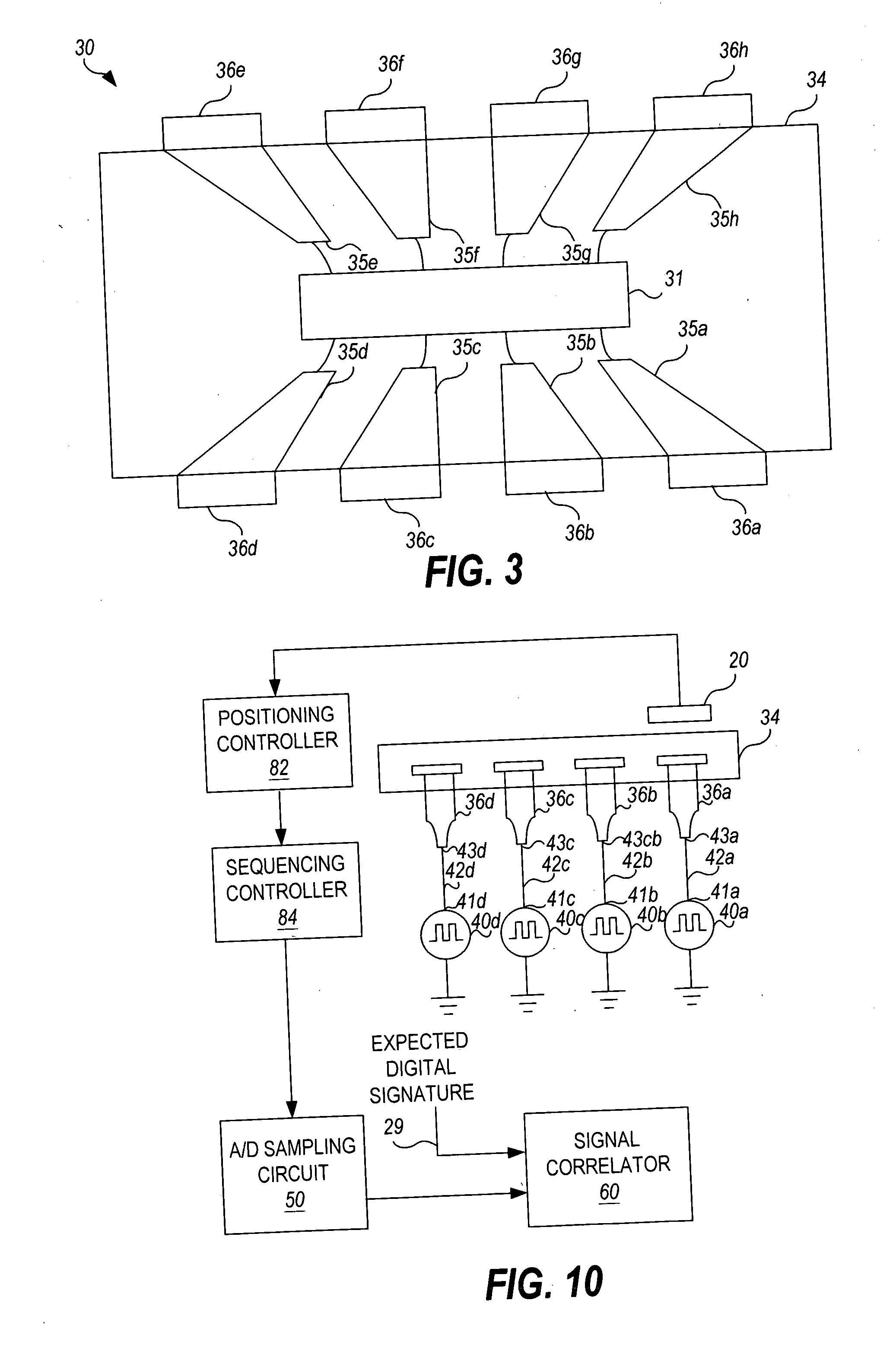

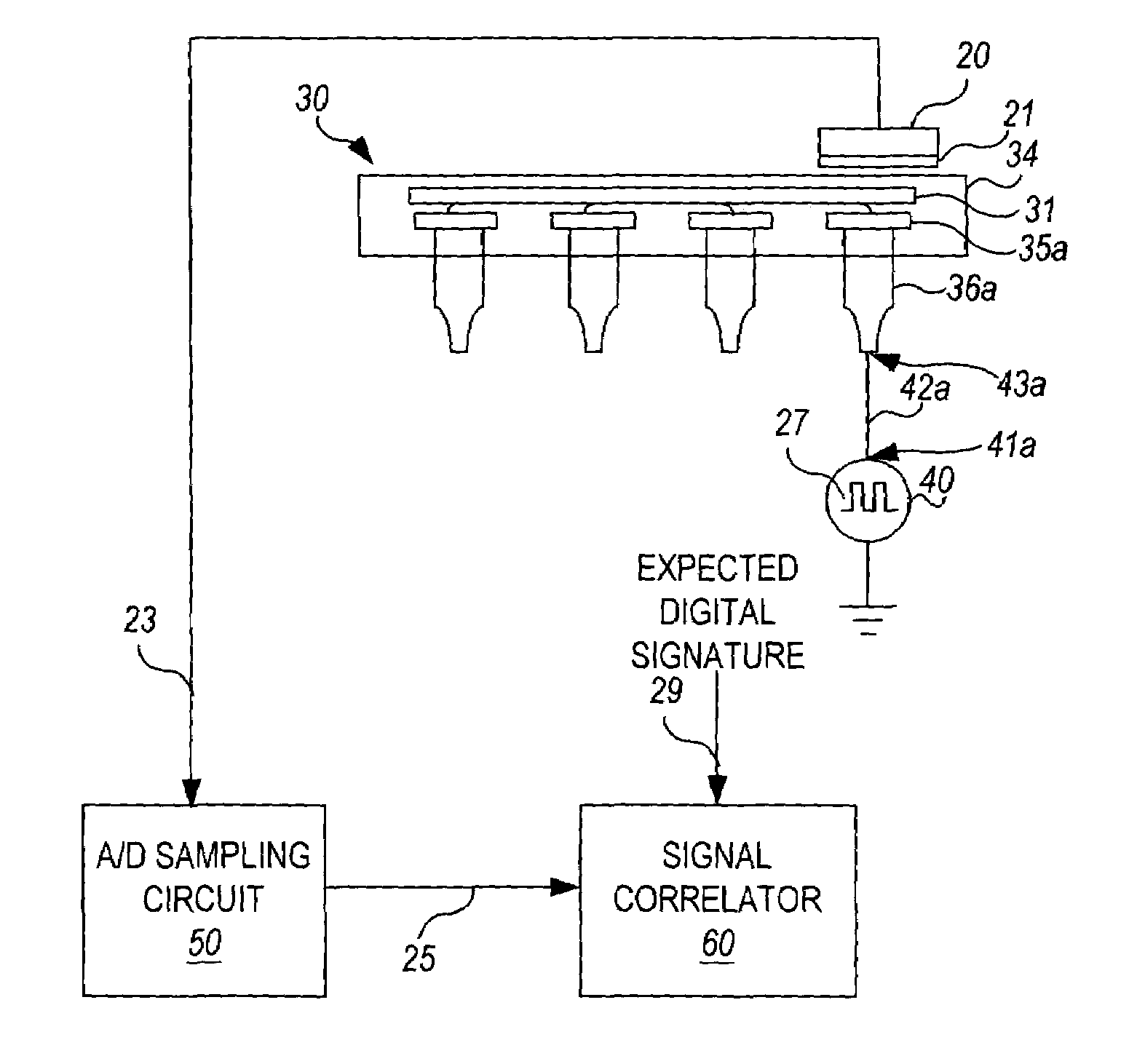

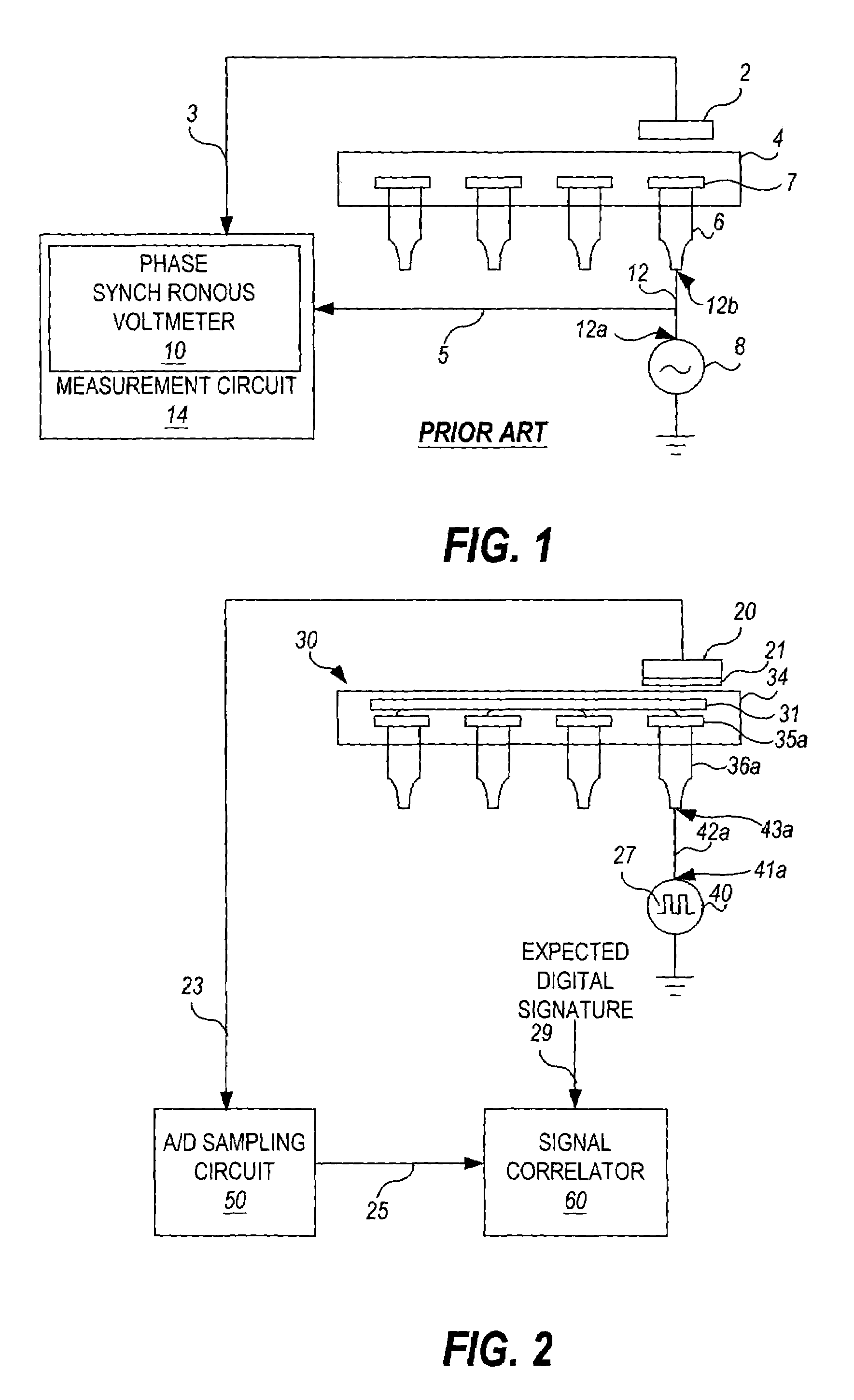

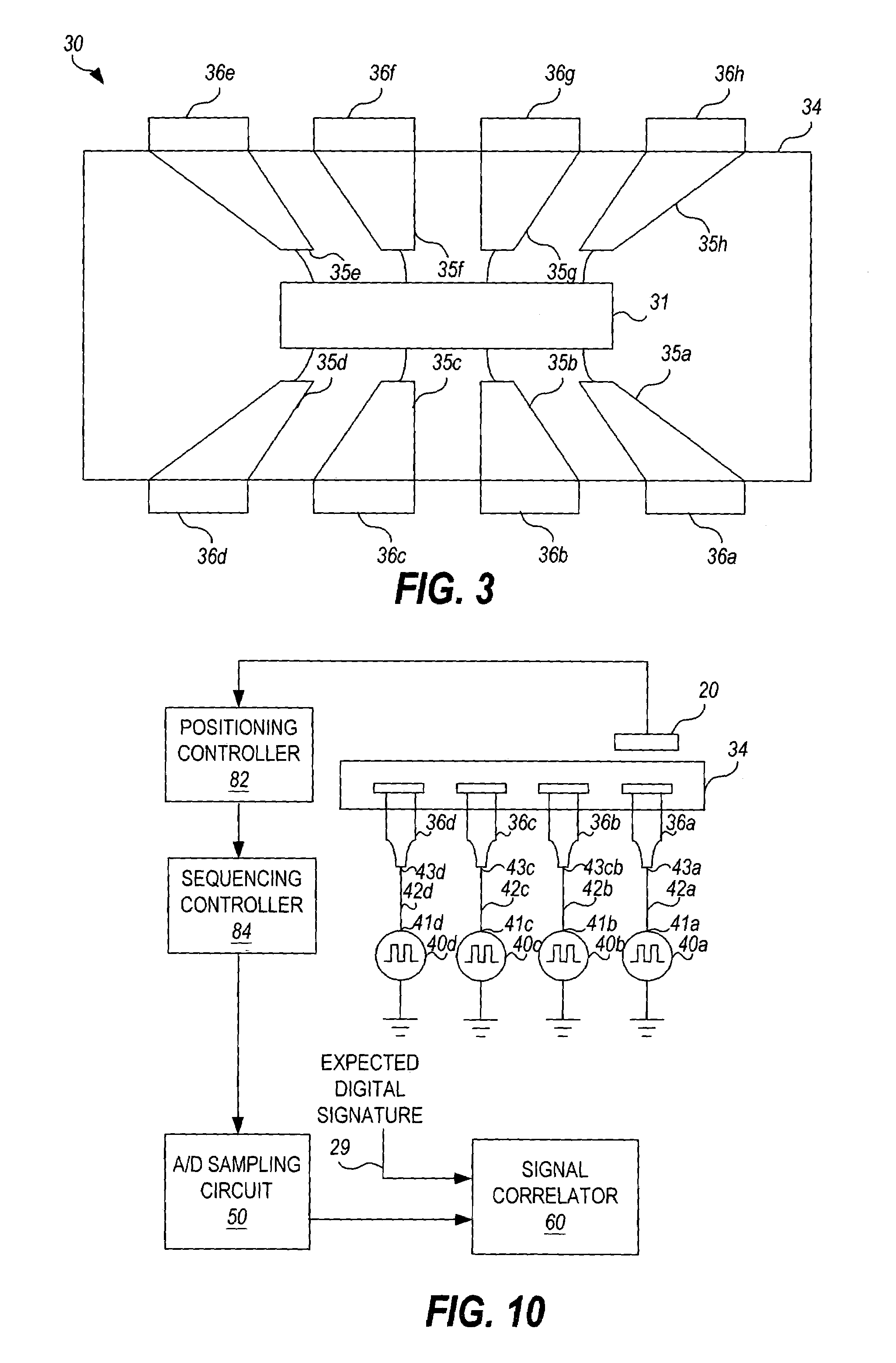

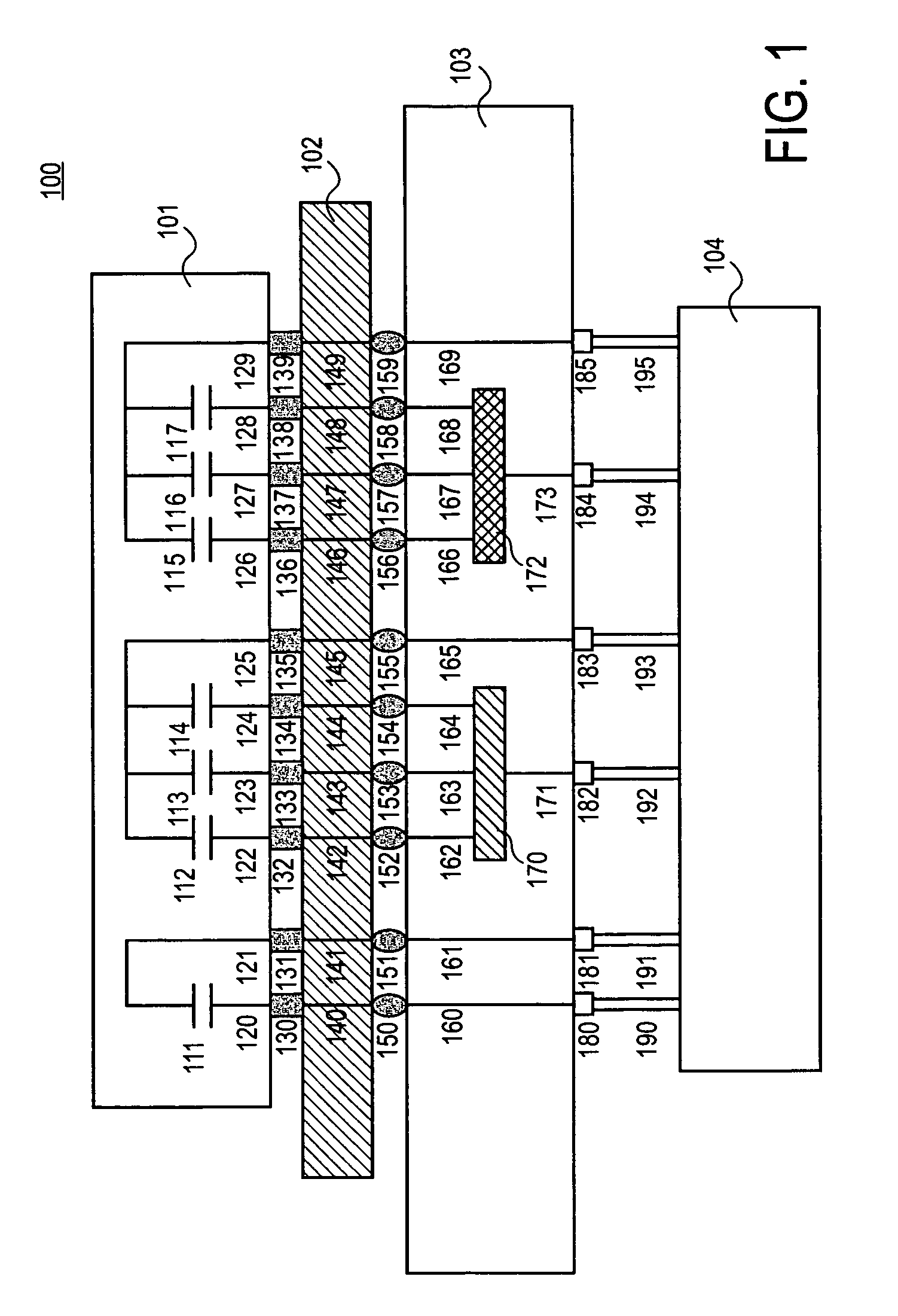

Capacitive sensor measurement method for discrete time sampled system for in-circuit test

