Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

74results about How to "Effective migration" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

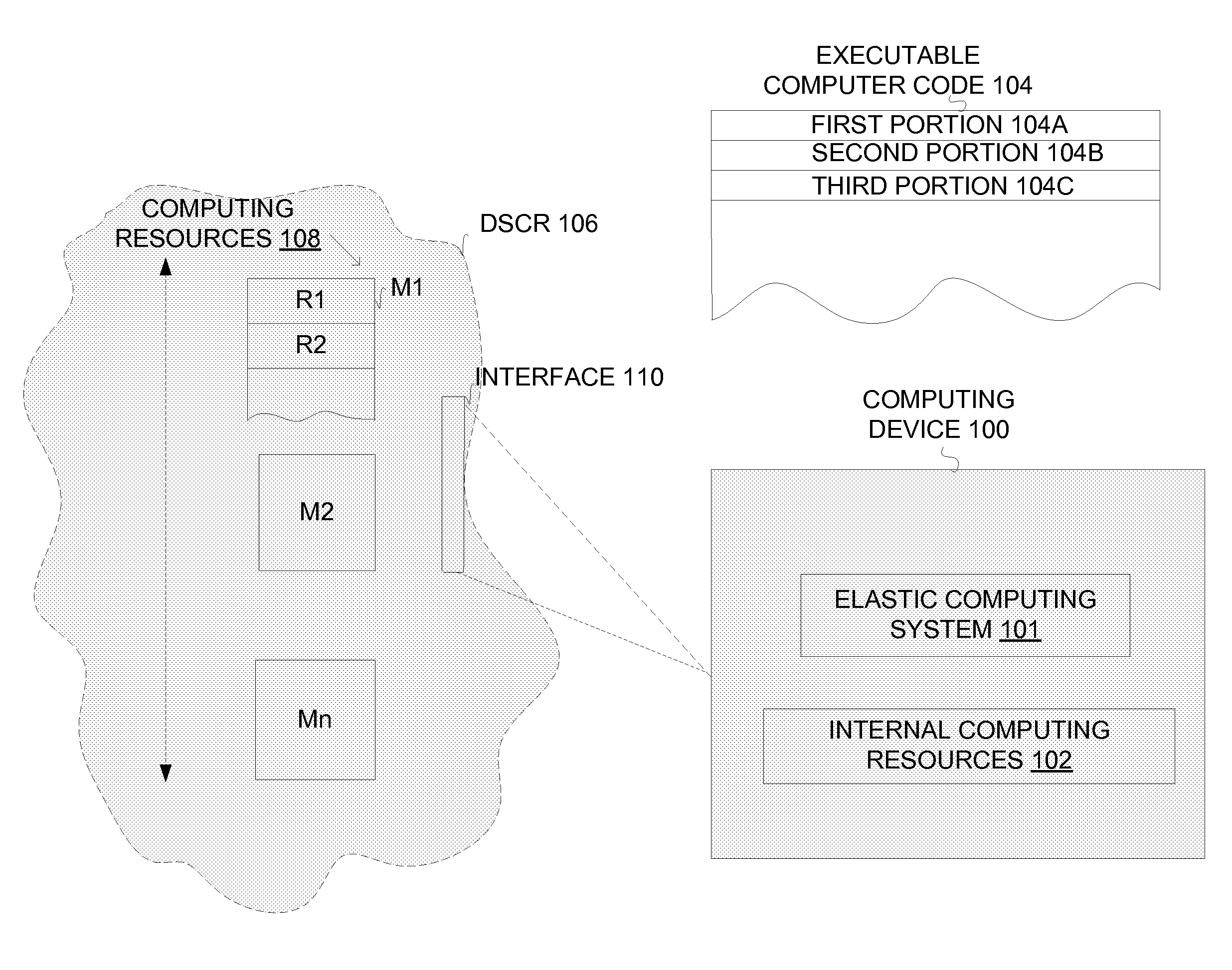

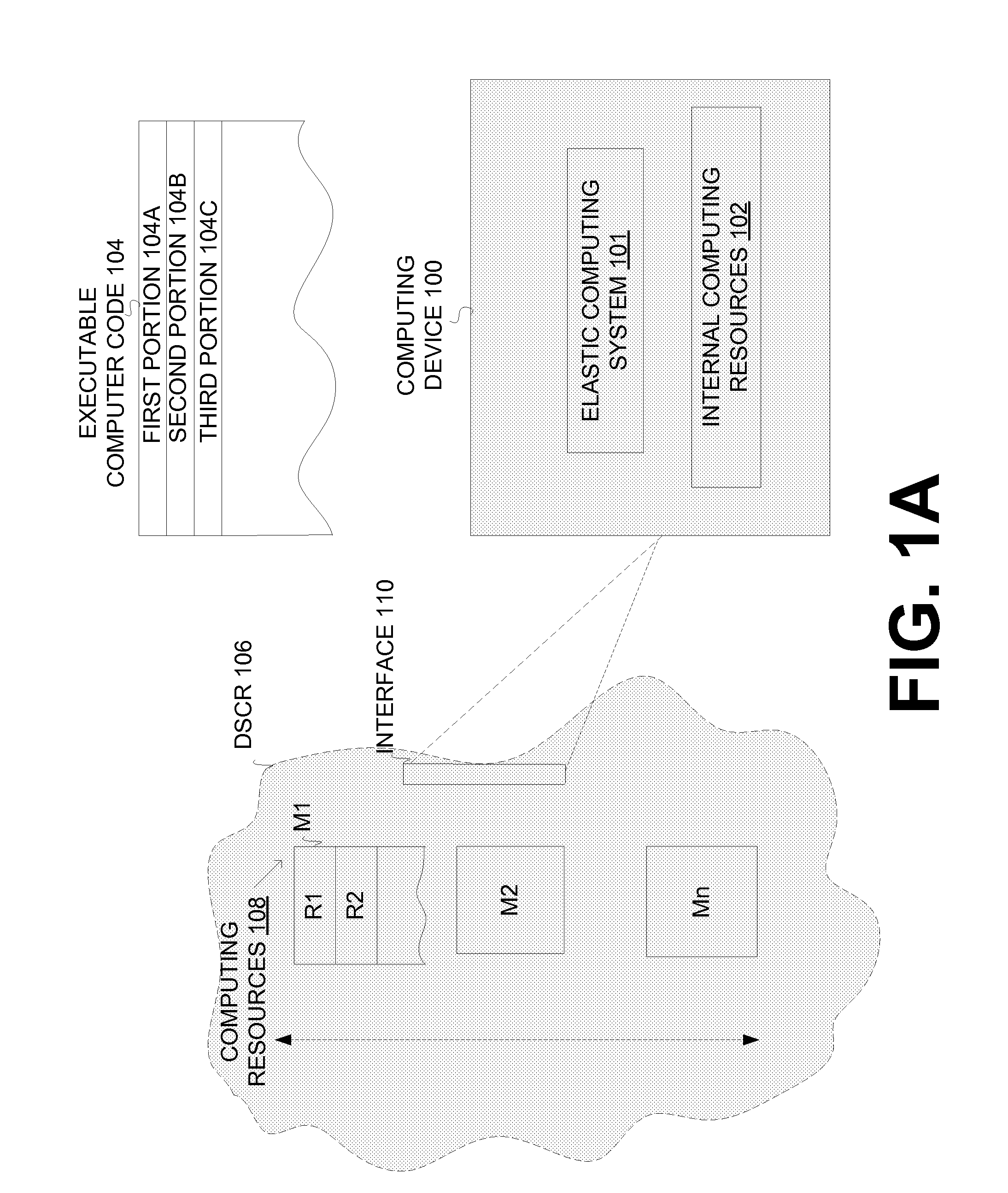

Extending the capability of computing devices by using dynamically scalable external resources

