Composition for adhesive hydrogel and use thereof

An adhesive hydrogel, composition technology, applied in the direction of adhesive type, acid copolymer adhesive, film/sheet adhesive, etc. Product life, resource saving, high adhesive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0091] Stir and dissolve 14.4 parts by weight of acrylic acid, 9.6 parts by weight of tert-butylacrylamide sulfonic acid (TBAS) and 3 parts by weight of N-vinyl-2-caprolactam as polymerizable monomers; 0.04 parts by weight of N,N'-methylenebisacrylamide (MBAA); 44 parts by weight of glycerin as a polyol; 3 parts by weight of polyvinylpyrrolidone (CREEJUS K30, Dai-ichi Kogyo Seiyaku Co., Ltd. .preparation, K-value: 29.2); 0.5 parts by weight of sodium chloride as electrolyte; and 0.2 parts by weight of 1-[4-(2-hydroxyethoxy)-phenyl] as ultraviolet photopolymerization initiator -2-Hydroxy-2-methyl-propan-1-one (product name: Irgacure 2959, manufactured by Ciba Specialty Chemicals K.K.), to obtain a monomer mixed solution.

[0092] Thereafter, the mixed solution was adjusted to have a pH of 4.0 to 5.0 with 8 parts by weight of a 50% by weight aqueous NaOH solution, and ion-exchanged water was added thereto until the water amount was 17.3 parts by weight. Then, use a metal halide...