InactiveUS20050068051A1Reduce setup timeEasy to useFault locationContactless circuit testingDigital signatureCapacitive coupling

Disclosed is a novel method and apparatus for acquiring multiple capacitively sensed measurements from a circuit under test. Multiple digital sources are respectively connected to stimulate multiple respective first ends of multiple respective nets of interest. Respective second ends of the multiple respective nets of interest are capacitively sensed. The respective capacitively coupled signals are digitally sampled and shift correlated with respective expected digital signatures. If a high level of correlation is found for a given net, the net is electrically intact; otherwise, the net is characterized by either an open or some other fault that prevents it from meeting specification.

Owner:AGILENT TECH INC

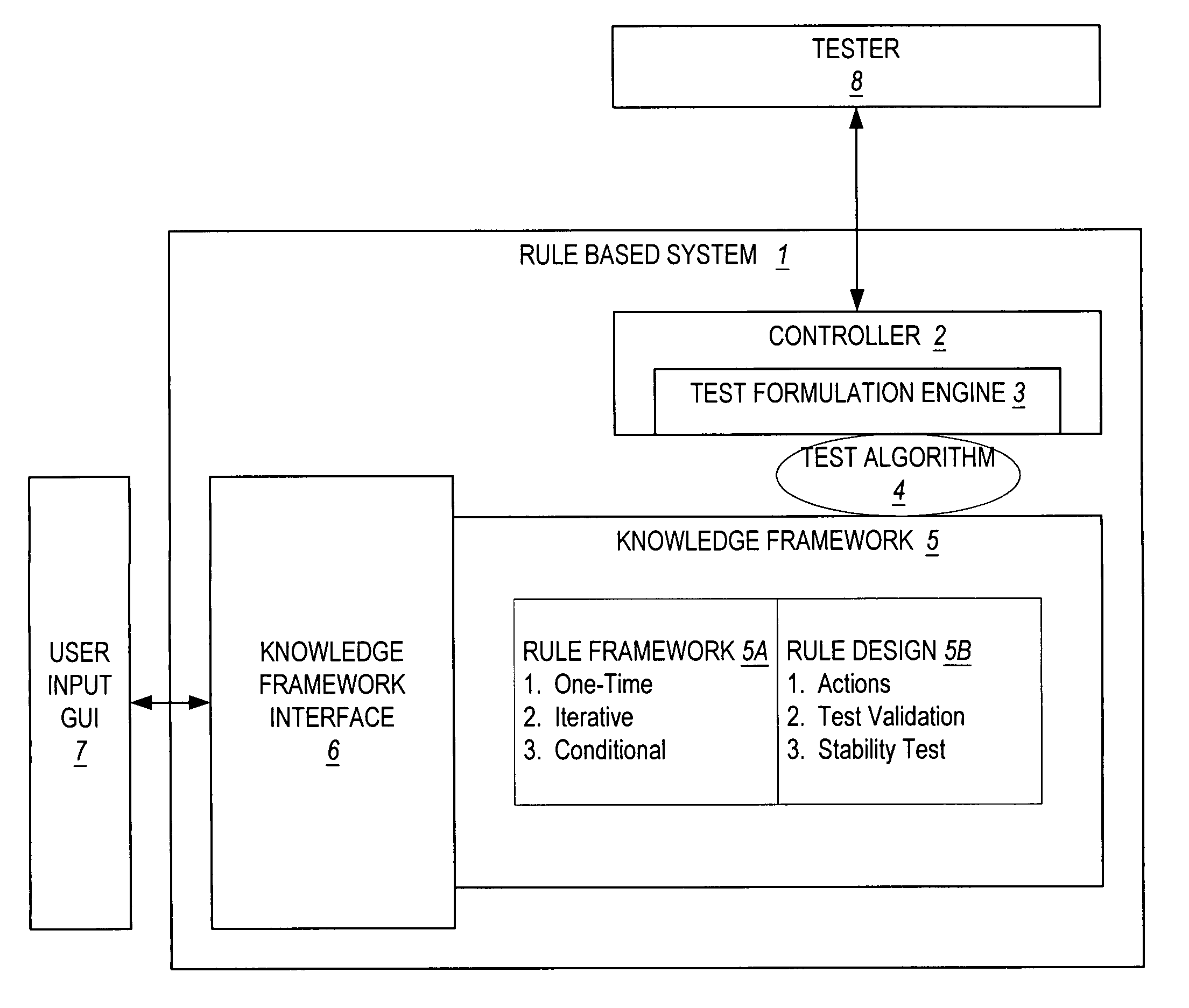

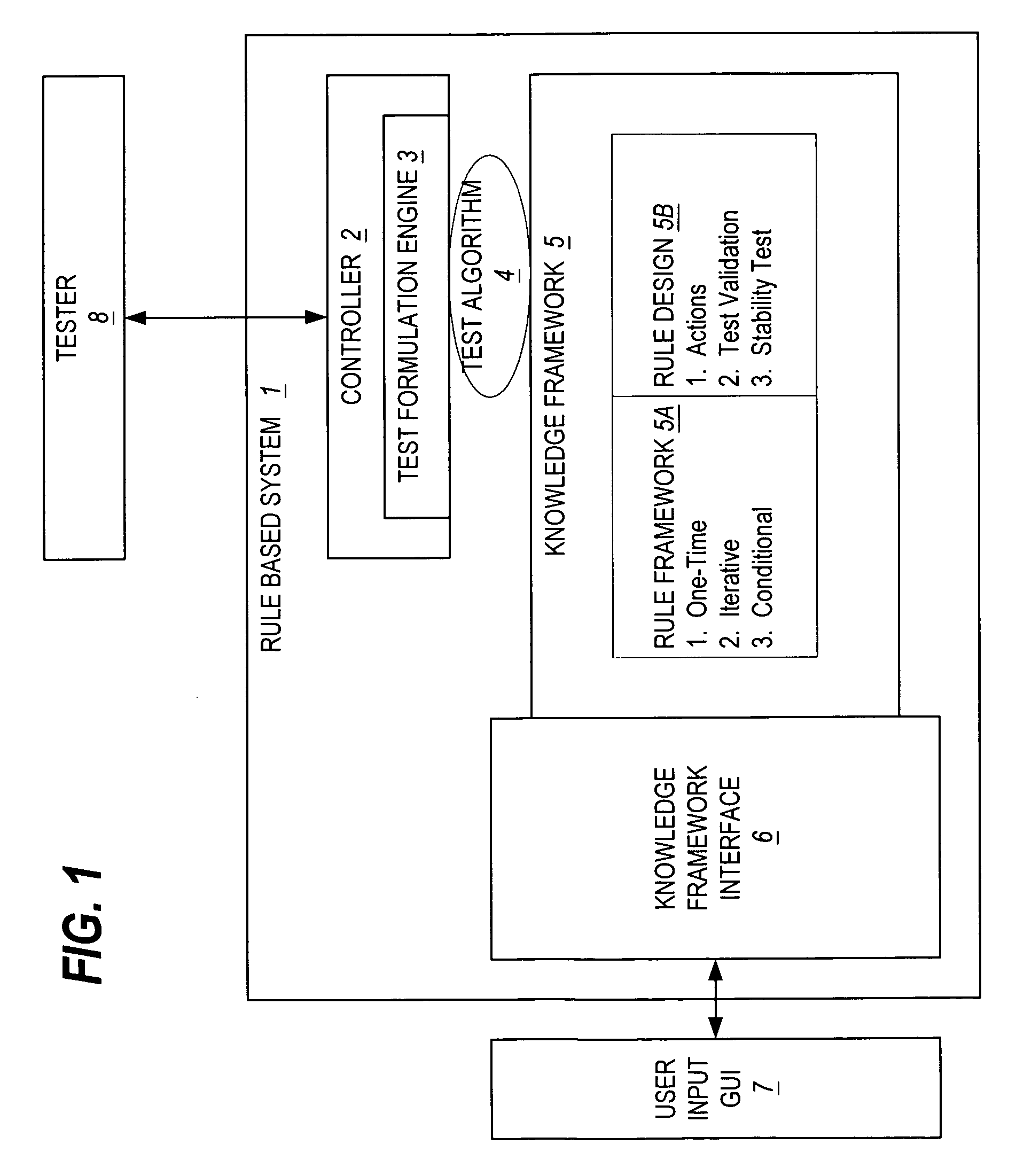

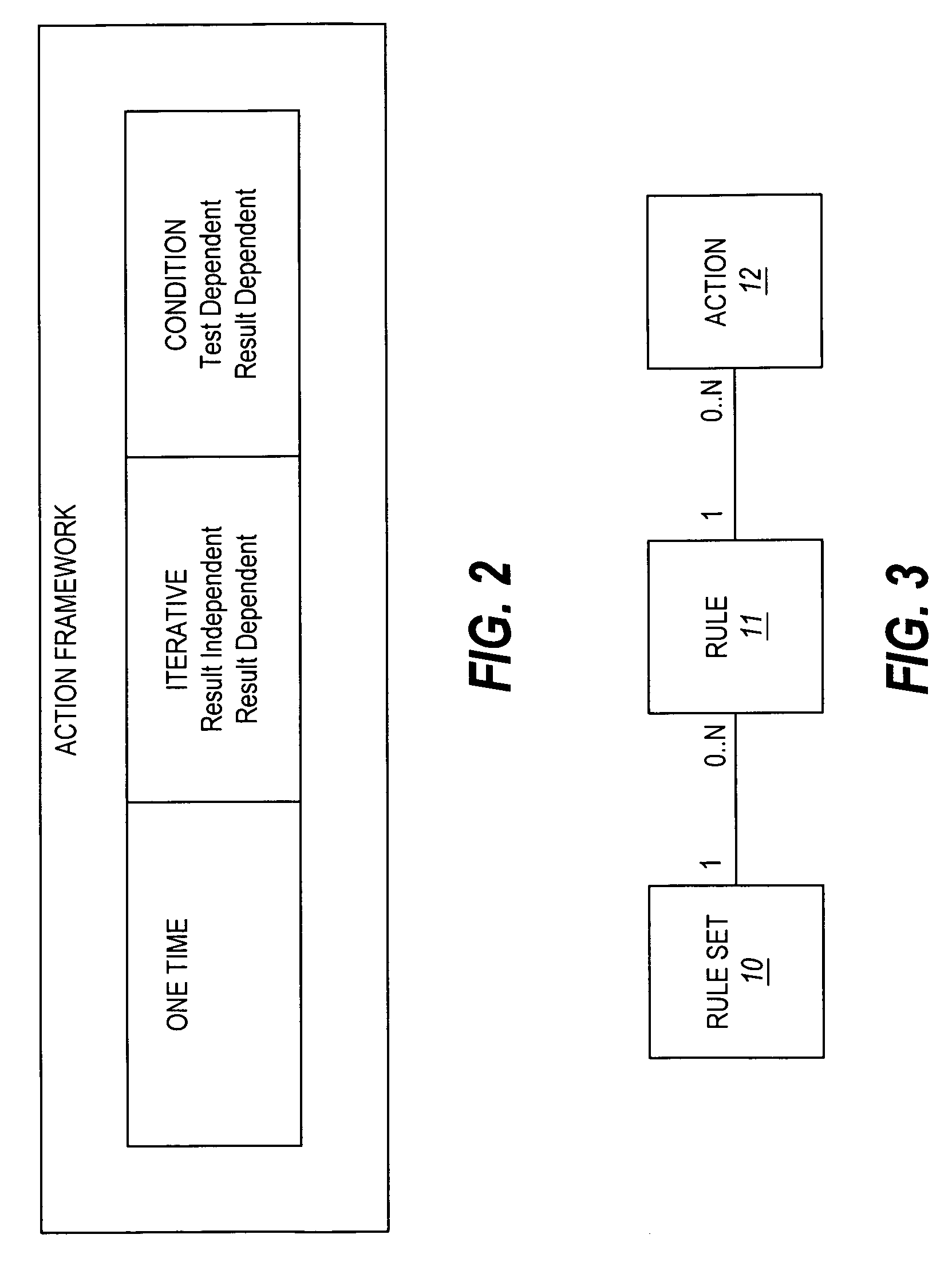

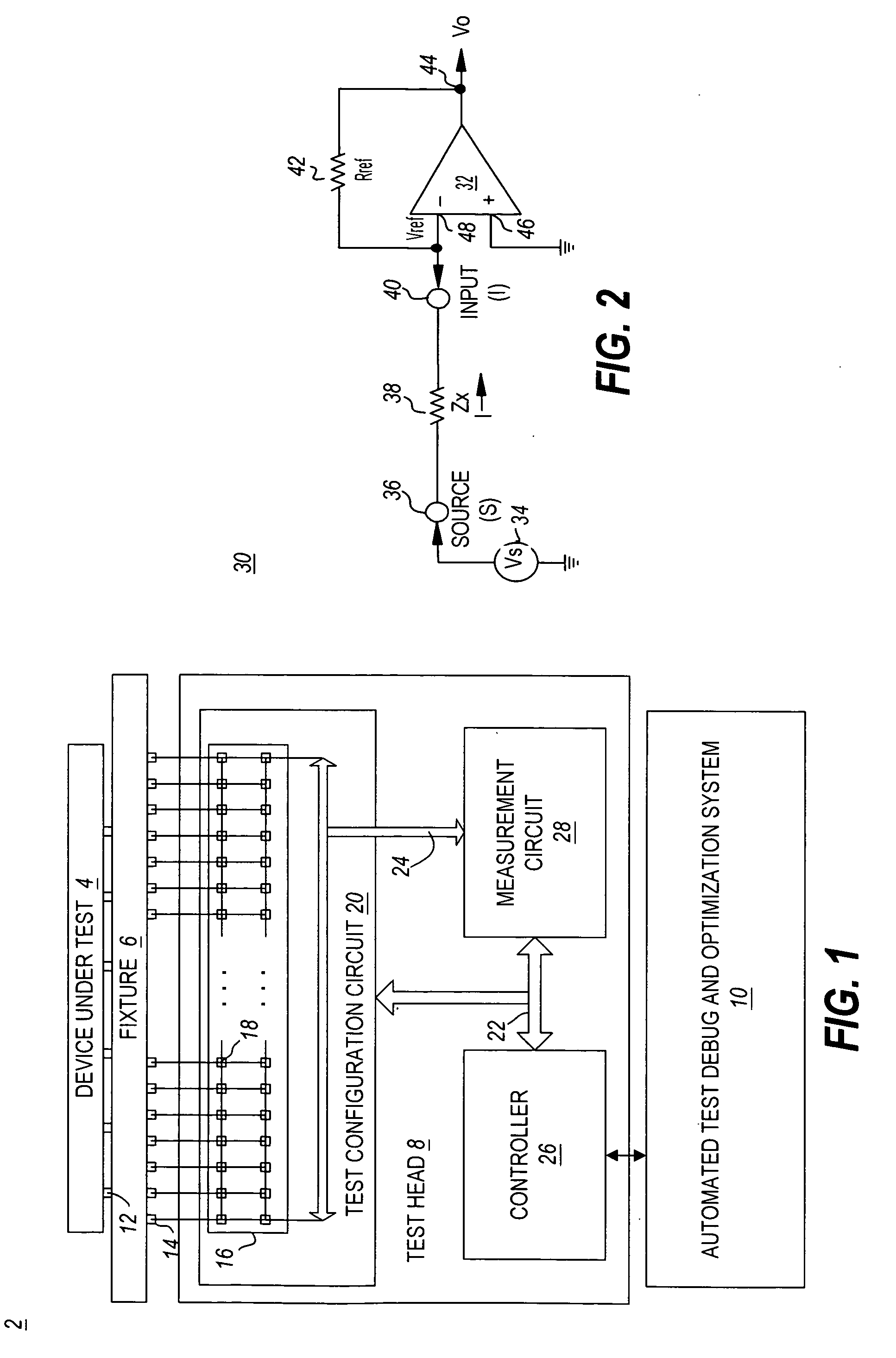

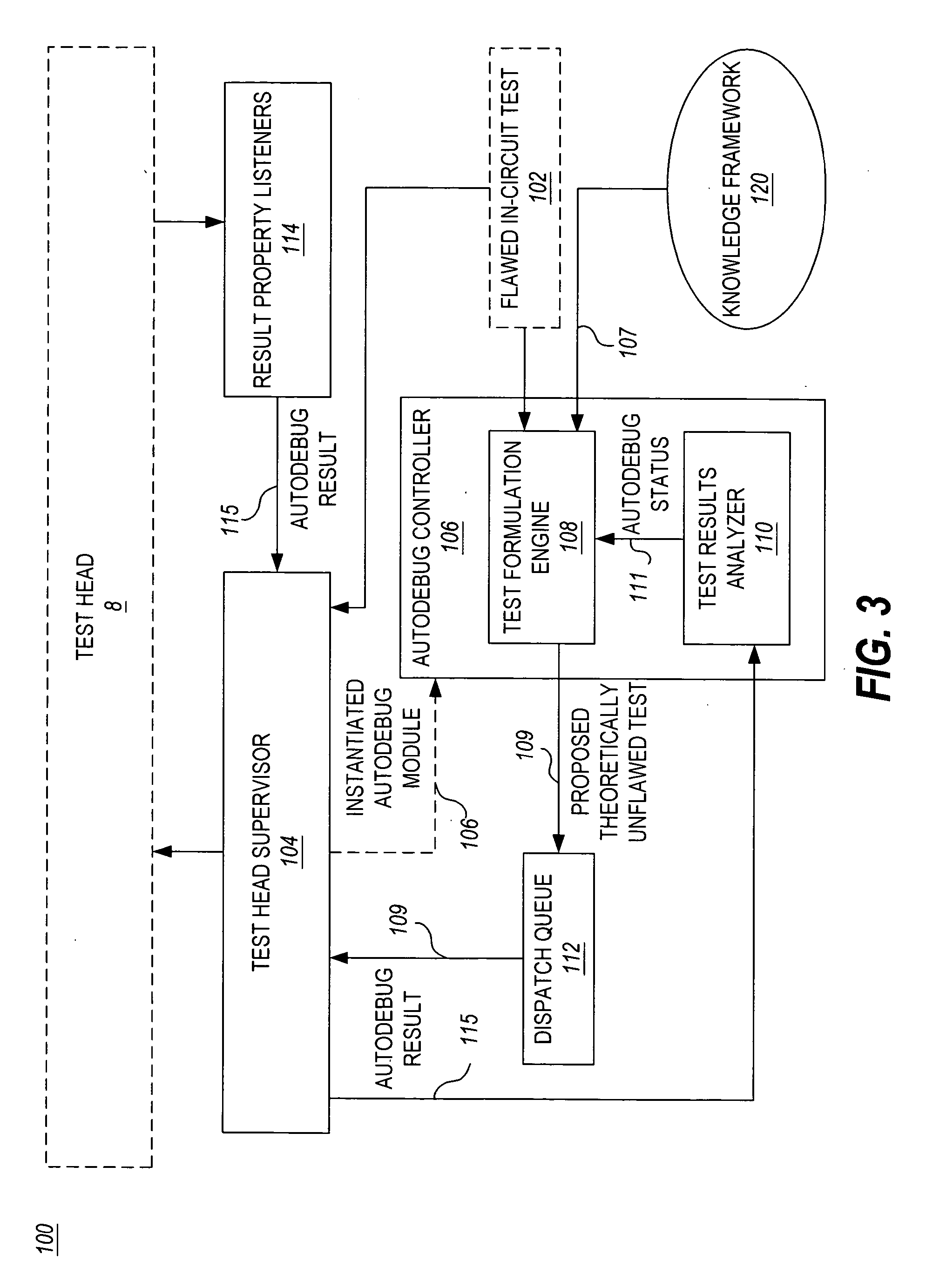

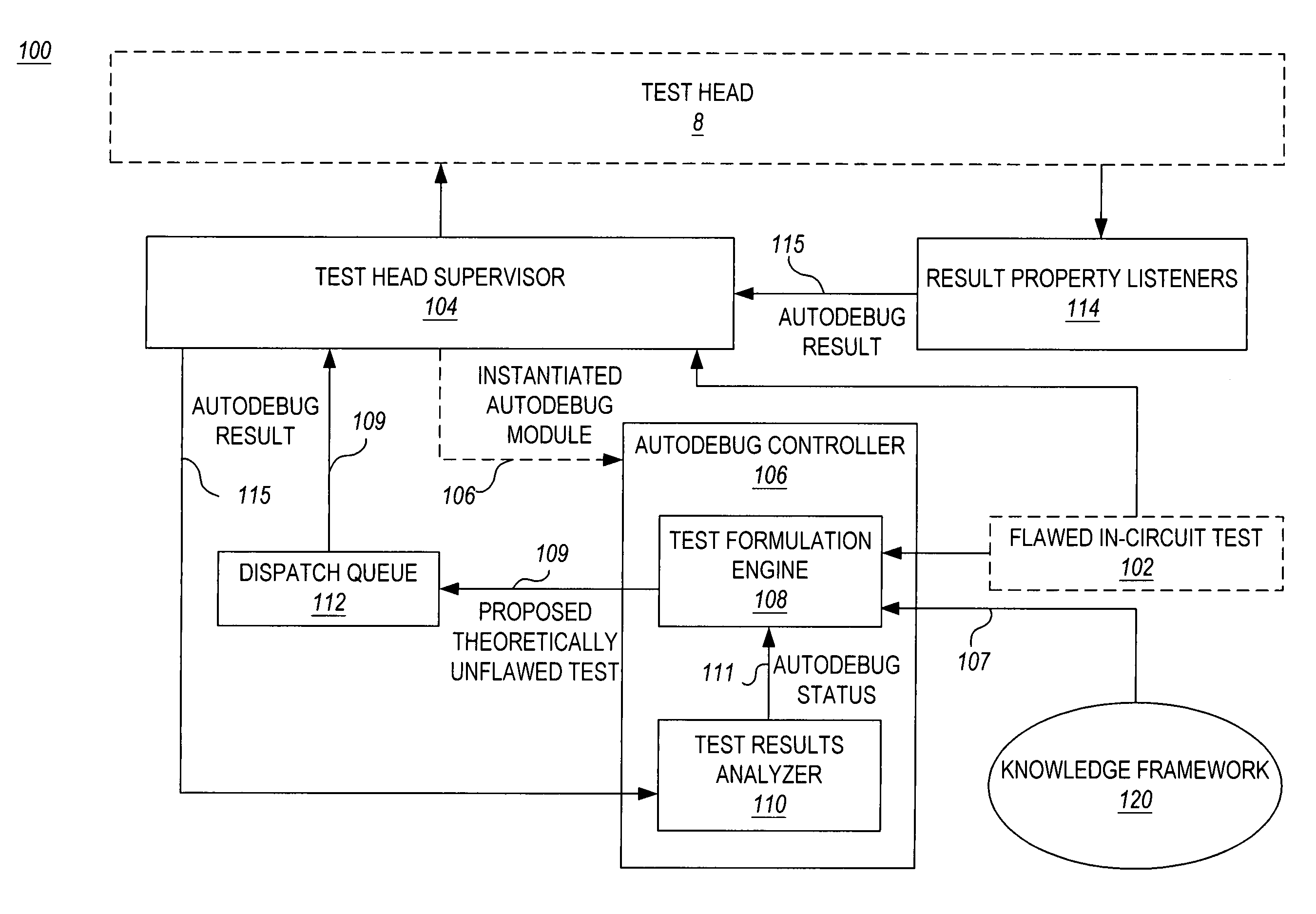

