Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

52 results about "Polyol formation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Oxylated vegetable-based polyol having increased functionality and urethane materials formed using the polyol

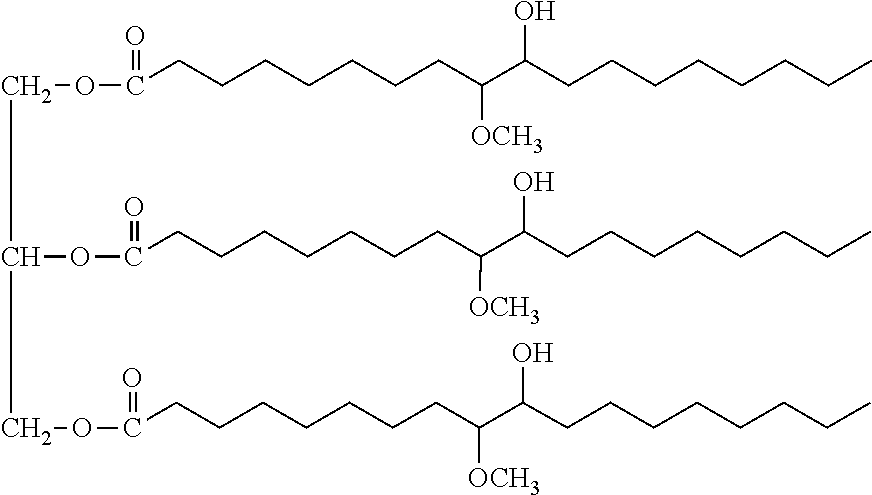

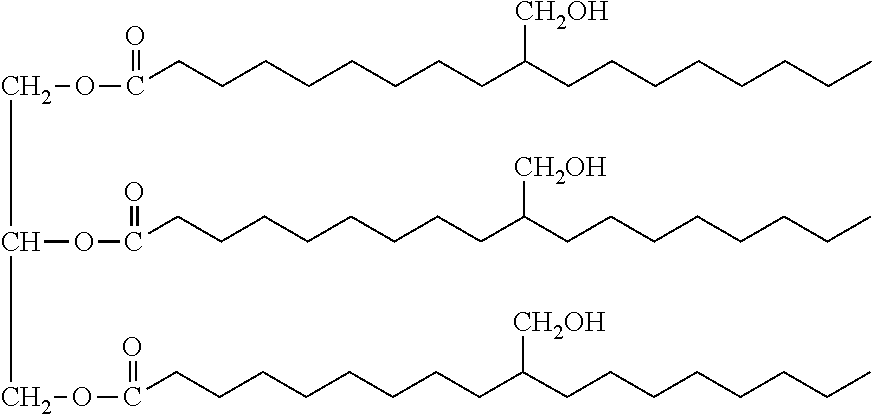

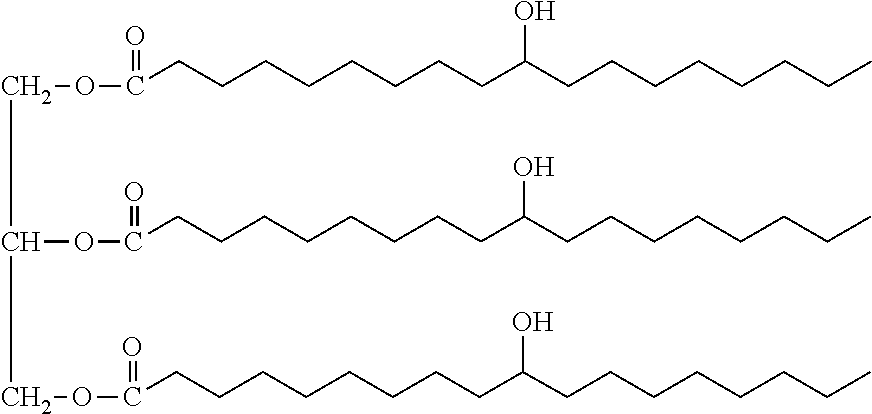

The present invention generally includes material comprising the reaction product of an A-side comprising an isocyanate and a B-side comprising a crosslinker, a catalyst, and a modified vegetable oil. The present invention also generally includes a material comprising the reaction product of an A-side comprising an isocyanate and a B-side comprising an oxylation compound, a modified vegetable oil, and a catalyst.

Owner:URETHANE SOY SYST

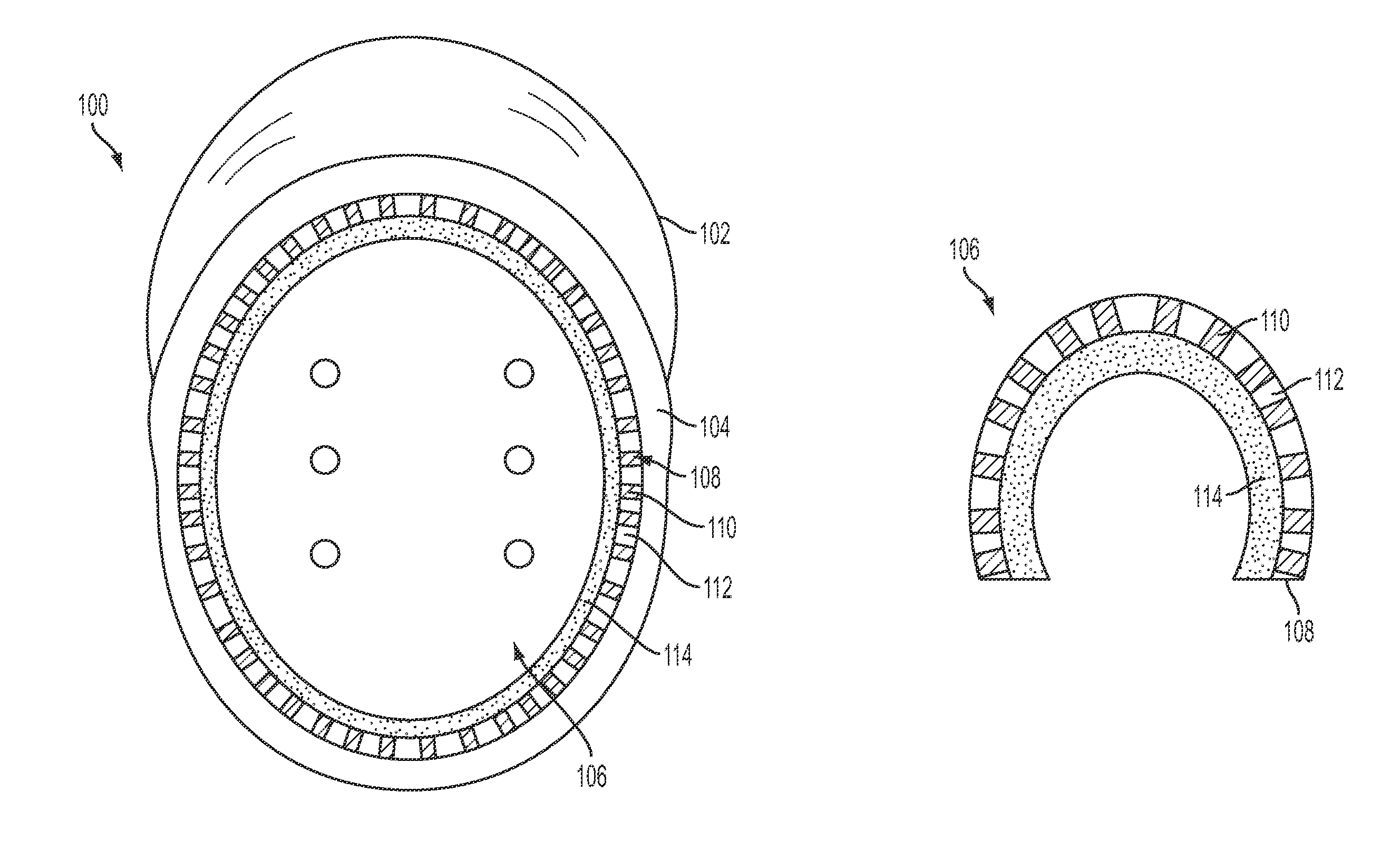

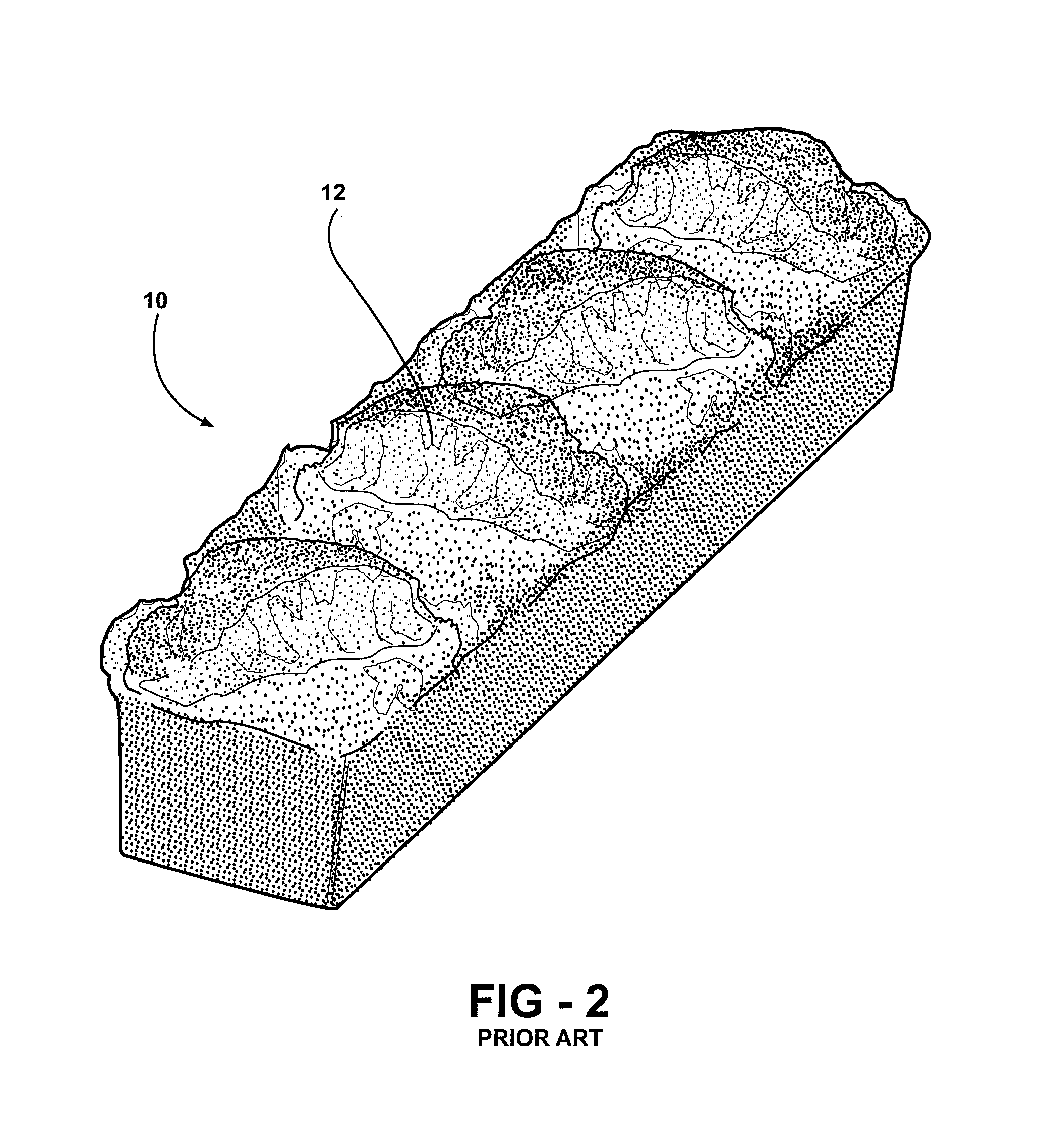

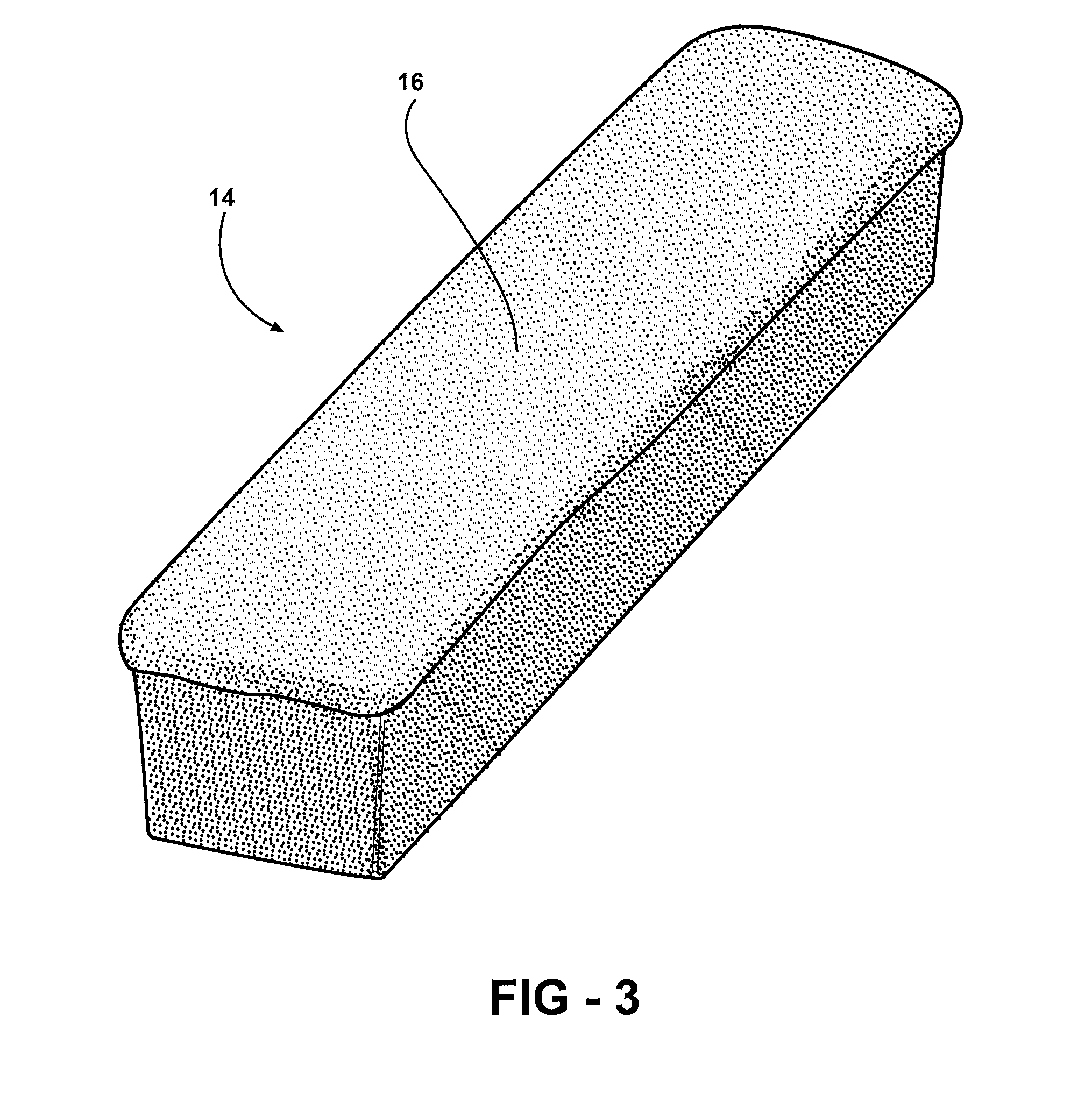

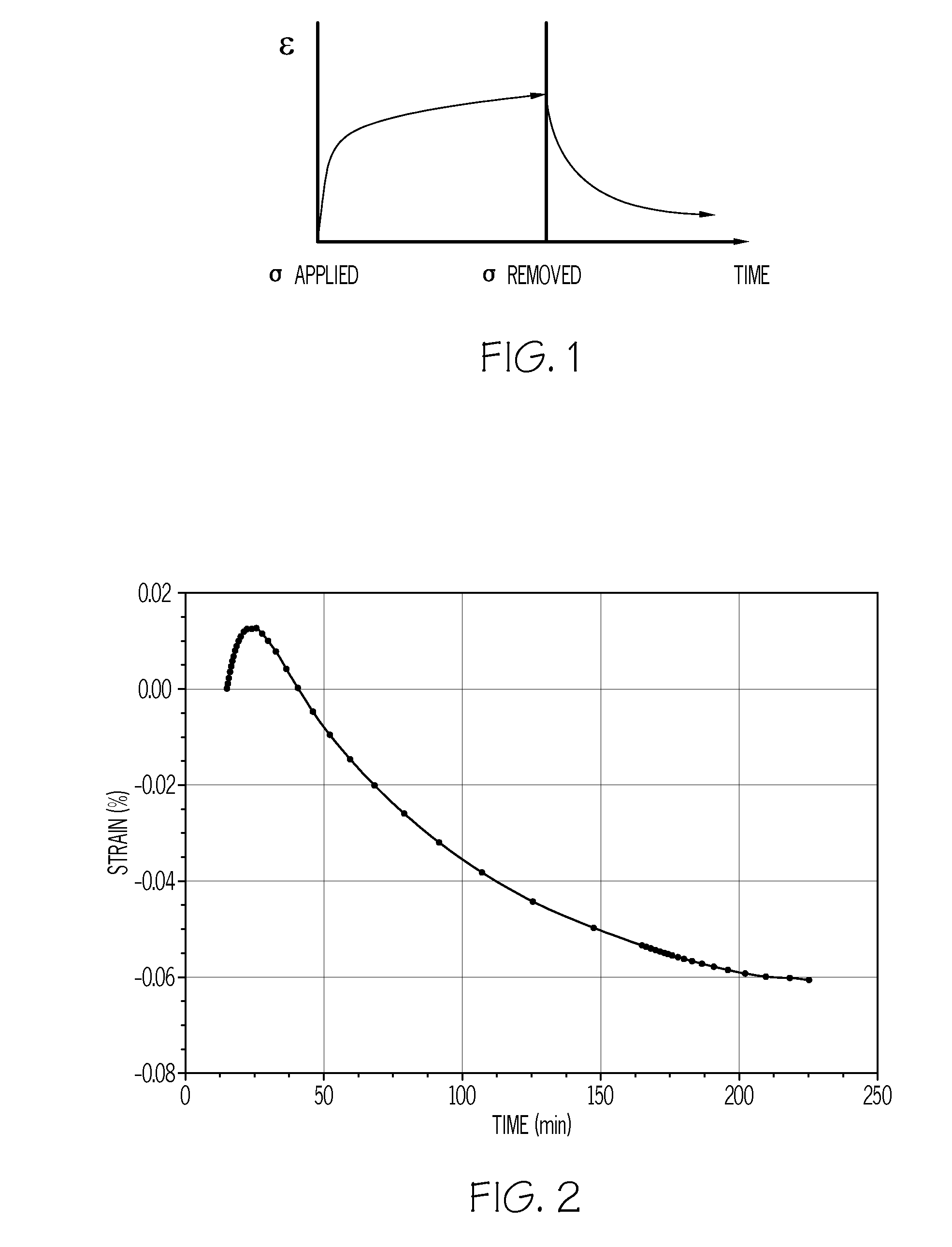

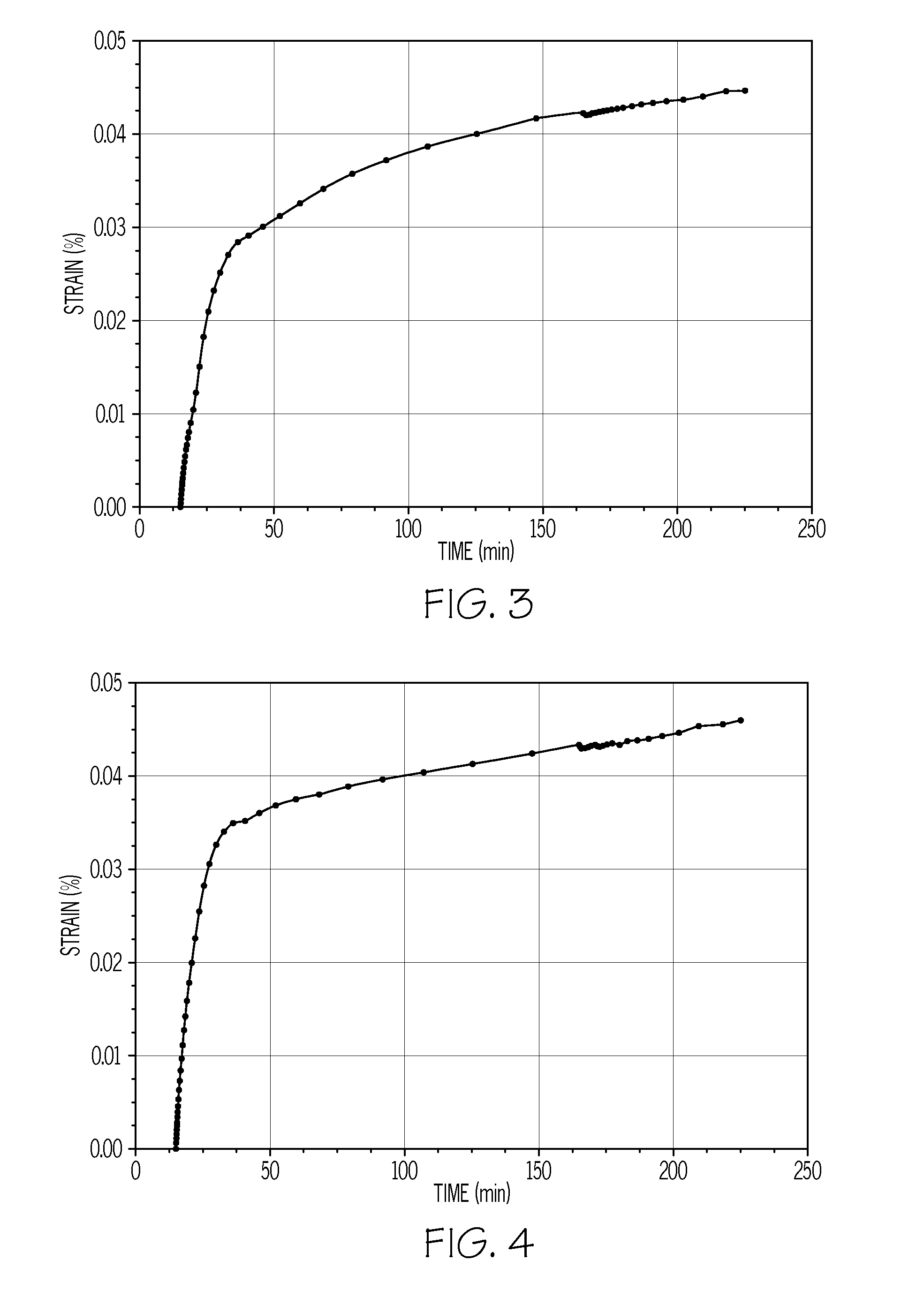

Flexible Polyurethane and Polyurethane/Polyorganosiloxane Foam Materials that Absorb Impact Energy

