Housing and method for making same

A manufacturing method and shell technology, applied to the device for coating liquid on the surface, electrical equipment casing/cabinet/drawer, decorative art, etc., can solve the problem of not being able to present a bright metal texture, feel the metal texture and added value, etc. problem, to achieve the effect of good decorative effect, elegant appearance and bright metal appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

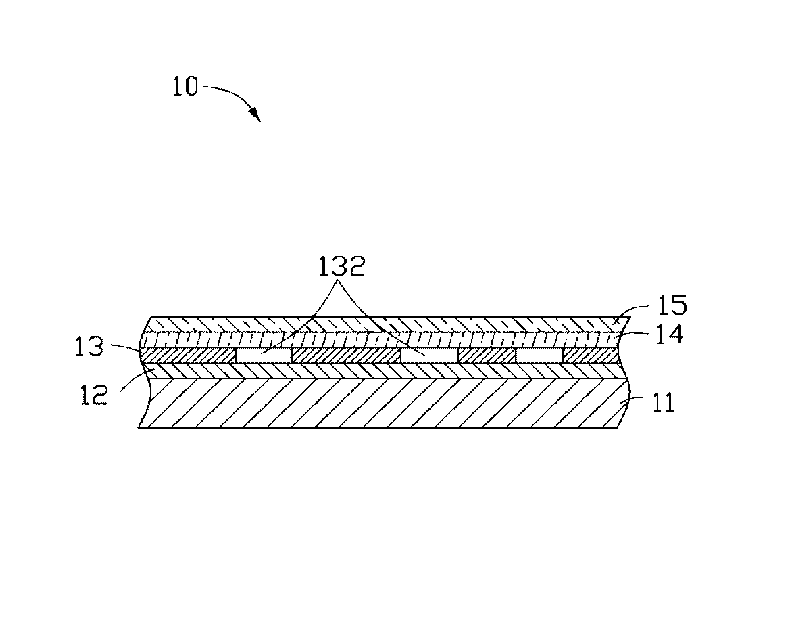

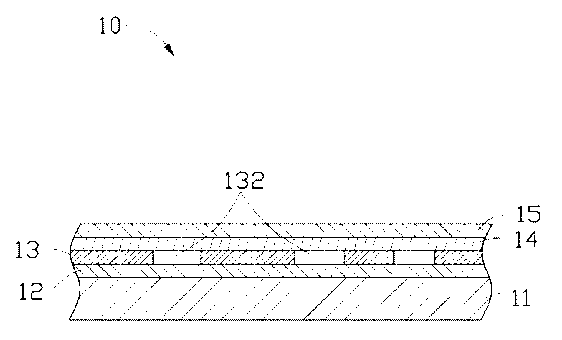

[0017] see figure 1 As shown, the housing 10 of the preferred embodiment of the present invention includes a plastic substrate 11 , a primer layer 12 , a vacuum coating layer 13 , a transparent middle paint layer 14 and a transparent top paint layer 15 .

[0018] The primer layer 12 is directly formed on the surface of the substrate 11 . The vacuum coating layer 13 is formed on the surface of the primer layer 12 . The vacuum coating layer 13 is a metal-like coating. The material forming the vacuum coating layer 13 can be a metal material, such as any one of tin, aluminum, titanium, indium, chromium, gold, vanadium, stainless steel or indium-tin alloy, and can also be a nonmetal with a metallic appearance, such as Any of titanium carbide, titanium nitride, titanium oxide or aluminum oxide. The vacuum coating layer 13 is partially hollowed out, and the hollowed out area forms a pattern 132 . The middle paint layer 14 is formed on the surface of the vacuum coating layer 13, w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com