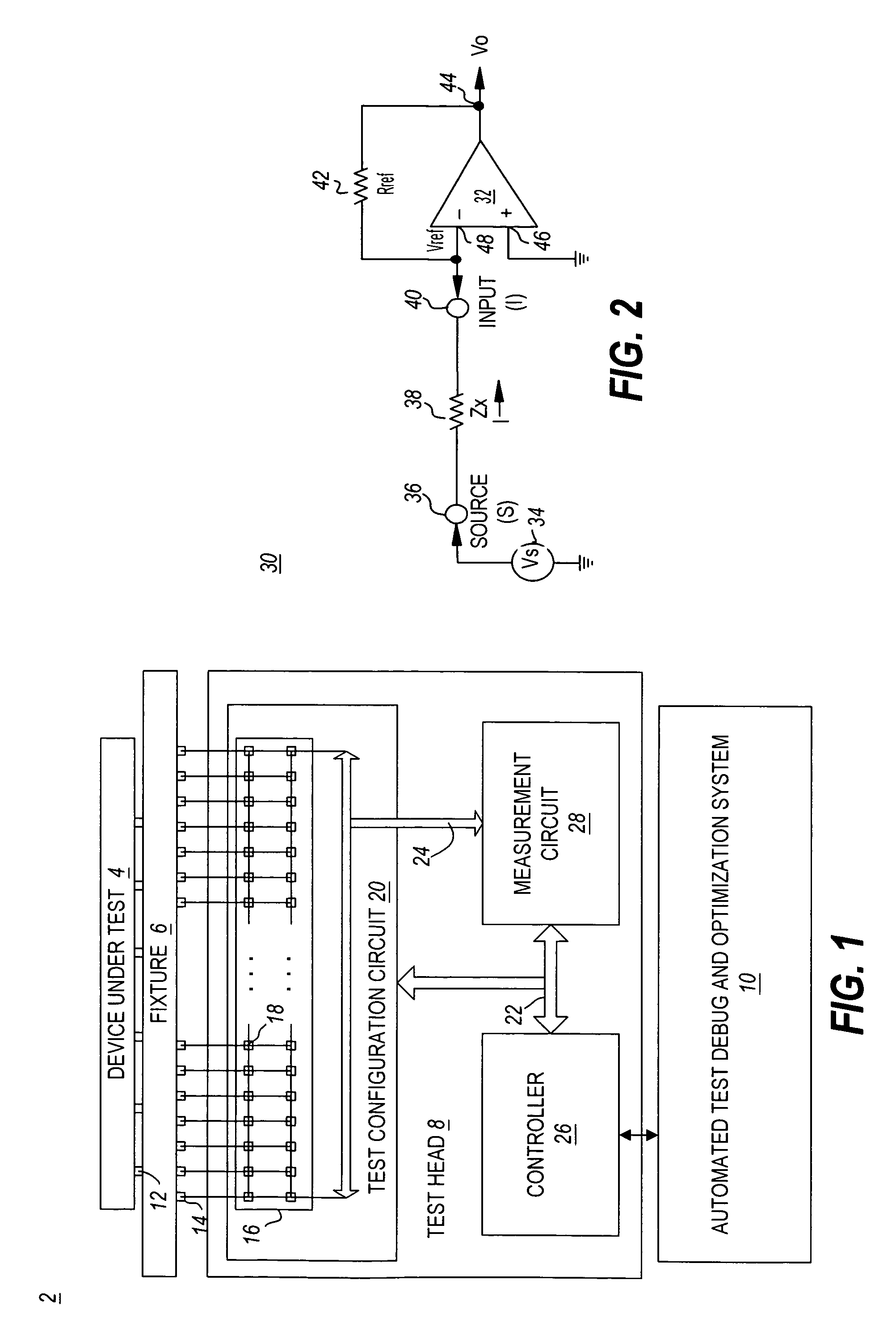

Method and apparatus for configuration of automated debug of in-circuit tests

InactiveUS20060036390A1Resistance/reactance/impedenceNuclear monitoringComputer hardwareKnowledge framework

A method for configuring an automated in-circuit test debugger is presented. The novel test debug and optimization configuration technique configures expert knowledge into a knowledge framework for use by an automated test debug and optimization system for automating the formulation of a valid stable in-circuit test for execution on an integrated circuit tester. In a system that includes a rule-based controller for controlling interaction between the test-head controller of an integrated circuit tester and an automated debug system, the invention includes a knowledge framework and a rule-based editor. The knowledge framework stores test knowledge in the representation of rules that represent a debugging strategy. The rule-based editor facilitates the use of rules as knowledge to debug or optimize an in-circuit test that is to be executed on the integrated circuit tester.