A polyurethane foam, a polyurethane / polyorganosiloxane foam, and a polyurethane foam polyurethane / polyorganosiloxane foam material are disclosed and described herein. The materials are formed in the presence of a polymerization reaction initiator (an isoprenoid compound), and a polymerization reaction accelerator. The polyurethane foam is formed from an isocyanate and a polyol. The polyurethane foam polyurethane / polyorganosiloxane foam material comprises the polyurethane foam which is cross-linked to the polyurethane backbone to a polyurethane / polyorganosiloxane foam. Optional gelling agents, emulsification control agents, reinforcement fillers, cross-linkers, reinforcement polymers, rubber reinforcers, silk proteins, emollients, stabilizers and colorants are also described. The polyurethane and polyurethane-polyorganosiloxane foam materials exhibit a high degree of flexibility, resilience and excellent impact absorption.

Owner:VIRFEX LLC

Polyurethane adhesive for windshield applications

A polyurethane adhesive which is useful in bonding porous and non-porous surfaces is provided. The adhesive is especially useful in bonding windshield glass into automotive frames under a variety of environmental conditions, particularly in after market windshield replacement applications. The polyurethane includes at least one urethane prepolymer which is based on at least one thermoplastic polyol. In one embodiment, the urethane prepolymer may be formed from one or more polyisocyanates, one or more polyetherpolyols and one or more thermoplastic polyesterpolyols, wherein the prepolymer has a free isocyanate content of from about 0.6 to about 3.5% by weight, based on the weight of the polyurethane. In another embodiment, a one-part adhesive composition is provided which includes an isocyanate-functional and thermoplastic polyurethane prepolymer having a free isocyanate content of from about 0.6 to about 3.5% by weight, based on the weight of the polyurethane, and a combination of several catalysts which are capable of catalyzing the reaction of isocyanate moieties with isocyanate-reactive moieties while providing less temperature dependent catalyzing of the reaction between isocyanate moieties and water. Also provided is a process for bonding two or more substrates together utilizing the polyurethane adhesive. In automotive windshield replacement applications, the polyurethane adhesive allows for a sufficient working time and development of green strength to provide a safe drive-away time within 1 hour at a temperature from about 0 to about 100° C.

Owner:SIKA TECH AG

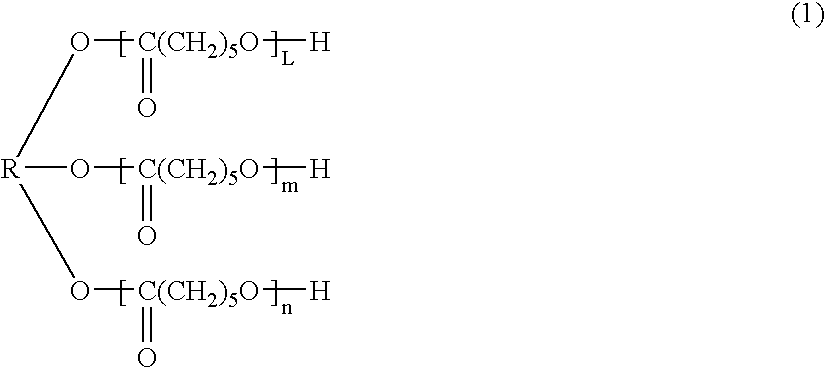

Biodegradable polyols having higher biobased content

InactiveUS20180155490A1Promote degradationHigh biobased contentOrganic chemistryPolymer scienceTriol

The present invention is directed to biodegradable polyester polyol polymers having high bio-based content and methods for producing biodegradable polyester polyol polymers having high bio-based content. In preferred embodiments, β-lactone monomers may be produced from epoxide and carbon monoxide having high bio-based content. In certain preferred embodiment, the β-lactone is β-propiolactone produced from ethylene oxide and carbon monoxide. In certain embodiments, β-lactones may be polymerized with diols, triols, and polyols to form the biodegradable polyester polyol polymers having high bio-based content. In some embodiments, the biodegradable polyester polyol polymers having high bio-based content may be terpolymers formed from a first β-lactone, a diol, triol, or polyol, and a second β-lactone. In some other embodiments, the biodegradable polyester polyol polymers having high bio-based content may be copolymers formed from a polylactone oligomer and a diol, triol, or polyol.

Owner:NOVOMER INC

Flexible polyurethane and polyurethane/polyorganosiloxane foam materials that absorb impact energy

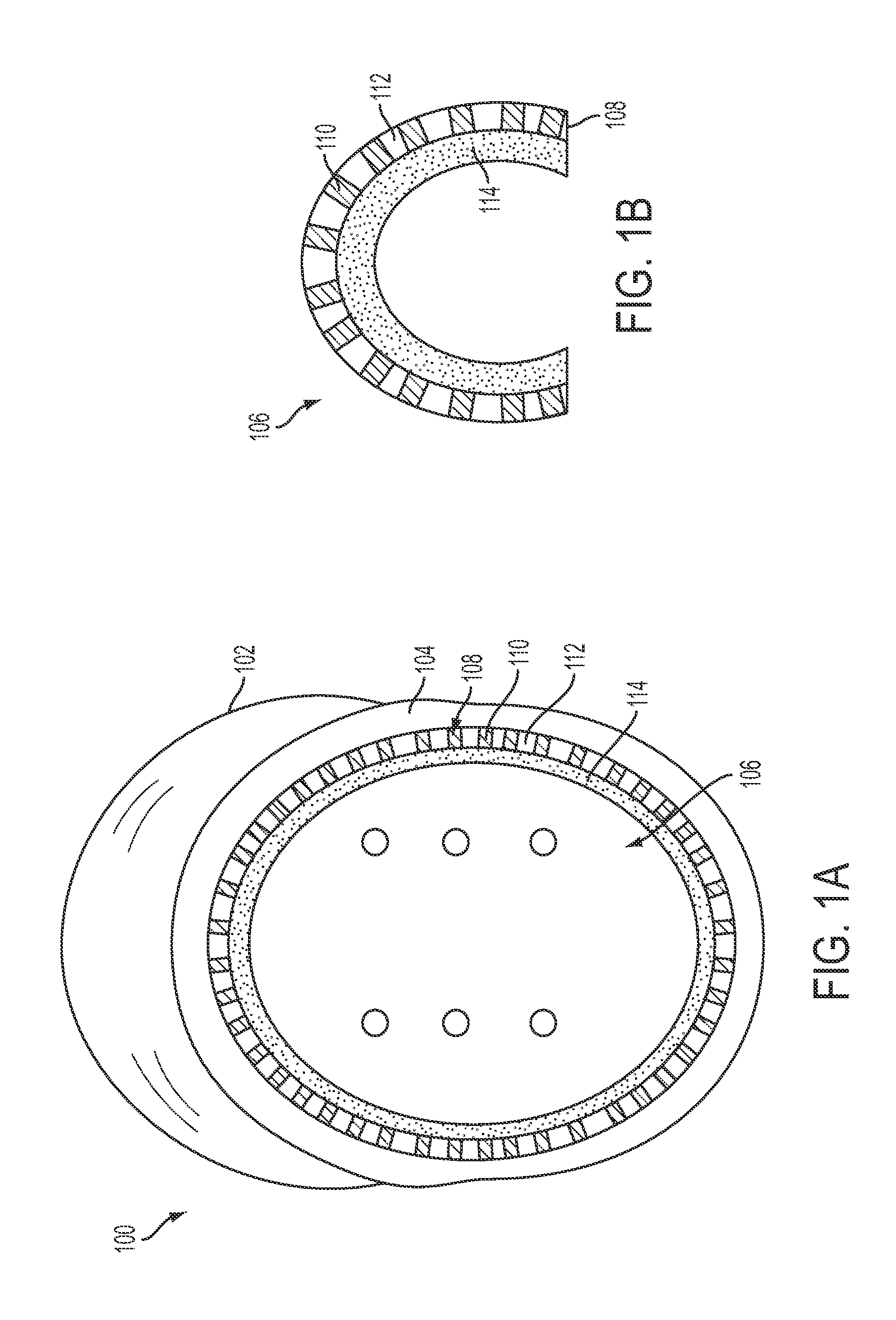

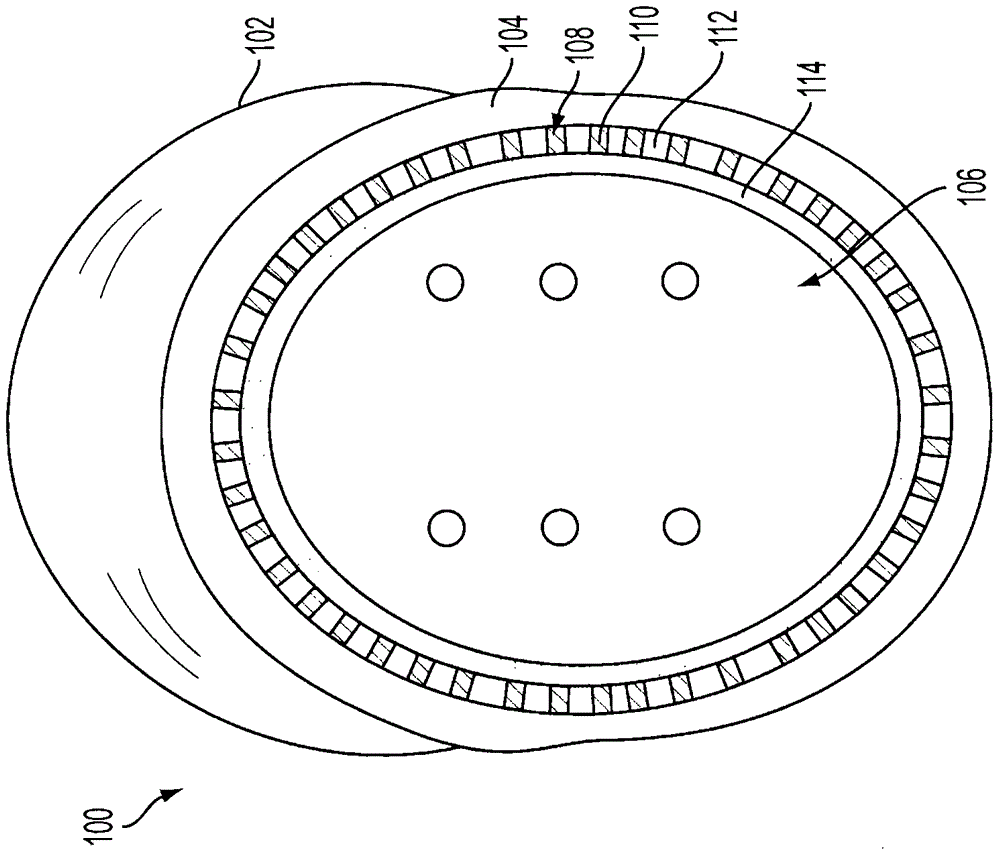

A polyurethane foam (110), a polyurethane / polyorganosiloxane foam (112), and a polyurethane foam polyurethane / polyorganosiloxane foam composite (108) are disclosed and described herein. The materials are formed in the presence of a polymerization reaction initiator (an isoprenoid compound), and a polymerization reaction accelerator. The polyurethane foam (110) is formed from an isocyanate and a polyol. The polyurethane foam polyurethane / polyorganosiloxane foam material comprises the polyurethane foam which is cross-linked to the polyurethane backbone to a polyurethane / polyorganosiloxane foam (112).

Owner:G·德恩

Biobased-petrochemical hybrid polyols

A method of making a biobased-petrochemical hybrid polyol is provided. This method includes reacting a cyclic ether with a vegetable oil-based polyol in the presence of a cationic catalyst or a coordinative catalyst that includes a vegetable oil-based polyol ligand to form the biobased-petrochemical hybrid polyol. The biobased-petrochemical hybrid polyol that is created has a number average molecular weight of about 3,000 to about 6,000 and has a structure that is about 22% to about 36% biobased. In one aspect of the present invention, the cyclic ether is propylene oxide, and the propoxylated polyol formed from the propylene oxide and vegetable oil-based polyol is then reacted with ethylene oxide in the presence of a superacid catalyst to create a block copolymer with a terminal polyethylene oxide block having a high percentage of terminal primary hydroxyl groups. If the cyclic ether is a homogeneous mixture of ethylene oxide and propylene oxide, then propylene oxide-ethylene oxide random copolymers are formed by polyaddition to vegetable oil polyols. The biobased-petrochemical hybrid polyol may be reacted with an isocyanate so as to create a flexible polyurethane that has good hydrolytic resistance.

Owner:PITTSBURG STATE UNIVERSITY

Method of forming a graft polyol and polyurethane article formed from the graft polyol

A graft polyol is used to form a polyurethane article including the reaction product of the graft polyol and an isocyanate. The graft polyol is formed from a method including the steps of providing a polymerizable monomer, providing a chain transfer agent, providing a carrier polyol, and providing a free radical initiator. The polymerizable monomer includes styrene and acrylonitrile. The chain transfer agent includes from three to nine carbon atoms, at least one thiol moiety, and at least one hydrophilic moiety. The carrier polyol includes a polyetherol and the free radical initiator includes a diimide. The method also includes the step of combining the polymerizable monomer, the chain transfer agent, the carrier polyol, and the free radical initiator including free radicals. The method further includes the step of reacting the polymerizable monomer and the free radicals to polymerize the polymerizable monomer and form the graft polyol.