Embodiment 2 to 16 and comparative example 1 to 9

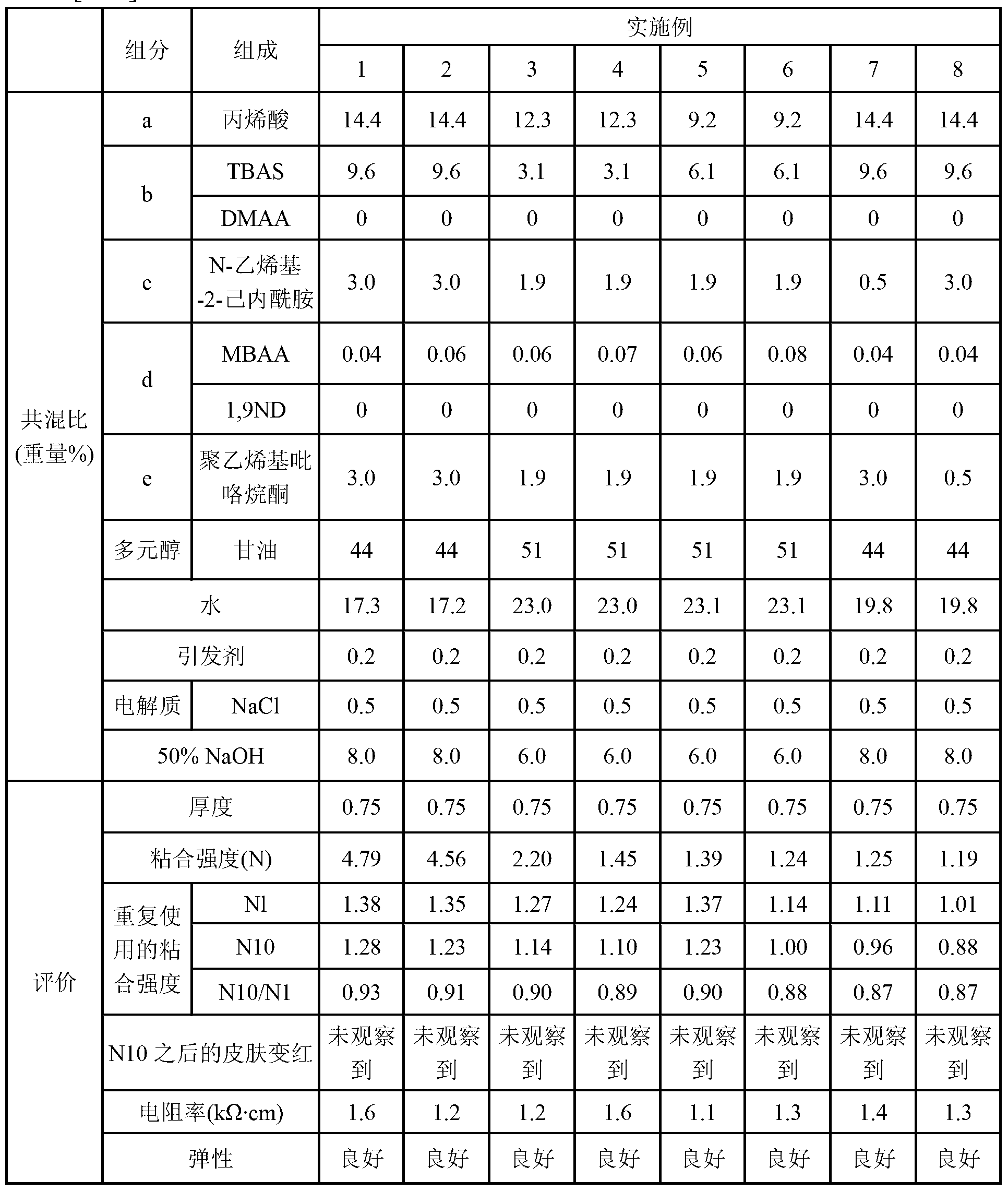

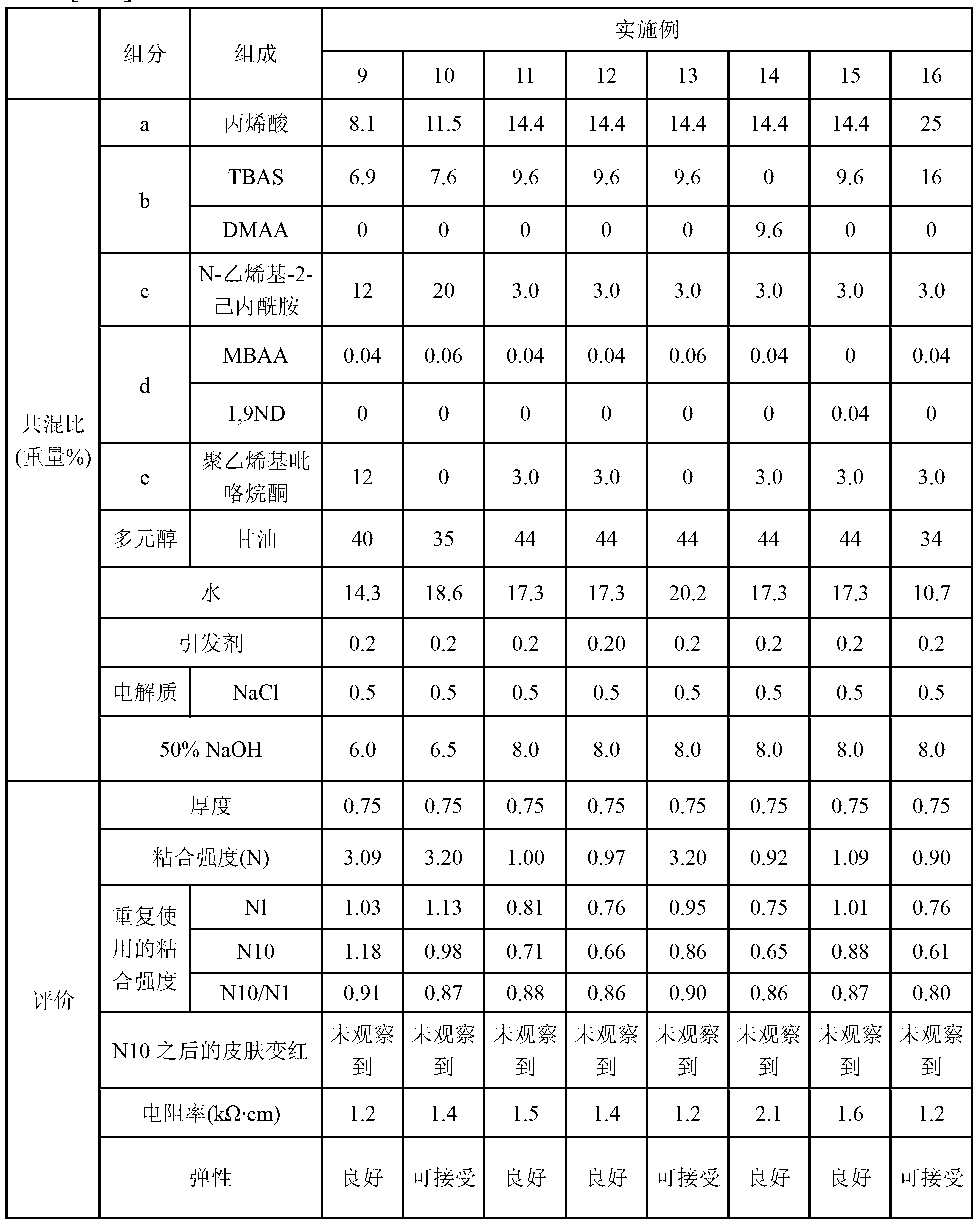

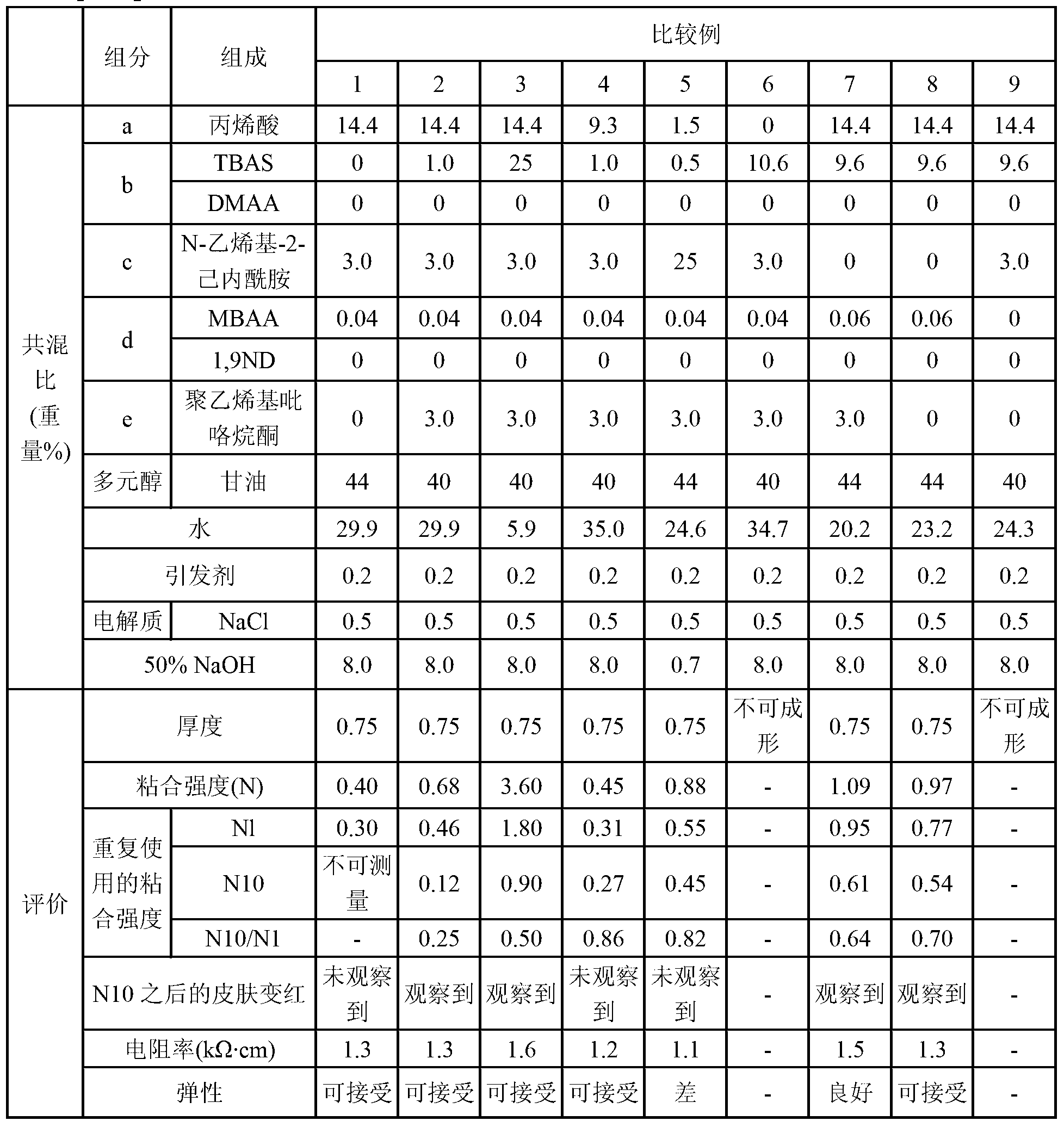

[0094] Adhesive hydrogels were prepared in the same manner as in Example 1 except that the composition was changed according to the compositions shown in Tables 1 to 3 . Forming was not possible in Comparative Example 6 and Comparative Example 9.

[0095] In Tables 1 to 3, DMAA refers to N,N-dimethylacrylamide, and 1,9ND refers to 1,9-nonanediol dimethacrylate.

[0096] (method used to measure bond strength)

[0097] Each of the prepared adhesive hydrogels was cut into strips of 20 mm×100 mm and lined with a non-woven fabric ("spunlace non-woven fabric #8021", manufactured by Du Pont Kabushiki Kaisha, thickness: 0.38 mm) to obtain A test piece was attached to a phenolic resin board (phenolic resin sheet, product number: PL113, manufactured by Sumitomo Bakelite Co., Ltd.) and set in a Tensilon (manufactured by Orientec Co., Ltd.). Then, the test piece was separated at an angle of 90° at a speed of 300 mm / min according to JIS-Z0237 and the strength required thereby was measured ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com