Owner:AGILENT TECH INC

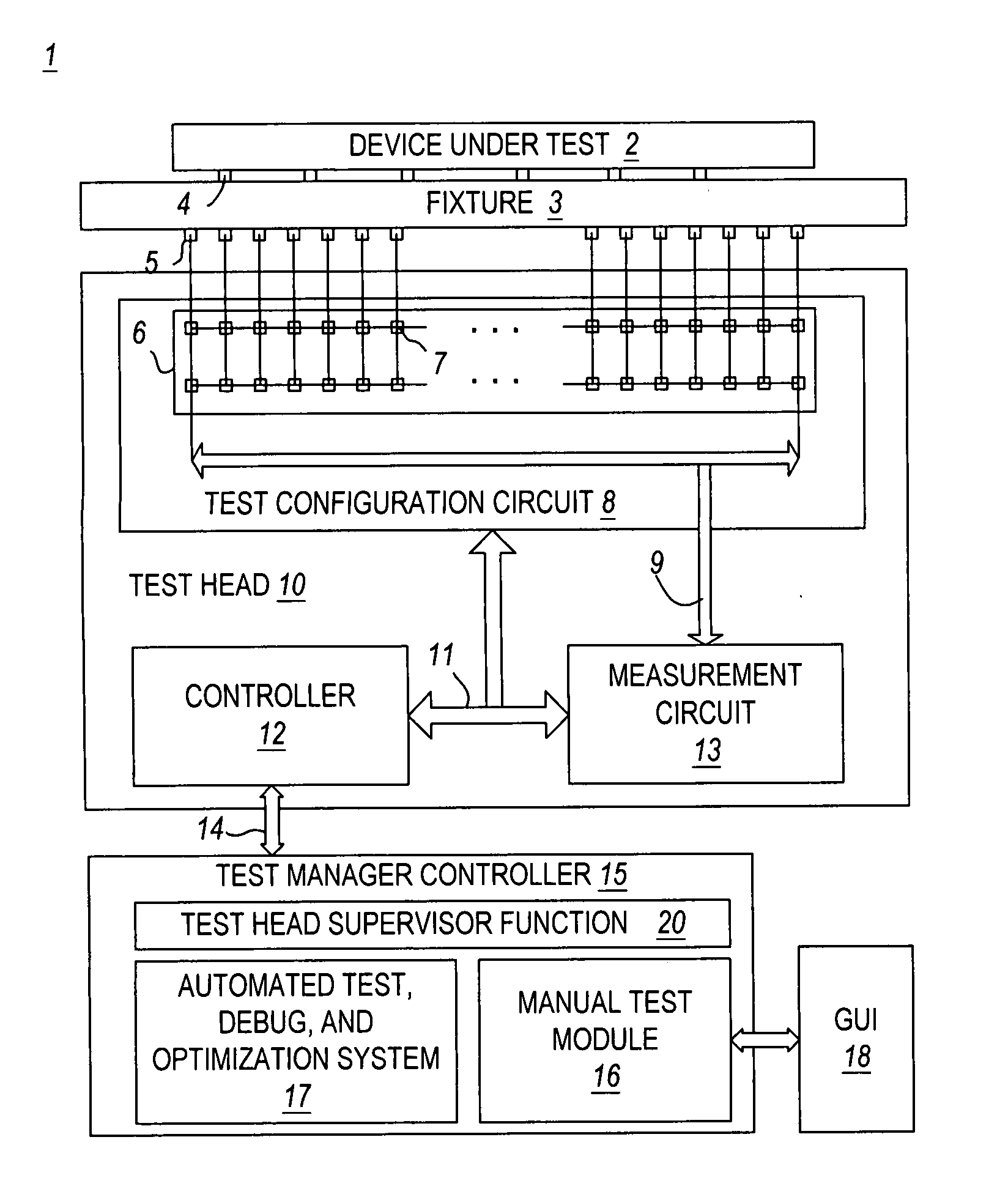

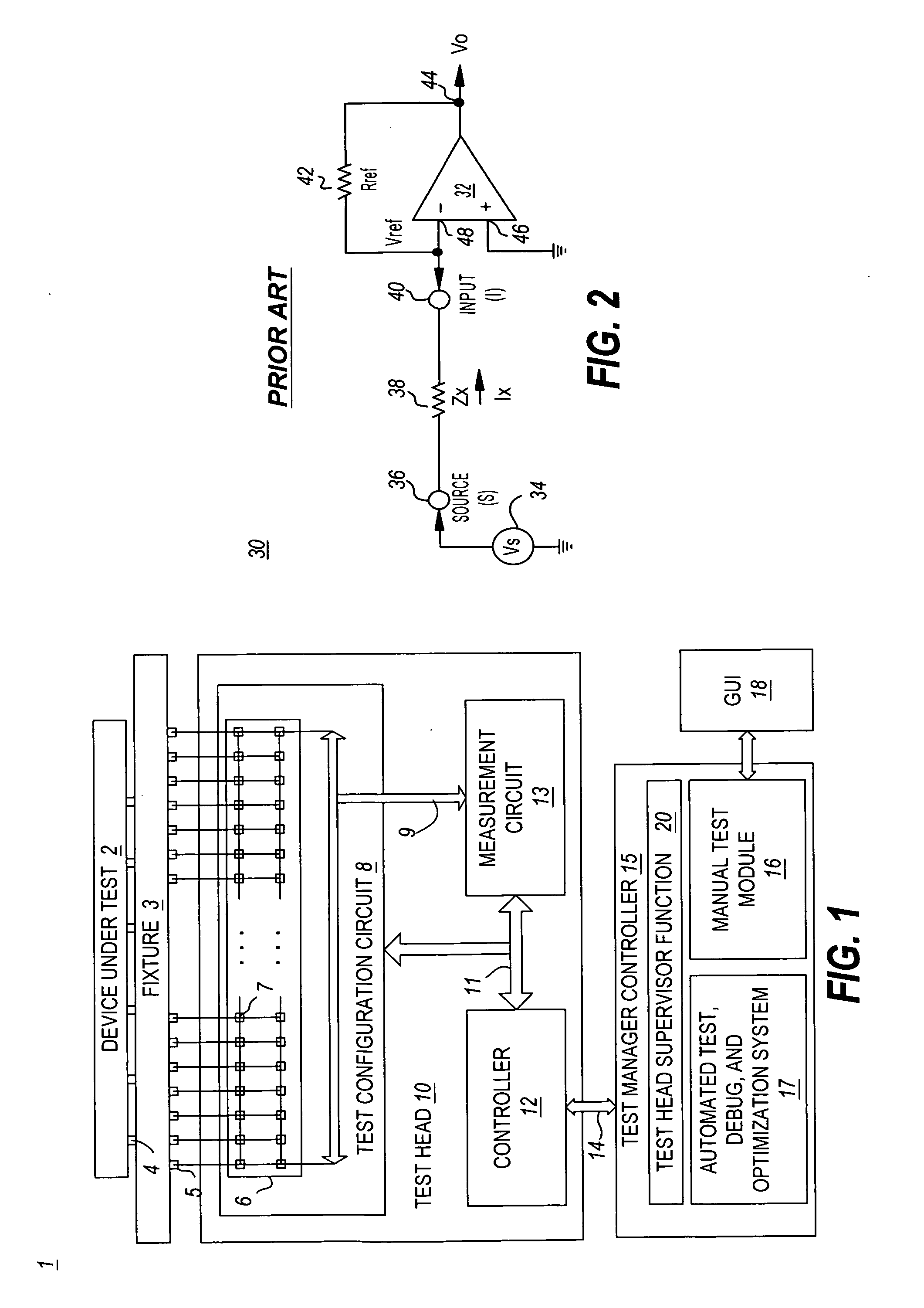

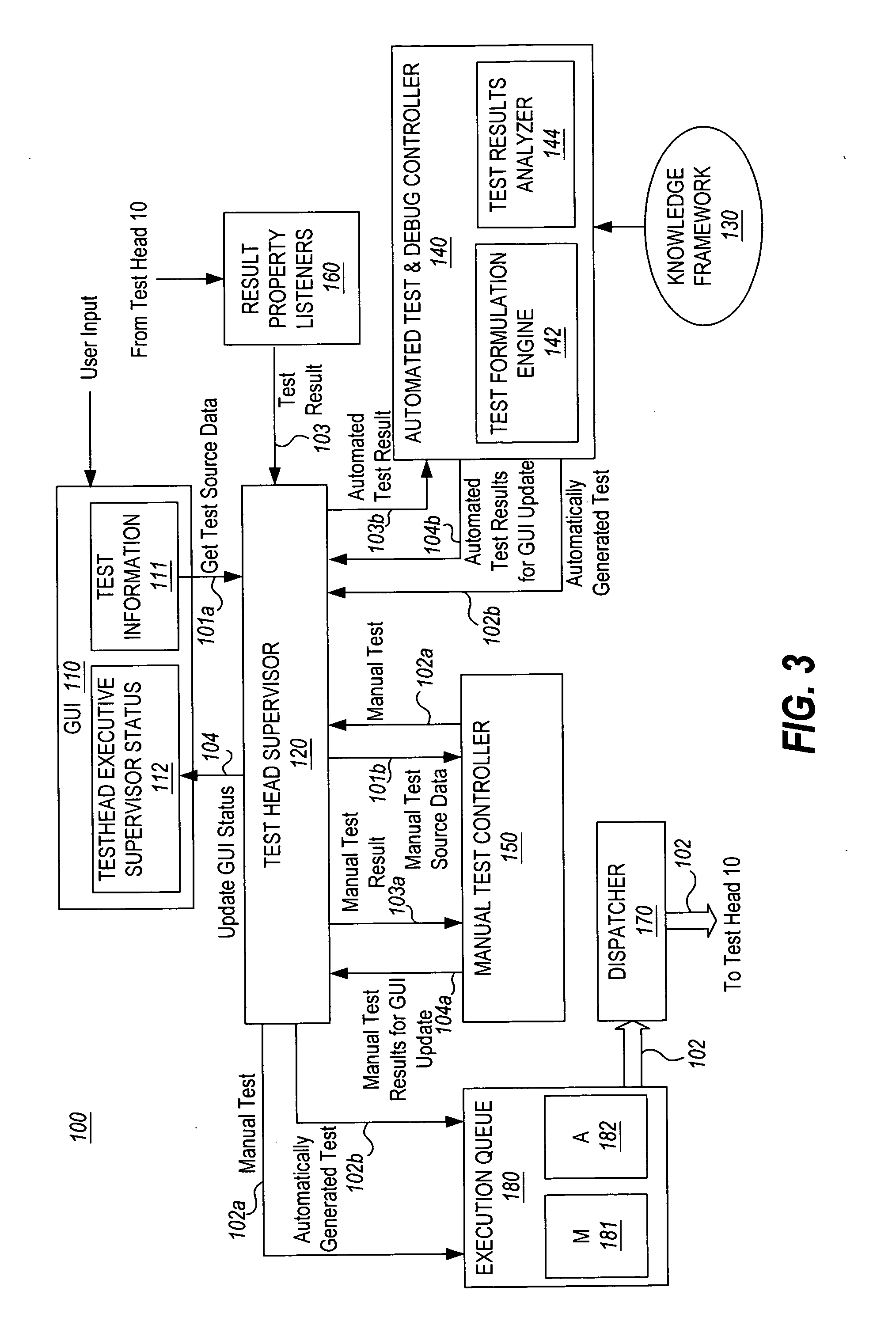

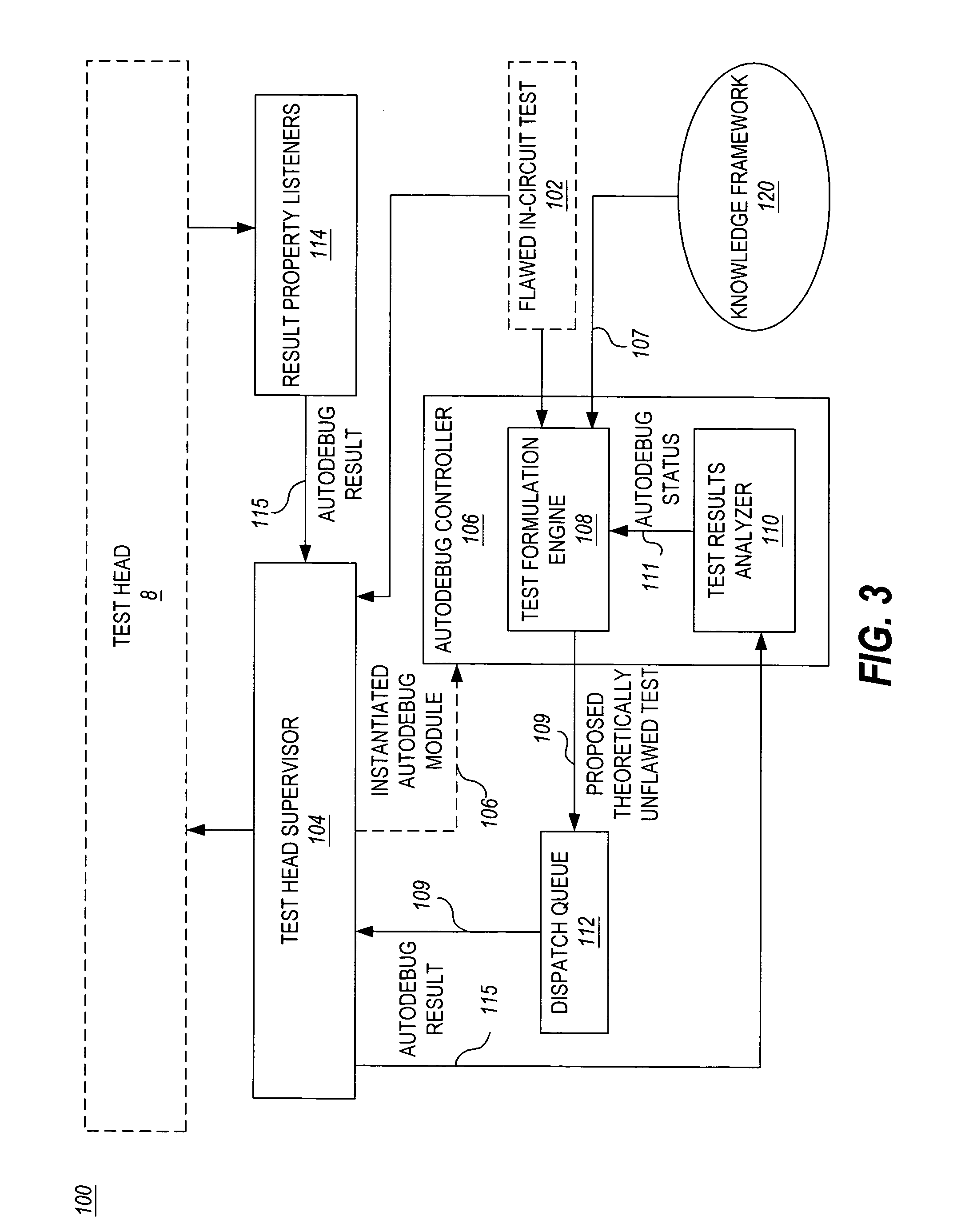

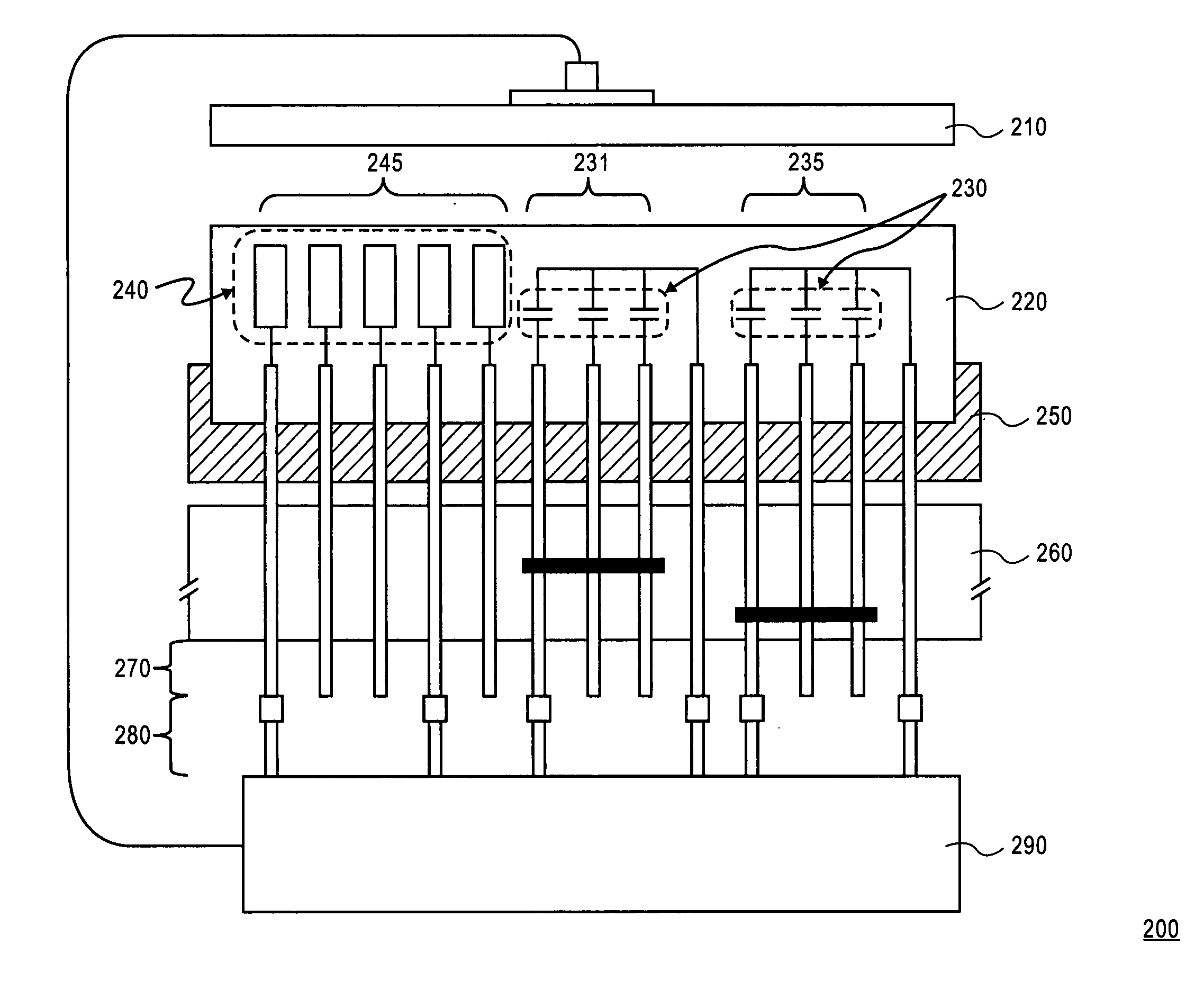

Framework that maximizes the usage of testhead resources in in-circuit test system

InactiveUS20070013362A1Maximize useElectronic circuit testingFault location by increasing destruction at faultComputer hardwareGraphics

A method and apparatus for maximizing the usage of a testhead of an in-circuit tester is presented. A testhead execution supervisor interfaces between a testhead controller and a graphical user interface used to enter manual tests. The testhead execution supervisor adds tests to be submitted to the testhead to one or more queues according to a priority scheme. Tests may be submitted to the testhead execution supervisor both as manual tests entered via the graphical user interface and as automatically generated tests generated by an automatic debug module. The automatic debug module may automatically generate tests for execution by the testhead that are executed when the testhead is idle, for example when no higher priority manual tests are scheduled.

