Shell having knitted patterns and manufacturing method thereof

A production method and pattern technology, which can be applied to special patterns, patterns of imitation art products, electrical equipment casings/cabinets/drawers, etc., can solve the problems of no three-dimensional texture, messy weaving patterns, easy to fall off, etc., and achieve the appearance effect. Good, clear outline, neat texture effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

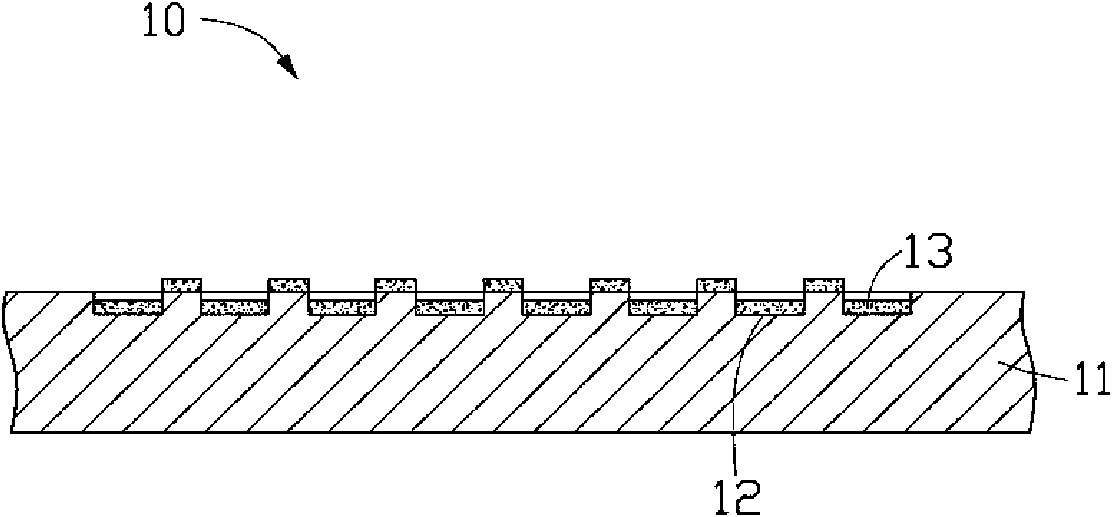

[0016] Please refer to figure 1 and figure 2 As shown, the housing 10 of the preferred embodiment of the present invention includes a metal base 11 on which several groove groups 12 are formed, and a decoration layer 13 is disposed on the metal base 11 and the several groove groups 12 .

[0017] The material of the metal base 11 can be metals such as aluminum, aluminum alloy, titanium, titanium alloy or stainless steel.