Owner:BASF CORP

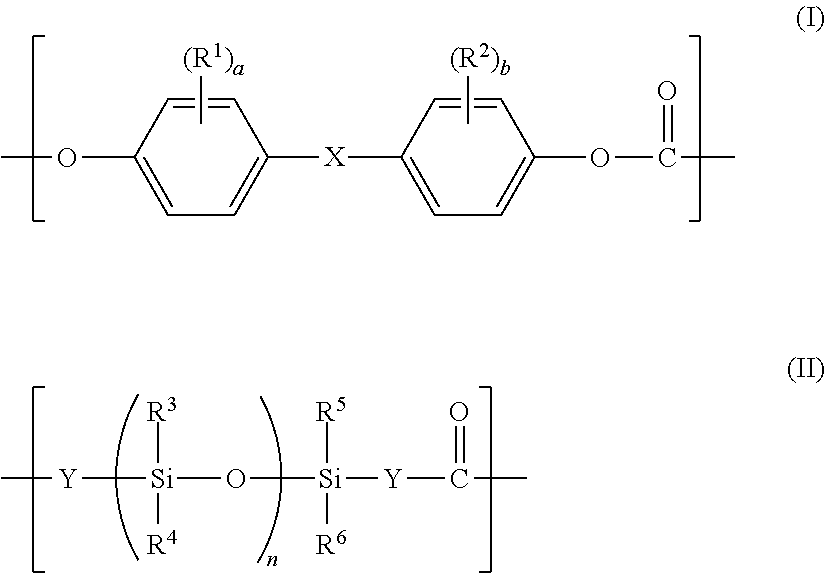

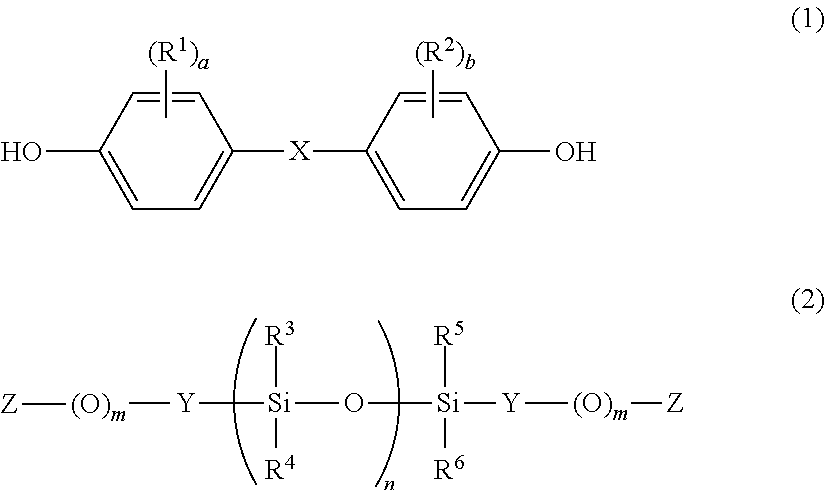

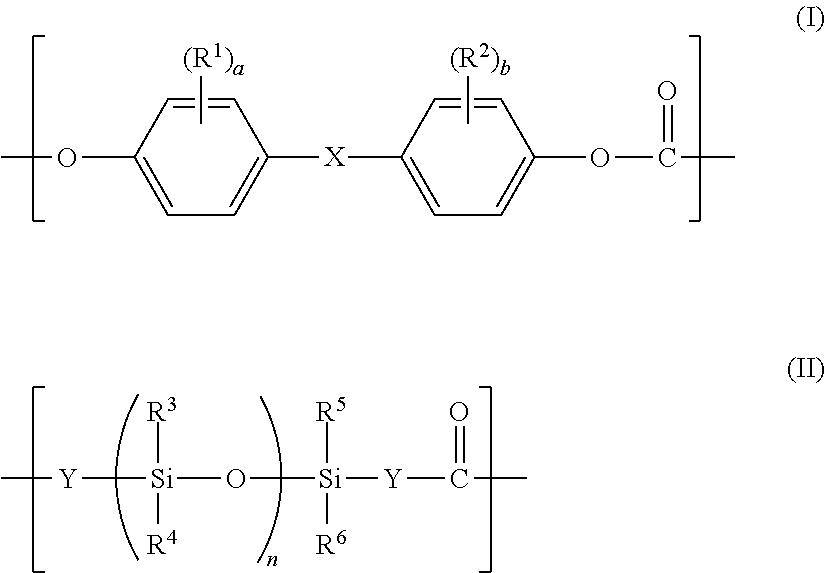

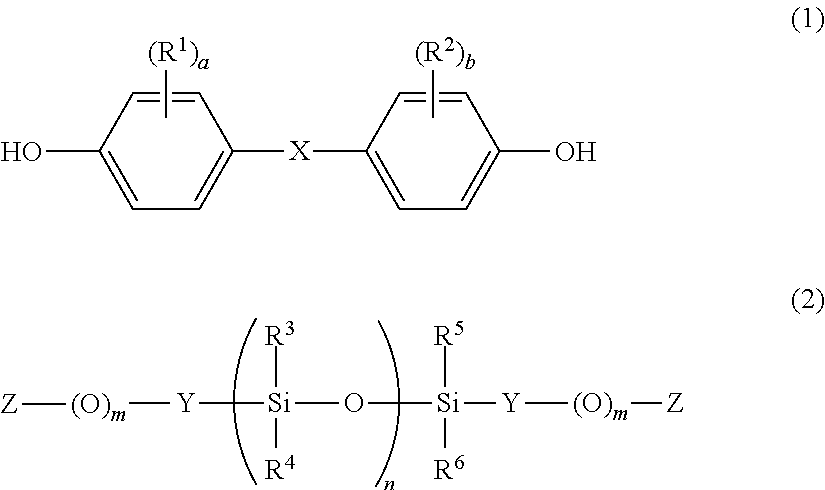

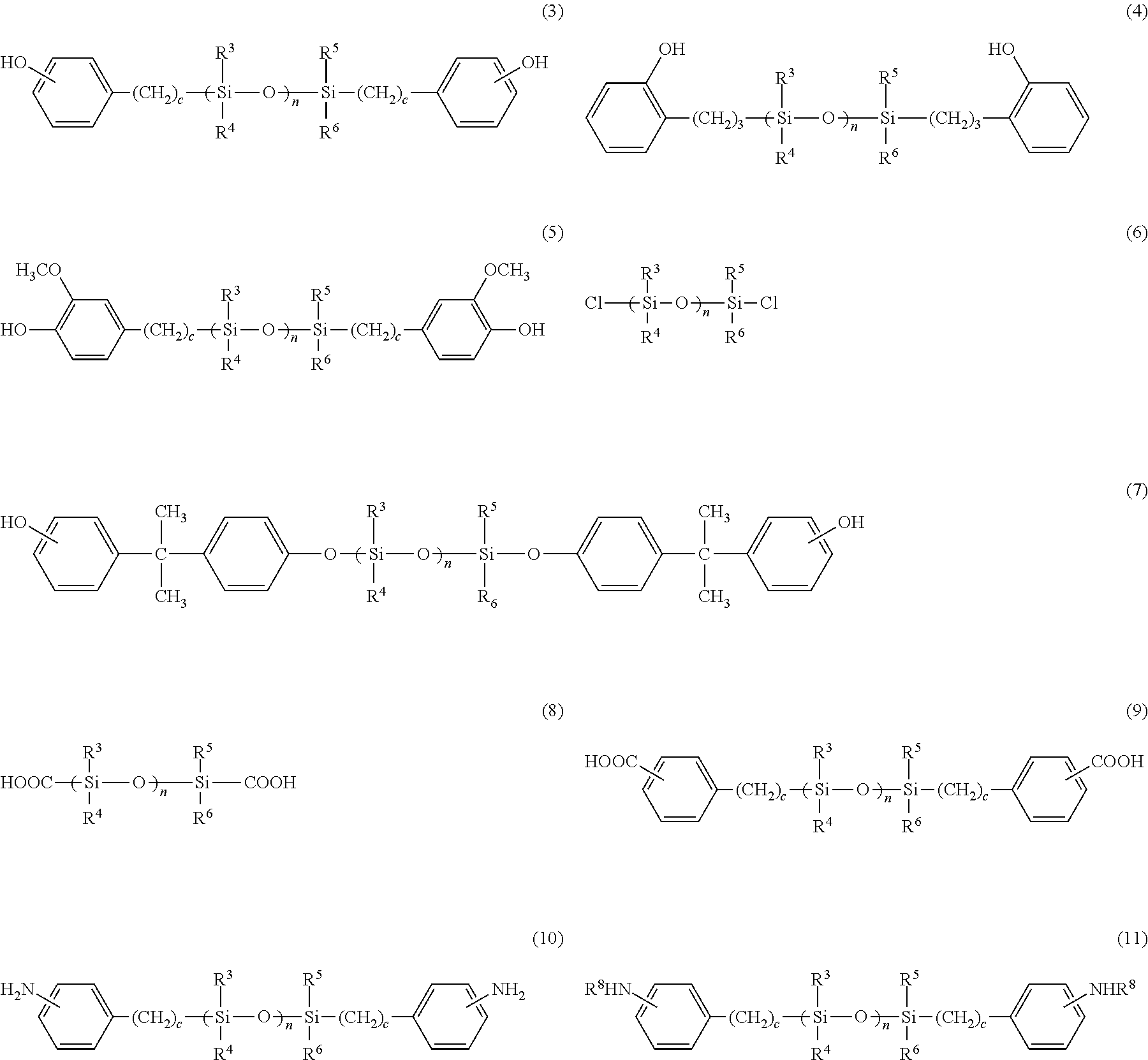

Polycarbonate resin composition, molded article and structure member for solar photovoltaic power generation

ActiveUS20130303672A1Improve flame retardant performanceImpact characteristicPhotovoltaicsPhotovoltaic energy generationFiberSolar power

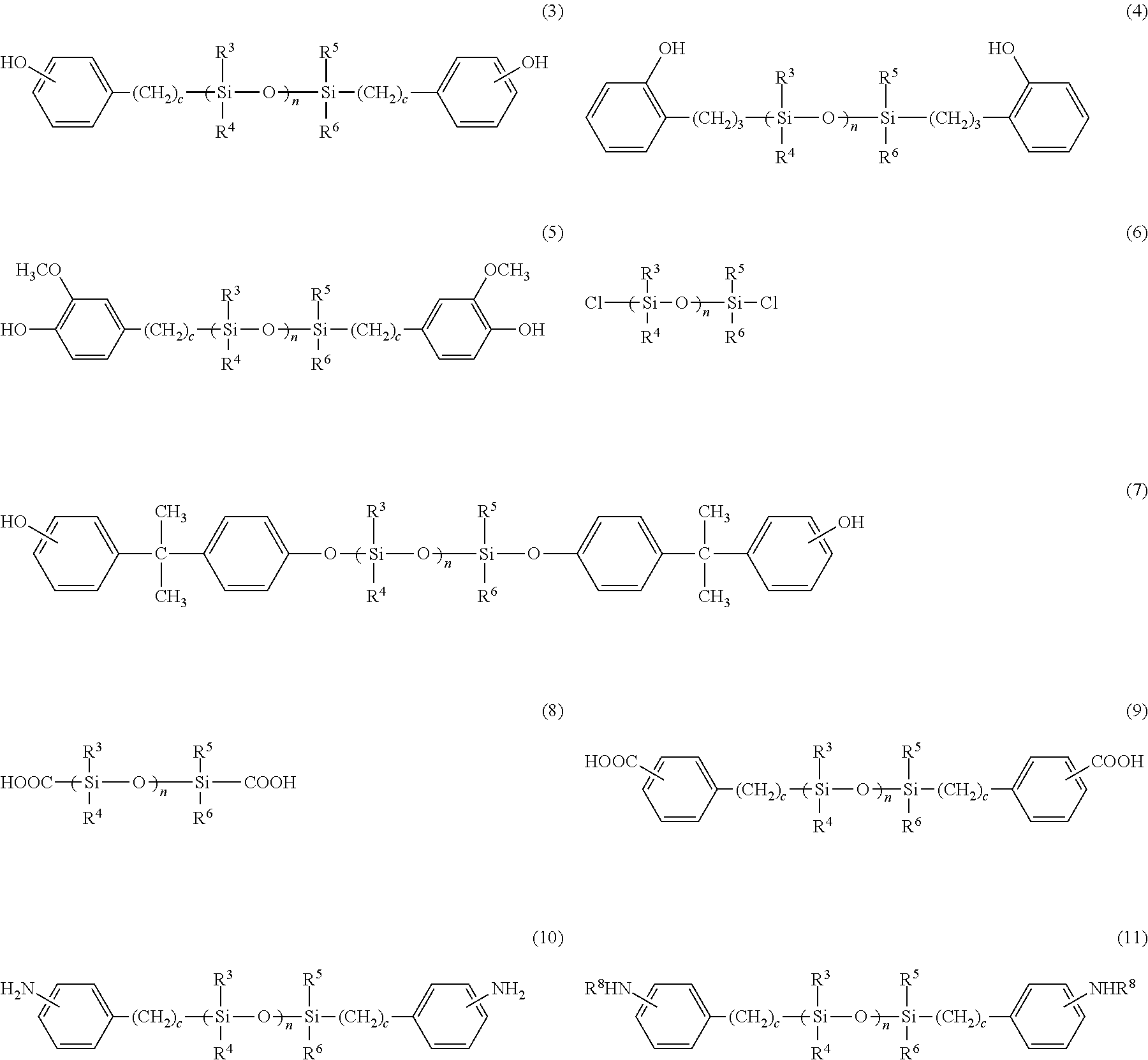

Provided are: a polycarbonate-based resin composition, including: (A) 100 parts by mass of a resin mixture formed of: 30 to 100 mass % of a PC-POS copolymer (A-1) which has constituent units represented by a general formula (I) and a general formula (II), and in which an average repetition number n of organosiloxane constituent units in the general formula (II) is 70 to 500; and 70 to 0 mass % of an aromatic polycarbonate resin (A-2) except the PC-POS copolymer (A-1); (B) 0.01 to 0.15 part by mass of an alkaline (earth) metal salt of an organic sulfonic acid; (C) 0.1 to 1 part by mass of a polytetrafluoroethylene having a fibril-forming ability; and (D) 2 to 15 parts by mass of titanium dioxide particles each having, on an outermost surface thereof, a coating layer formed of a polyol free of a nitrogen atom; a molded article obtained by molding the resin composition; and a structure member for solar photovoltaic power generation formed of the molded article. The polycarbonate-based resin composition, molded article, and structure member for solar photovoltaic power generation each have excellent flame retardancy and excellent tracking resistance without impairing a low-temperature impact characteristic which a PC-POS copolymer has.