Owner:AGILENT TECH INC

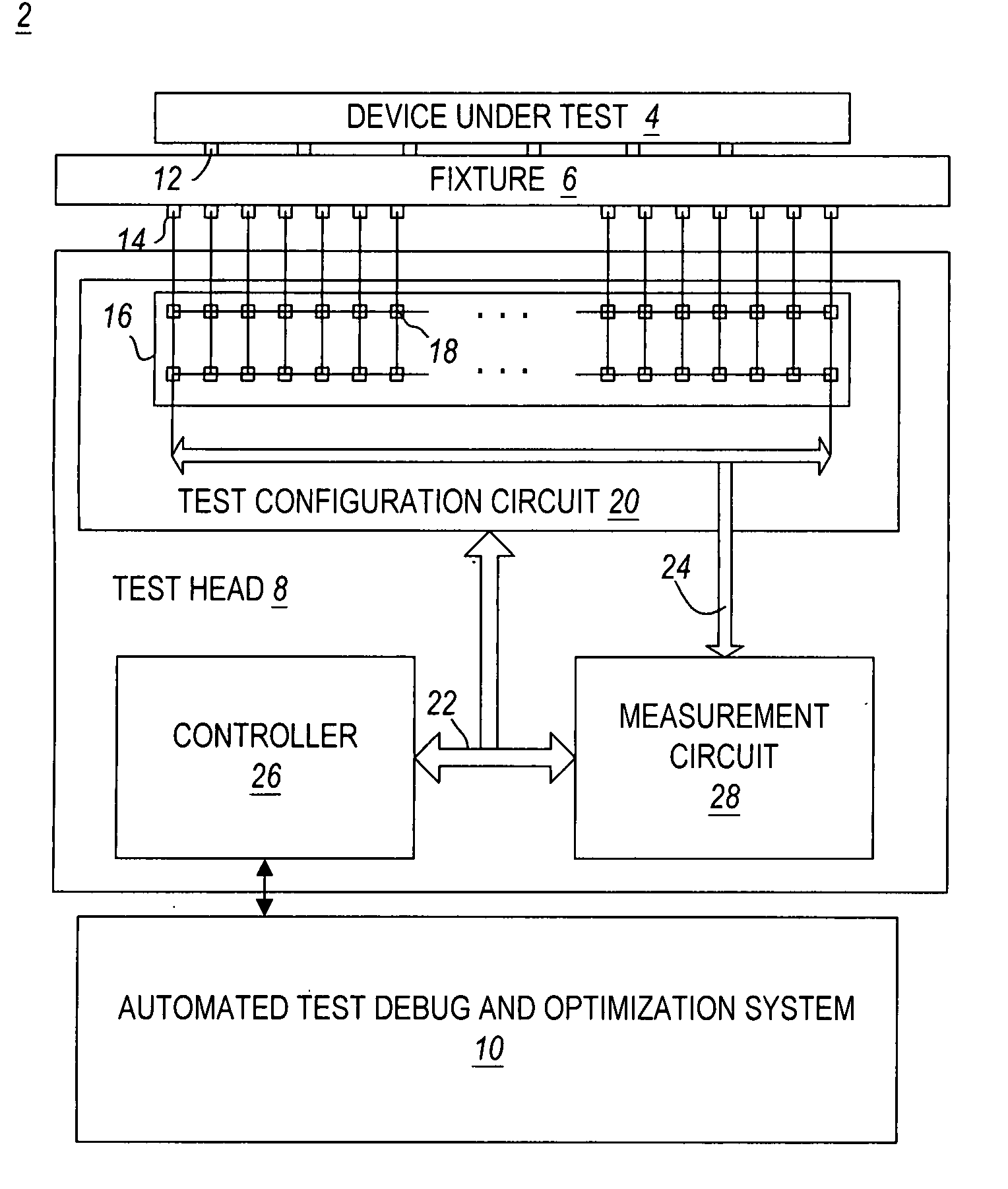

Method and apparatus for automated debug and optimization of in-circuit tests

A method and apparatus for automatically debugging and optimizing an in-circuit test that is used to test a device under test on an automated tester is presented. The novel test debug and optimization technique extracts expert knowledge contained in a knowledge framework and automates the formulation of a valid stable, and preferably optimized, test for execution on an integrated circuit tester.

Owner:AGILENT TECH INC

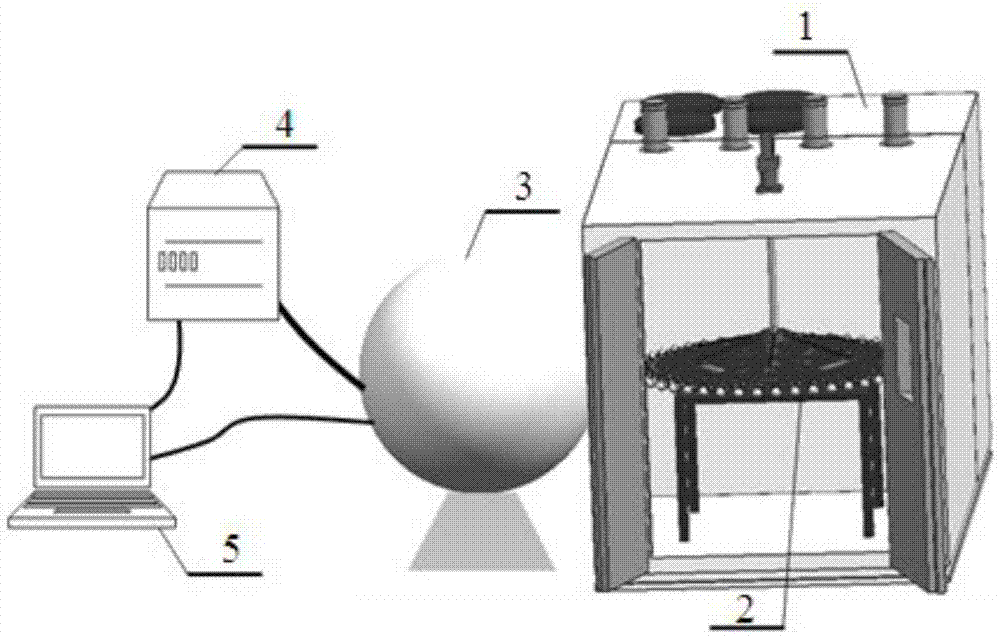

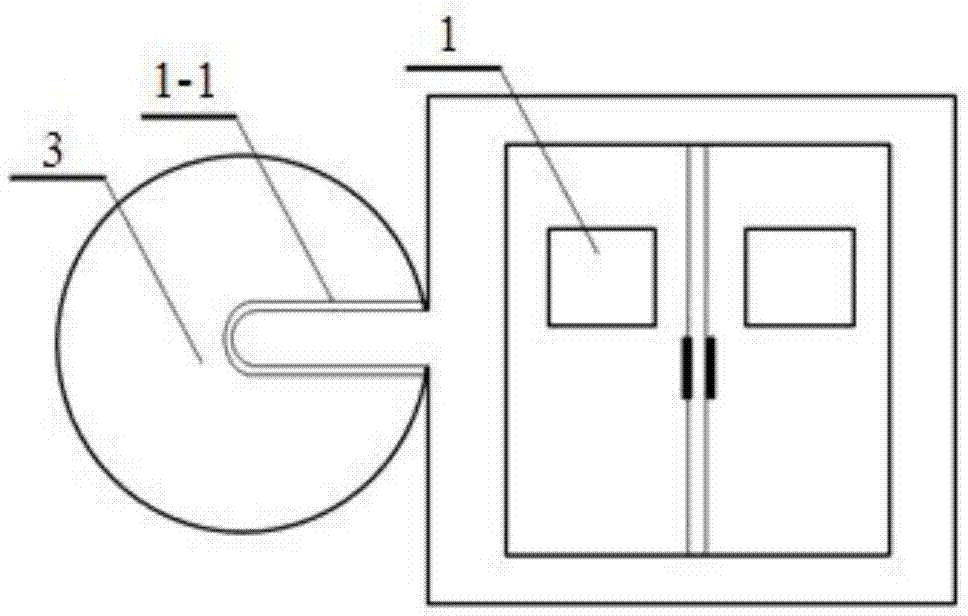

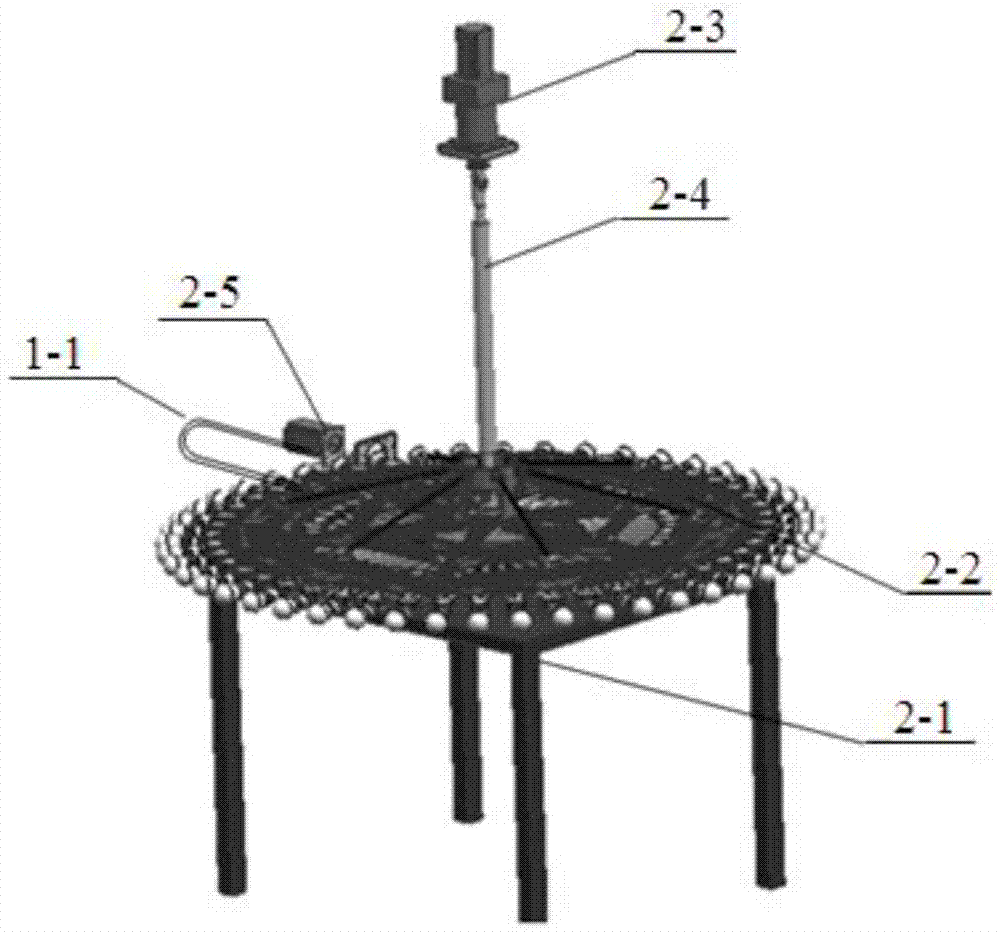

LED-lamp accelerated-life on-line detection equipment

InactiveCN105444995AQuick performanceAvoid environmental problemsTesting optical propertiesThermal insulationEngineering

LED-lamp accelerated-life on-line detection equipment belongs to the reliability detection field of a semiconductor device. In order to solve a problem in the prior art, the invention provides the equipment. The equipment comprises a test box body, a lamp clamp apparatus, an external connection integrating sphere system, a control host and a computer, wherein the test box body comprises an optical measurement channel and a temperature applying unit; the optical measurement channel is located at a connection position of the test box body and the external connection integrating sphere system; the lamp clamp apparatus is arranged in the test box body and is a positive-negative 360-degree rotary type multi-station independent lamp bracket; a detected LED lamp sample is installed on the lamp clamp apparatus; the external connection integrating sphere system is tightly connected to the test box body and there is no light leakage, and a thermal-insulation vacuum-pumping double-layer glass tube is arranged in the external connection integrating sphere system; the control host is connected to the test box body, the external connection integrating sphere system and the computer through a data line respectively and is used for controlling setting of an acceleration temperature of the test box body and setting of a test parameter of an external connection integrating sphere; and the computer is used for displaying on-line data of the control host in real time. By using the equipment, performance of a LED lamp product can be rapidly shown.

Owner:CHANGCHUN INST OF OPTICS FINE MECHANICS & PHYSICS CHINESE ACAD OF SCI

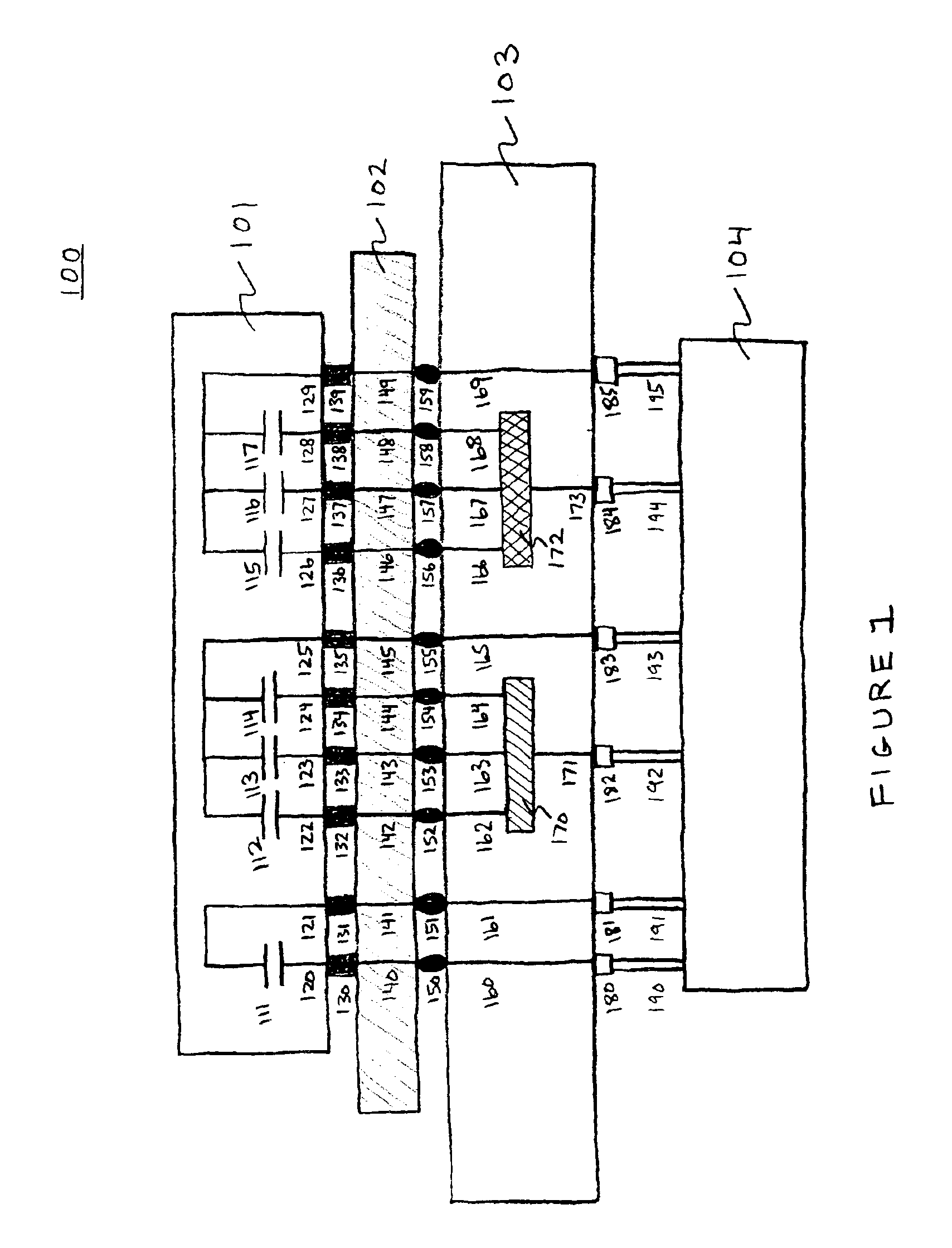

Integrated back-end integrated circuit manufacturing assembly

InactiveUS6931298B1Increase throughput timeProficiently performSemiconductor/solid-state device testing/measurementSolid-state devicesIntegrated circuit manufacturingVisual inspection

An integrated back-end integrated circuit (IC) manufacturing assembly is disclosed. In one embodiment, the present invention has a front-of-line portion comprising a plurality of integrated sub-stations for operating on a first plurality of die-strips on an in-line basis to produce a second plurality of die-strips. The present embodiment further comprises an end-of-line portion coupled to the front-of-line portion and comprising a plurality of integrated sub-stations for operating on the second plurality of die-strips on an in-line basis to produce die-strip components. The present embodiment also comprises an in-line test portion coupled to the end-of-line portion for testing the die-strip components. The present embodiment further comprises a finish portion coupled to the in-line test portion and comprising a plurality of integrated sub-stations operating on tested die-strip components. In addition, camera systems perform automated visual inspection of dies on the die-strip and maintain a database that can be used for automated reject management.

