High-melt-strength polypropylene as well as preparation method and application thereof

A technology of polypropylene and grafted polypropylene, applied in the field of polypropylene, can solve problems such as poor compatibility and decreased mechanical properties of polypropylene, and achieve the effects of low reaction temperature, avoiding degradation and short reaction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

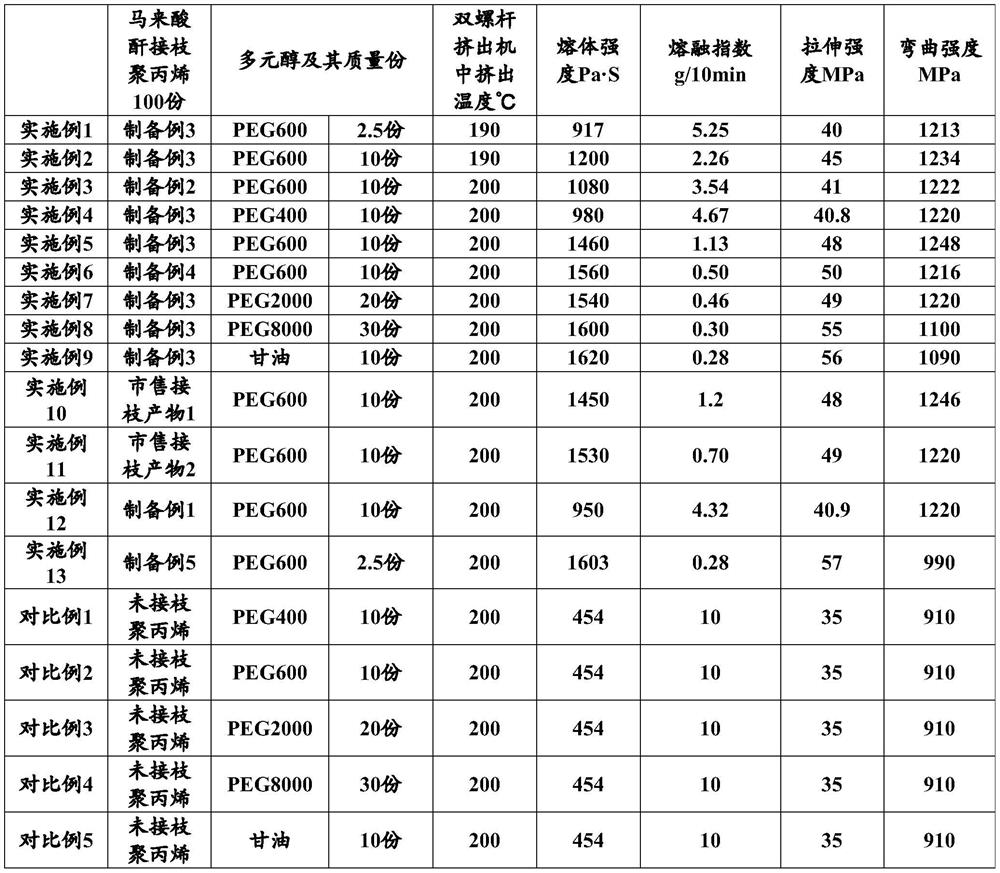

Examples

preparation example Construction

[0037]The preparation method of the present invention will be further described in detail in conjunction with specific examples below. It should be understood that the following examples are only for illustrating and explaining the present invention, and should not be construed as limiting the protection scope of the present invention. All technologies realized based on the above contents of the present invention are covered within the scope of protection intended by the present invention.

[0038] The experimental methods used in the following examples are conventional methods unless otherwise specified; the reagents and materials used in the following examples can be obtained from commercial sources unless otherwise specified.

[0039] The polypropylene (PP) raw material (ungrafted polypropylene) used in the following examples is homopolypropylene powder, the average particle size is <0.06mm, and the melt index is 9g / 10min.

[0040] The brand name of commercially available ...

preparation example 1

[0049] Weigh 100g of polypropylene powder and place it in a closed reaction kettle, vacuumize and fill with nitrogen three times to ensure that the reaction is carried out under a nitrogen atmosphere, and dissolve 0.5g of graft monomer maleic anhydride and 0.5g of initiator TBPB in 20mL of xylene , added to the reactor, stirring and swelling at room temperature for about 0.5h. After heating up to 120° C. for 3 hours to obtain PP grafted maleic anhydride, the product was purified by Soxhlet extraction with acetone for 6 hours to obtain purified maleic anhydride grafted polypropylene. It is measured that the corresponding graft ratio is 0.005, and the melt index is 9.5g / 10min.

preparation example 2

[0051] Adopt the preparation method of above-mentioned preparation example 1, difference is, by adjusting monomer maleic anhydride addition amount, the addition amount of initiator and reaction temperature, prepare the maleic anhydride grafted polypropylene of different graft ratio and melt index . The experimental conditions and test results of Preparation Example 1-7 are shown in Table 1

[0052]

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com