Owner:IDEMITSU KOSAN CO LTD

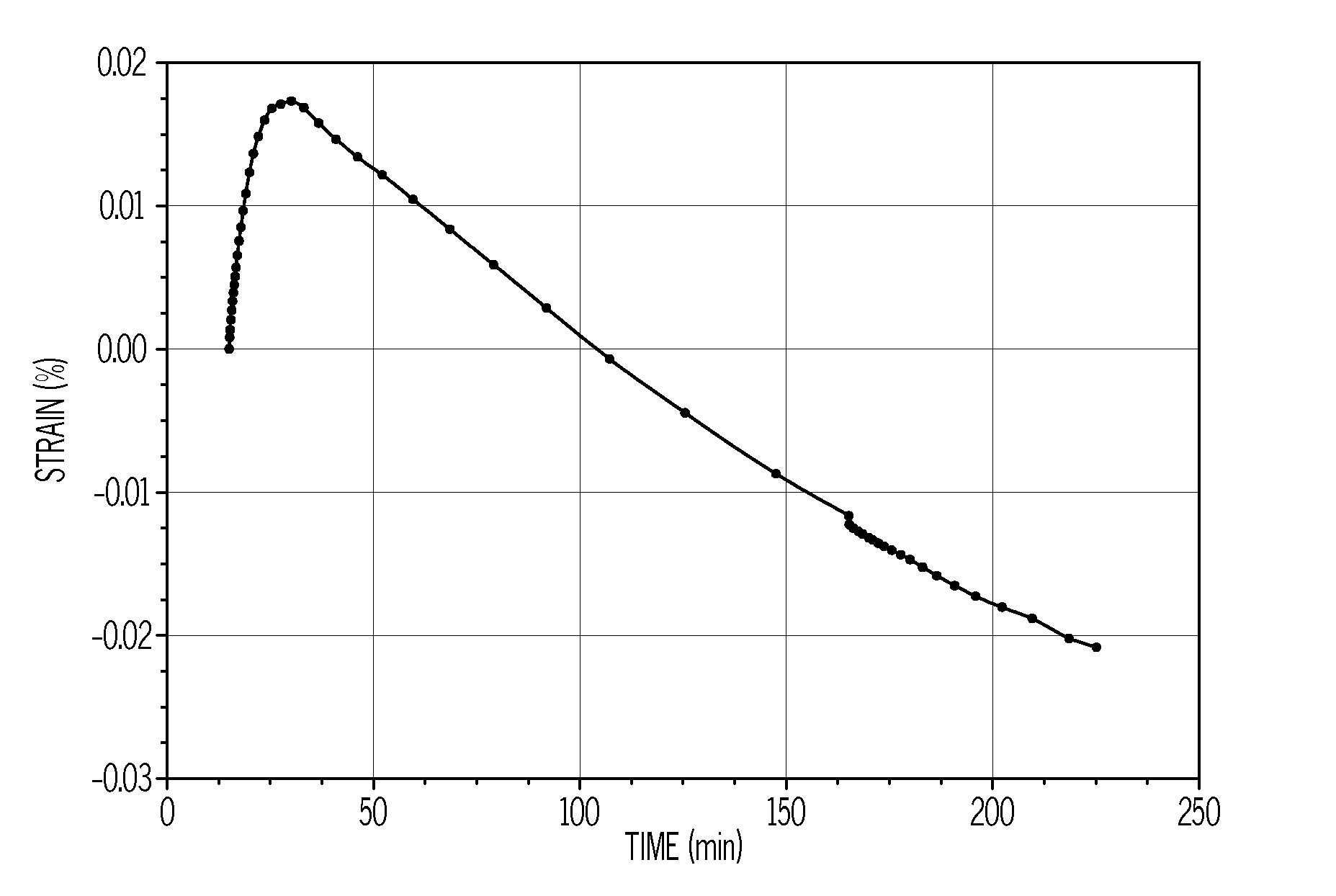

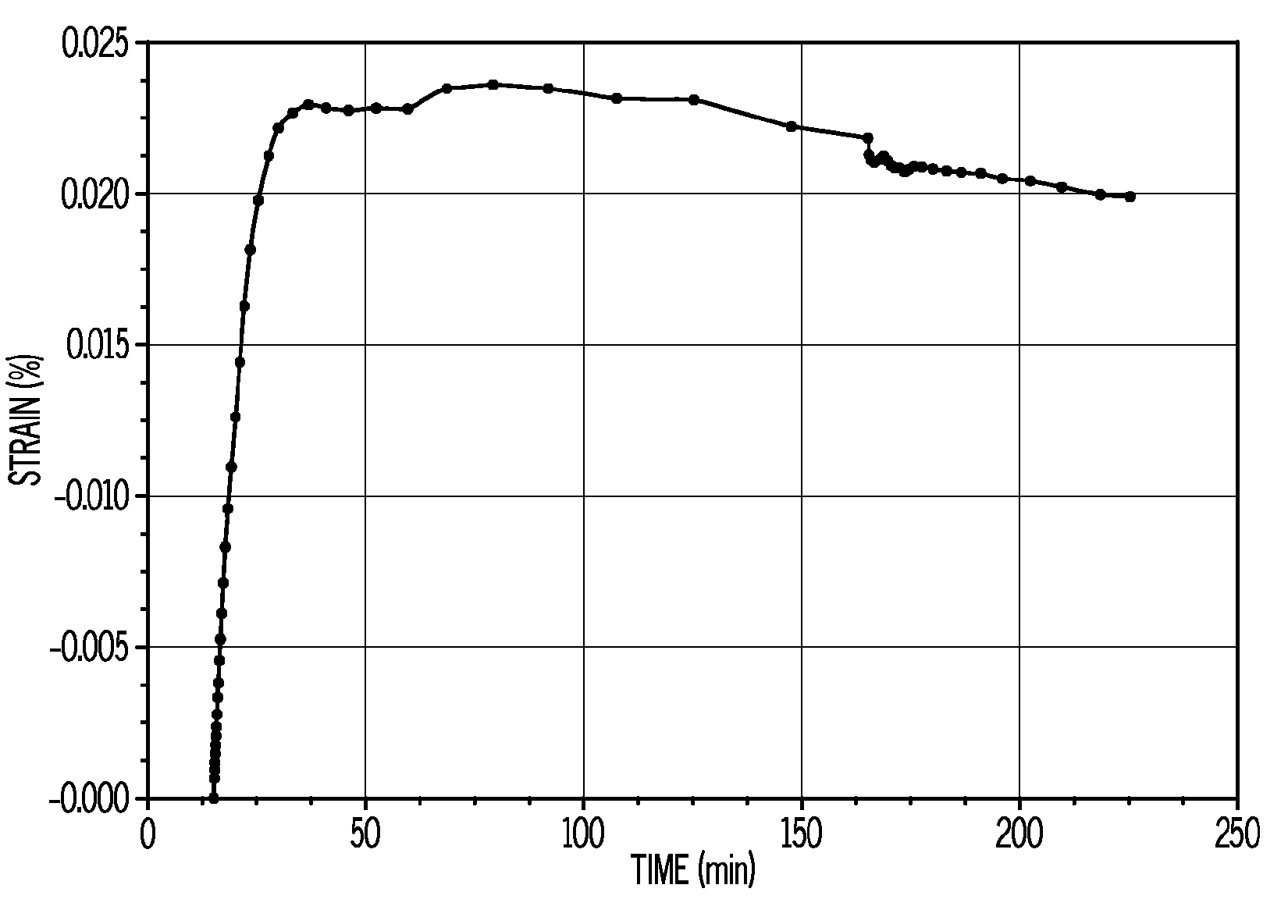

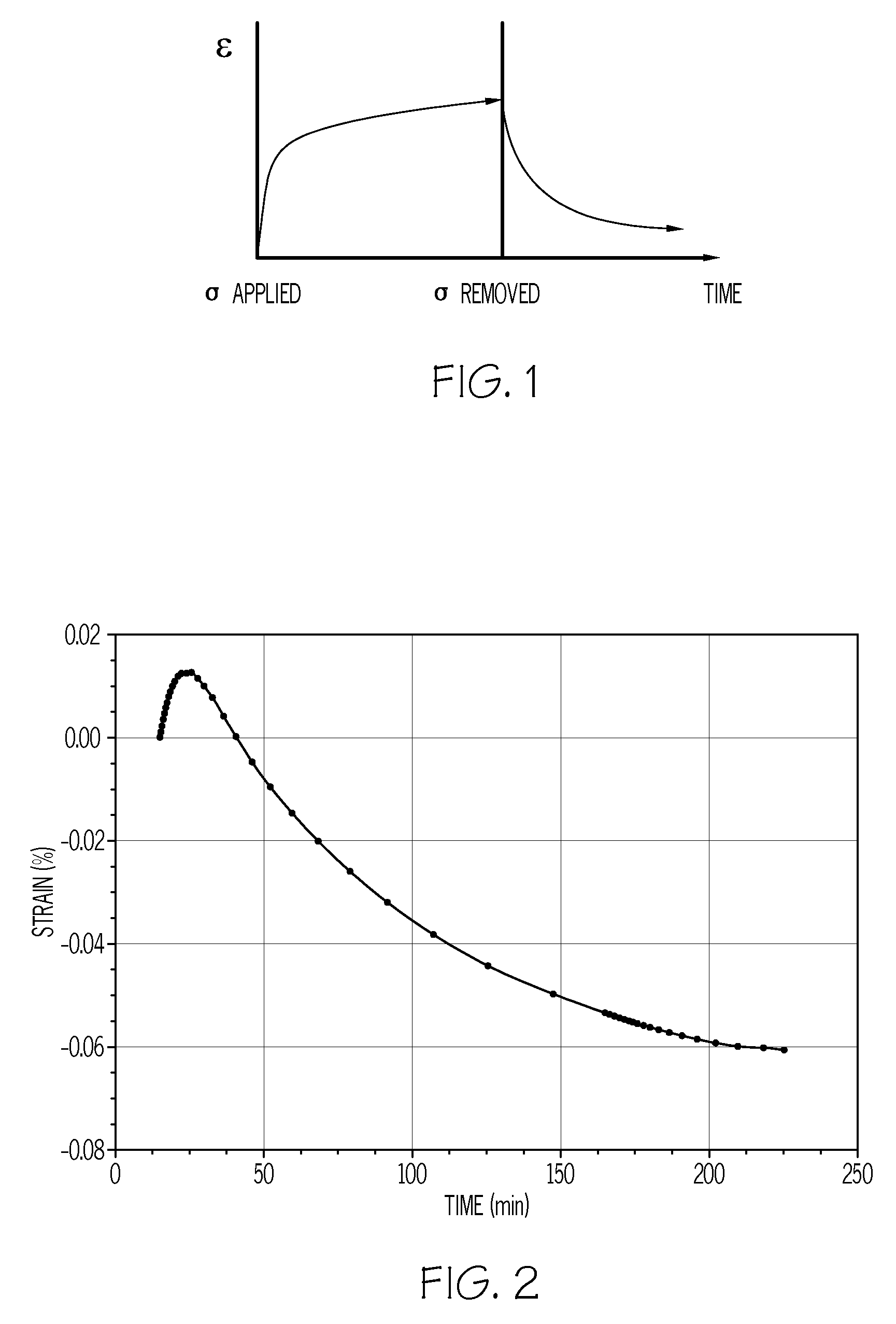

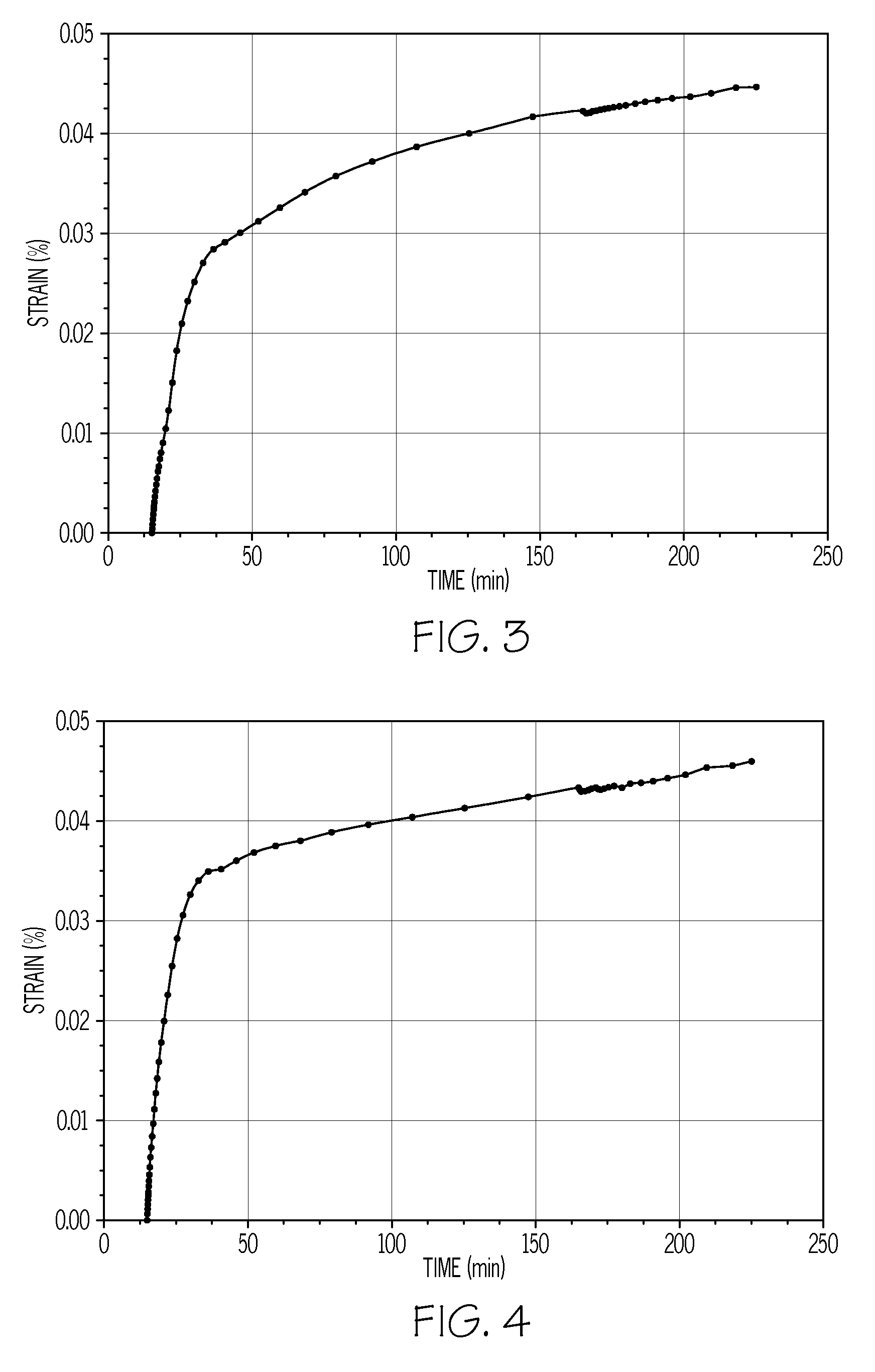

Creep-resistant polishing pad window

The polishing pad is useful for polishing at least one of magnetic, optical and semiconductor substrates. The polishing pad includes a polishing layer having a polyurethane window. The polyurethane window has a cross-linked structure formed with an aliphatic or cycloaliphatic isocyanate and a polyol in a prepolymer mixture. The prepolymer mixture is reacted with a chain extender having OH or NH2 groups and having an OH or NH2 to unreacted NCO stoichiometry less than 95%. The polyurethane window has a time dependent strain less than or equal to 0.02% when measured with a constant axial tensile load of 1 kPa at a constant temperature of 60° C. at 140 minutes, a Shore D hardness of 45 to 90 and an optical double pass transmission of at least 15% at a wavelength of 400 nm for a sample thickness of 1.3 mm.

Owner:ROHM & HAAS ELECTRONICS MATERIALS CMP HLDG INC

High temperature stable lubricant mixed polyol ester composition containing an aromatic carboxylic acid and method for making the same

InactiveUS6884761B2Economical, high temperatureIncrease temperatureOrganic chemistryHeat-exchange elementsBenzoic acidCarboxylic acid

Owner:BP CORP NORTH AMERICA INC

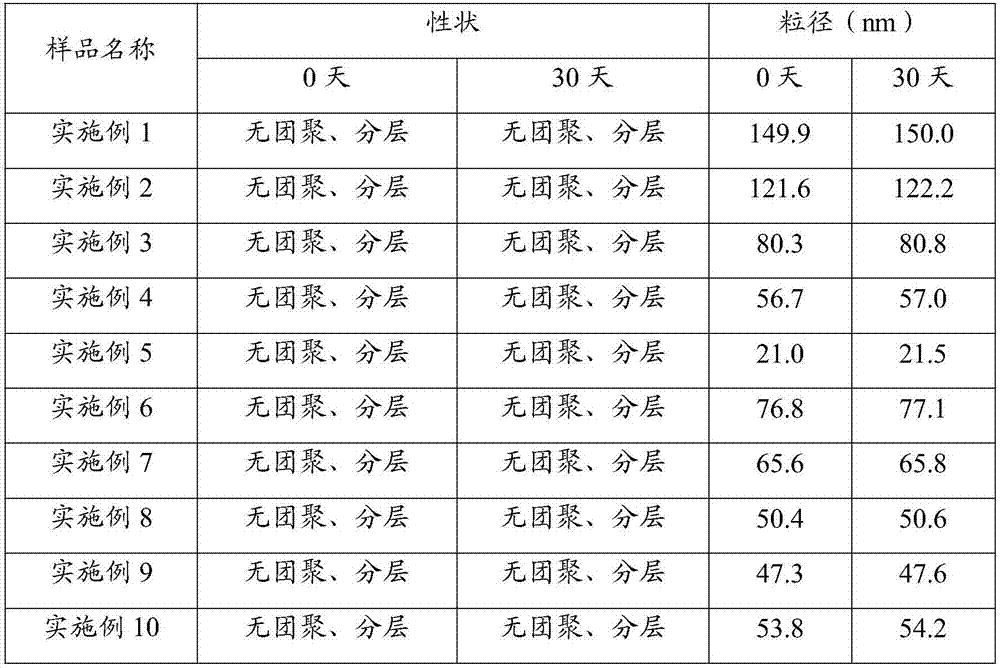

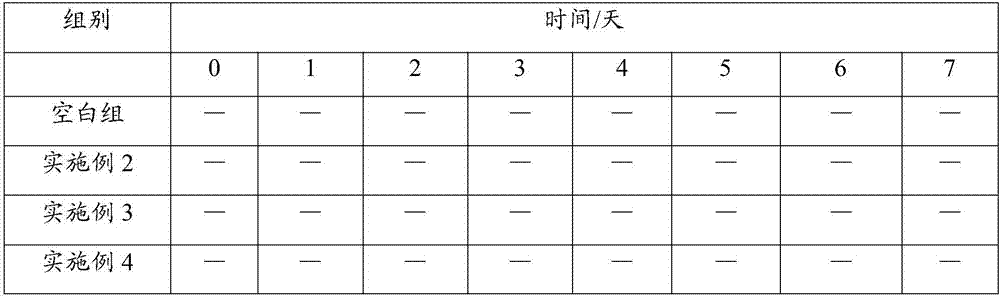

Kaempferol nanometer composition and its preparation method and application

InactiveCN107496186AEasy to prepareThe process is simple and easy to controlCosmetic preparationsToilet preparationsAlcoholAnti bacterial

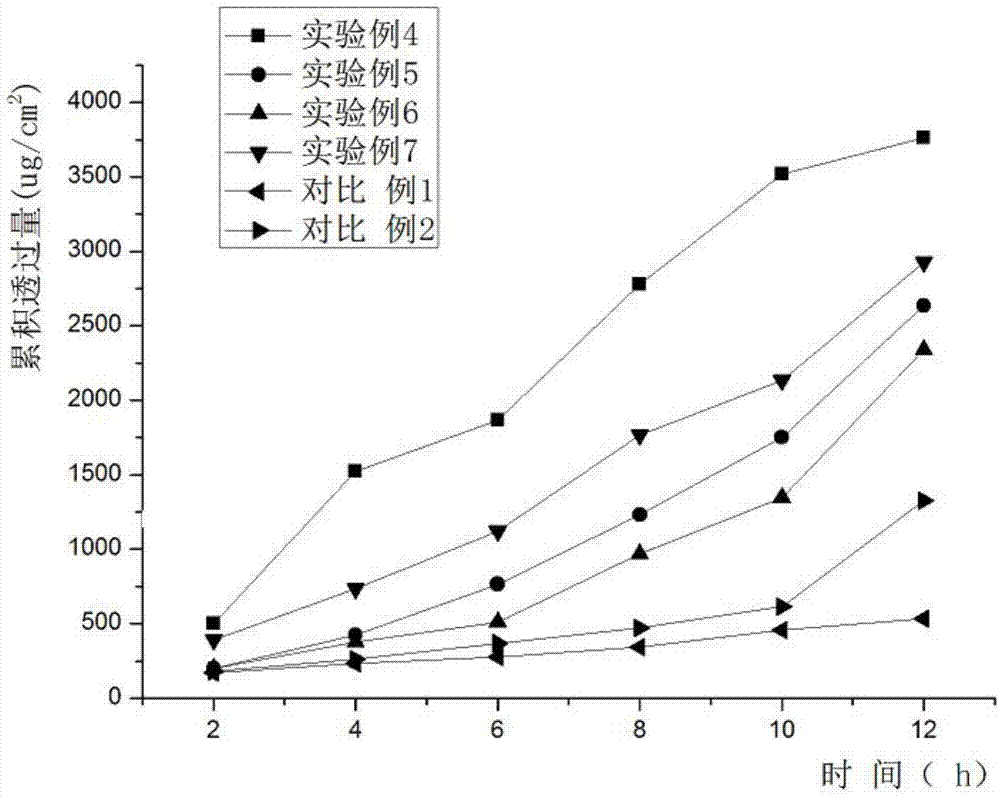

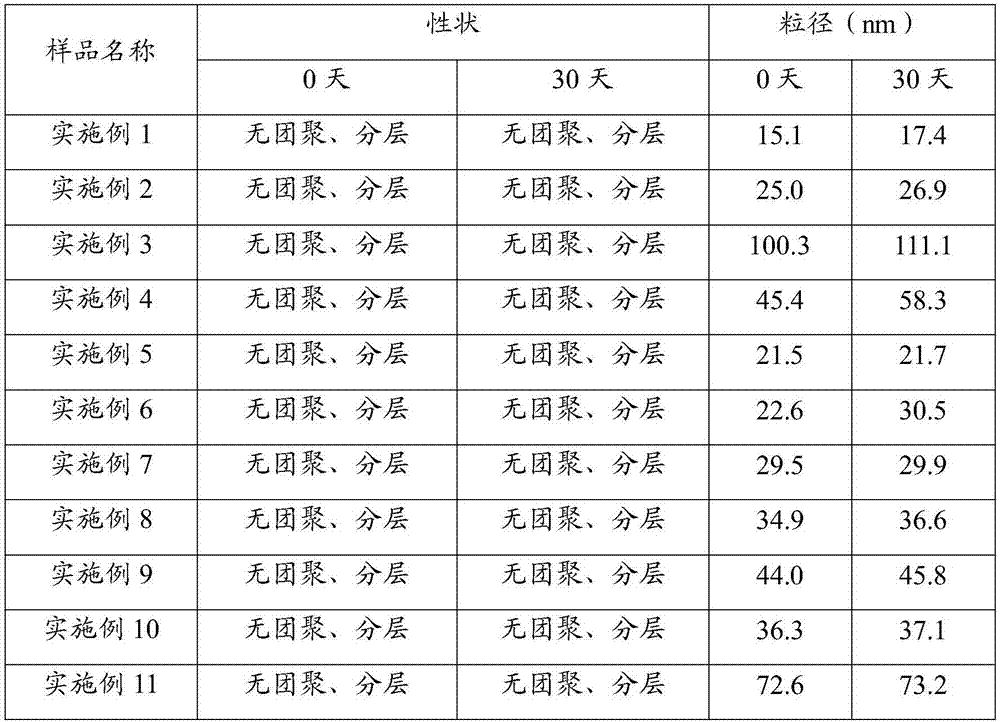

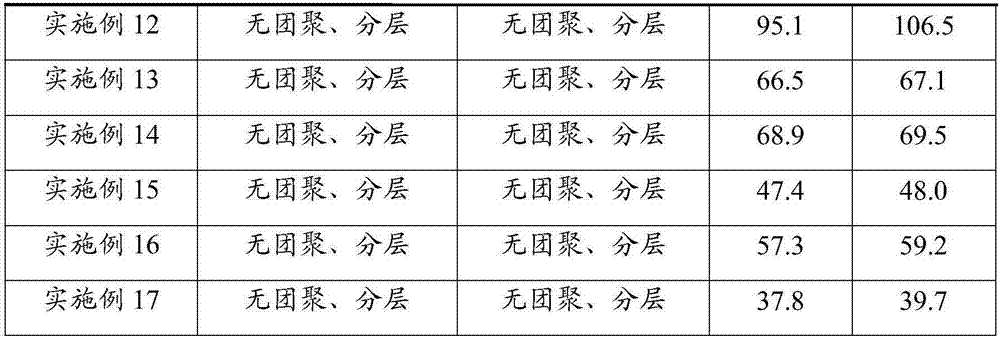

The invention provides a kaempferol nanometer composition, and belongs to the field of cosmetics. The kaempferol nanometer composition is prepared from, by mass percent, 0.1-10.0% of kaempferol, 8.0-70.0% of emulgator, 10.0-30.0% of co-emulsifier, 1.0-15.0% of liquid lipid, and 5.0-45.0% of polyhydric alcohols. In the invention, the emulsifier, the co-emulsifier, the liquid lipid, and the polyhydric alcohols are formed to be a homogeneous phase dispersing system with stable thermodynamics; thus the kaempferol nanometer composition is good in stability, quick in skin absorption, good in permeability, and excellent in biocompatibility; the synergistic effect of the emulsifier and the co-emulsifier can stabilize the active matter kaempferol; the provided kaempferol nanometer composition is big in drug carrying capacity, and the concentration of the kaempferol carrying with more active matters is up to 10.0%; the kaempferol nanometer composition used as a transdermal storage base can continuously release kaempferol, maintain effective concentration for a long time, inhibit 5 alpha-reductase activity better, and display the antibiosis and anti-oxidizing effects.

Owner:WUHAN BEST CARRIER NANO TECH

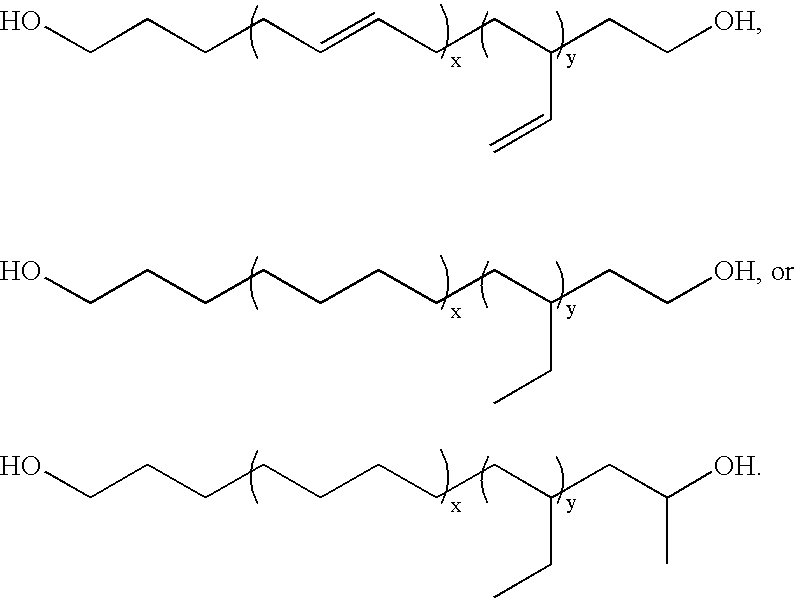

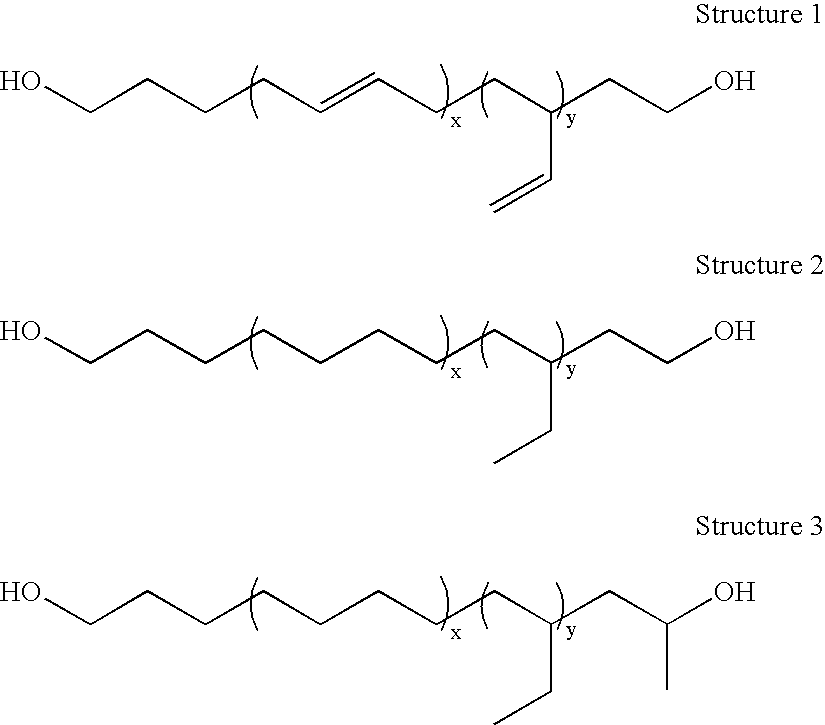

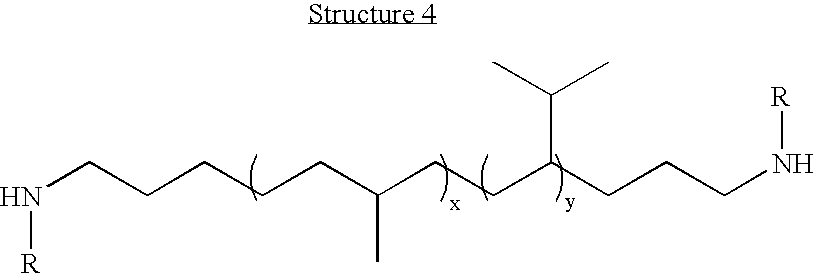

Monodisperse telechelic diol-based polyurethanes for use in golf balls

A golf ball including a core and a cover layer including a curing agent and a polyurethane prepolymer formed from a polyisocyanate and a monodisperse telechelic polyol having a polydispersity of from about 1.0 to about 1.3, and having the formula: T-Zn-C—Y—C-Zn-T where Y is at least one molecule or mixtures of molecules having at least two independently polymerized vinyl groups, such as 1,3-divinylbenzene or 1,4-divinylbenzene; C is a hydrogenated or unsaturated block derived by anionic polymerization of at least one monomer selected from the group consisting of conjugated dienes, alkenyl-substituted aromatics, and mixtures thereof; Zn is a branched or straight chain hydrocarbon connecting group which contains n=1-50 carbon atoms; and T is hydroxyl.

