Preparation method of oligomerization aspartic resin

A technology of resin and aspartame, which is applied in the field of preparation of aspartame resin, can solve the problems such as the performance discount of aspartame polyurea, and achieve the effect of increasing crosslinking density and improving performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

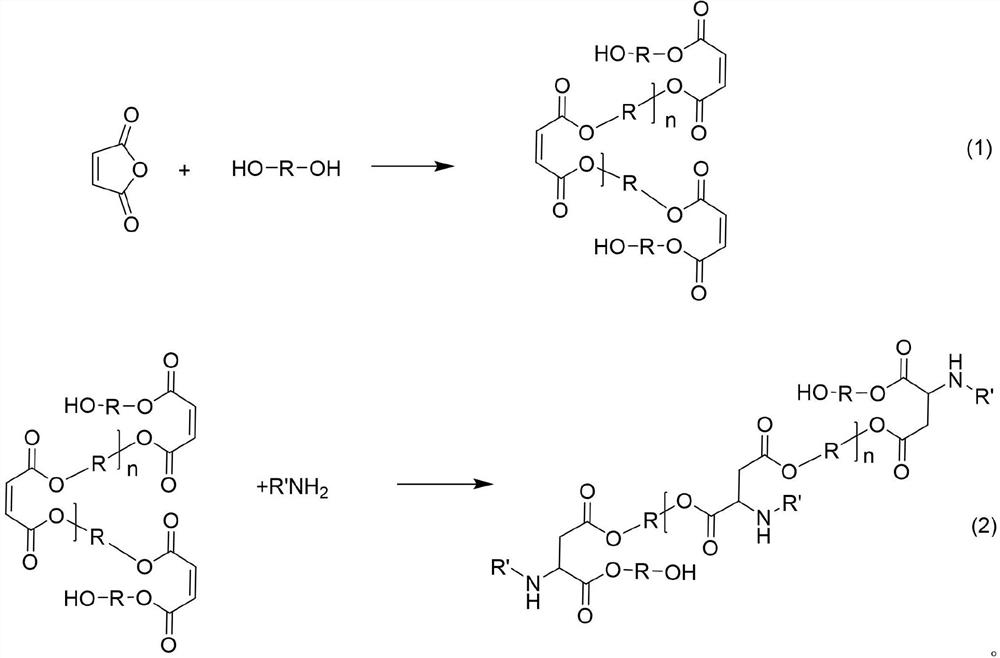

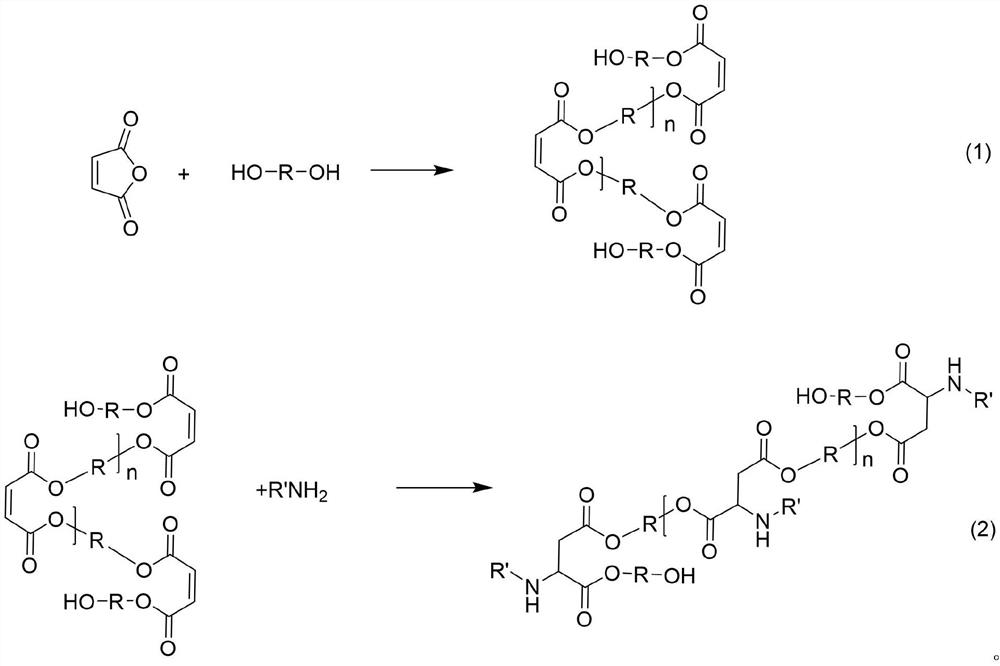

[0012] The present invention proposes a kind of preparation method of oligomeric aspartame resin, comprises the steps:

[0013] 98g of maleic anhydride and 142g of hexanediol were subjected to an esterification reaction at a temperature of 150 degrees centigrade under the protection of nitrogen. The end point of the reaction was monitored by measuring the acid value, and the reaction was stopped when the acid value was 11.

[0014] The oligomeric unsaturated polyester obtained by the above reaction was added dropwise to a flask containing 226 g (2 equiv.) of 2-methylcyclohexylamine under a nitrogen atmosphere. The temperature was raised to 60°C, and the end point of the reaction was monitored by measuring the amine value. The excess 2-methylcyclohexylamine was distilled off under reduced pressure to obtain the corresponding oligomerized aspart resin.

Embodiment 2

[0016] The present invention proposes a kind of preparation method of oligomeric aspartame resin, comprises the steps:

[0017] 98g of maleic anhydride and 19.8g of neopentyl glycol, 3.04g of propylene glycol, 32.28g of ethylene glycol, 4.24g of diethylene glycol and 34.88g of dipropylene glycol, at a temperature of 150 degrees Celsius, carry out an esterification reaction under nitrogen protection , monitor the end point of the reaction by measuring the acid value, and stop the reaction when the acid value is 10.

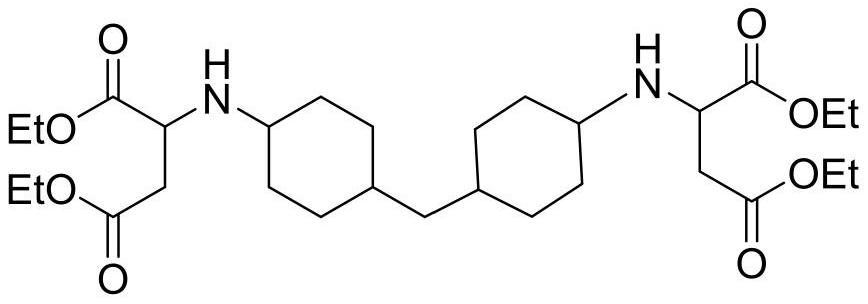

[0018] The oligomeric unsaturated polyester obtained by the above reaction was added dropwise to a flask containing 200 g (2 equiv.) of cyclohexylamine under a nitrogen atmosphere. The temperature was raised to 60°C, and the end point of the reaction was monitored by measuring the amine value. The excess cyclohexylamine was distilled off under reduced pressure to obtain the corresponding oligomerized aspart resin.

Embodiment 3

[0020] The present invention proposes a kind of preparation method of oligomeric aspartame resin, comprises the steps:

[0021] Maleic anhydride 98g and 31.66g ethylene glycol, 72.45g dipropylene glycol, under the temperature of 150 degrees centigrade, under the situation of nitrogen protection, carry out esterification reaction, monitor the reaction end point by acid value measurement, stop when the acid value is 12 reaction.

[0022] The oligomeric unsaturated polyester obtained by the above reaction was added dropwise to a flask containing 254 g (2 equiv.) of 2-ethylcyclohexylamine under a nitrogen atmosphere. The temperature was raised to 80°C, and the end point of the reaction was monitored by measuring the amine value. The excess 2-ethylcyclohexylamine was distilled off under reduced pressure to obtain the corresponding oligomerized aspart resin.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com