Production method of chromium-aluminium alloy target material

A chrome-aluminum alloy and production method technology, applied in metal material coating process, ion implantation plating, coating and other directions, can solve the problems of low density and low degree of alloying of chrome-aluminum alloy targets

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

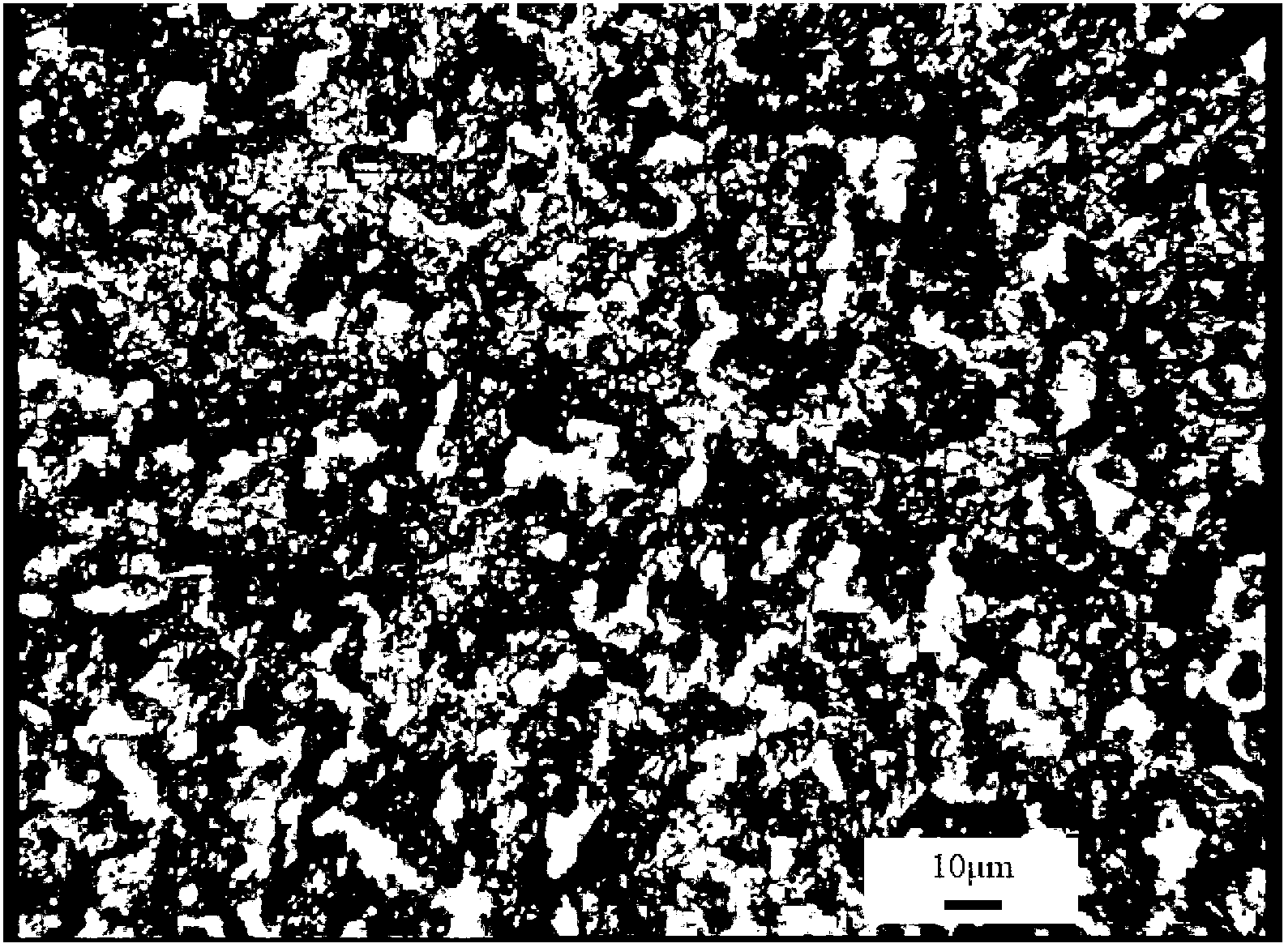

Embodiment 1

[0027] In this embodiment, a method for manufacturing a chromium-aluminum alloy target includes the following steps in sequence:

[0028] (1) Select chromium powder with a purity greater than 99.5wt% and aluminum powder with a purity greater than 99.99wt% as raw materials. The particle size distribution range of the chromium powder and aluminum powder is -100 mesh + 200 mesh. According to the required ratio (mass of chromium and aluminum The ratio is 7:3) into the V-shaped blender, and then vacuum the blender to 10 -1 Pa level, feed argon, then vacuumize, repeat 3 times, then set the speed of 30 rpm to mix for 8 hours;

[0029] (2) Put the mixed powder in a cold isostatic pressure bag, vacuumize it and seal it, press it under a pressure of 200MPa for 10 minutes, and then put the pressed green body in a vacuum self-propagating high-temperature synthesis furnace , to carry out self-propagating reaction (the protective atmosphere is argon, and the reaction vacuum is ab...