Owner:ACUSHNET CO

Neem oil nanometer composition, and preparation method and applications thereof

InactiveCN107468549AImprove stabilityGood mosquito repellentCosmetic preparationsAntipyreticSolubilityAlcohol

The invention provides a neem oil nanometer composition, and belongs to the field of cosmetic. The neem oil nanometer composition comprises, by weight, 1.0 to 30.0% of neem oil, 25.0 to 75.0% of an emulsifier, 0.8 to 17.0% of a co-emulsifier, 1.0 to 65.0% of a polyhydric alcohol, 0.01 to 2.0% of an anti-oxidant, and 0.01 to 4.0% of an antiseptic. According to a preparation method, a homogeneous disperse system with thermodynamic stability is formed by neem oil, the emulsifier, the co-emulsifier, and the polyhydric alcohol, water solubility is high, stability is high, no floating oil is generated, no aggregation is caused, and excellent mosquito repelling, bacteria inhibiting, inflammation relieving, and pain eliminating effects are achieved. The neem oil nanometer composition is high in drug loading capacity, is capable of entering skin deep tissue through skin stratum corneum, releasing neem oil continuously, and achieving excellent mosquito repelling, bacteria inhibiting, inflammation relieving, and pain eliminating effects.

Owner:WUHAN BEST CARRIER NANO TECH

Polyurethane composite material and application

InactiveUS20080319103A1Improve application performanceImpression capsDentistry preparationsThermoplastic polyurethaneSoft segment

The present invention discloses a Polyurethane (PU) composite material comprising a thermoplastic polyurethane and a filler. The thermoplastic polyurethane comprises a linear polyurethane main-chain, and the polyurethane main-chain comprises a soft segment and a hard segment. The hard segment of the polyurethane main-chain is formed by a diisocyanate and a chain extender, and the soft segment of the polyurethane main-chain is formed by a polyol. The present invention also teaches the application of the disclosed thermoplastic polyurethane composite material in dental root canal material.

Owner:NAT TAIWAN UNIV

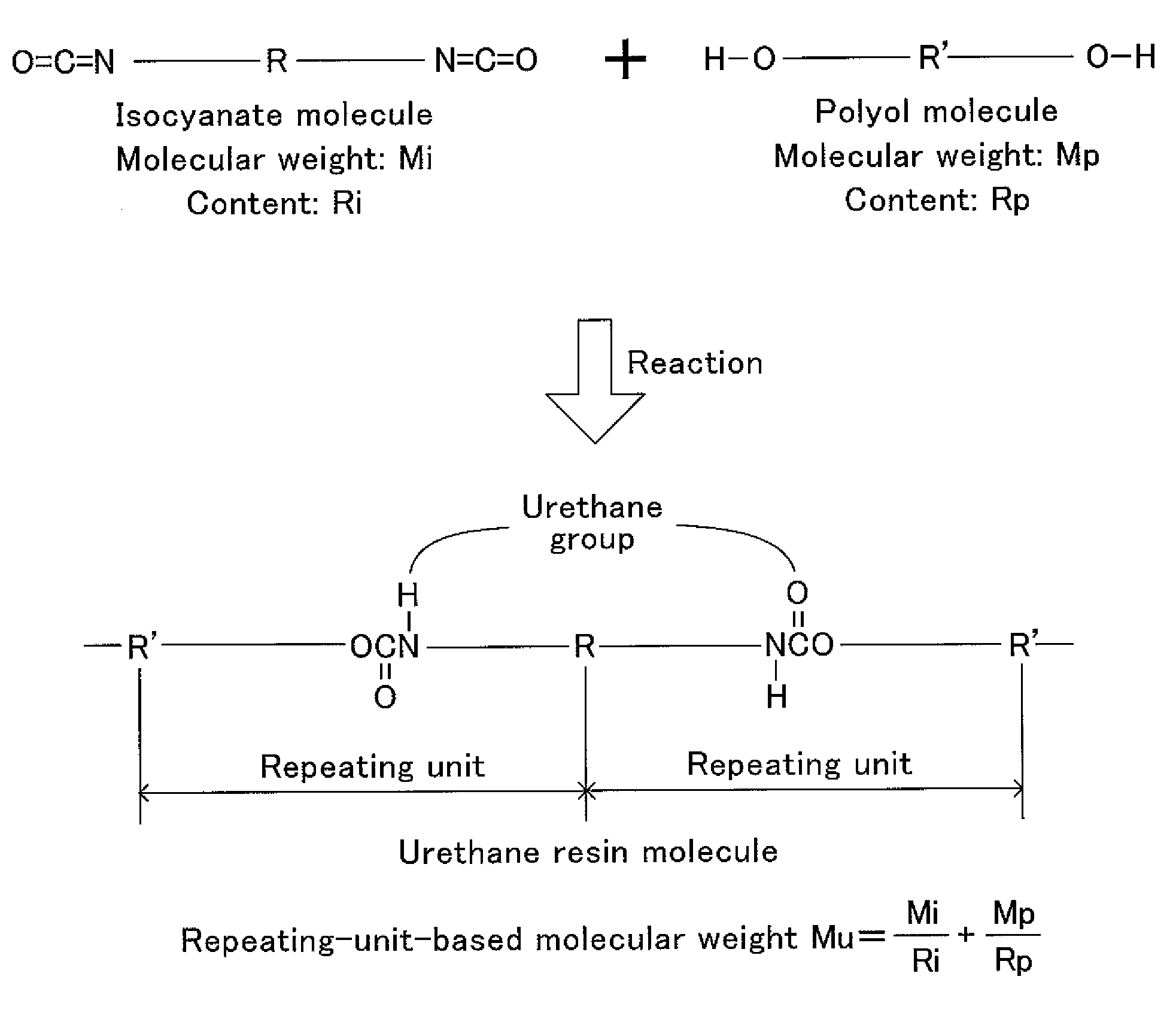

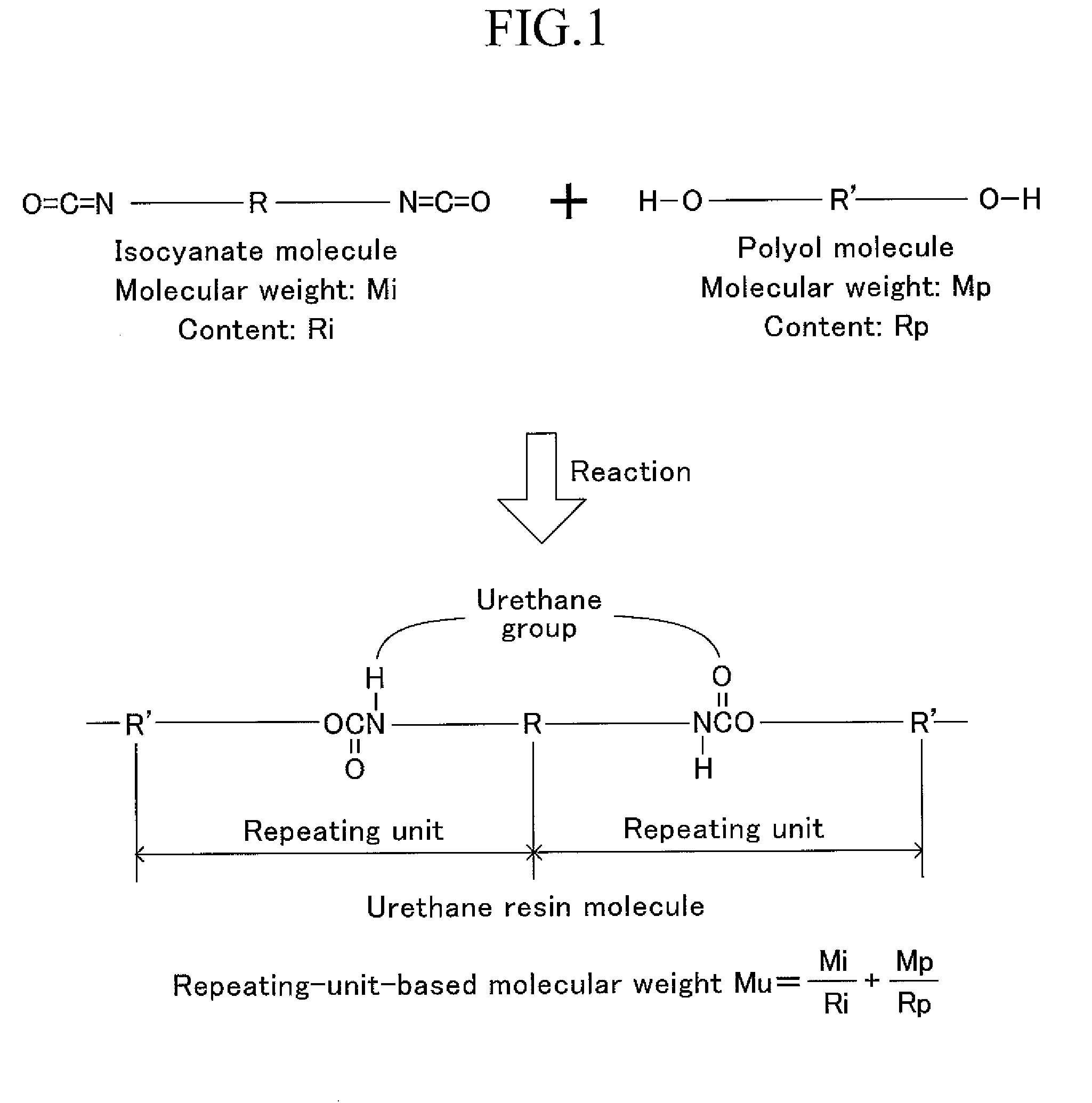

Ceramic green sheet and method for producing the same

ActiveUS20090209700A1Satisfactory plasticitySatisfactory propertyCeramic shaping apparatusCoatingsAdditive ingredientSlurry

The invention provides a ceramic green sheet having plasticity, punching property, and sinterability of satisfactory levels as well as a low percent (heat) shrinkage. In the production of a ceramic slurry serving as a raw material of the sheet, ingredients thereof are mixed under such conditions that the functional group ratio (polyol to isocyanate) is 1.5 / 11.5 to 11.5 / 11.5; the urethane resin formed from isocyanate and polyol has a repeating-unit-based molecular weight of 290 to 988; and the ratio by weight of the urethane resin to a ceramic powder falls within a range of 4.5 to 10 parts by weight of the urethane resin with respect to 100 parts by weight of the ceramic powder. As a result, a ceramic green sheet having, in well balance, all of the properties (i.e., plasticity, punching property, sinterability, and (heat) shrinkage) required for facilitating subsequent processes such as mechanical working and firing can be provided.

Owner:NGK INSULATORS LTD

Polycarbonate resin composition, molded article and structure member for solar photovoltaic power generation

ActiveUS8871836B2Improve flame retardant performanceImpact characteristicWood treatment detailsPhotovoltaicsFiberPolycarbonate

Provided are: a polycarbonate-based resin composition, including: (A) 100 parts by mass of a resin mixture formed of: 30 to 100 mass % of a PC-POS copolymer (A-1) which has constituent units represented by a general formula (I) and a general formula (II), and in which an average repetition number n of organosiloxane constituent units in the general formula (II) is 70 to 500; and 70 to 0 mass % of an aromatic polycarbonate resin (A-2) except the PC-POS copolymer (A-1); (B) 0.01 to 0.15 part by mass of an alkaline (earth) metal salt of an organic sulfonic acid; (C) 0.1 to 1 part by mass of a polytetrafluoroethylene having a fibril-forming ability; and (D) 2 to 15 parts by mass of titanium dioxide particles each having, on an outermost surface thereof, a coating layer formed of a polyol free of a nitrogen atom; a molded article obtained by molding the resin composition; and a structure member for solar photovoltaic power generation formed of the molded article. The polycarbonate-based resin composition, molded article, and structure member for solar photovoltaic power generation each have excellent flame retardancy and excellent tracking resistance without impairing a low-temperature impact characteristic which a PC-POS copolymer has.

Owner:IDEMITSU KOSAN CO LTD

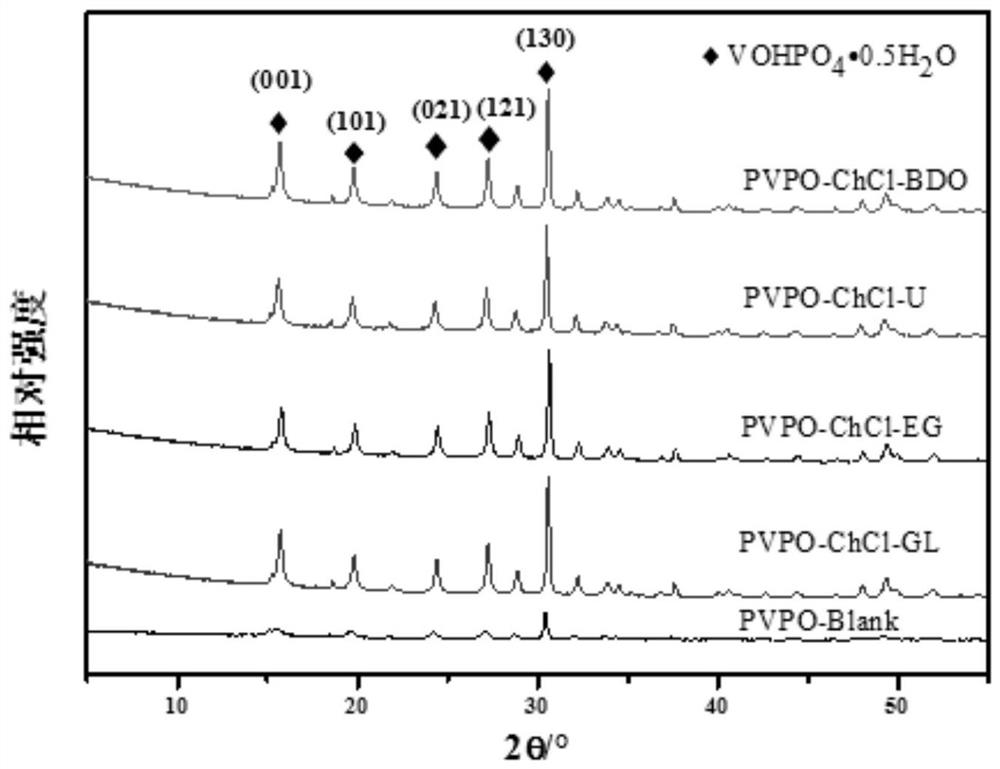

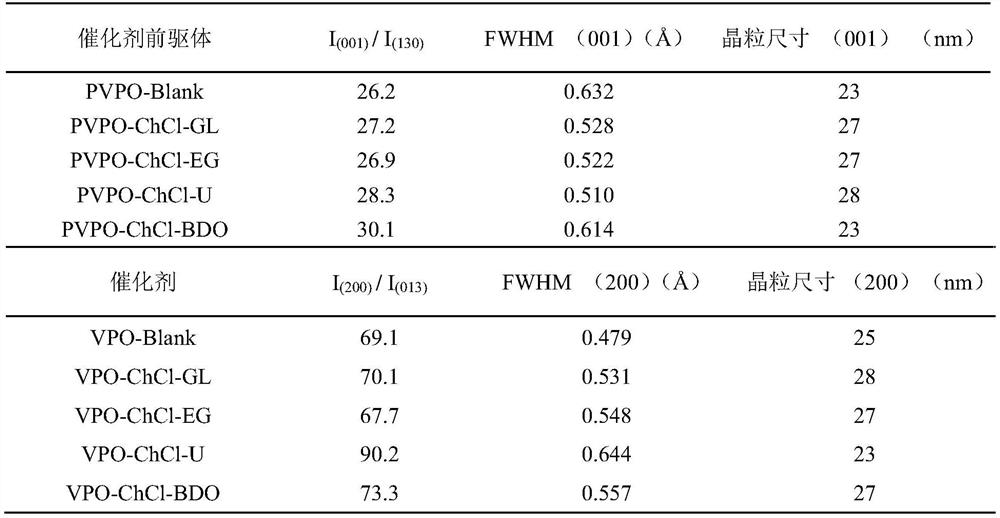

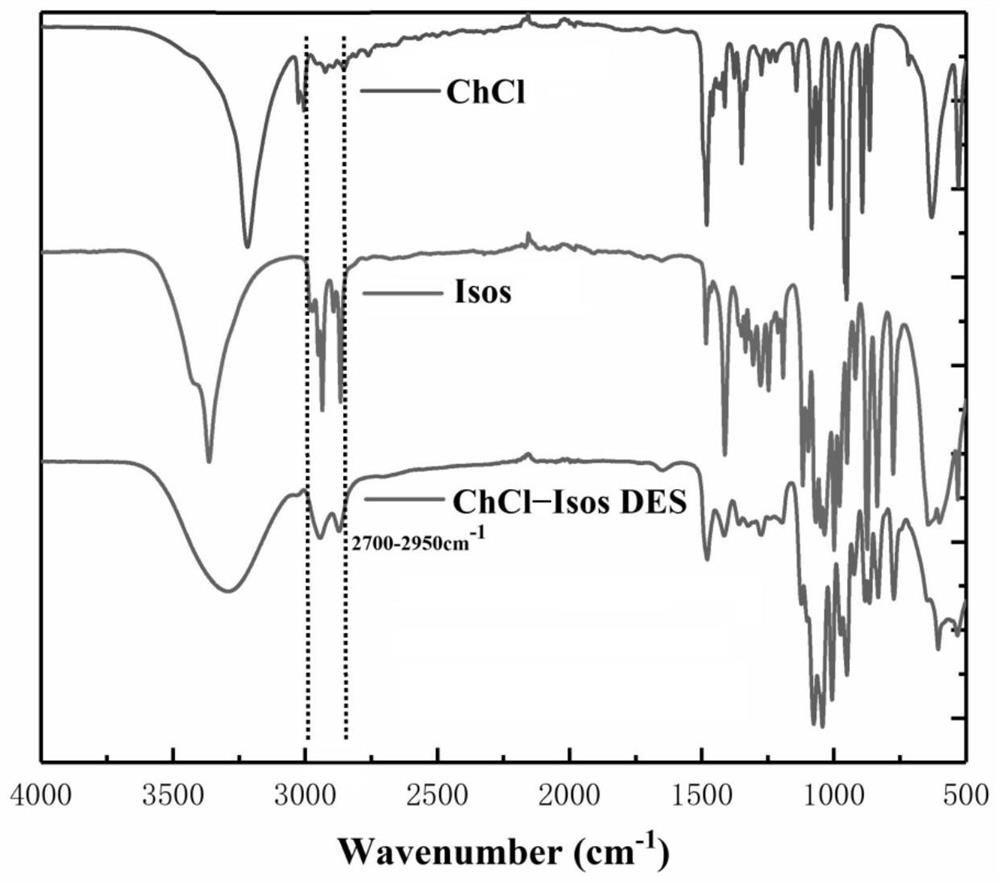

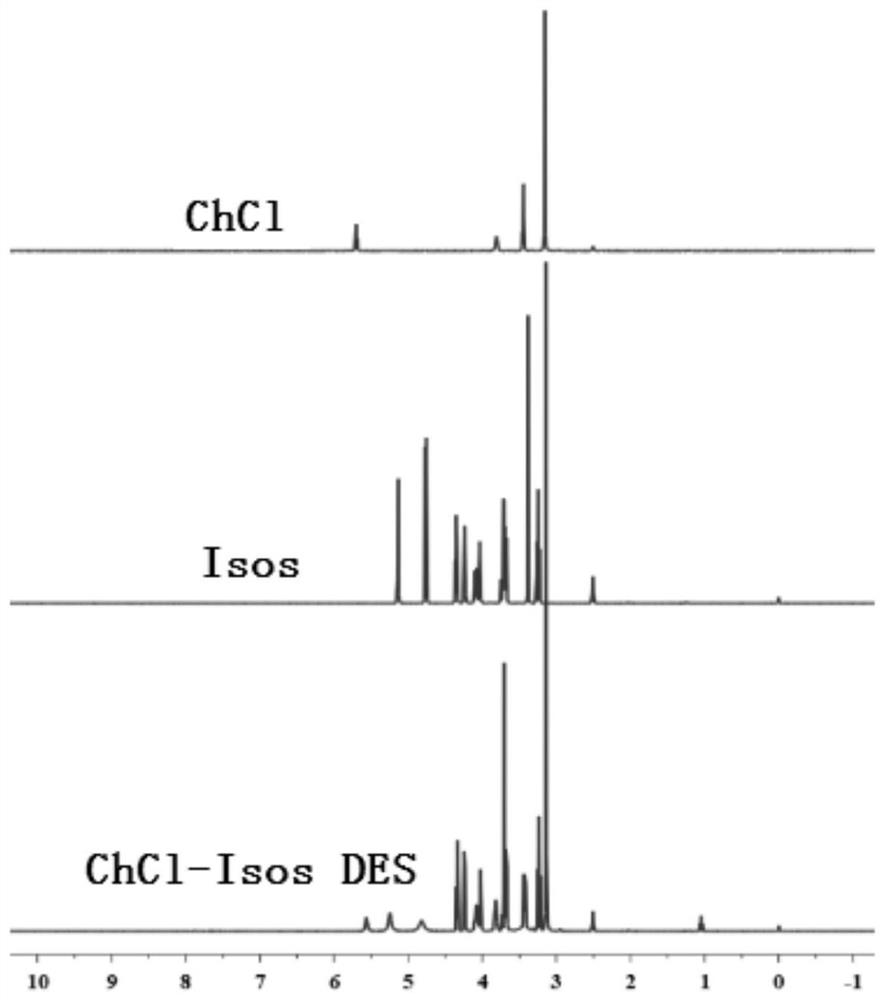

Preparation method and application of vanadyl phosphate catalyst

ActiveCN108246325AEasy to synthesizeChange shapeOrganic chemistryCatalyst activation/preparationCongruent meltingPhosphate