InactiveUS20100131590A1Limited and/or reduce computing resourceEffective migrationResource allocationMultiple digital computer combinationsDynamic ExtensionOn demand

Techniques for extending the capabilities of computing environments and / or systems are disclosed. A scalable and dynamic external computing resource can be used in order to effectively extend the internal computing capabilities of a computing environment or system. The scalable and dynamic external computing resource can provide computing resources that far exceed the internal computing resources, and provide the services as needed, and in a dynamic manner at execution time. As a result, a computing device may function with relatively limited and / or reduced computing resources (e.g., processing power, memory) but have the ability to effectively provide as much computing services as may be needed, and provide the services when needed, on demand, and dynamically during the execution time.

Owner:SAMSUNG ELECTRONICS CO LTD

Gas-permeable moisture-absorption type environmentally-friendly polyvinyl chloride synthetic leather and manufacturing method thereof

InactiveCN102505513AEffective migrationHas vapor permeability and moisture absorption conductivitySynthetic resin layered productsTextiles and paperPolyurethane adhesivePlasticizer

The invention discloses a gas-permeable moisture-absorption type environmentally-friendly polyvinyl chloride synthetic leather and a manufacturing method thereof. The synthetic leather is prepared from an environmentally-friendly polyvinyl chloride formula by adopting release paper knife-coating. The gas-permeable moisture-absorption functional environmentally-friendly polyvinyl chloride synthetic leather is manufactured by adding gas-permeable moisture-absorption type protein powder to a non-phthalate environmentally-friendly plasticizer and an environmentally-friendly color paste, and simultaneously adopting aqueous polyurethane adhesive slurry to replace a traditional paste resin adhesion layer. The synthetic leather has high peeling strength and has gas permeability and moisture absorption property of true leather; the minus 20DEG C low-temperature flex resistance of the synthetic leather is up to 30000 times; and through third-party testing, the product can completely achieve European union REAC 46 environmentally-friendly tests.

