Coal seam reaming system using three-dimensional (3D) swirling water jet and reaming and fracturing method for permeability enhancement

A technology of three-dimensional rotation and water jet, which is applied in the direction of mining fluid, earth square drilling, drilling with liquid/gas jet, etc. It can solve the problems of increased pressure in the hole, low cutting efficiency, and large amount of drilling construction, and achieves The overall pressure relief is sufficient, the effect of improving cutting efficiency and shortening the pre-pumping time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

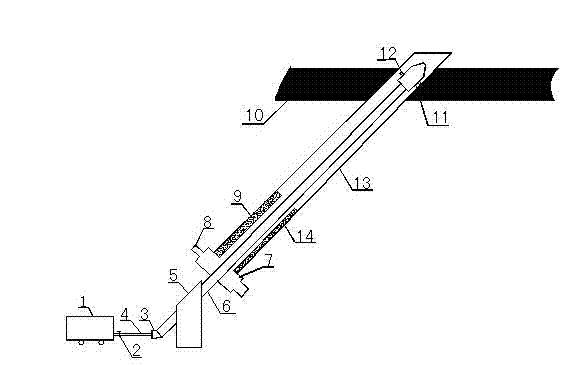

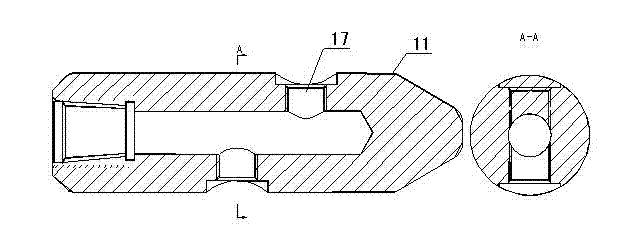

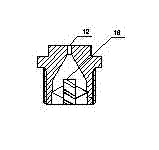

[0029] see figure 1 , 2 , 3, 4, for the coal seam 10 where there is no risk of coal and gas outburst and no drilling self-spraying phenomenon, a three-dimensional rotating water jet coal seam reaming system, which consists of a high-pressure hydraulic pump station 1 through a high-pressure rubber hose with a shut-off valve 2 4 is connected to the rotary high-pressure rotary joint 3, which is characterized in that it is connected to the high-pressure water jet drill pipe 6 after passing through the drilling rig 5, and the front end of the high-pressure water jet drill pipe 6 is connected to the high-pressure water jet nozzle 11 with a nozzle base 17, on the nozzle base A high-pressure rotating water jet nozzle 12 is installed.

[0030] Wherein: two nozzle bases 17 are alternately arranged in a direction perpendicular to the axis of the high-pressure water jet nozzle 11, so that their projection on a plane perpendicular to the axis of the high-pressure water jet nozzle 11 forms...

no. 2 example

[0034] see figure 1 , 2 , 3, 4, for the coal seam 10 that has the danger of coal and gas outburst or the phenomenon of drilling self-spraying, a three-dimensional rotating water jet coal seam reaming system, which consists of a high-pressure hydraulic pump station 1 through a high-pressure rubber hose with a shut-off valve 2 4 is connected to the rotary high-pressure rotary joint 3, which is characterized in that it is connected to the high-pressure water jet drill pipe 6 after passing through the drilling rig 5, and the front end of the high-pressure water jet drill pipe 6 is connected to the high-pressure water jet nozzle 11 with a nozzle base 17, on the nozzle base A rotating water jet nozzle 12 is installed.

[0035] Wherein: three nozzle bases 17 are staggered in a direction perpendicular to the axis of the high-pressure water jet nozzle 11, so that their projection on a plane perpendicular to the axis of the high-pressure water jet nozzle 11 forms an angle of 120 degree...

no. 3 example

[0040] see figure 1 , 2 , 3, 4, 5, a three-dimensional rotary water jet coal seam reaming and fracturing anti-permeability method, for the coal seam 10 that does not have the danger of coal and gas outburst and does not have the phenomenon of drilling self-injection, use the drilling rig 5 to drill from the roadway to the coal seam 10 A hydraulic reaming borehole 13, some control boreholes 15 are made around the hydraulic reaming borehole 13, characterized in that the high-pressure water jet drill pipe 6 connected to the high-pressure water jet nozzle 11 is driven by the drilling rig 5, and the high-pressure water jet nozzle 11 is sent After reaching the predetermined position of the coal seam 10, start the high-pressure hydraulic pumping station 1, turn on the drilling rig 6, drive the high-pressure water-jet drilling rod 6 to rotate, and at the same time make the high-pressure water-jet drilling rod 6 slowly reciprocate in the hydraulic reaming borehole 13. The rotary jet p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com