Owner:MONTEREY RES LLC

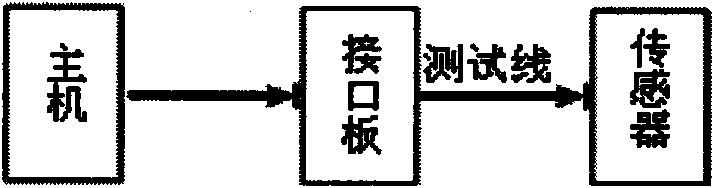

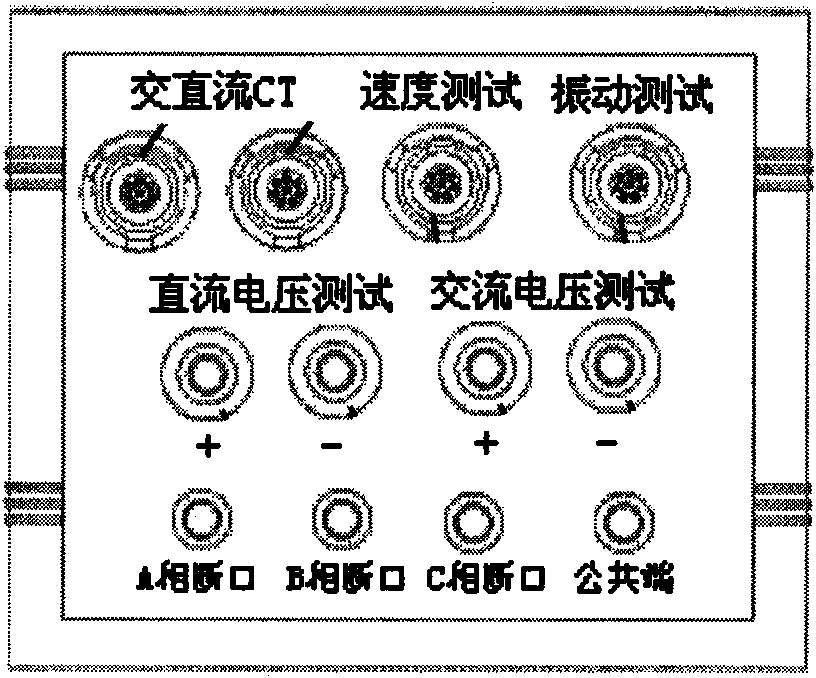

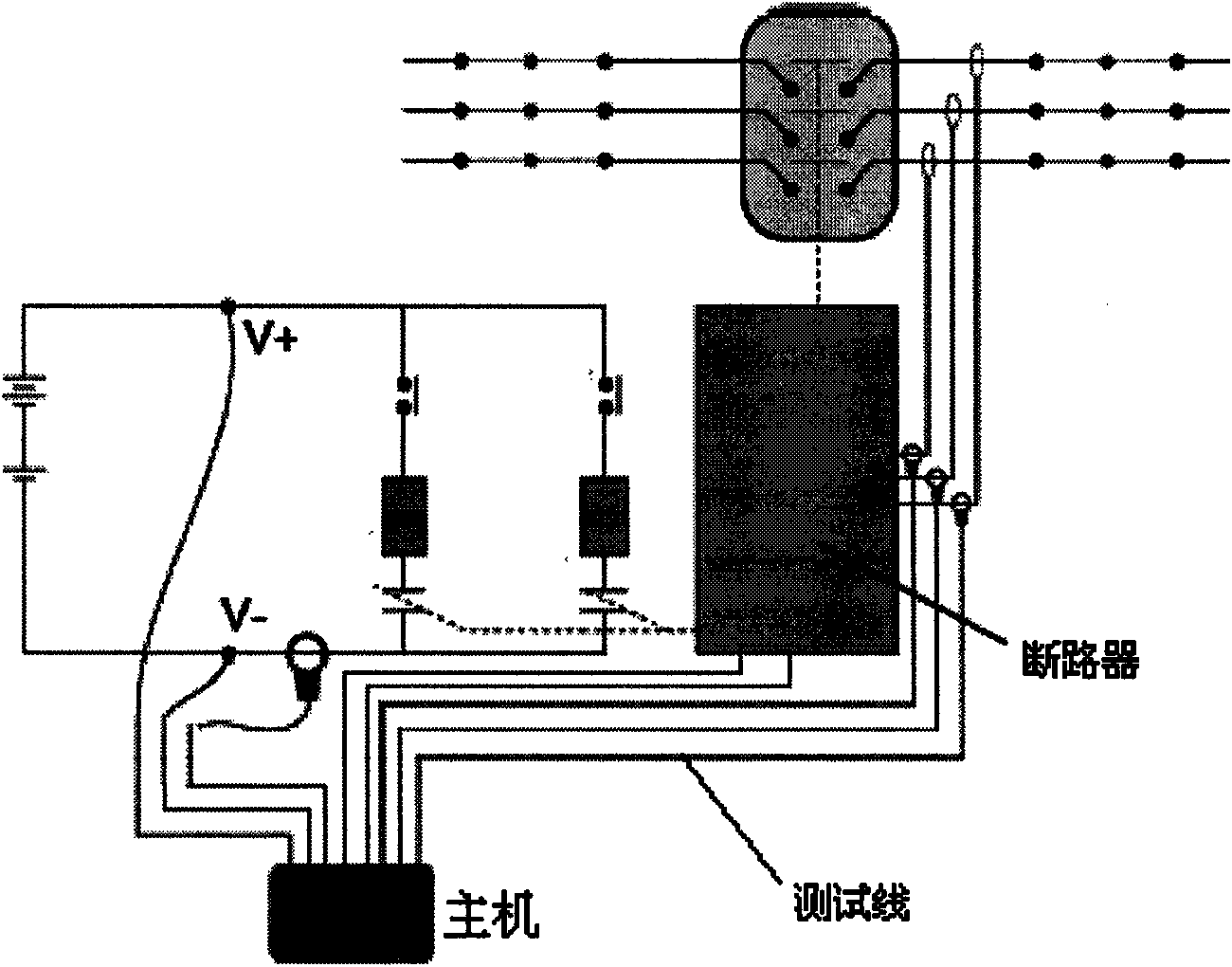

System for testing mechanical properties of integral circuit breaker

InactiveCN101592559APowerfulDiagnosed health conditionStructural/machines measurementCircuit interrupters testingElectric power systemEngineering

The invention discloses a system for testing mechanical properties of an integral circuit breaker, which comprises a host computer and an interface board is arranged on the host computer, wherein the interface board is provided with a testing line, an AC-DC terminal, a speed testing terminal, a vibration testing terminal, a direct current voltage testing terminal, an alternating current voltage testing terminal, an A-phase fracture, a B-phase fracture, a C-phase fracture and a common port terminal, wherein the interface board is connected with a sensor through the testing line. The sensor is provided with a bracket and a magnetic base. The system has abundant program control functions, wherein the sensor includes the triggering mode, the channel selection, the triggering level, and a sampling time base, a recording parameter block and the like which can be set through program control, and also includes incomparable abundant triggering functions. The system provides an ideal and effective testing tool for carrying out the overhaul of the state of a high-voltage circuit breaker for an electric power system, can be used for testing the mechanical properties of the circuit breaker on line, and performs data storage, analysis and comparison so as to quickly and accurately diagnose the health condition of the circuit breaker on line.

Owner:SHANGQIU POWER SUPPLY ELECTRIC POWER OF HENAN

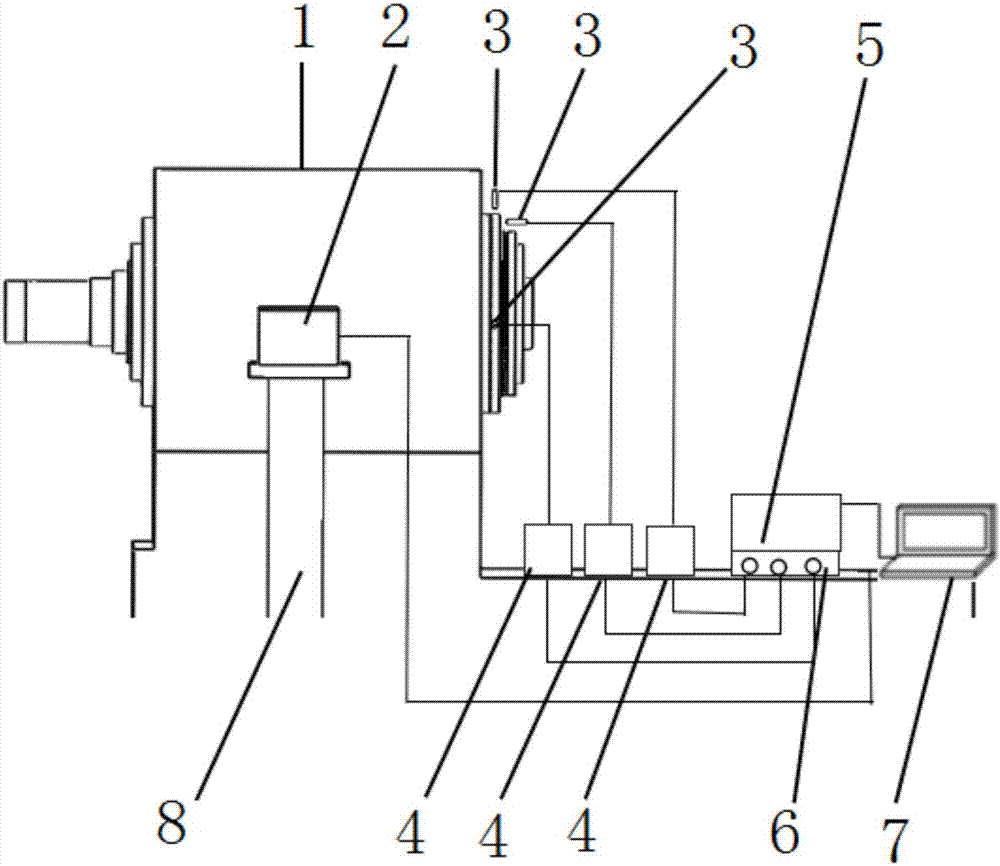

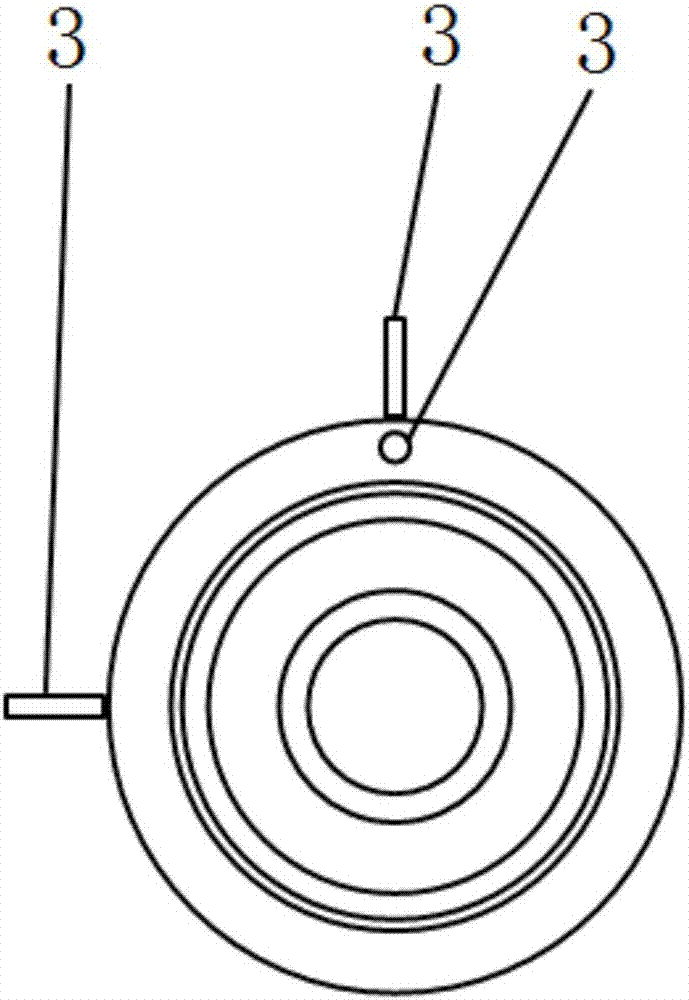

Online testing device and testing method used in machine tool spindle thermal error

ActiveCN106908240AHigh measurement accuracyStrong real-time processingMachine gearing/transmission testingProgramme control in sequence/logic controllersThermal deformationEngineering

The invention discloses an online testing device and testing method used in a machine tool spindle thermal error. The testing method comprises the steps of using an eddy current sensor and a thermal imaging instrument to measure in real time the temperature of a spindle temperature sensitive point and thermal deformation at the front end of the spindle in the axial direction and the radial direction of a machine tool in an actual working condition, then the temperature and thermal deformation data are transmitted to a computer through the thermal imaging instrument and a PLC respectively, through a data processing part of thermal error testing software, a temperature sensitive point temperature rise-time curve, a spindle axial thermal deformation-time curve, and a spindle radial thermal deformation-time curve are obtained, and finally a spindle thermal error model is obtained through calculation. The testing device comprises the thermal imaging instrument, the eddy current sensor, a sensor signal conditioner, the PLC, a PLC analog quantity unit, the computer and a support; the thermal imaging instrument is utilized to take the place of a temperature sensor to measure the temperature data of the spindle temperature sensitive point, and the problems that the number of temperature sensors is large, wiring is complicated, and installation is difficult in actual measurement are solved.

