Optical rotation film, preparation method thereof and photoelectric device

A technology of photoelectric devices and optical films, applied in the field of optical films, can solve problems such as insufficient rigidity, changing polarized light, and increasing the number of replacements of polarizing films, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0039] The present invention also provides a method for preparing the above-mentioned optically active film, including:

[0040] S1, providing a solution containing polyurethane, the polyurethane includes a soft segment and a hard segment, and the soft segment is composed of molecular chains formed by chiral polypolyols;

[0041] S2. Provide a substrate, place the solution on the substrate, and form an optically active film.

[0042] In step S1, the solvent of the solution includes at least one of dichloroethane, trichloroethane, tetrachloroethane, tetrahydrofuran, and N,N-dimethylformamide, preferably trichloroethane. The mass ratio of the polyurethane to the solvent is 1:5˜1:10, preferably 1:8 in order to make the forming process of the optically active film more perfect.

[0043] In step S2, the substrate is preferably a single crystal silicon wafer, the forming temperature is 0° C. to 60° C., the forming time is 24 hours to 72 hours, and different processing temperatures ...

Embodiment 1

[0048] Polyurethane and trichloroethane are configured into a solution at a mass ratio of 1:5. Among them, polyurethane is obtained by copolymerization of L-polylactic acid polyol, polytetrahydrofuran polyol, 1,4-butanediol, and 4,4'-dicyclohexylmethane diisocyanate, with a number average molecular weight of 30,000 g / mol, including soft segments and hard segments. segment, wherein the structural unit of L-polylactic acid polyol accounts for 20% of the total mass of the soft segment, and the mass ratio of the soft segment to the hard segment is 10:6.