The invention relates to a vanadyl phosphate catalyst, an intensified preparation method by low congruent melting solvent, and application of the vanadyl phosphate catalyst. The method comprises the following steps: 1) mixing a vanadium source, low congruent melting solvent, benzyl alcohol and C3-C8 monohydric alcohol to obtain mixed materials, and reacting, wherein the low congruent melting solvent is formed by choline chloride and organic polyhydric alcohols; 2) mixing a reaction product obtained in 1) with a phosphorus source, raising the temperature to 100-200DEG C, and continuously reacting to obtain a vanadyl phosphate precursor; 3) roasting to obtain the vanadyl phosphate catalyst. The method is characterized in that green and low-price low congruent melting solvent is subjected tointensified preparation to obtain the vanadyl phosphate catalyst, the defects of secondary pollution, high cost, complex preparation process and the like since the performance of the vanadyl phosphatecatalyst is improved on the basis of noble metal are overcome. When the vanadyl phosphate catalyst is used for catalytic normal butane selectivity oxidation maleic anhydride reaction, the difficulties including low yield, poor selectivity and the like, are solved, and defects of high cost and serious pollution in a traditional catalyst improvement method are overcome.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Cleaning blade member

InactiveUS20050268424A1Improve wear resistanceBrushesWork treatment devicesPolycarbonateUltimate tensile strength

A cleaning blade member comprising a polyurethane formed by using a polyol consisting essentially of a polycarbonatediol, a polyisocyanate, and a crosslinking agent containing a short chain diol and a triol, the polyurethane having a tensile strength at 60° C. of 200 kg / cm2 or higher, and a tensile strength retention ΔT, represented by the following equation, of 40% or more: ΔT(%)=T60 / T10×100 where T10 denotes a tensile strength at 10° C., and T60 denotes the tensile strength at 60° C.

Owner:SYNZTEC

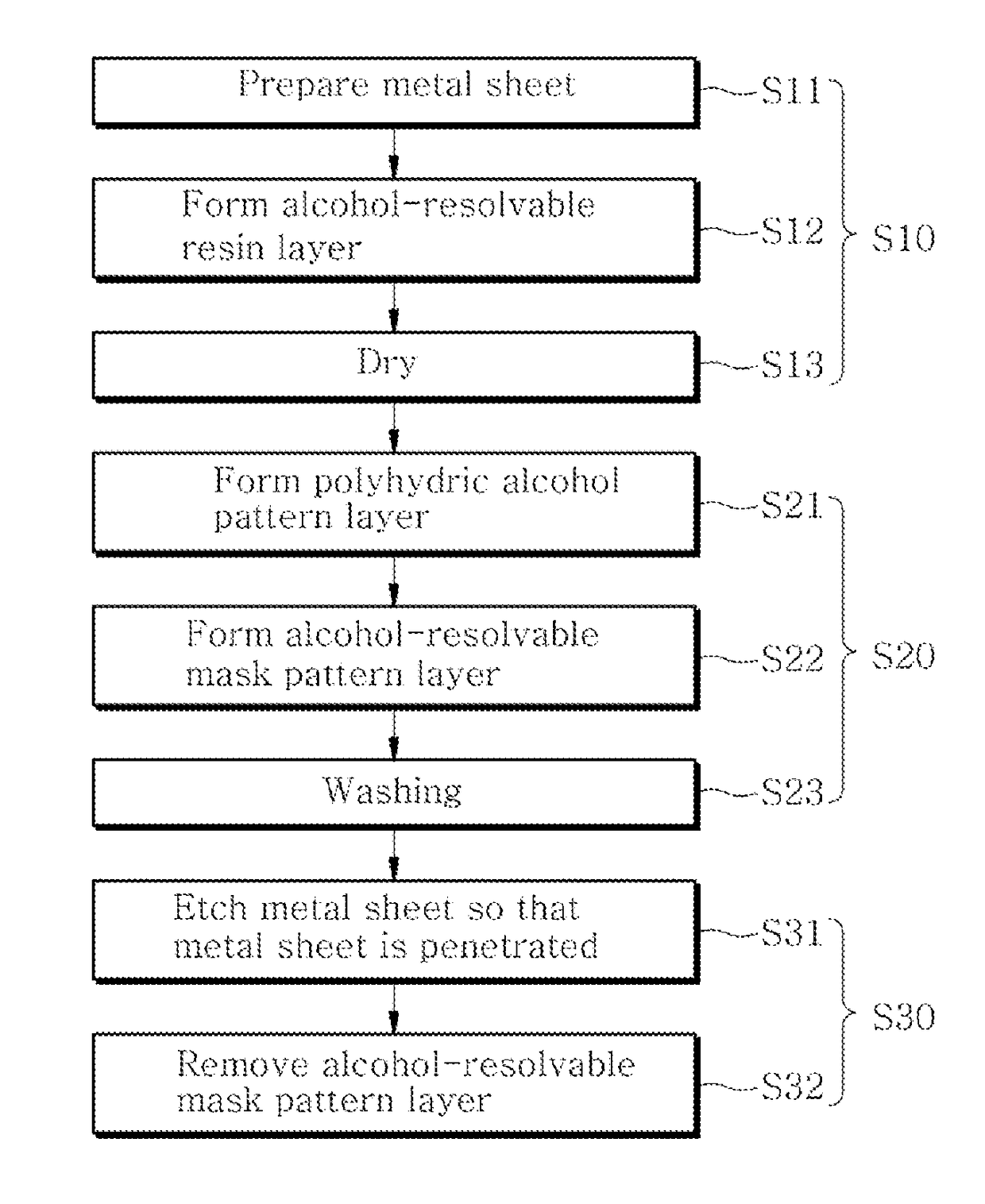

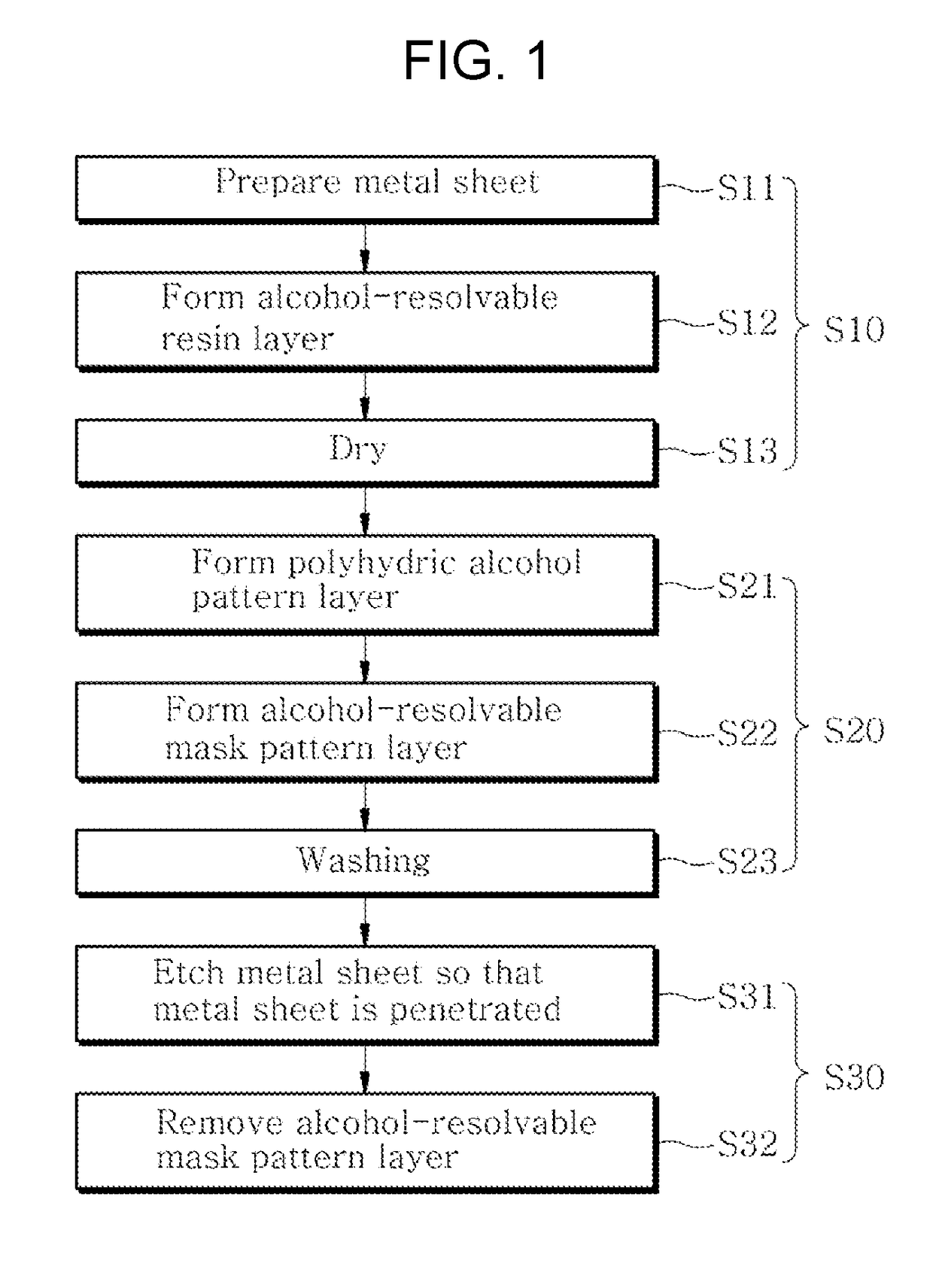

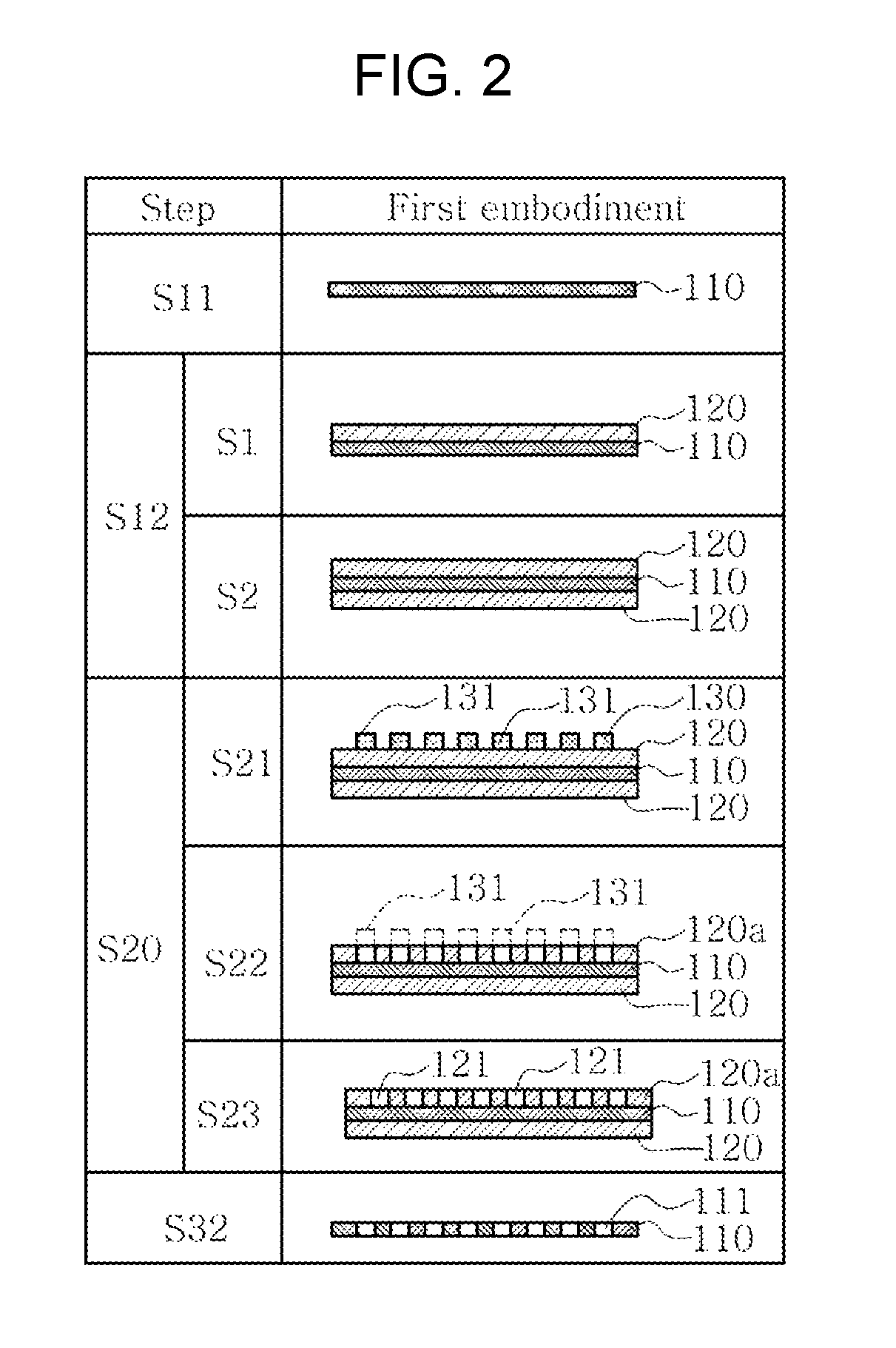

Method of manufacturing porous current collector

ActiveUS10096433B1Reduce manufacturing costImprove productivityHybrid capacitor electrodesElectrode carriers/collectorsMetal sheetMaterials science

Provided is a method of manufacturing a porous current collector, which can fabricate a porous current collector in such a way as to fabricate alcohol-resolvable resin as an etch mask pattern by printing polyhydric alcohol on a surface of the alcohol-resolvable resin in a pattern and to form a plurality of through holes in a metal sheet using the etch mask pattern. The method includes the steps of forming an alcohol-resolvable resin layer by coating alcohol-resolvable resin on a surface of a metal sheet, forming an alcohol-resolvable mask pattern layer by printing polyhydric alcohol on a surface of the alcohol-resolvable resin layer after the alcohol-resolvable resin layer is formed, and etching the metal sheet so that a plurality of through holes is formed in the metal sheet using the alcohol-resolvable mask pattern layer as a mask after the alcohol-resolvable pattern layer is formed.

Owner:KOREA JCC CO LTD

Cleaning blade member

InactiveUS7645849B2Improve wear resistanceVehicle cleaningElectrography/magnetographyPolycarbonateUltimate tensile strength

A cleaning blade member comprising a polyurethane formed by using a polyol consisting essentially of a polycarbonatediol, a polyisocyanate, and a crosslinking agent containing a short chain diol and a triol, the polyurethane having a tensile strength at 60° C. of 200 kg / cm2 or higher, and a tensile strength retention ΔT, represented by the following equation, of 40% or more:ΔT(%)=T60 / T10×100where T10 denotes a tensile strength at 10° C., and T60 denotes the tensile strength at 60° C.