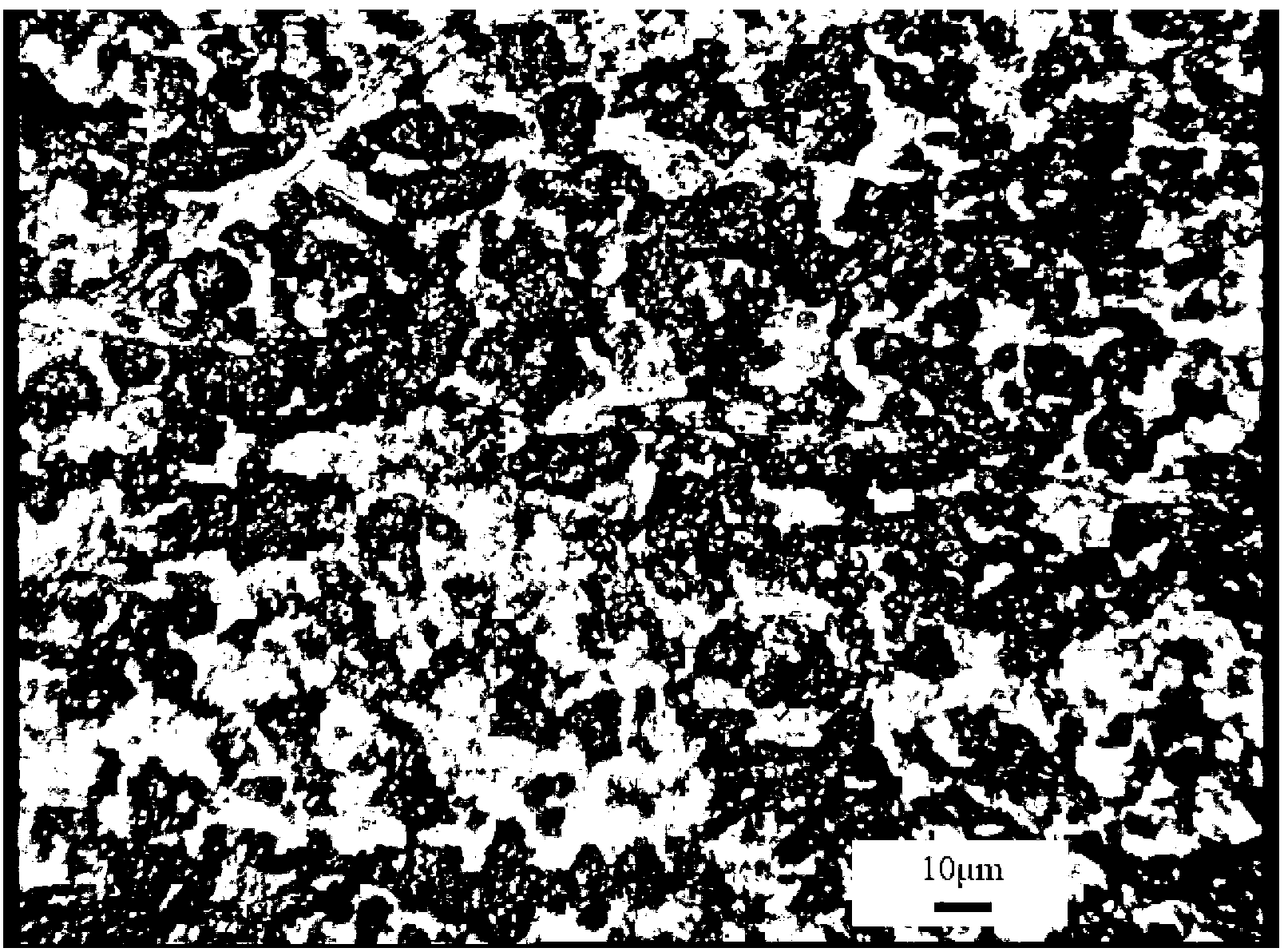

Embodiment 2

[0034] In this embodiment, a method for manufacturing a chromium-aluminum alloy target includes the following steps in sequence:

[0035] (1) Select chromium powder with a purity greater than 99.5wt% and aluminum powder with a purity greater than 99.99wt% as raw materials. The particle size distribution range of the chromium powder and aluminum powder is -100 mesh + 200 mesh. According to the required ratio (mass of chromium and aluminum The ratio is 1:1) into the V-shaped blender, then vacuum the blender to 10 -1 Pa level, feed argon, then vacuumize, repeat 3 times, then set the speed of 10 rpm to mix for 10 hours;

[0036] (2) Put the mixed powder in a cold isostatic pressure bag, vacuumize it and seal it, press it under a pressure of 100MPa for 20 minutes, and then put the pressed green body in a vacuum self-propagating high-temperature synthesis furnace , carry out self-propagating reaction (the protective atmosphere is argon, the reaction vacuum is about 20Pa),...