Owner:HEFEI ANSHAN COATING FABRICS

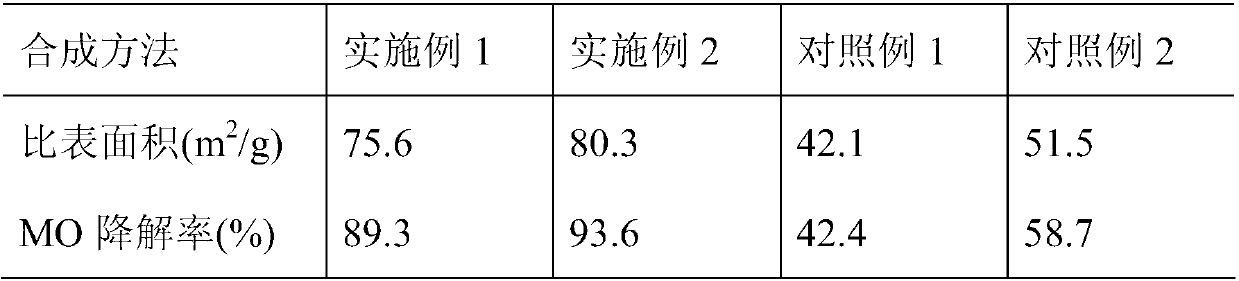

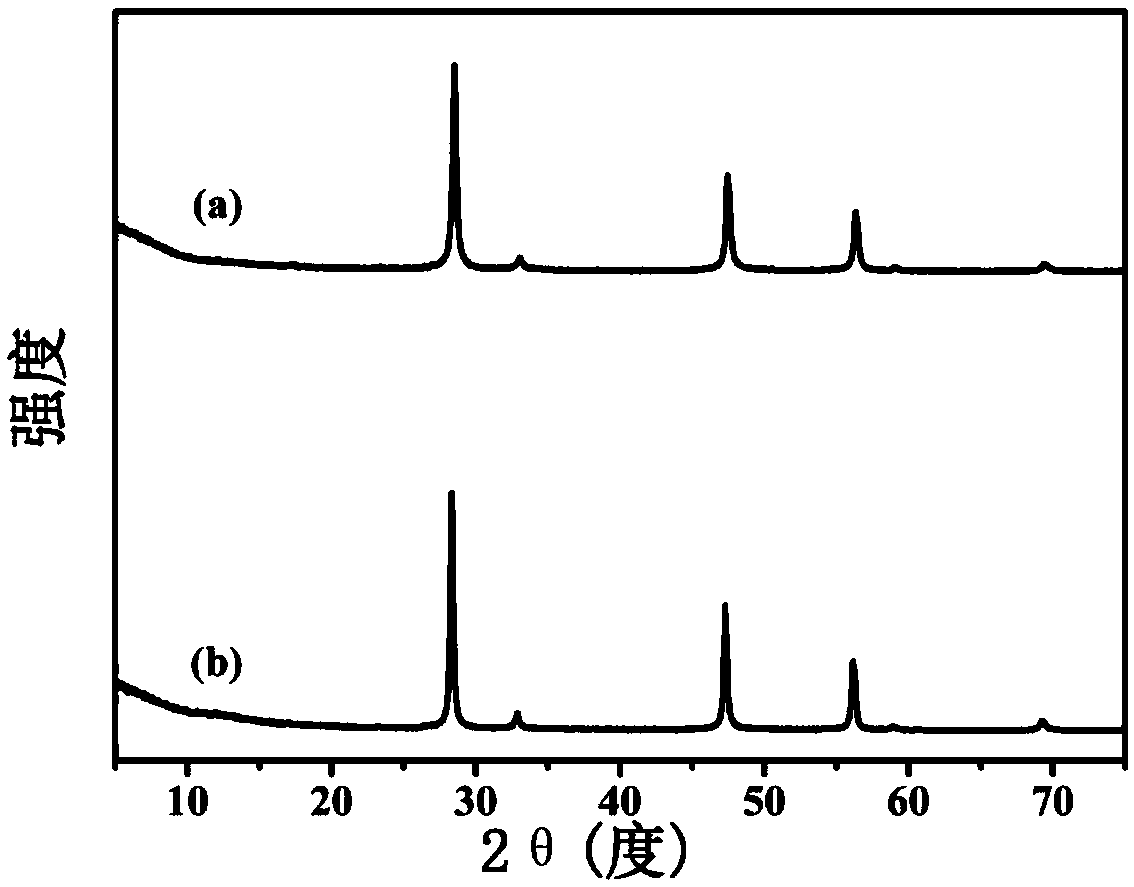

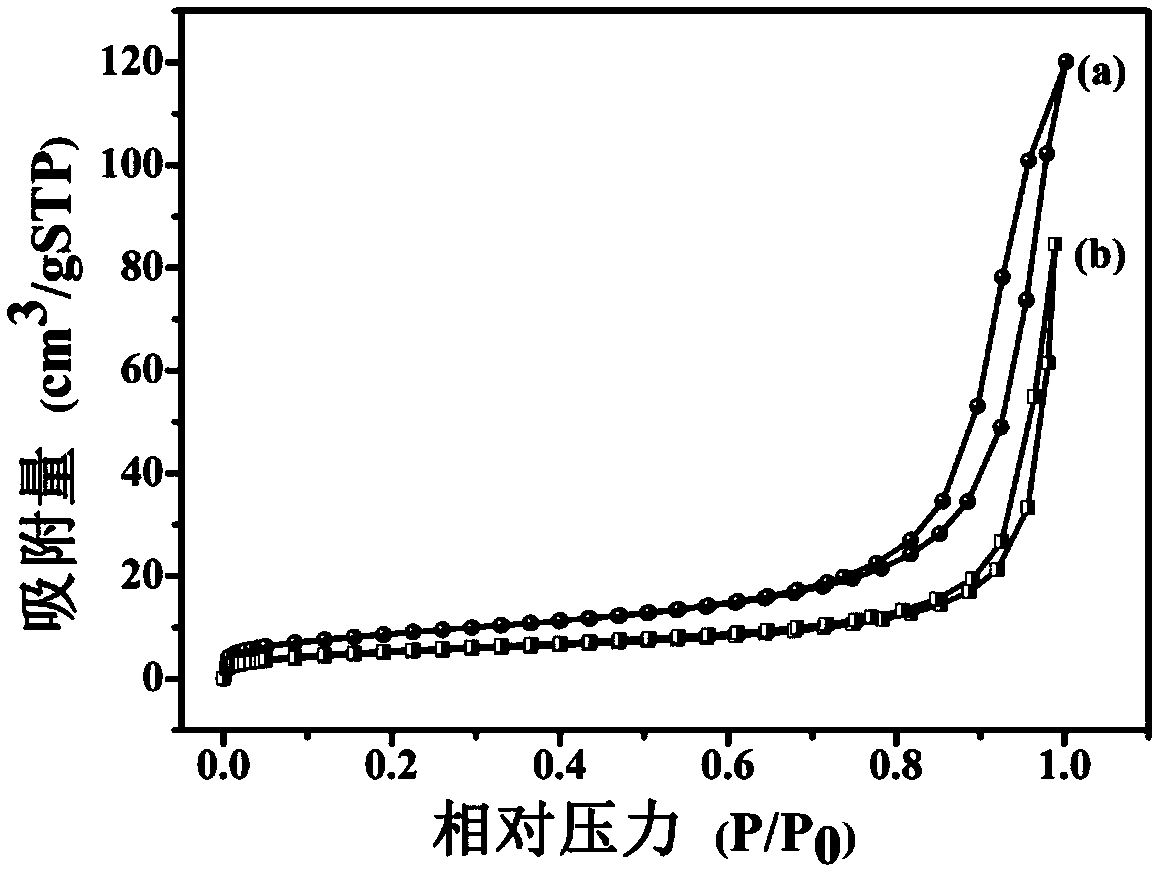

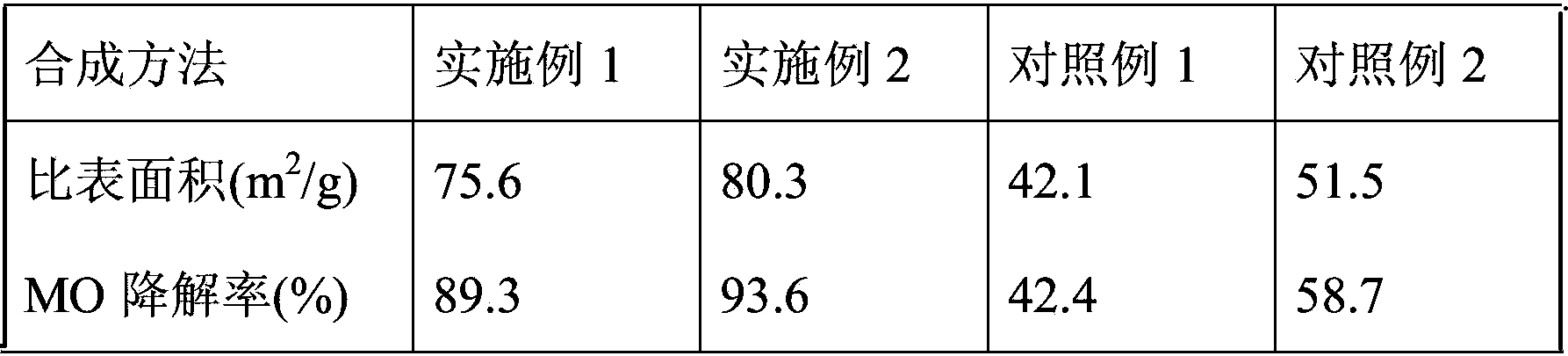

Preparation method of ZnO / g-C3N4 composite photocatalyst

InactiveCN102950016AHigh crystallinityGood dispersionPhysical/chemical process catalystsWastewaterSolvent

