Method for designing coating uniformity correction mask for spherical optical elements on planetary rotating jigs of vacuum coating machines

A technology of vacuum coating machine and correcting baffles, which is applied in vacuum evaporation coating, sputtering coating, ion implantation coating, etc., and can solve the problems that the mathematical expression of correcting baffles cannot be directly obtained, and it takes a long time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

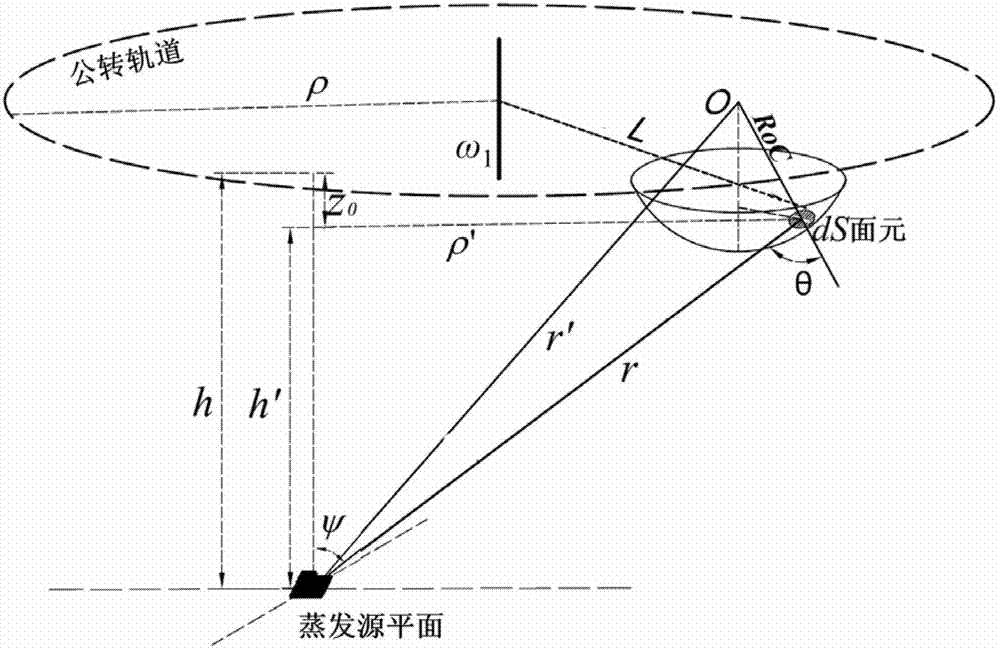

[0033] attached figure 1 is a schematic diagram of the coating process of spherical optical elements on the planetary rotating fixture of the vacuum coating machine, where r represents the vector from the evaporation source to the deposition position (dS bin) length θ is The angle between and the surface normal of the optical element, ψ is The included angle with the normal of the source plane, r' is the distance between the center of the sphere where the convex or concave sphere is located and the evaporation source, h' and ρ' are the vertical and horizontal distances from the evaporation source to the panel dS, respectively , ρ is the orbital radius of the planetary rotating jig, h is the distance between the orbital plane of the planetary rotating jig and the plane of the evaporation source. The center of the sphere where the spherical surface of the optical element is located is marked by O, and the radius of curvature of the sphere is RoC. The position of the sur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com