Slow-expansion water-absorbable salt-resistant gel particle, and preparation and applications thereof

A technology of gel particles and slow expansion, which is applied in the direction of drilling compositions, chemical instruments and methods, etc. It can solve the problems of poor plugging, unstoppable plugging agent, prolonging the expansion time, etc., and achieves easy operation and adaptability Strong, low-cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

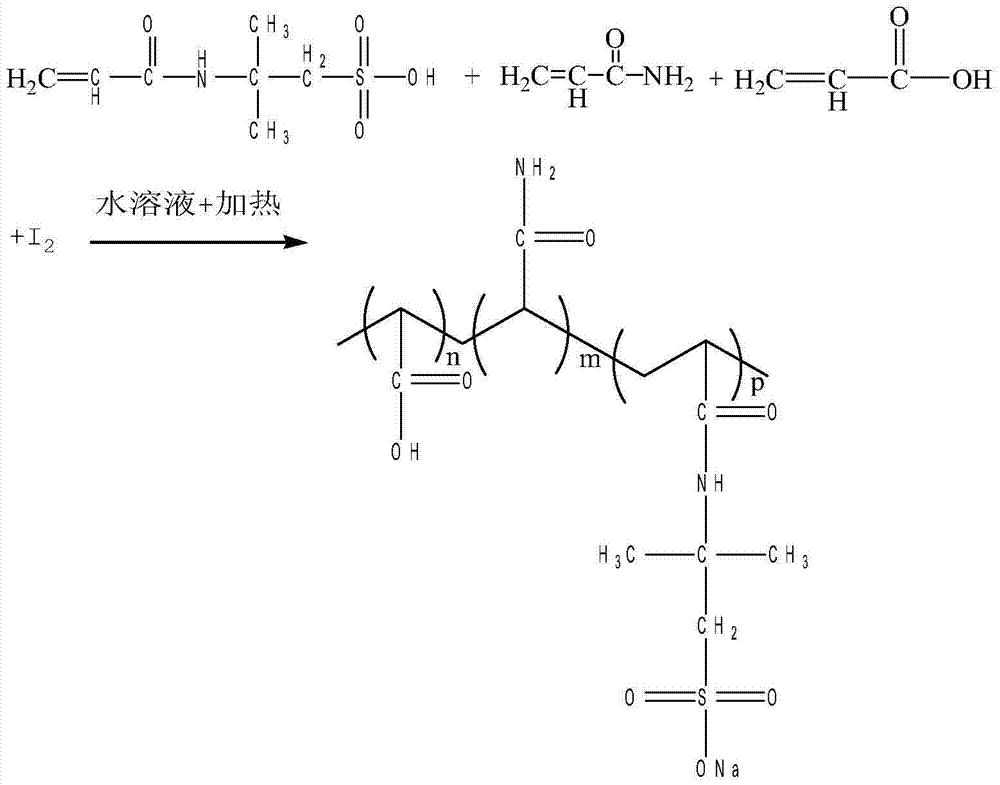

Method used

Image

Examples

Embodiment 1

[0027] A kind of slow swelling type strong water-absorbing gel particle, it is made up of the raw material of following percentage by weight:

[0028] A. Acrylamide monomer 12.5%;

[0029] B. Acrylic acid 4%;

[0030] C. Methylenebisacrylamide 0.05%;

[0031] D. 2-acrylamido-2-methylpropanesulfonic acid 0.05%

[0032] E. Ammonium persulfate 0.05%;

[0033] F. Clay 25%;

[0034] G. Sodium hydroxide 6%;

[0035] H. Sodium dodecylbenzenesulfonate 0.1%;

[0036] 1, water; Surplus is water.

[0037] The preparation method of the slow swelling type strong water-absorbing gel particles is as follows:

[0038] (1) Add raw materials B, G, and I into the reactor and stir for 10 minutes, and adjust the pH value to 7.0-8.0;

[0039] (2), then add the raw materials A, C, D, E, F, H into the reaction kettle and stir for 1-2 hours;

[0040] (3) Put the material into the reaction tank and heat it to 60°C, and react for 3-5 hours;

[0041] (4) Cut the reactants into pieces, dry them ...

Embodiment 2

[0043] A kind of slow swelling type strong water-absorbing gel particle, it is made up of the raw material of following percentage by weight:

[0044] A. Acrylamide monomer 15%;

[0045] B. Acrylic acid 4%;

[0046] C. Methylenebisacrylamide 0.05%;

[0047] D. Sodium styrene sulfonate 0.1%

[0048] E. Potassium persulfate 0.05%;

[0049] F. Starch 25%;

[0050] G. Sodium carbonate 8%;

[0051] H. Sodium dodecylbenzenesulfonate 0.1%;

[0052] 1, water; Surplus is water.

[0053] The preparation method of the slow swelling type strong water-absorbing gel particles is as follows:

[0054] (1) Add raw materials B, G, and I into the reactor and stir for 10 minutes, and adjust the pH value to 7.0-8.0;

[0055] (2), then add the raw materials A, C, D, E, F, H into the reaction kettle and stir for 1-2 hours;

[0056] (3) Put the material into the reaction tank and heat it to 60°C, and react for 3-5 hours;

[0057] (4) Cut the reactants into pieces, dry them in the sun, crush...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com