Aerogel recombination flexible thermal insulation heat-proof thin film and process for preparing same

A thermal insulation and aerogel technology, applied in the field of thermal insulation materials, can solve problems such as difficulty in forming, hindering widespread use, and not in the field of thermal insulation, etc., and achieve the effects of reduced production costs, expanded application range, and high porosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Mix 100ml of tetraethyl orthosilicate, 1000ml of absolute ethanol, 50ml of distilled water and 10ml of HF evenly, stir for 0.5hr, and store it statically for 3hr to obtain SiO 2 wet gel. Then SiO 2 The wet gel was put into a solution uniformly mixed with 1000ml of n-hexane and 100ml of trimethylchlorosilane for surface modification. Take it out after 24 hours, put it into an oven after the surface is dry, and heat it to 200°C for heat treatment to obtain transparent SiO 2 porous airgel.

Embodiment 2

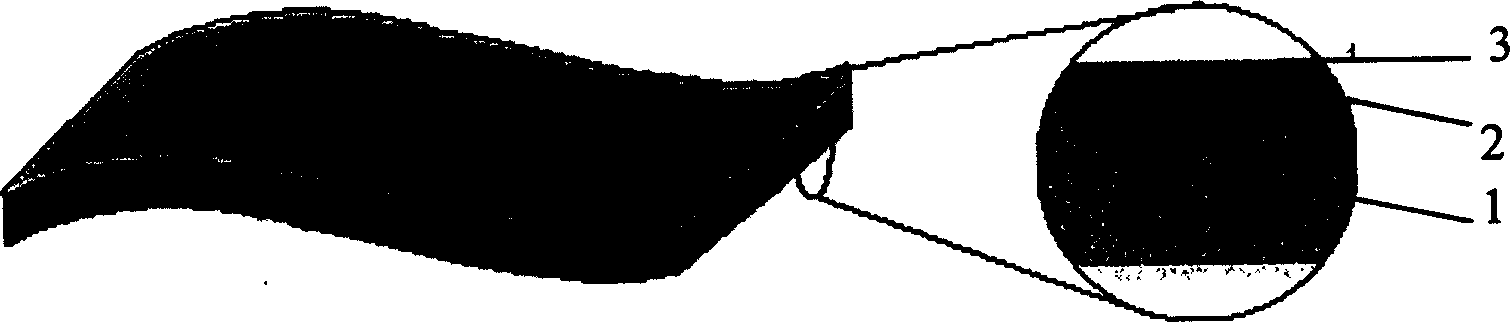

[0026] The modified transparent SiO 2 Porous airgel is sieved and crushed to small particles with a diameter of less than 3mm, mixed with silicone resin at a volume ratio of 1:0.6 to form a paste, poured into the hopper of the coating machine, and coated on polyamide with a coating machine. On the imide film, the coating thickness is 3mm. The running speed of the film on the coating machine is 5m / min, the temperature of the drying tunnel is 110°C, and the film is dried in the drying tunnel of the coating machine.

Embodiment 3

[0027] Embodiment 3: The coated composite film is sent into a continuous vacuum coating machine, and a metal aluminum (Al) film is deposited on the surface of the film that is not coated with the composite material with a conventional vacuum aluminum plating method. The working vacuum is 4×10 -2 pa, the evaporation source is 98% aluminum wire, and the running speed of the film on the coating machine is 50m / min. That is, the desired flexible thermal insulation film with good performance can be obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com