Owner:HEBEI UNIV OF TECH

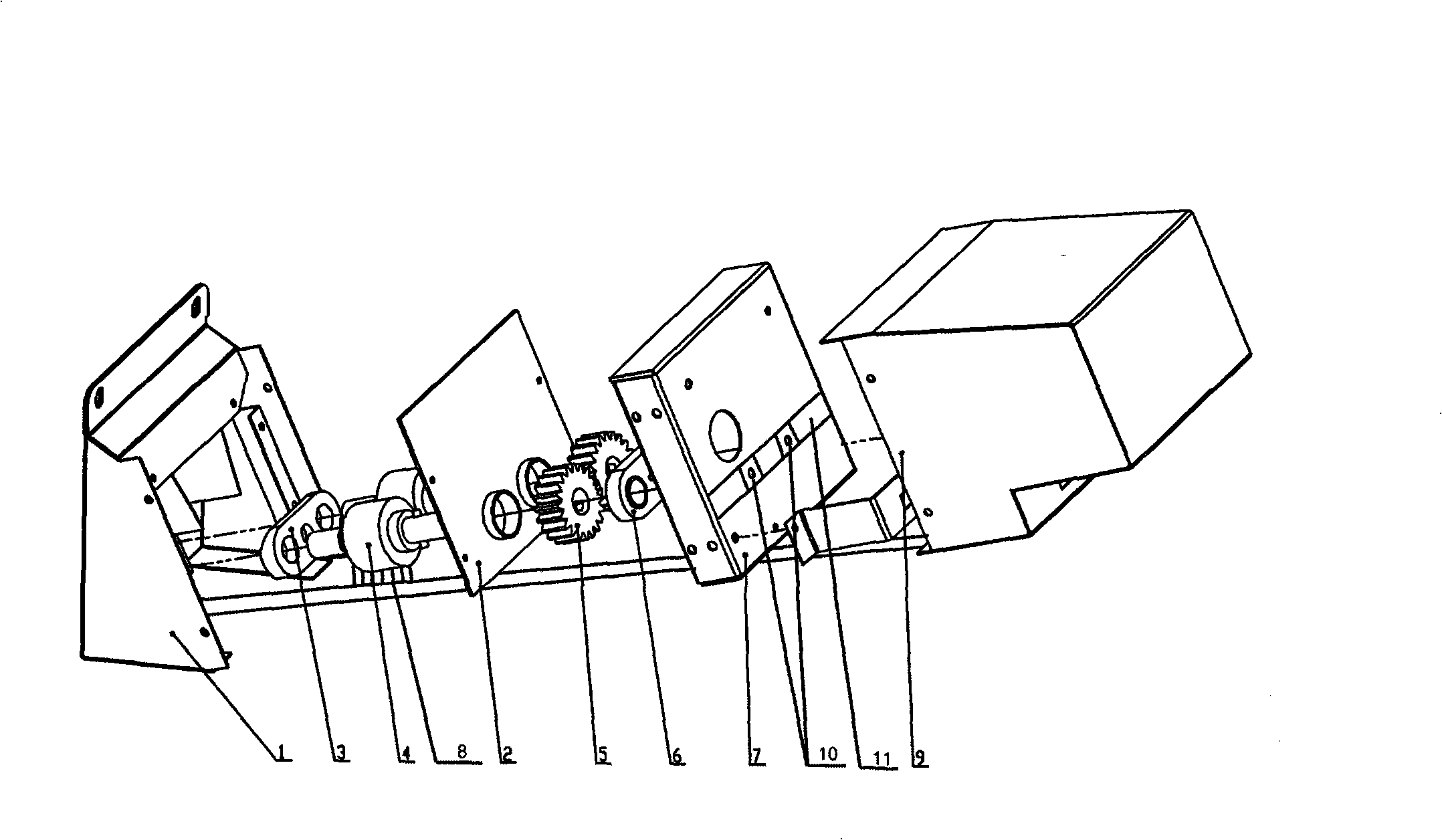

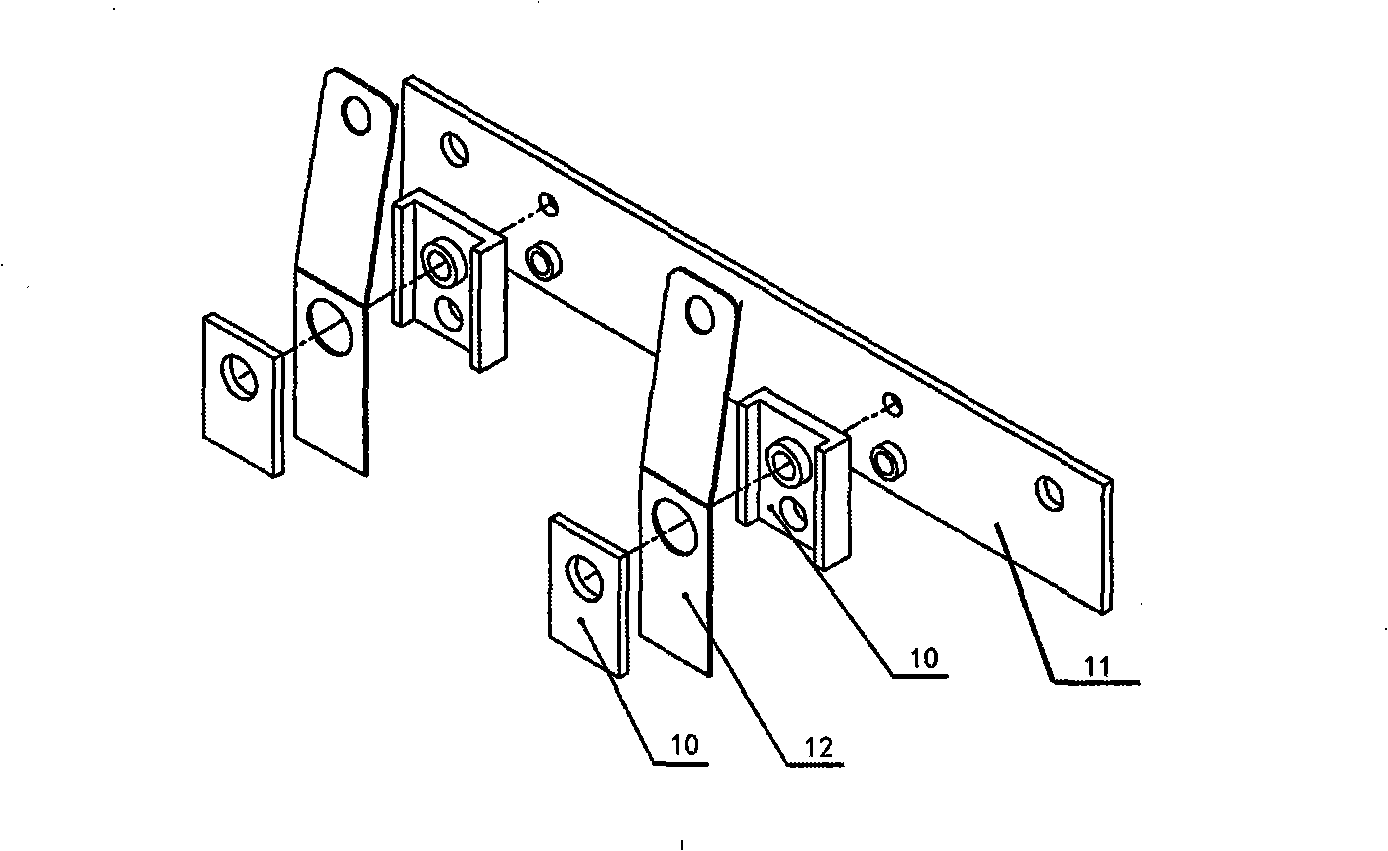

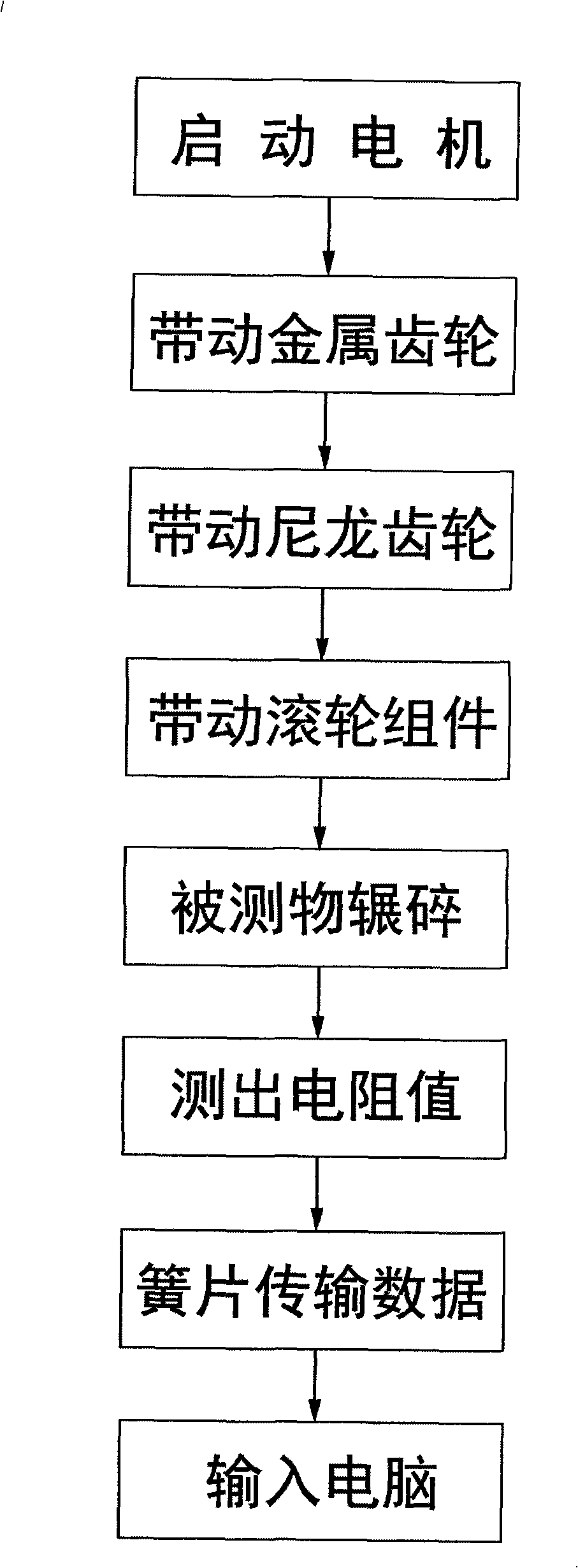

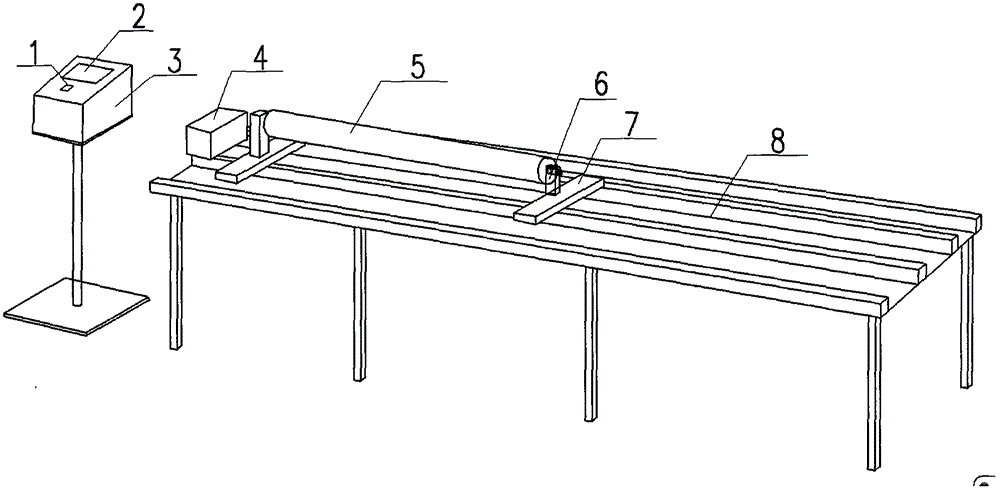

Automatic sampling apparatus of resistor type cereal on-line moisture tester

InactiveCN101354372AGuaranteed sealing performanceAccurate samplingMaterial resistanceElectrical resistance and conductanceAgricultural engineering

The invention provides an automatic sampling device of an online resistance-typed corn moisture teller, which comprises a diversion case component 1, shaft sleeves 3 and 6, a rolling wheel component 4, a gear 5, a back cover component 7 and a back cover 9. The shaft sleeves 3 and 6 are respectively and firmly fixed with the diversion case component 1 and the back cover component 7 by combined bolts, a rotating shaft is transversely arranged between the shaft sleeves 3 and 6, the rolling wheel component 4 and the gear 5 are arranged on the rotating shaft and are transmission connected with each other through the rotating shaft, and a baffle 2 is arranged between the rolling wheel component 4 and the gear 5. A steel wire brush 8 is arranged under the rolling wheel component 4, and two ends of the steel wire brush 8 are respectively connected with the diversion case component 1 and the back cover component 7. A contact sheet component is arranged on the back cover component 7, a spring sheet is fixed on the top of the rotating shaft through a fixing block and a fixing plate, and an electric motor is arranged above the contact sheet component. The diversion case component 1 and the back cover component 7 adopt plate metal structure. The automatic sampling device is characterized by not only low cost but also high intensity. The online resistance-typed corn moisture measurement is widely applied to foreign high-performance corn driers, and due to a corn resistance and temperature measuring method and moisture conversion according to a certain mathematical model, the online resistance-typed corn moisture teller has the advantages of high precision, good stability and noninterference, is especially suitable for being used in online testing, and has good random repeatability, safety and reliability.

Owner:朱希

Method and apparatus for automated debug and optimization of in-circuit tests

A method and apparatus for automatically debugging and optimizing an in-circuit test that is used to test a device under test on an automated tester is presented. The novel test debug and optimization technique extracts expert knowledge contained in a knowledge framework and automates the formulation of a valid stable, and preferably optimized, test for execution on an integrated circuit tester.

Owner:AGILENT TECH INC

Intelligent on-line test device of power characteristics of carbon dioxide laser devices

InactiveCN104483102ARealize real-time detectionEnsuring Power Sampling AccuracyTesting optical propertiesMicrocontrollerResonant cavity

The invention discloses an intelligent on-line test device of power characteristics of carbon dioxide laser devices. The intelligent on-line test device comprises a power supply, a touch screen, a control box, a laser power device, a laser tube, a bracket, a bracket mounting plate, an optical test table, an output mirror, a medium total reflective mirror, an attenuator, a detector and a resonant cavity, wherein the power supply, a single-chip microcomputer system and an analog-to-digital conversion unit are mounted in the control box; the touch screen is arranged on the control box; the control box is externally provided with a communication interface; the control box is connected with a laser power device through a data line; the resonant cavity is formed in the front of the laser power device; the output mirror and the medium total reflective mirror are arranged inside the resonant cavity; the mirror surface of the output mirror faces inwards; the mirror back of the medium total reflective mirror faces towards the attenuator; the detector is arranged at the bottom of the attenuator; the rear end of the laser power device is connected with the laser tube; two ends of the laser tube are fixed on the bracket; the bracket is vertically mounted on the bracket mounting plate; the bracket mounting plate is arranged on an optical test table; the optical test table is provided with a plurality of channels; real-time detection of the laser powder is implemented.

Owner:WENZHOU INST OF TECH TESTING & CALIBRATION

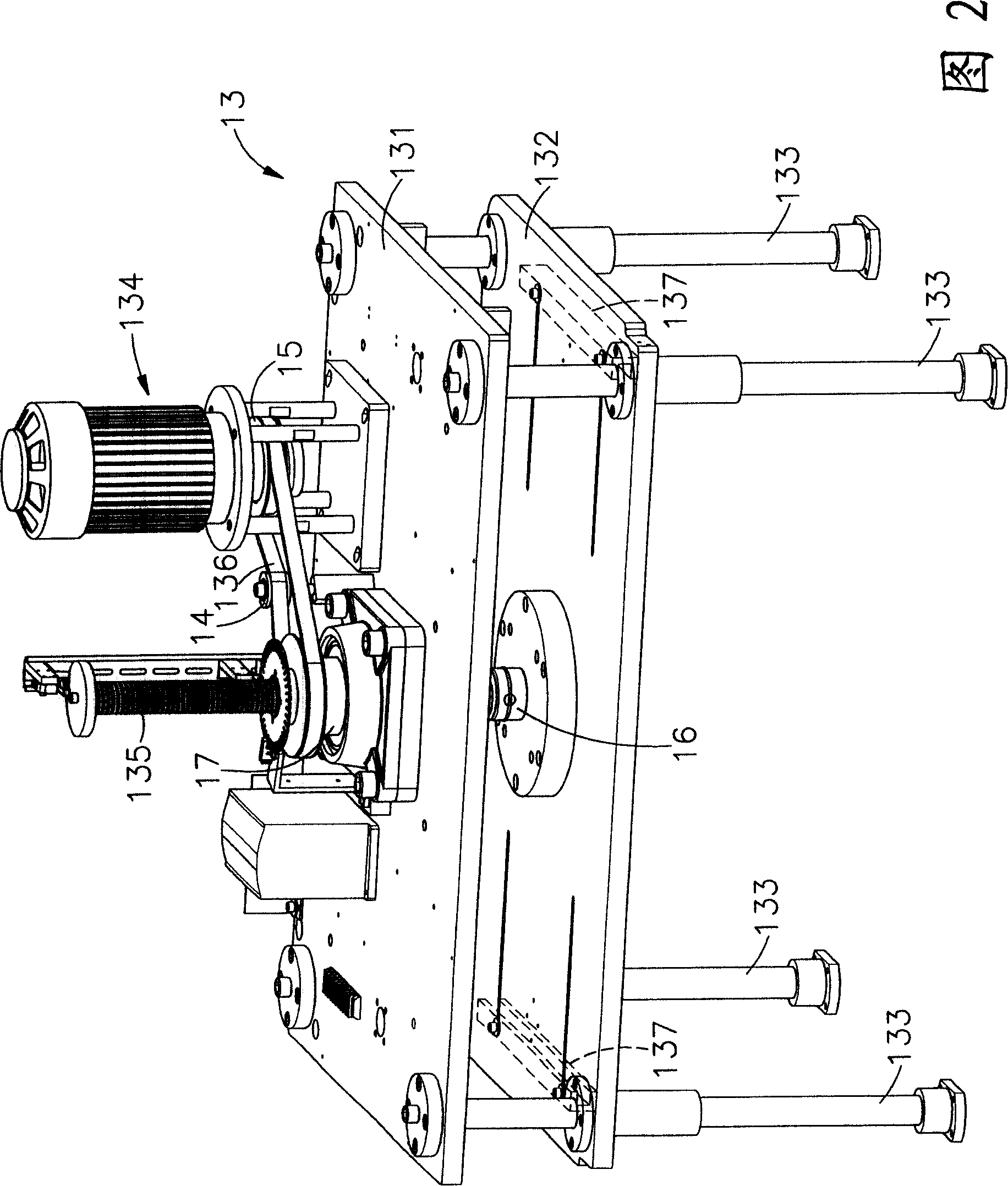

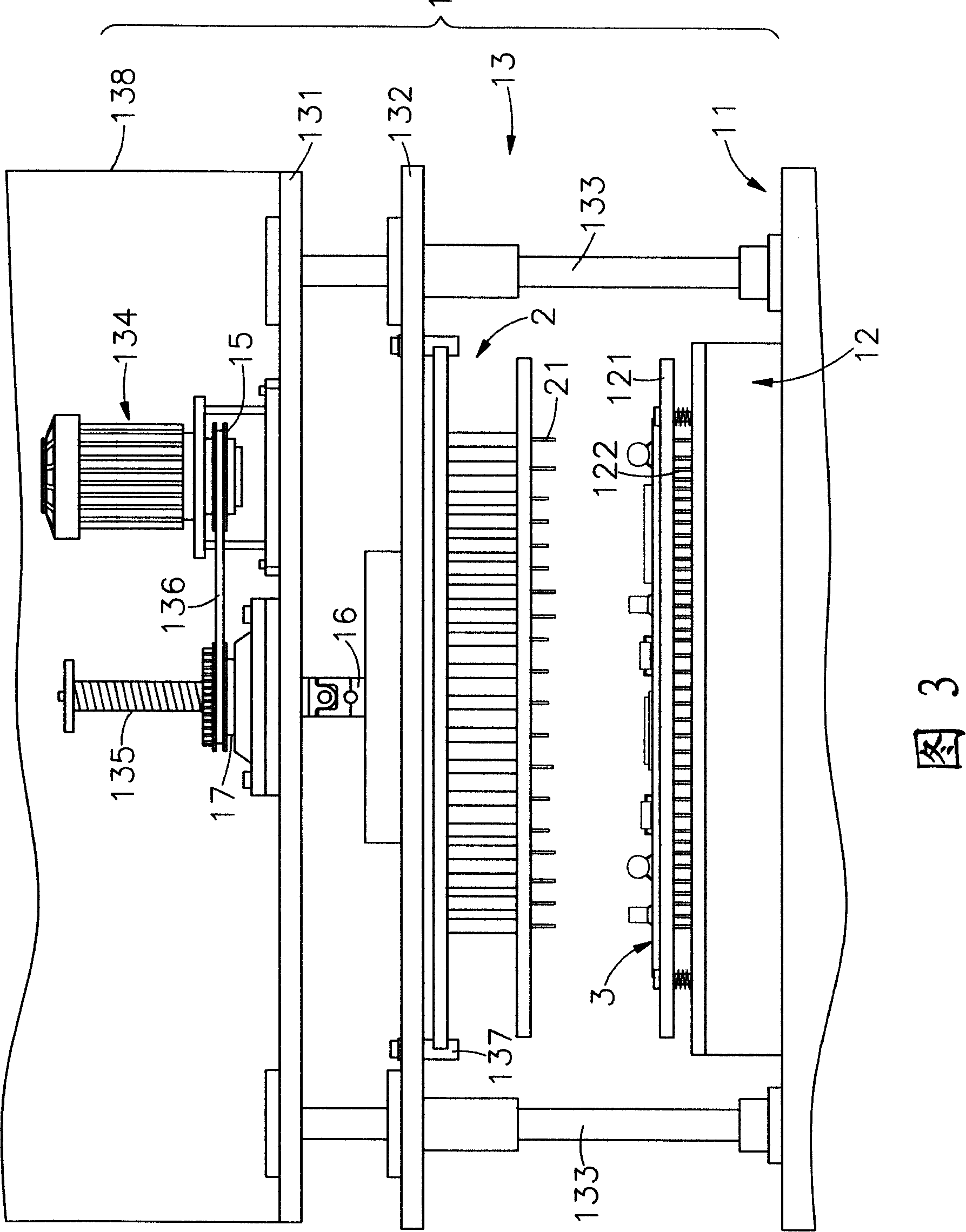

On-line test attachment

InactiveCN101173959AAccurate and stable contactEasy to change positioningElectronic circuit testingElectrical measurement instrument detailsDrive motorIn-circuit test