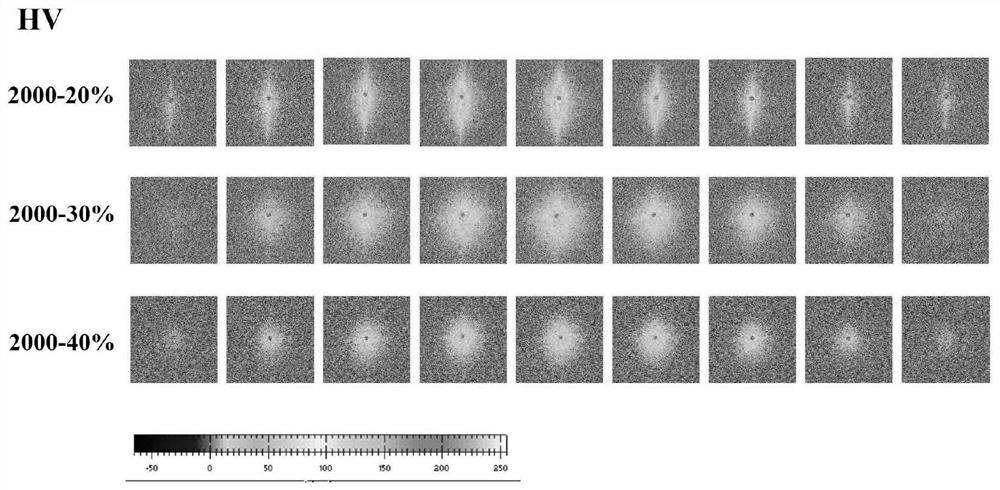

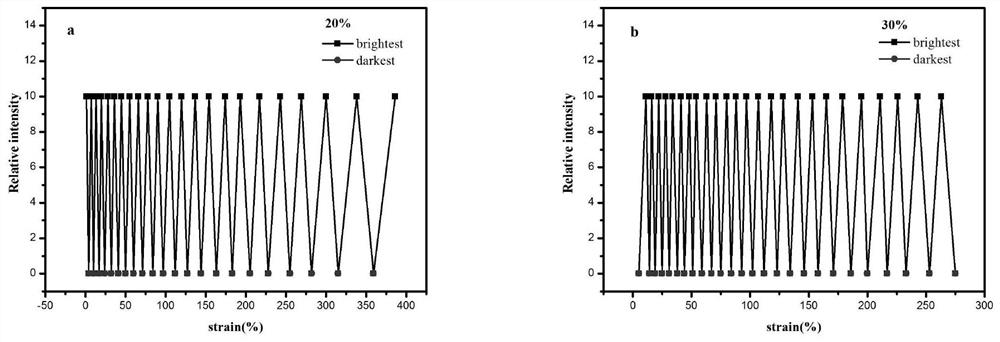

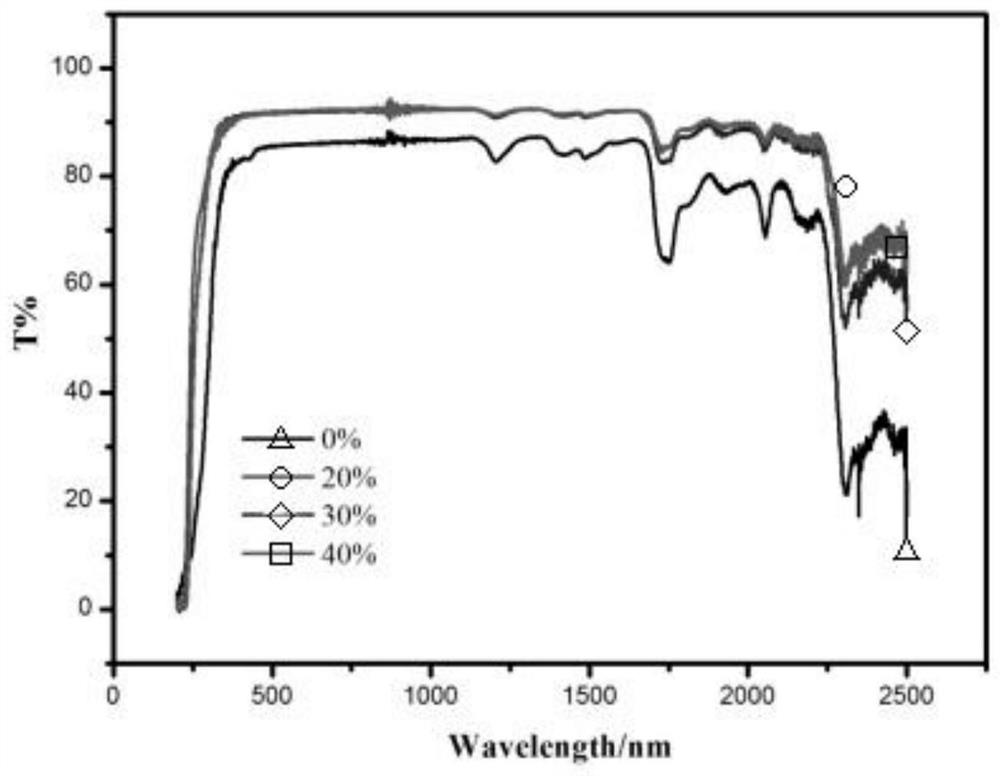

[0049] Put the above solution on a single crystal silicon wafer and mold it at 5°C for 54 hours to obtain an optically active film with a thickness of 0.1mm. When the strain range of the optically active film is 0-10%, it can make the polarized light in the range of 0-360° It changes periodically, and the polarized light passing through the optical film can be reduced from the strongest light intensity to zero.

Embodiment 2

[0051] Polyurethane and trichloroethane are configured into a solution at a mass ratio of 1:7. Among them, polyurethane is obtained by copolymerization of L-polylactic acid polyol, polytetrahydrofuran polyol, 1,4-butanediol, and 4,4'-dicyclohexylmethane diisocyanate, with a number average molecular weight of 28000g / mol, including soft segments and hard segments. segment, wherein the structural unit of L-polylactic acid polyol accounts for 30% of the total mass of the soft segment, and the mass ratio of the soft segment to the hard segment is 10:7.

[0052] Place the above solution on a single crystal silicon wafer, and mold it at 5°C for 54 hours to obtain an optically active film with a thickness of 0.15mm. It changes periodically, and the polarized light passing through the optical film can be reduced from the strongest light intensity to zero.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| modulus | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com