Microcapsules containing organic fluorescent agent

An organic fluorescent agent and microcapsule technology, which is applied in microcapsule preparations, organic chemistry, medical preparations containing active ingredients, etc., can solve the problems that it is difficult to balance the effect of makeup and the effect of protecting or activating the skin

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0342] Embodiment 1 (organic fluorescent agent is covalently bonded to the microcapsule of shell)

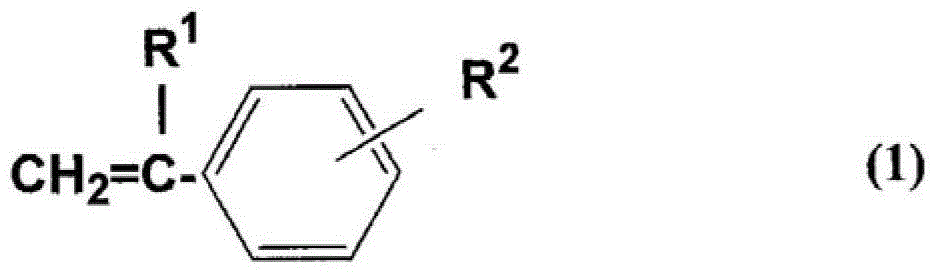

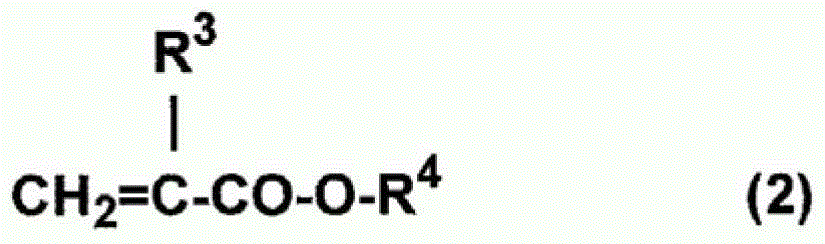

[0343] In a solution obtained by dissolving 1.95 g of polyvinyl alcohol in 190.35 g of water, 51 g of p-methoxycinnamic acid-2-ethylhexyl as an organic ultraviolet absorber and a crosslinkable monomer as a monomer component were uniformly mixed 51 g of ethylene glycol dimethacrylate, 20 mg of monomer 7-(p-vinylbenzyl)amino-4-methylcoumarin having a fluorescent site in the side chain, 5.1 g of polystyrene as an auxiliary polymer, 2 mg of indigo as an organic dye and 0.6 g of 2,2'-azobis(2,4-dimethylvaleronitrile) as a polymerization initiator were formed into a solution and suspended. For the suspension method, a high-speed stirrer (manufactured by T.K. ROBOMICS, PRIMIX) was used to stir at a stirring speed of 7000 rpm for 5 minutes and at a stirring speed of 10000 rpm for 10 minutes at room temperature.

[0344] Next, the suspension was put into a separable flask, and suspens...

Embodiment 2

[0359] Embodiment 2 (inner microcapsule of organic fluorescent agent)

[0360] In a solution obtained by dissolving 1.95 g of polyvinyl alcohol in 190.35 g of water, 51 g of p-methoxycinnamic acid-2-ethylhexyl as an organic ultraviolet absorber and a crosslinkable monomer as a monomer component were uniformly mixed 51 g of ethylene glycol dimethacrylate, 20 mg of organic fluorescent agent 7-N,N-diethylamino-4-methylcoumarin, 5.1 g of polystyrene as an auxiliary polymer, 2 mg of indigo as an organic pigment, And 0.6 g of 2,2'- azobis (2, 4- dimethylvaleronitrile) as a polymerization initiator was made into a solution, and it suspended. For the suspension method, a high-speed stirrer (manufactured by T.K. ROBOMICS, PRIMIX) was used to stir at a stirring speed of 7000 rpm for 5 minutes and at a stirring speed of 10000 rpm for 10 minutes at room temperature.

[0361] Next, the suspension was put into a separable flask, and suspension polymerization was carried out at 50° C. for...

Embodiment 3

[0364] Embodiment 3 (the microcapsule that organic fluorescent agent is present in shell by acid-base combination)

[0365] In a solution obtained by dissolving 1.95 g of polyvinyl alcohol in 190.35 g of water, 51 g of p-methoxycinnamic acid-2-ethylhexyl as an organic ultraviolet absorber and a crosslinkable monomer as a monomer component were uniformly mixed 51g of ethylene glycol dimethacrylate, 20mg of methacrylic acid as a monomer forming an acid-base pair with an organic fluorescent agent, 20mg of an organic fluorescent agent 7-N,N-diethylamino-4-methylcoumarin, 5.1 g of polystyrene as an auxiliary polymer, 2 mg of indigo as an organic dye, and 0.6 g of 2,2'-azobis(2,4-dimethylvaleronitrile) as a polymerization initiator were formed into a solution, and Suspend it. For the suspension method, a high-speed stirrer (manufactured by T.K. ROBOMICS, PRIMIX) was used to stir at a stirring speed of 7000 rpm for 5 minutes and at a stirring speed of 10000 rpm for 10 minutes at r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com