The invention relates to a preparation method of a ZnO / g-C3N4 composite photocatalyst. A two-stage solvent thermal / ultrasonic dispersing method is employed to prepare the ZnO / g-C3N4 composite photocatalyst. After the two-stage solvent thermal treatment, porous ZnO nano crystalline with high dispersion grown on the g-C3N4 can be obtained, and the ZnO nanocrystalline and the g-C3N4 can form a good composite structure; the ultrasonic treatment reduces agglomeration among the ZnO / g-C3N4 composite particles, and improves dispersion of the composite catalyst; and the nano composite particles with high dispersion strengthen effective utilization of sun light by the catalyst, and improve activity of the catalyst. The preparation method provided by the invention has the advantages of cheap raw materials and simple process; and the prepared composite photocatalyst has a broad application prospects in the fields of wastewater treatment and gas purification.

Owner:EAST CHINA UNIV OF SCI & TECH +1

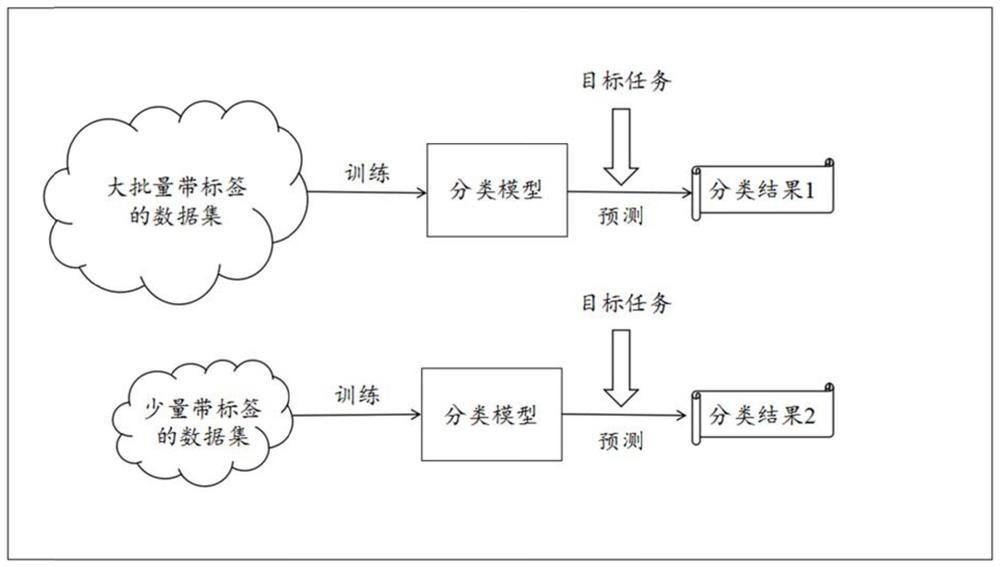

Training method and device for financial risk identification model, computer equipment and medium

PendingCN111724083AImprove generalization abilityEfficient training processFinanceCharacter and pattern recognitionEngineeringRisk identification

The invention discloses a training method and device for a financial risk identification model, computer equipment and a medium, and the method comprises the steps: obtaining first user data, with a first credit risk label, of a target domain financial project, inputting the first user data into a meta-learning device for training, and obtaining a classifier corresponding to the target domain financial project for risk identification. According to the method, the classifier corresponding to the target domain financial project is trained in a meta-learning mode, priori knowledge in a source domain task can be effectively migrated, so that the data volume of labeled samples required by model training is small, the generalization performance of the recognition model is improved, and the training process of the model is faster and more efficient. Besides, in the training process of the meta-learner, the source domain correlation among the categories of the task sets is learned, so that prior knowledge can be effectively migrated from tasks closer to the current target domain task during migration learning, and the accuracy of model recognition can be improved. The method can be widelyapplied to the technical field of machine learning.