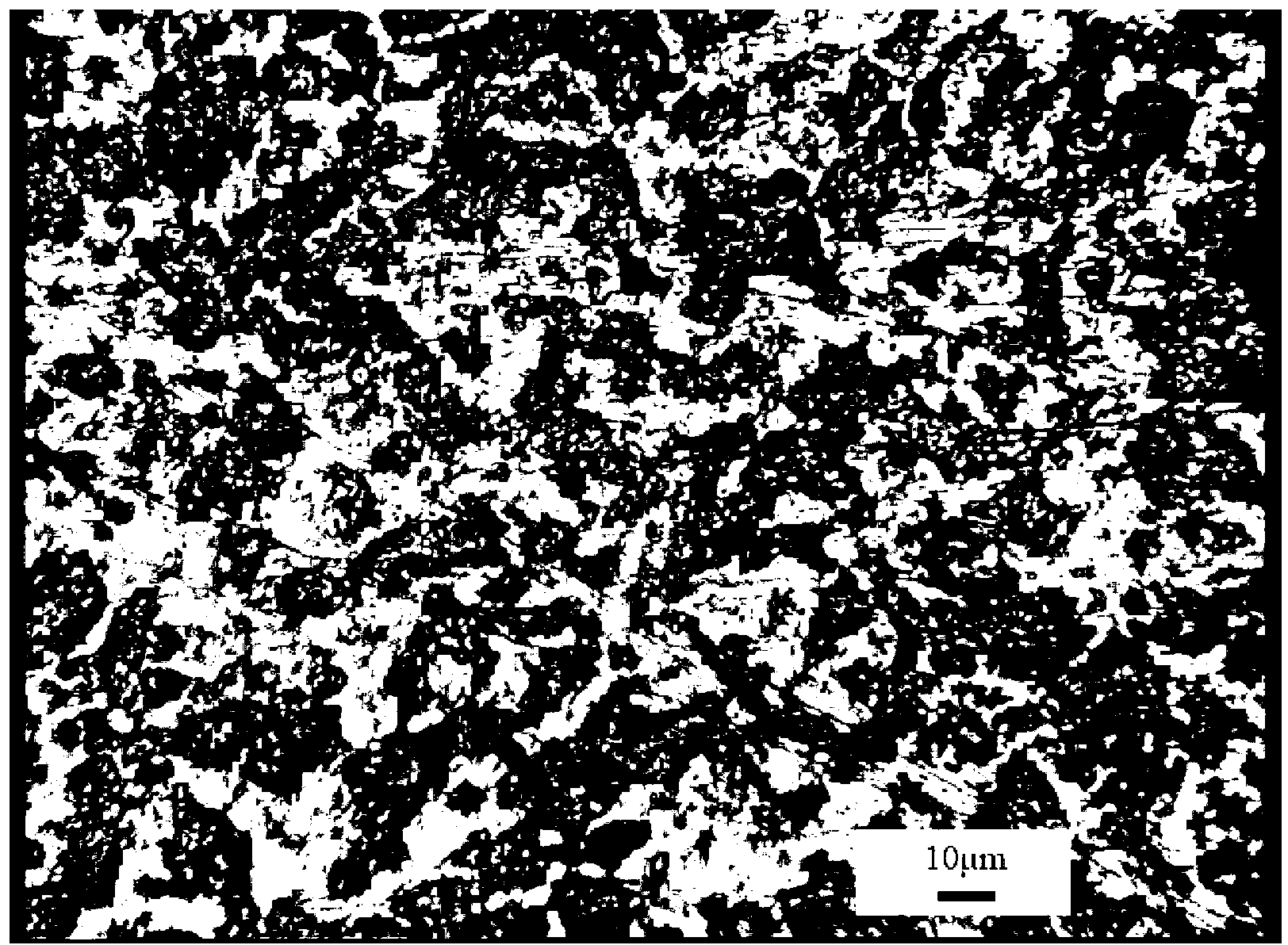

Embodiment 3

[0041] In this embodiment, a method for manufacturing a chromium-aluminum alloy target includes the following steps in sequence:

[0042] (1) Select chromium powder with a purity greater than 99.5wt% and aluminum powder with a purity greater than 99.99wt% as raw materials. The particle size distribution range of the chromium powder and aluminum powder is -100 mesh + 200 mesh. According to the required ratio (mass of chromium and aluminum The ratio is 3:7) into the V-shaped blender, and then vacuum the blender to 10 -1 Pa level, feed argon, then vacuumize, repeat 3 times, then set the speed of 20 rpm to mix for 8 hours;

[0043] (2) Put the mixed powder in a cold isostatic pressure bag, vacuumize it and seal it, press it under a pressure of 300MPa for 10 minutes, and then put the pressed green body in a vacuum self-propagating high-temperature synthesis furnace , carry out self-propagating reaction (the protective atmosphere is argon, the reaction vacuum is about 20P...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com