The invention relates to an in-circuit testing equipment, comprising a testing machine station, a jig box and a press machine station, wherein after the testing pinned testboard is transshipping-located on the location slot rail arranged under the pressing board of the press machine station, the circuit board under test can be arranged on the substrate of the jig box, simultaneously the shaft lever of the driving motor of the press machine station is switched on to rotate in forward direction or reversely, and a guide screw is driven downward or upward by a transmission component, so that the pressing board can be accurately controlled further to displace downward or upward to enable the other ejector of the testing pinned testboard to be propped-pressed on the circuit board in appropriate strength or displace upward, and the accurate and stable contact between the circuit board and the testing pinned testboard can be kept, so that the testing process of the circuit board under test can be operated to ensure the quality of the circuit board products, and improve the repair efficiency of the defective products.

Owner:JET TECHNOLOGY CO LTD

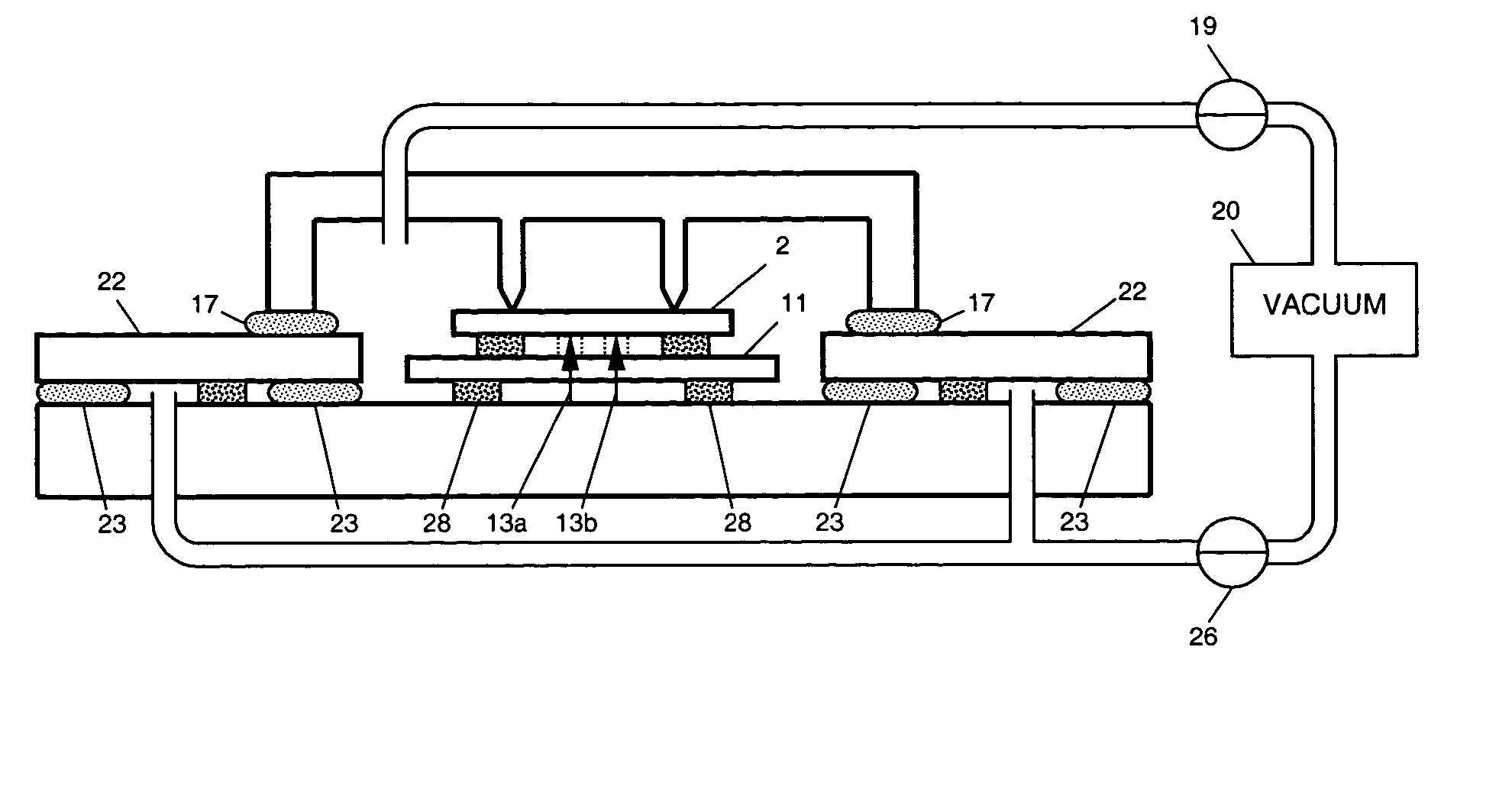

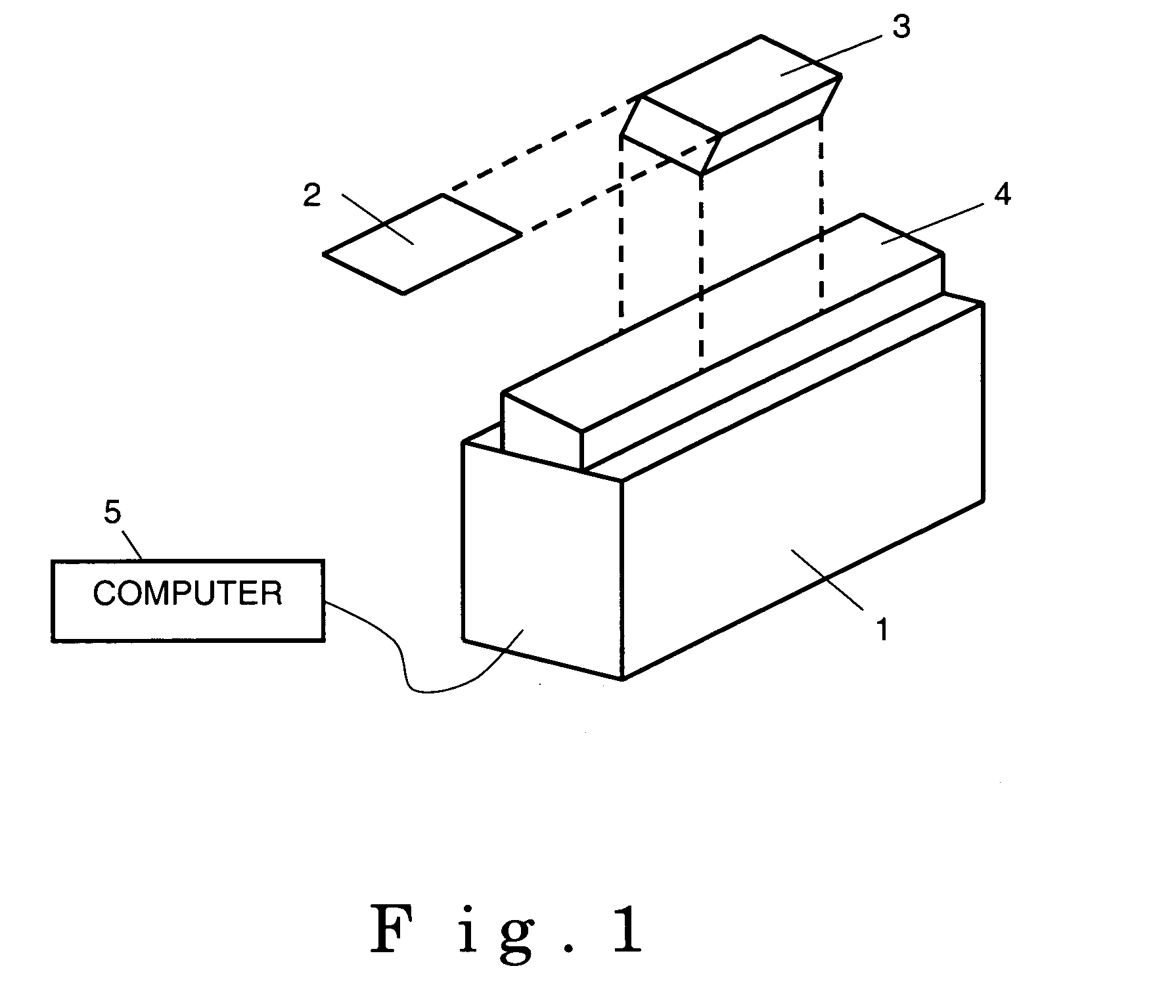

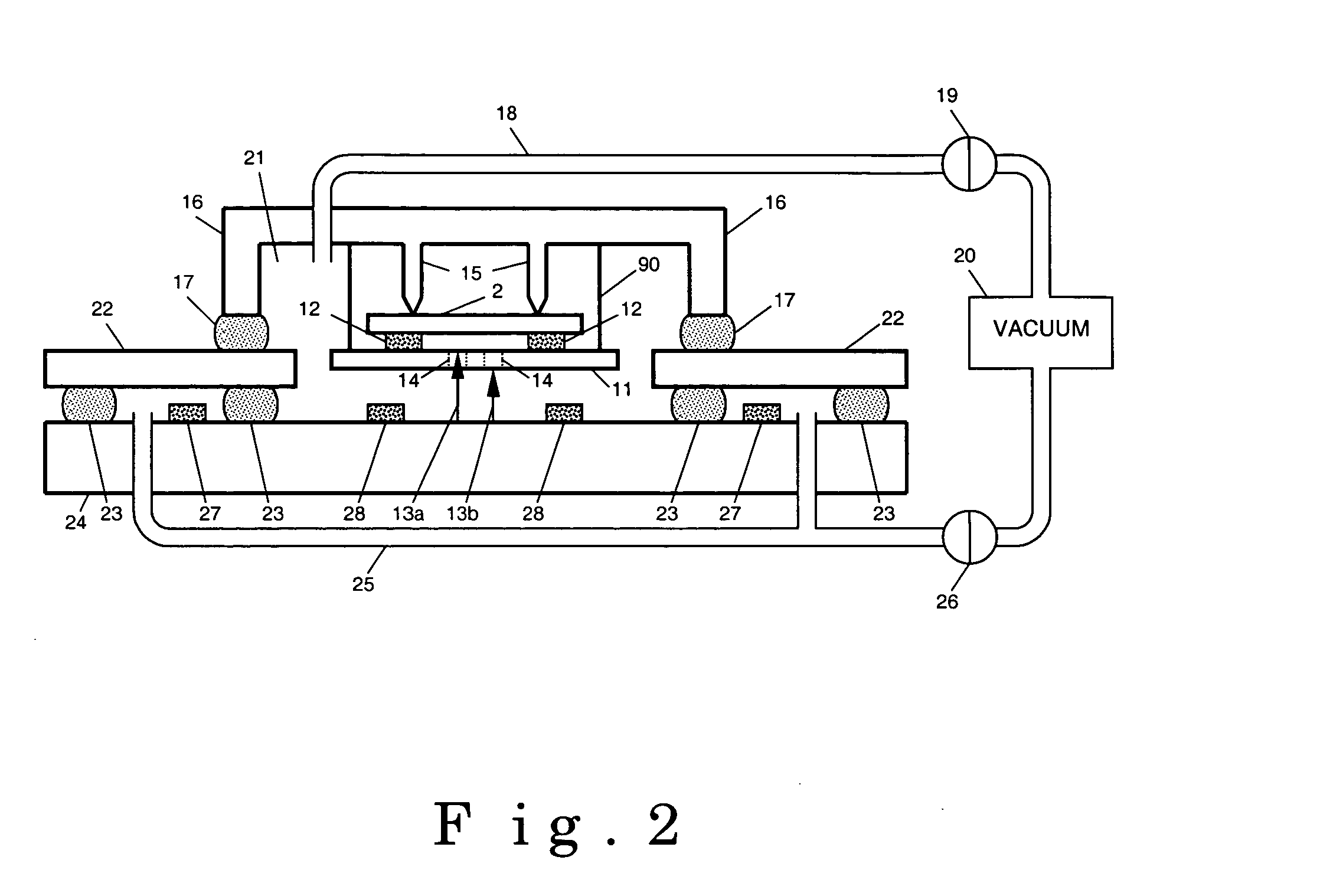

Vacuum chamber with two-stage longitudinal translation for circuit board testing

ActiveUS20050261854A1Resistance/reactance/impedencePrinted circuit testingDual stageFunctional testing

A circuit board tester that uses a dual-stage translation to bring a unit under test (UUT) into physical and electric contact first with a series of tall probes, then with a series of short probes. Initially, the UUT is mounted on a support plate, and spaced apart from both the tall and short probes. First, in order to perform a functional test on the UUT, a first vacuum stage is engaged, and atmospheric pressure translates the UUT longitudinally until contact is made with a first hard stop, defining a first position. At this first position, the UUT is in contact with a series of tall probes, and is spaced apart from a series of short probes. After a function test is performed, a second vacuum stage is engaged in addition to, and independent of, the first vacuum stage. Atmospheric pressure translates the UUT longitudinally until contact is made with a second hard stop, defining a second position. At this second position, the UUT is in contact with both tall and short probes (the tall probes being appropriately spring-loaded so as to maintain physical and electric contact with the UUT without damaging the UUT). After an in-circuit test is performed, both vacuum stages are released, and the UUT returns to its initial location, spaced apart from both the tall and short probes. The UUT may be replaced with another part to be tested, and the cycle is repeated.

Owner:CIRCUIT CHECK

Capacitive sensor measurement method for discrete time sampled system for in-circuit test

InactiveUS6998849B2Reduce setup timeEasy to useFault locationContactless circuit testingCapacitive couplingDigital signature

Disclosed is a novel method and apparatus for acquiring multiple capacitively sensed measurements from a circuit under test. Multiple digital sources are respectively connected to stimulate multiple respective first ends of multiple respective nets of interest. Respective second ends of the multiple respective nets of interest are capacitively sensed. The respective capacitively coupled signals are digitally sampled and shift correlated with respective expected digital signatures. If a high level of correlation is found for a given net, the net is electrically intact; otherwise, the net is characterized by either an open or some other fault that prevents it from meeting specification.

Owner:AGILENT TECH INC

Socket connection test modules and methods of using the same

InactiveUS20060006894A1Electronic circuit testingElectrical measurement instrument detailsCapacitancePin grid array

Test modules, systems, and methods employing capacitors for the testing of the solder joint connections between a printed circuit board (PCB) and a socket of a device are presented in embodiments of the current invention. A test module having capacitors in parallel, and in particular embedded capacitors, can be used to test tied traces and their solder joint connections by measuring the total capacitance of the capacitors. Embodiments of the current invention present no-power tests that can be used with a variety of testing platforms and test fixtures, such as in-circuit testing (ICT) and manufacturing defect analysis (MDA.) Additionally, the test module can be used with a variety of sockets, such as a ball grid array, a pinned grid array, and a land grid array.

Owner:INTEL CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com