Preparation method of aqueous / solvent-free composite environmentally friendly polyurethane synthetic leather

A water-based polyurethane, solvent-free technology, applied in the field of synthetic leather manufacturing, can solve problems such as being unfavorable to health and environmental protection, and achieve the effects of strong skin and skin feel, strong pattern three-dimensional effect, and moderate cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] The synthetic leather of this embodiment includes a water-based surface layer and a solvent-free intermediate layer, the water-based surface layer resin is a thermosetting polyether type water-based polyurethane resin, and the solvent-free intermediate layer is a thermosetting two-component polyether type solvent-free layer. Foamed polyurethane resin, the two-component material is a prepolymer of polyether type combination A material and polyether type B material.

[0051] In the present embodiment, the preparation method of water-based / solvent-free composite environment-friendly polyurethane synthetic leather specifically includes the following steps:

[0052] (1) Preparation of the water-based surface layer: coating the water-based surface layer slurry on the release paper, controlling the coating thickness of the water-based surface layer slurry to be 0.2 mm, drying at 120 ° C for 3 minutes and then curing and forming to obtain a water-based surface layer;

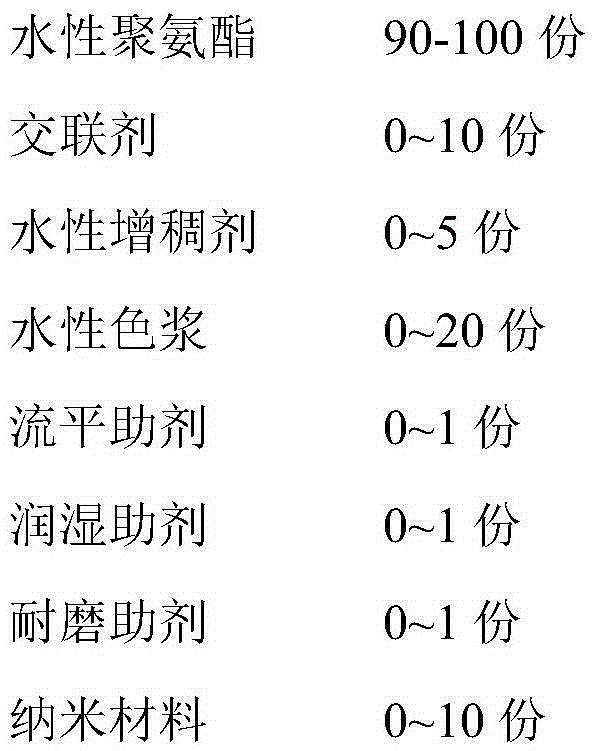

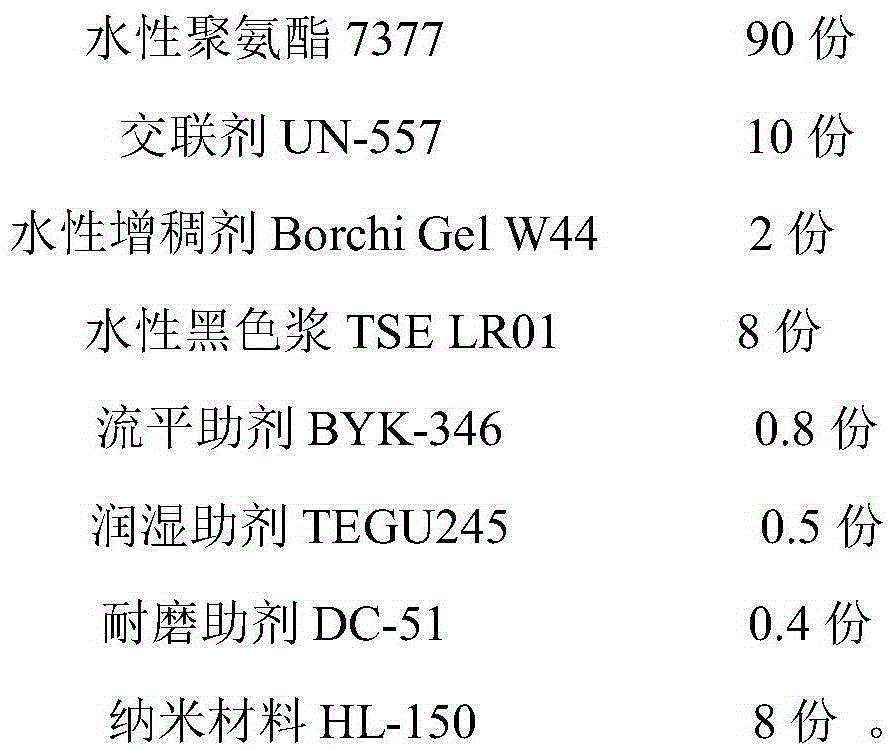

[0053] The...

Embodiment 2

[0062] The synthetic leather of this embodiment includes a water-based surface layer and a solvent-free intermediate layer, the water-based surface layer resin is a thermosetting polyether type water-based polyurethane resin, and the solvent-free intermediate layer is a thermosetting two-component polyether type solvent-free layer. Foamed polyurethane resin, the two-component material is a prepolymer of polyether type combination A material and polyether type B material.

[0063] In the present embodiment, the preparation method of water-based / solvent-free composite environment-friendly polyurethane synthetic leather specifically includes the following steps:

[0064] (1) Preparation of the water-based surface layer: coating the water-based surface layer slurry on the release paper, controlling the coating thickness of the water-based surface layer slurry to be 0.4 mm, drying at 130 ° C for 3 minutes and then curing and forming to obtain a water-based surface layer;

[0065] T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com