Owner:SYNZTEC

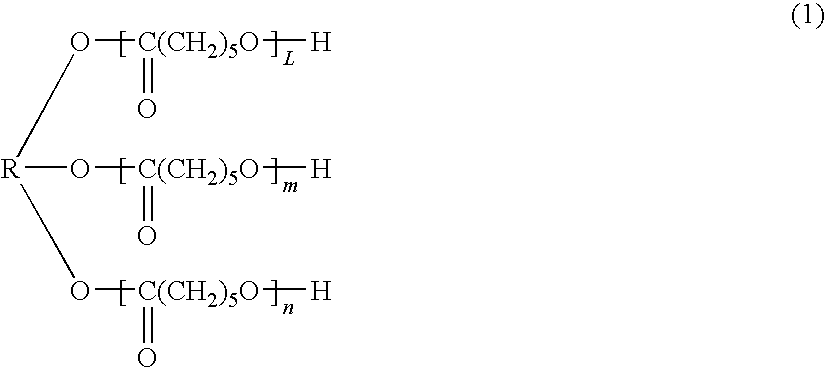

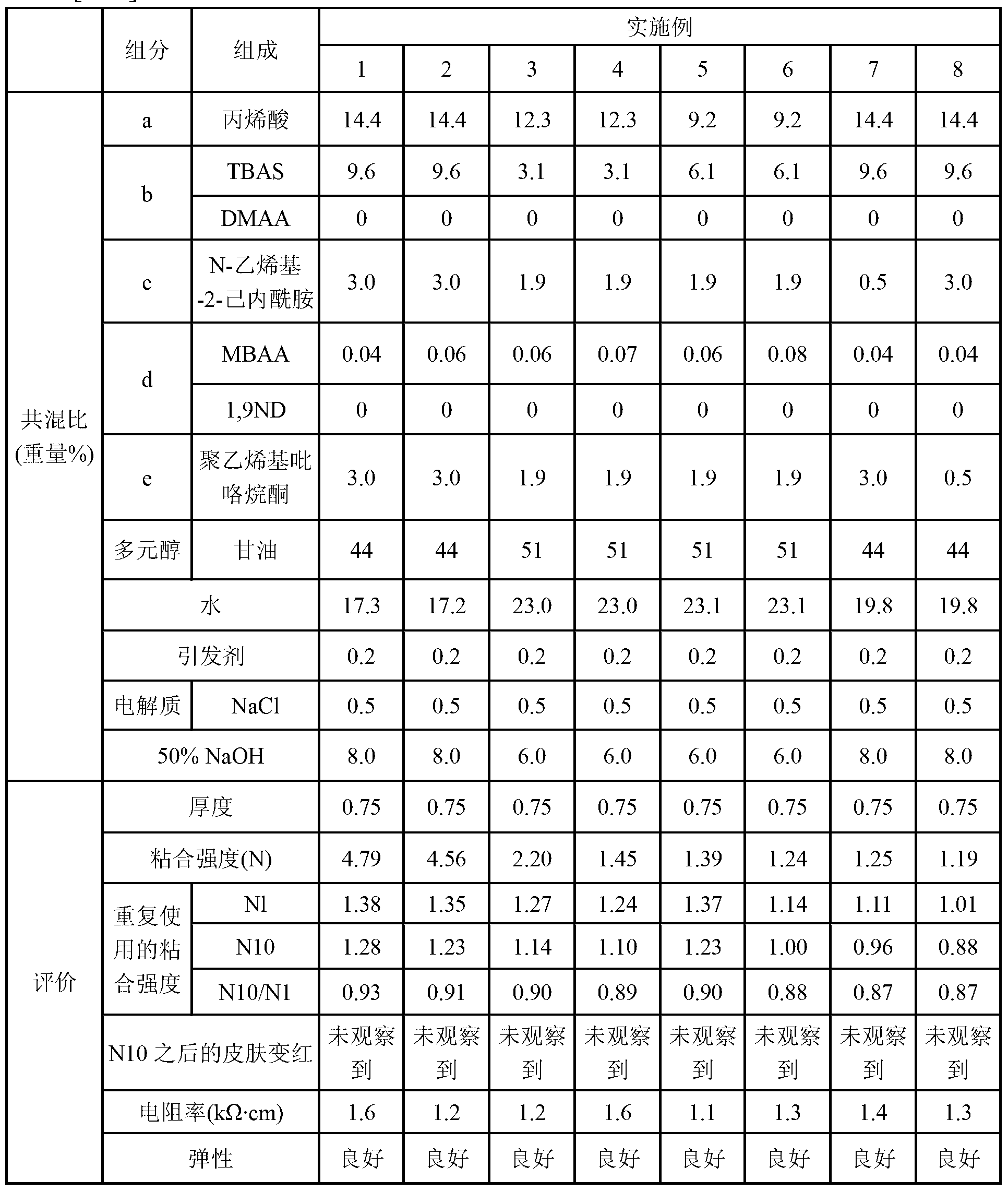

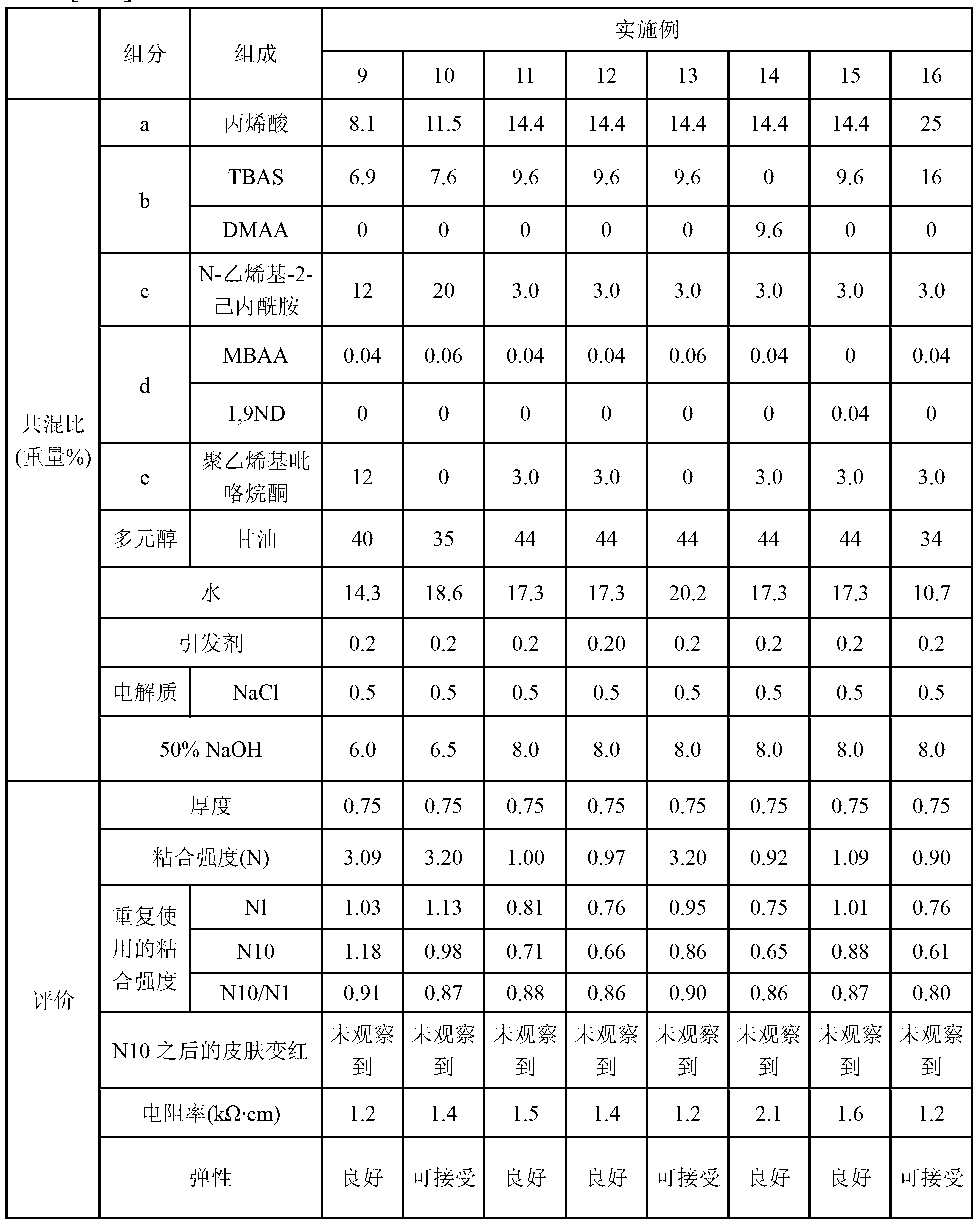

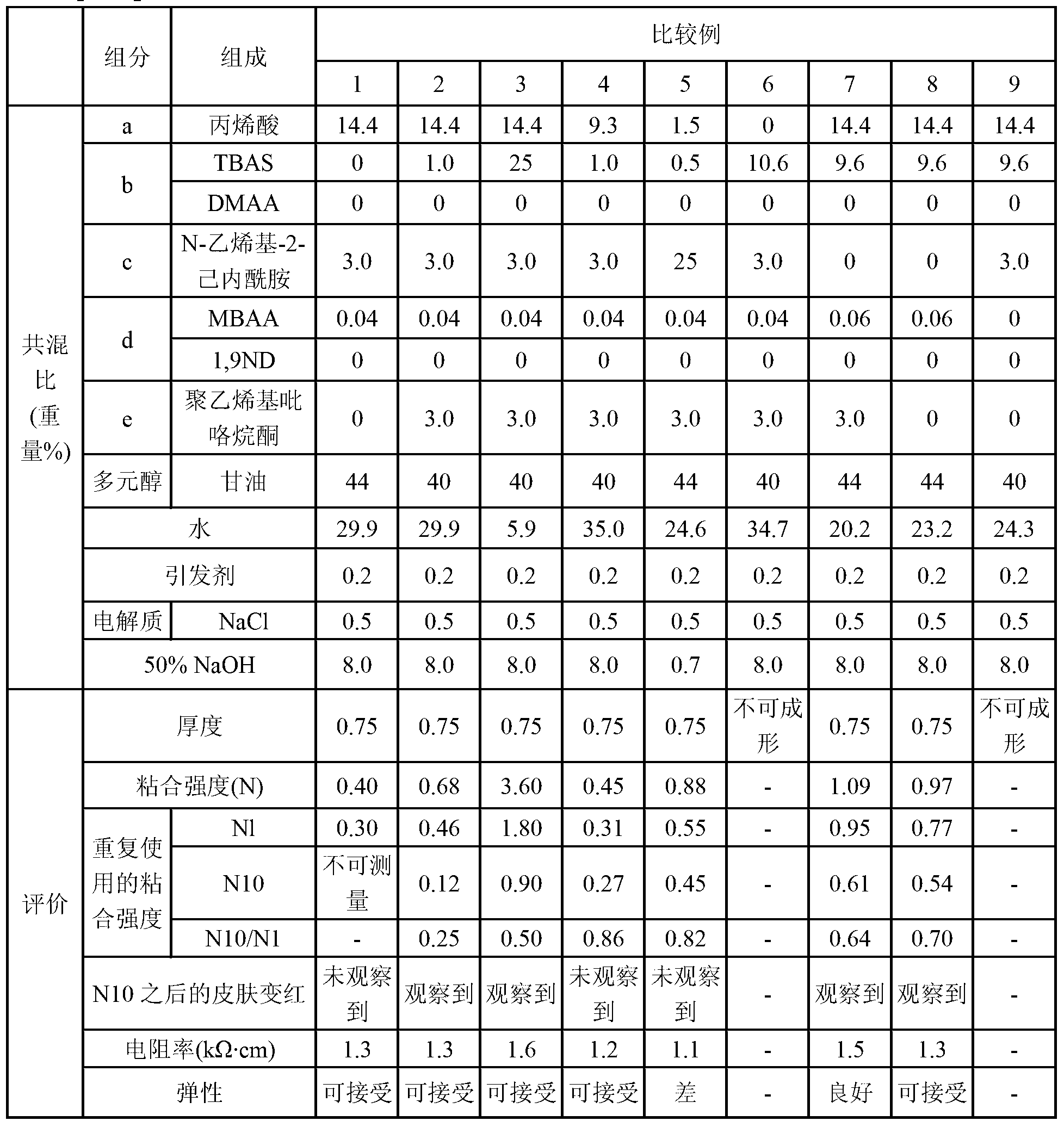

Composition for adhesive hydrogel and use thereof

ActiveCN103282458AImprove adhesionReduce stimulationCosmetic preparationsNon-macromolecular adhesive additivesPolymer scienceMeth-

The purpose of the present invention is to provide a composition for an adhesive hydrogel that shows adhesiveness appropriate for repeated use without requiring a special procedure such as rinsing with water and that has particularly weak skin irritability, and also to provide a use thereof (for instance, an adhesive hydrogel, gel sheet, or electrode). The present invention is a composition for an adhesive hydrogel formed from at least a polymer matrix forming material, water, and a polyvalent alcohol. The polymer matrix forming material is formed from at least: (a) a (meth)acrylic acid, a (meth)acrylic acid derivative, or a C4-5 vinyl derivative having two carboxyl groups; (b) a (meth)acrylamide or (meth)acrylamide derivative; (c) N-vinyl-2-caprolactam and / or N-vinyl-2-valerolactam; and (d) a crosslinkable monomer, wherein the content of (b) in the adhesive hydrogel composition is 2 to 20 wt%.

Owner:SEKISUI PLASTICS CO LTD

Fiber coatings with low young's modulus and high tear strength

Fiber coatings with low Young's modulus and high tear strength are realized with coating compositions that include an oligomeric material formed from an isocyanate, a hydroxy acrylate compound and a polyol. The oligomeric material includes a polyether urethane acrylate and a di-adduct compound, where the di-adduct compound is present in an amount of at least 2.35 wt%. The reaction mixture used to form the oligomeric material may include a molar ratio of isocyanate:hydroxy acrylate:polyol of n:m:p, where n may be greater than 3.0, m may be between n-1 and 2n-4, and p may be 2. Young's modulus and tear strength of coatings made from the compositions increase with increasing n. Coatings formed from the present oligomers feature high tear strength for a given Young's modulus.

Owner:CORNING INC

Thermoplastic polyurethane yarn and fabric manufactured therefrom

InactiveCN111936679AFast crystallizationEasy to stretchMonocomponent polyurethanes artificial filamentWoven fabricsYarnPolymer science

Disclosed are: a thermoplastic polyurethane yarn in which, in a thermoplastic polyurethane composition composed of isocyanate, glycol, and polyol, succinate is used as polyol, and when the isocyanate,glycol, and succinate are polymerized, a nano-silica having a particle size of 100 nm or less is mixed, and thus a crystallization rate during melt extrusion is increased such that the yarn can be continuously spun without being cut during cooling and drawing processes and has stretch and recovery characteristics; and a fabric manufactured from the yarn.

Owner:朴喜大

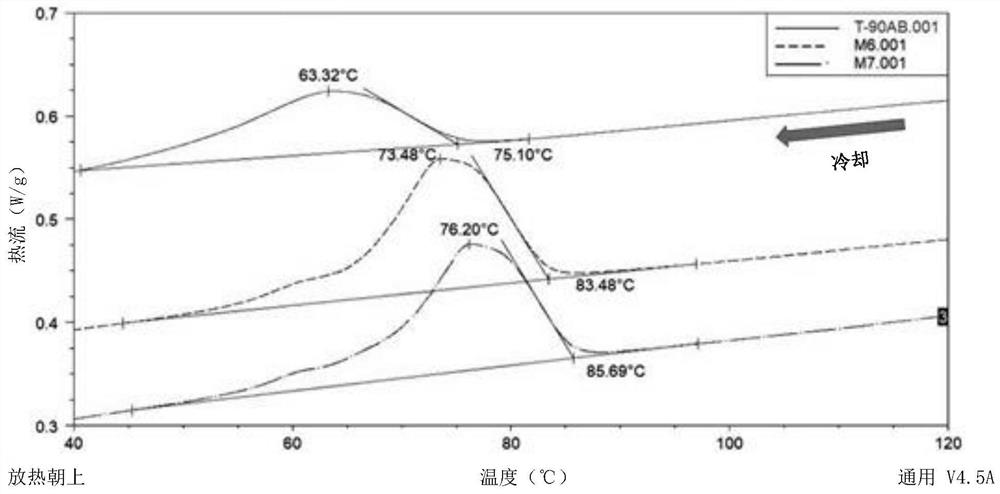

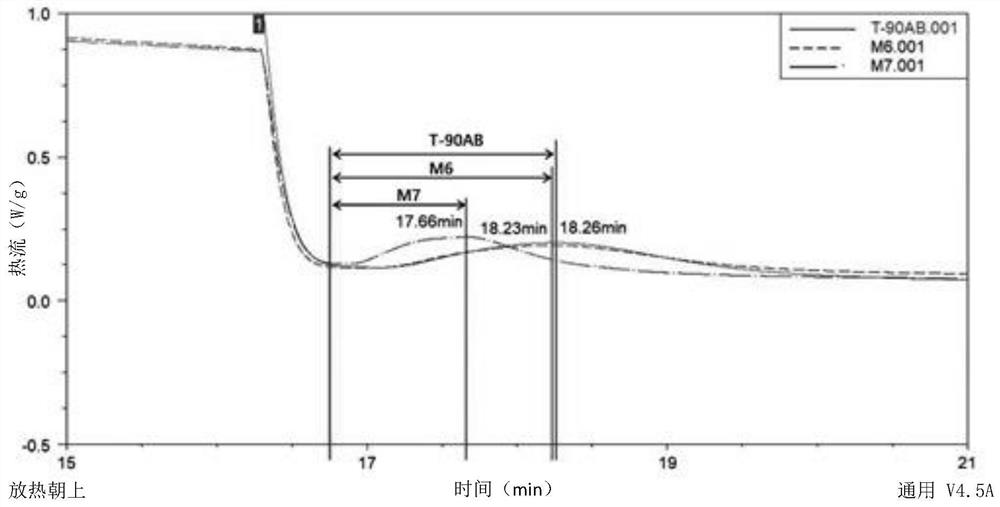

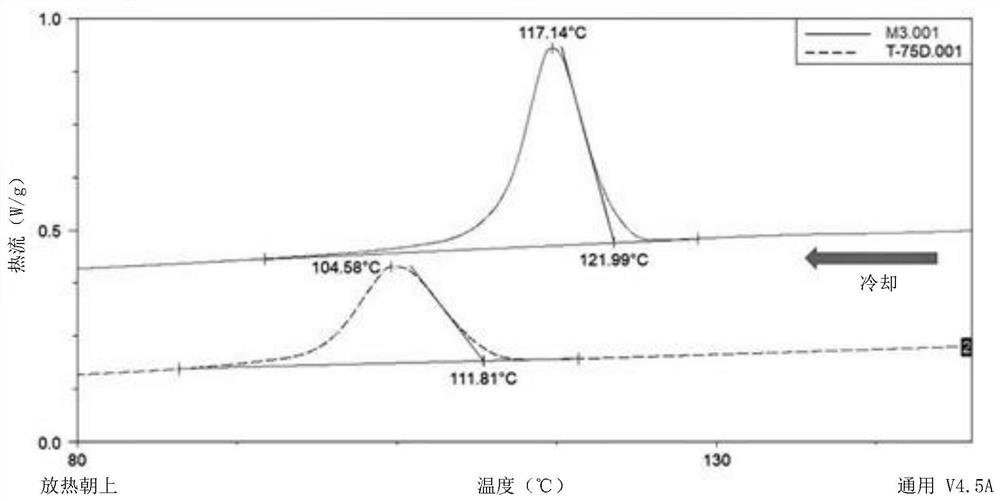

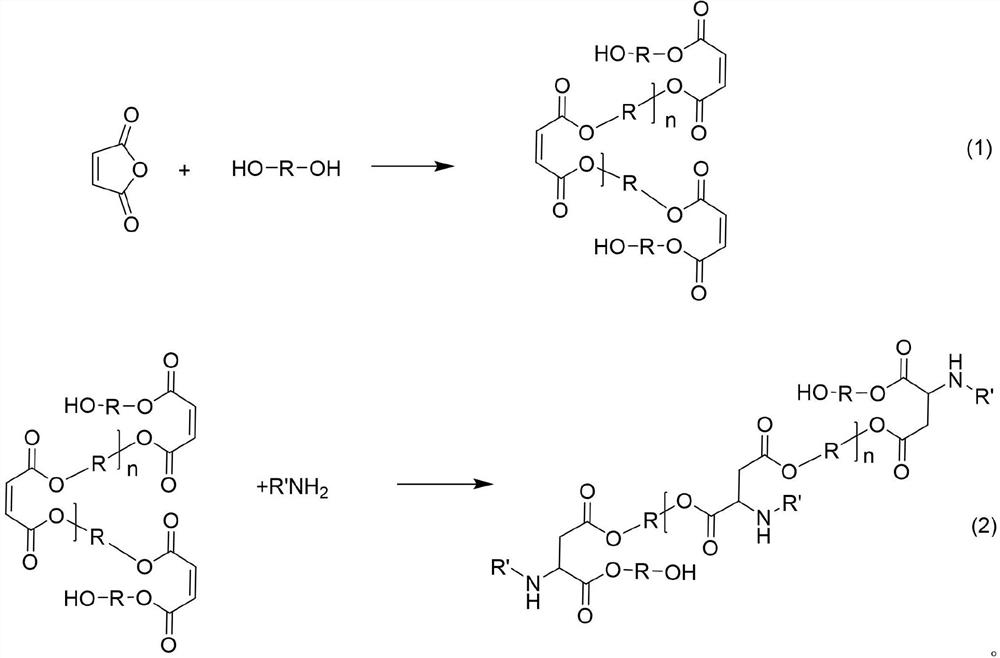

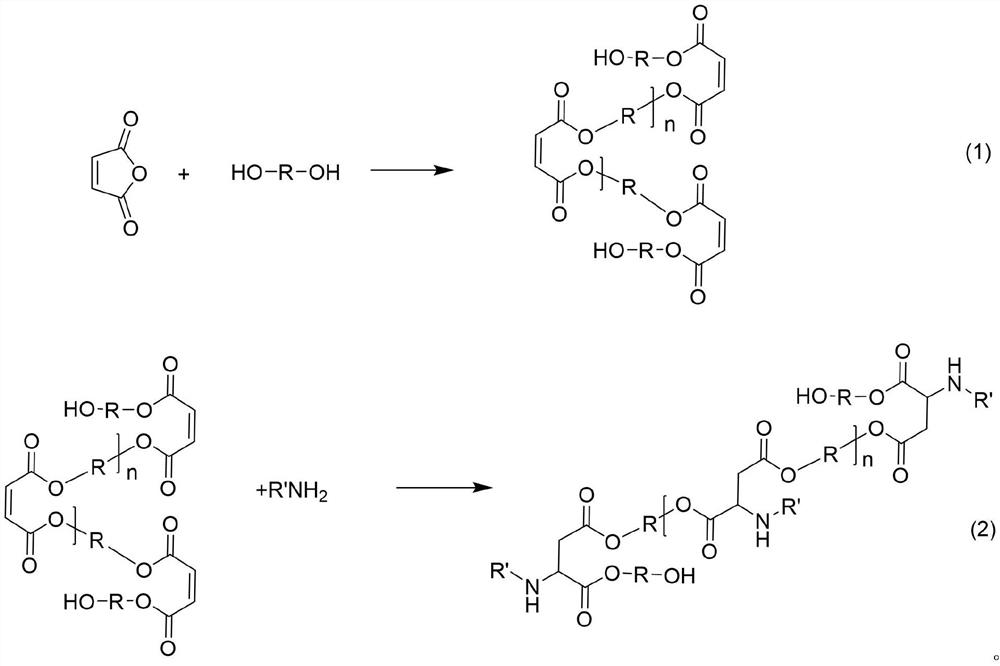

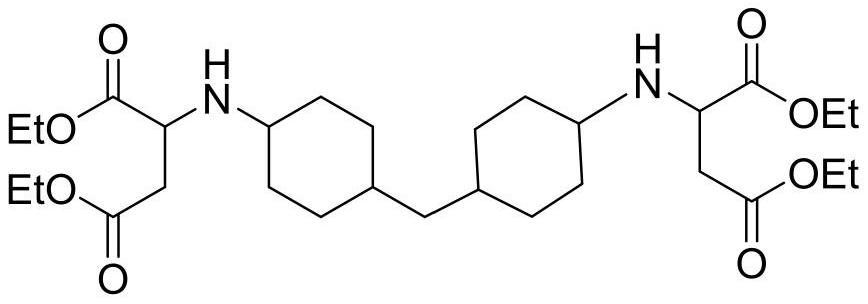

Preparation method of oligomerization aspartic resin

PendingCN112552195AImprove performanceIncrease crosslink densityOrganic compound preparationCarboxylic acid esters preparationPolyesterPolymer science

The invention discloses a preparation method of oligomerization aspartic resin. The preparation method comprises the following steps: maleic anhydride and dihydric alcohol or polyhydric alcohol form hydroxyl-terminated oligomerization polyester with the polymerization degree of 2-10; and then carrying out Michael addition reaction on the polyester by sterically hindered primary amine to synthesizethe oligomeric polyfunctional aspartic resin. By synthesizing the polyfunctional aspartic resin, namely improving the functionality of secondary amine in the polyaspartic acid ester, the crosslinkingdensity of the polyaspartic acid ester polyurea can be increased, so that the performance of the polyaspartic acid ester polyurea in an extreme environment is improved.