Owner:TENCENT TECH (SHENZHEN) CO LTD

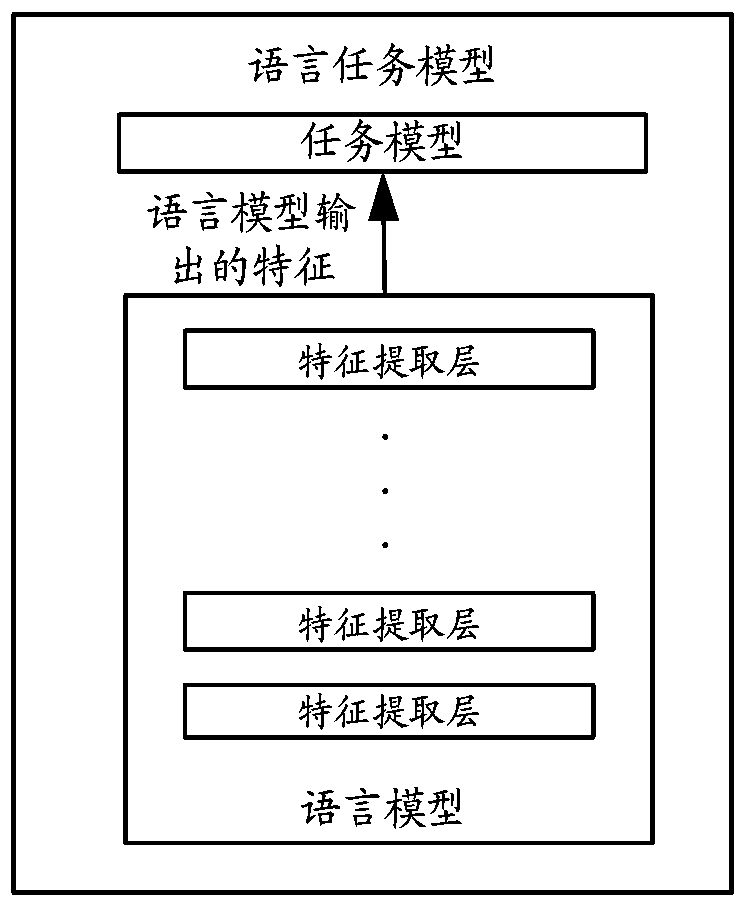

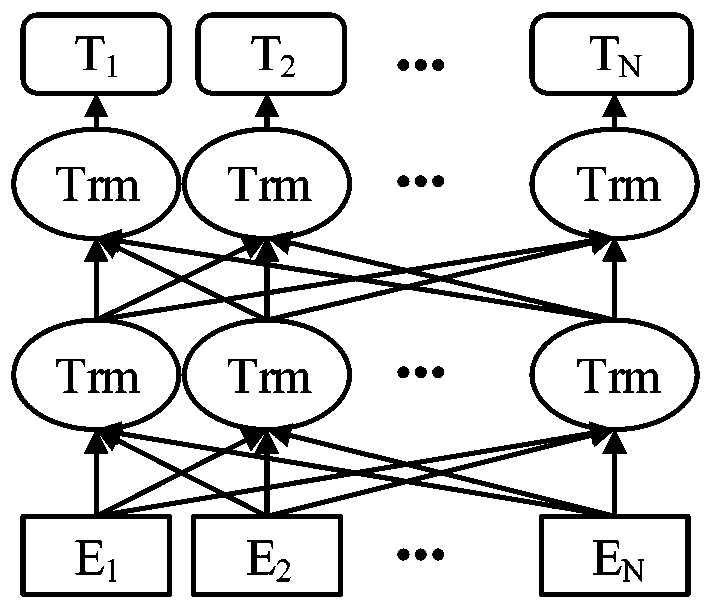

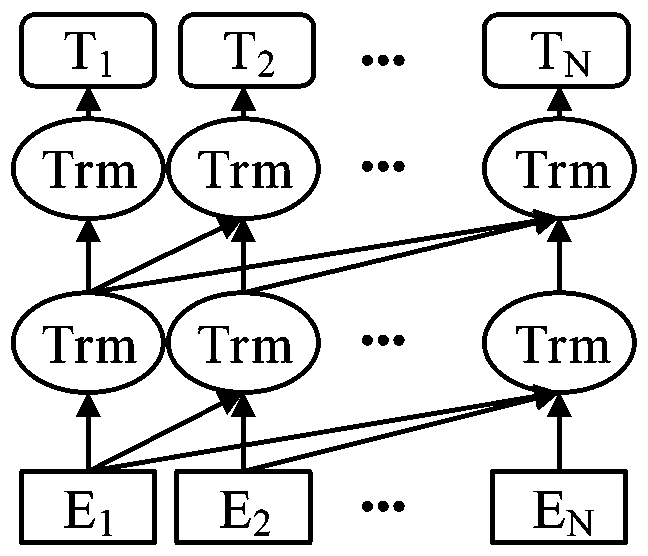