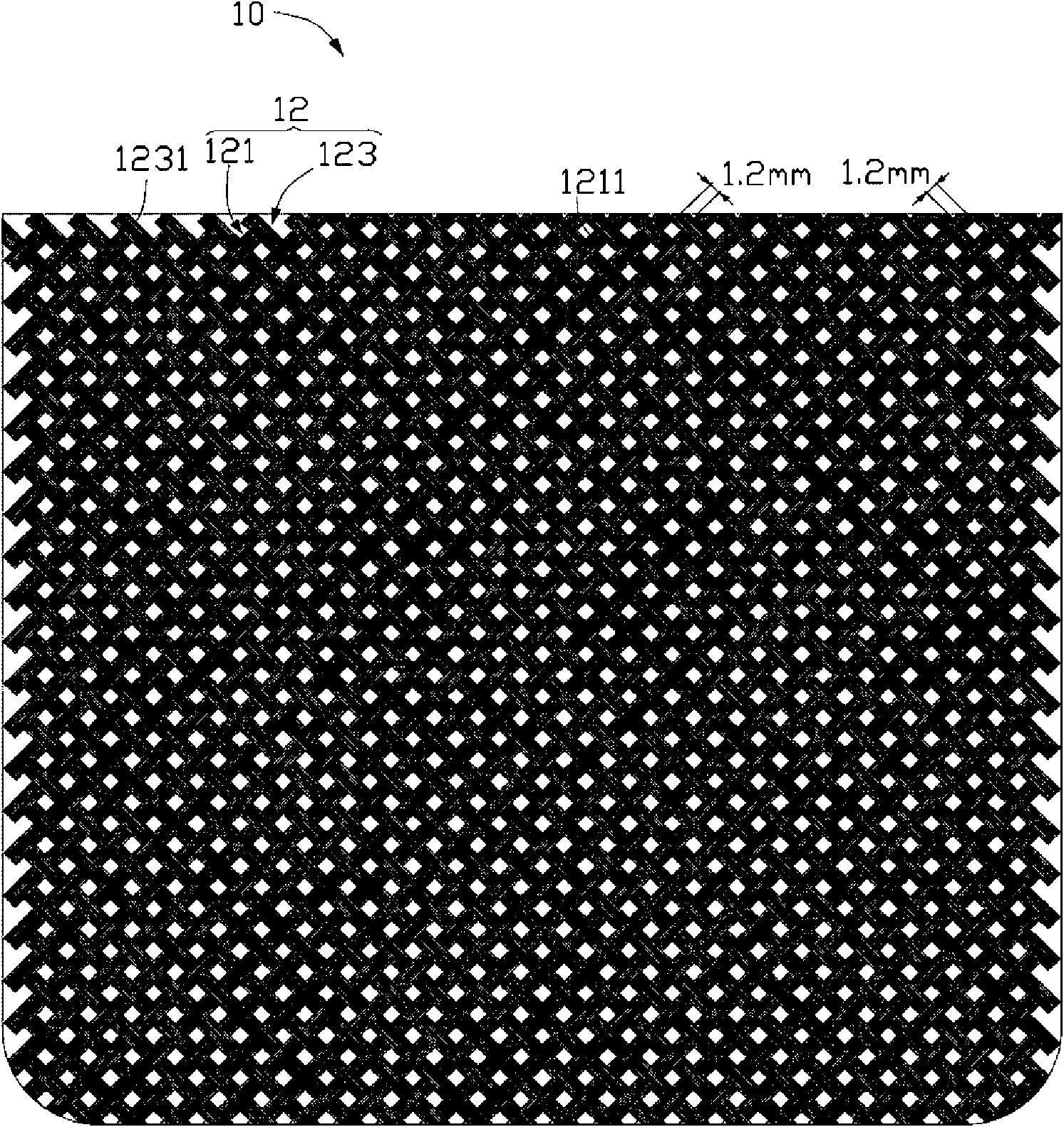

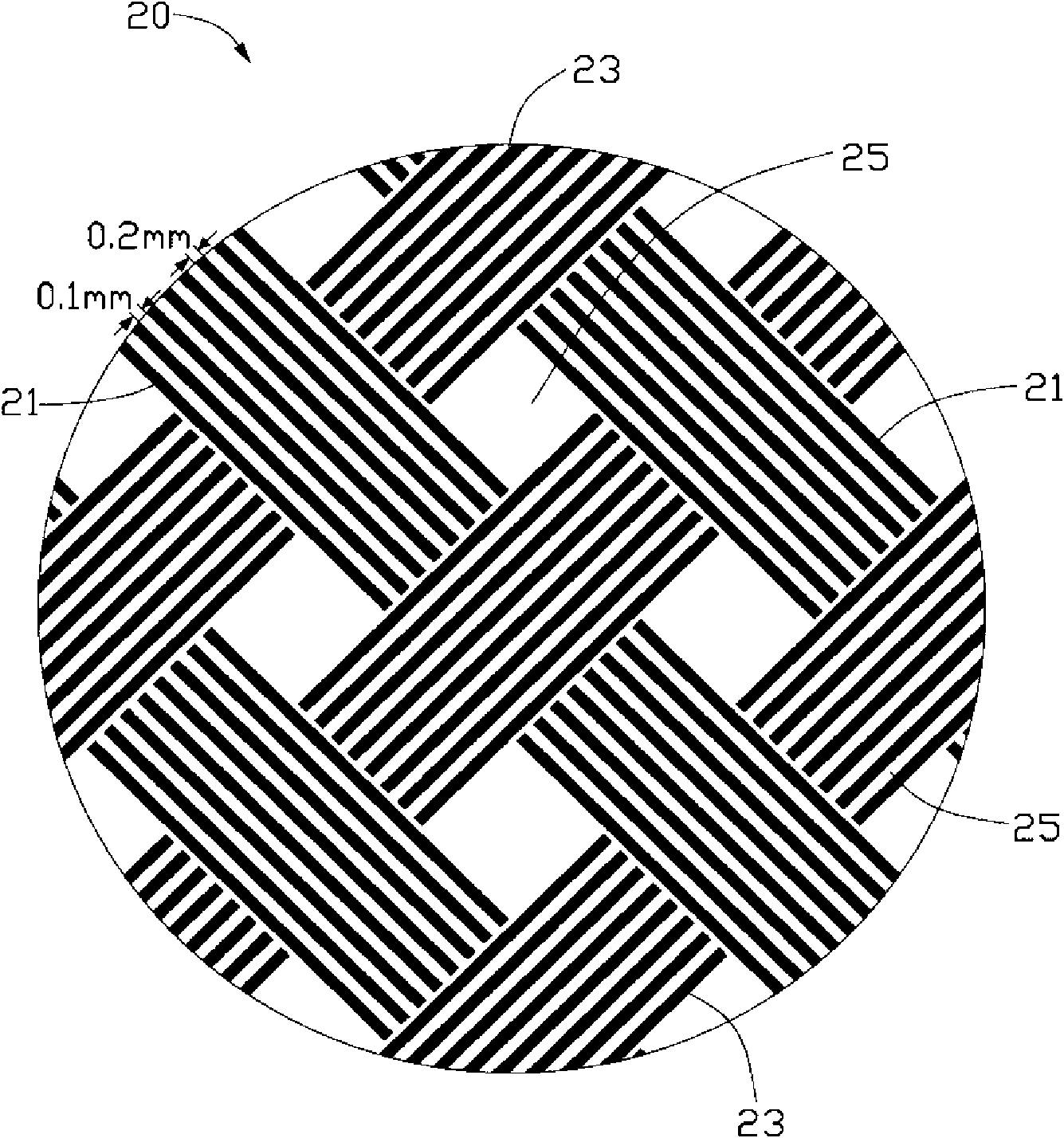

[0018] Several groove groups 12 are arranged in a weaving pattern. The plurality of groove groups 12 includes a plurality of first groove groups 121 arranged at intervals in parallel and a second group of grooves 123 arranged at intervals in parallel, and the plurality of first groove groups 121 and some second groove groups 123 are perpendicular to each other. Arranged in a cross direction to form the weaving pattern. The distance between adjacent first groove groups 121 and adjacent second groove groups 123 can be 1-1.4 mm, preferably 1.2 mm.

[0019] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com