Owner:深圳飞扬兴业科技有限公司

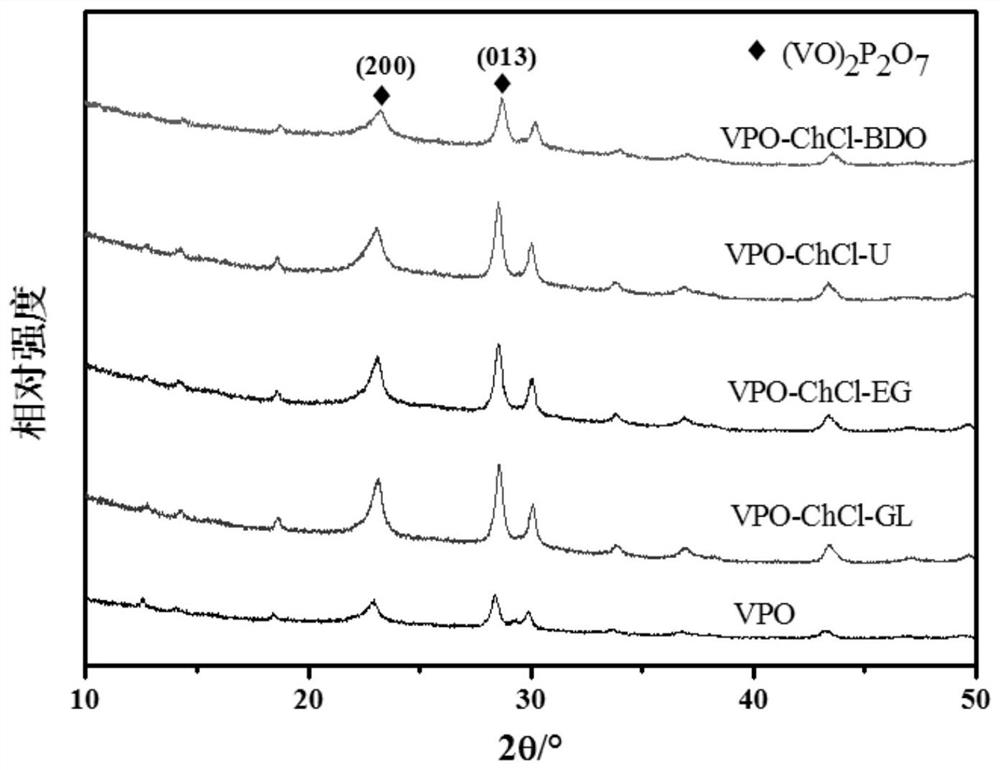

Method for regulating and controlling activity of vanadium phosphorus oxide catalyst and application thereof

ActiveCN113058625AHigh activityHigh selectivityOrganic chemistryCatalyst activation/preparationPtru catalystPhysical chemistry

The invention relates to a method for regulating and controlling the activity of a vanadium phosphorus oxide catalyst. The method comprises the following steps that a vanadium phosphorus oxide precursor is prepared; in a ball milling tank, the vanadium phosphorus oxide precursor and a deep eutectic solvent are mixed according to the mass ratio of (20-100): 1, balls are added according to the ball-powder mass ratio of 1: (0.5-2), then a ball mill is used for ball milling for 4-8 h, a ball milling product is obtained, and the deep eutectic solvent is formed by choline chloride and organic polyol; and the ball milling product isactivated to obtain the vanadium phosphorus oxide catalyst. According to the method, the deep eutectic solvent is regulated and added, so that the activity and selectivity of the vanadium phosphorus oxide catalyst product are remarkably improved compared with those of the existing catalyst, the cost is low, the method is convenient and fast, and the method has important significance on industrial production.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

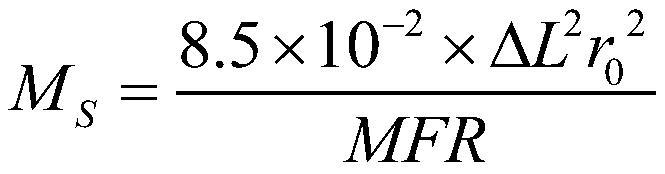

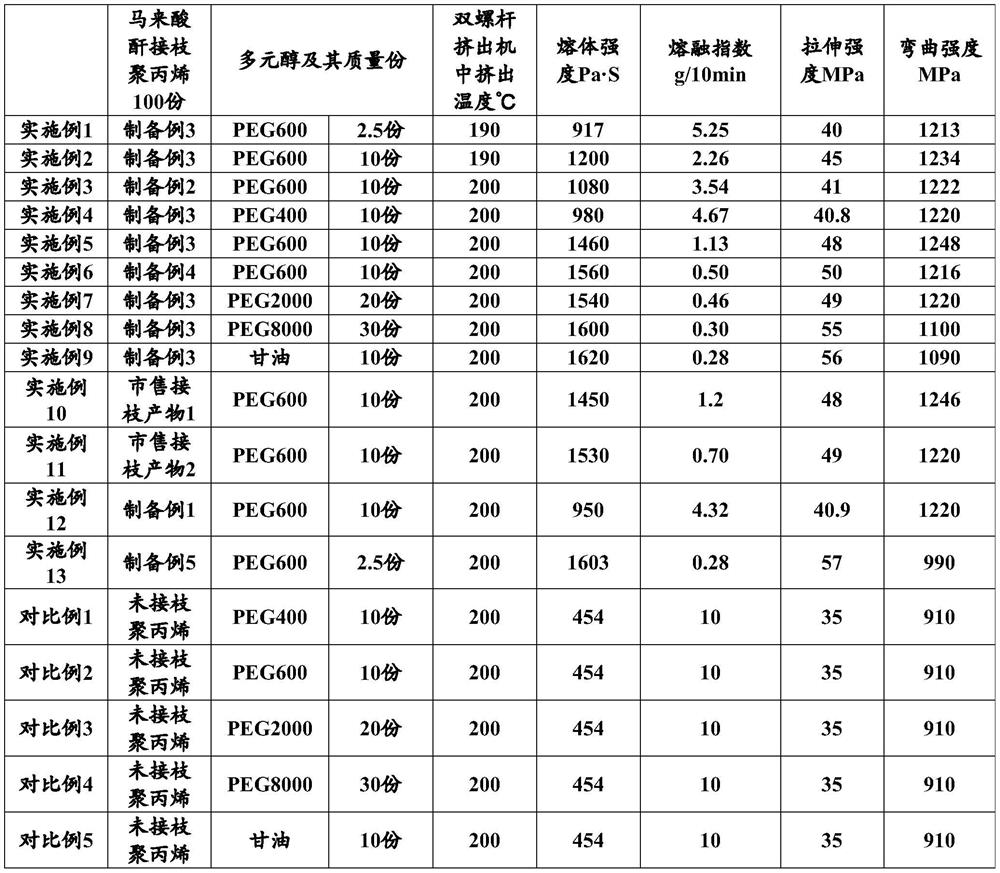

High-melt-strength polypropylene as well as preparation method and application thereof

ActiveCN112080100AImprove melt strengthImprove mechanical propertiesPolymer scienceReaction temperature

The invention provides high-melt-strength polypropylene as well as a preparation method and application thereof. According to the invention, special short branched chain maleic anhydride introduced into a polypropylene molecular chain is used as an active group, an anhydride group on a short branched chain reacts with an alcoholic hydroxyl group in a polyol molecule, and polyol is grafted to forma three-dimensional network structure, so that the polypropylene with high melt strength is prepared. The polypropylene also has excellent mechanical properties such as tensile strength, bending strength and the like. According to the invention, maleic anhydride grafted polypropylene is innovatively used as a matrix, short-chain branch maleic anhydride in a molecular chain is used as an active group, maleic anhydride reacts with alcoholic hydroxyl groups in polyol molecules, and high-melt-strength polypropylene is prepared by changing the structure of linear polypropylene; the method is carried out under mild conditions, the reaction temperature is low, the reaction time is short, and the degradation of the polypropylene molecular weight caused by high temperature is avoided, thereby avoiding influencing the mechanical properties of the product.

Owner:INST OF CHEM CHINESE ACAD OF SCI

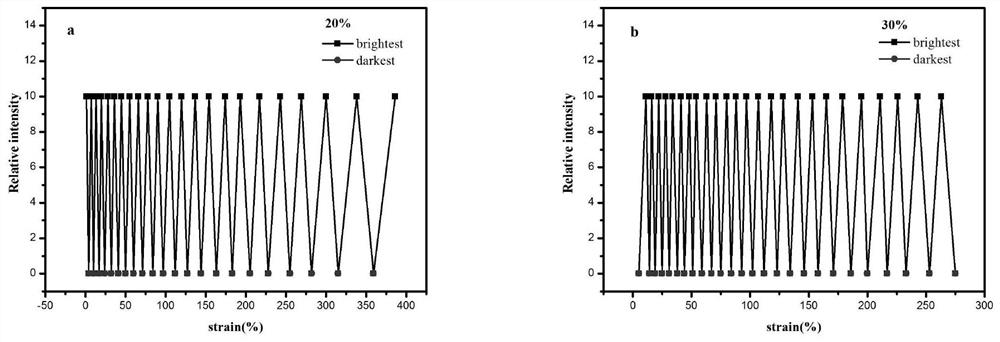

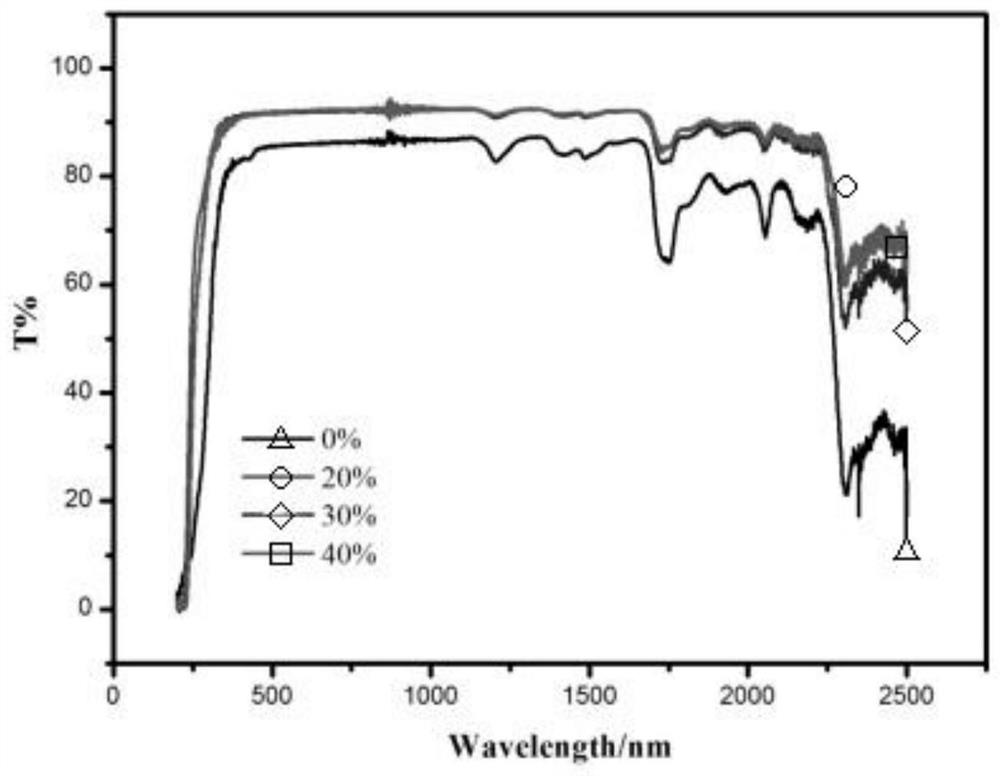

Optical rotation film, preparation method thereof and photoelectric device

PendingCN113534316AImprove mechanical propertiesDurablePolarising elementsOptical polarizationMaterials science

The invention relates to an optical rotation film. The optical rotation film is made of polyurethane, the polyurethane comprises a soft segment and a hard segment, and the soft segment is composed of a molecular chain formed by chiral polyalcohol. According to the optical rotation film, the polarization direction of linear polarized light can be controlled through strain, the adjusting range of the direction is 0-360 degrees, the polarized light penetrating through the optical rotation film can be reduced to 0 from the strongest light intensity so that brightness changes can be achieved in a photoelectric device, and in the dynamic stretching process, the changes can be periodically repeated. The invention also relates to a preparation method of the optical rotation film and a photoelectric device using the optical rotation film.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

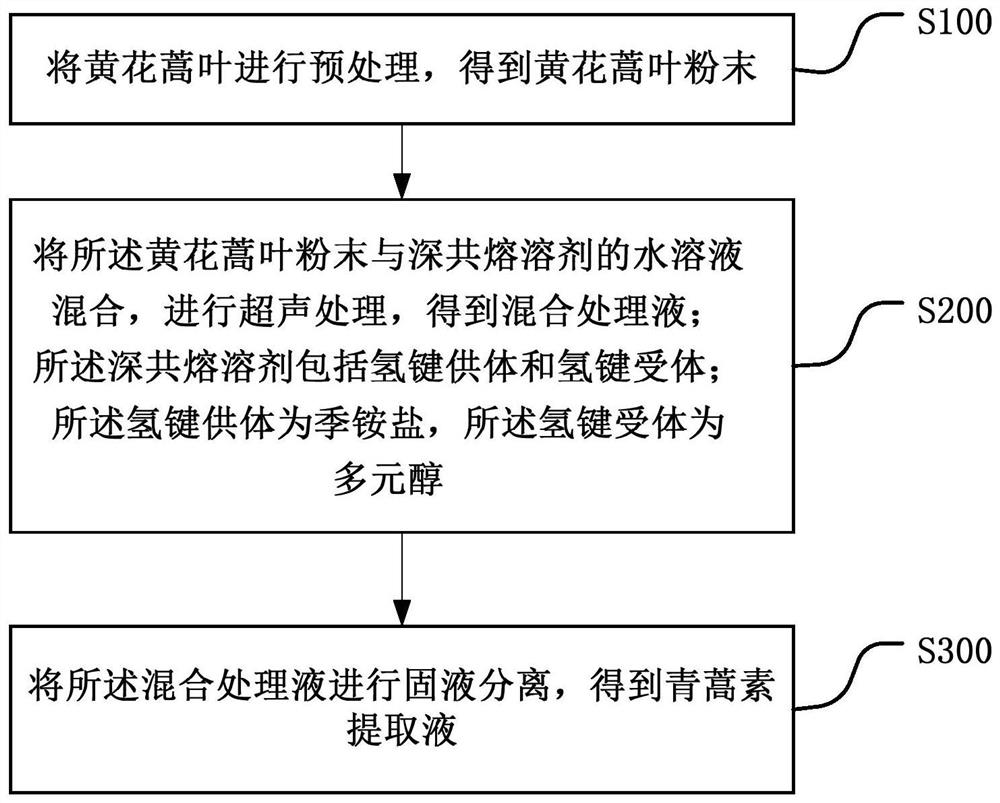

Method for ultrasonically extracting artemisinin by using deep eutectic solvent

The invention discloses a method for ultrasonically extracting artemisinin by using a deep eutectic solvent. The method comprises the following steps of: A, pretreating artemisia annua leaves to obtain artemisia annua leaf powder; B, mixing the artemisia annua leaf powder with an aqueous solution of a deep eutectic solvent, and carrying out ultrasonic treatment to obtain a mixed treatment solution, wherein the deep eutectic solvent comprises a hydrogen bond donor and a hydrogen bond acceptor, the hydrogen bond donor is quaternary ammonium salt, and the hydrogen bond acceptor is polyalcohol; and C, carrying out solid-liquid separation on the mixed treatment solution to obtain an artemisia apiacea extracting solution. The deep eutectic solvent formed by quaternary ammonium salt and polyalcohol and artemisinin belong to the same kind or analogues with similar substance components, and the deep eutectic solvent and artemisinin have similar action effects; removal is not needed after the artemisinin is ultrasonically extracted with the deep eutectic solvent, and the structure of the artemisinin cannot be damaged; and therefore, the process can be better simplified, the cost is saved, the extraction efficiency is improved, and the environment is protected.

Owner:HARBIN INST OF TECH SHENZHEN GRADUATE SCHOOL

Biodegradable polyols having higher biobased content

InactiveCN110352208AHigh Bio-Based Carbon ContentPromote degradationOrganic chemistryPolymer scienceOligomer

The present invention is directed to biodegradable polyester polyol polymers having high bio-based content and methods for producing biodegradable polyester polyol polymers having high bio-based content. In preferred embodiments, beta-lactone monomers may be produced from epoxide and carbon monoxide having high bio-based content. In certain preferred embodiment, the beta-lactone is beta-propiolactone produced from ethylene oxide and carbon monoxide. In certain embodiments, beta-lactones may be polymerized with diols, triols, and polyols to form the biodegradable polyester polyol polymers having high bio-based content. In some embodiments, the biodegradable polyester polyol polymers having high bio-based content may be terpolymers formed from a first beta-lactone, a diol, triol, or polyol,and a second beta-lactone. In some other embodiments, the biodegradable polyester polyol polymers having high bio-based content may be copolymers formed from a polylactone oligomer and a diol, triol,or polyol.

Owner:NOVOMER INC

Creep-resistant polishing pad window

The polishing pad is useful for polishing at least one of magnetic, optical and semiconductor substrates. The polishing pad includes a polishing layer having a polyurethane window. The polyurethane window has a cross-linked structure formed with an aliphatic or cycloaliphatic isocyanate and a polyol in a prepolymer mixture. The prepolymer mixture is reacted with a chain extender having OH or NH2 groups and having an OH or NH2 to unreacted NCO stoichiometry less than 95%. The polyurethane window has a time dependent strain less than or equal to 0.02% when measured with a constant axial tensile load of 1 kPa at a constant temperature of 60° C. at 140 minutes, a Shore D hardness of 45 to 90 and an optical double pass transmission of at least 15% at a wavelength of 400 nm for a sample thickness of 1.3 mm.

Owner:ROHM & HAAS ELECTRONICS MATERIALS CMP HLDG INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com