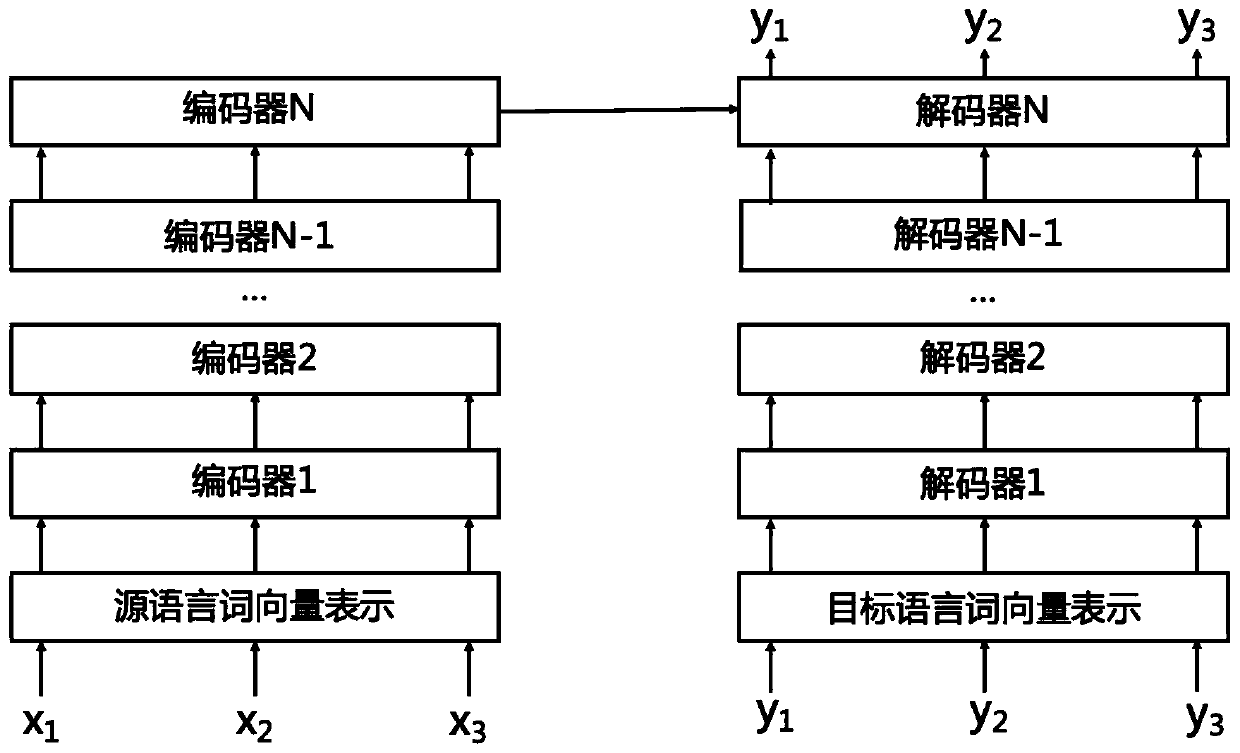

Language task model training method and device, electronic equipment and storage medium

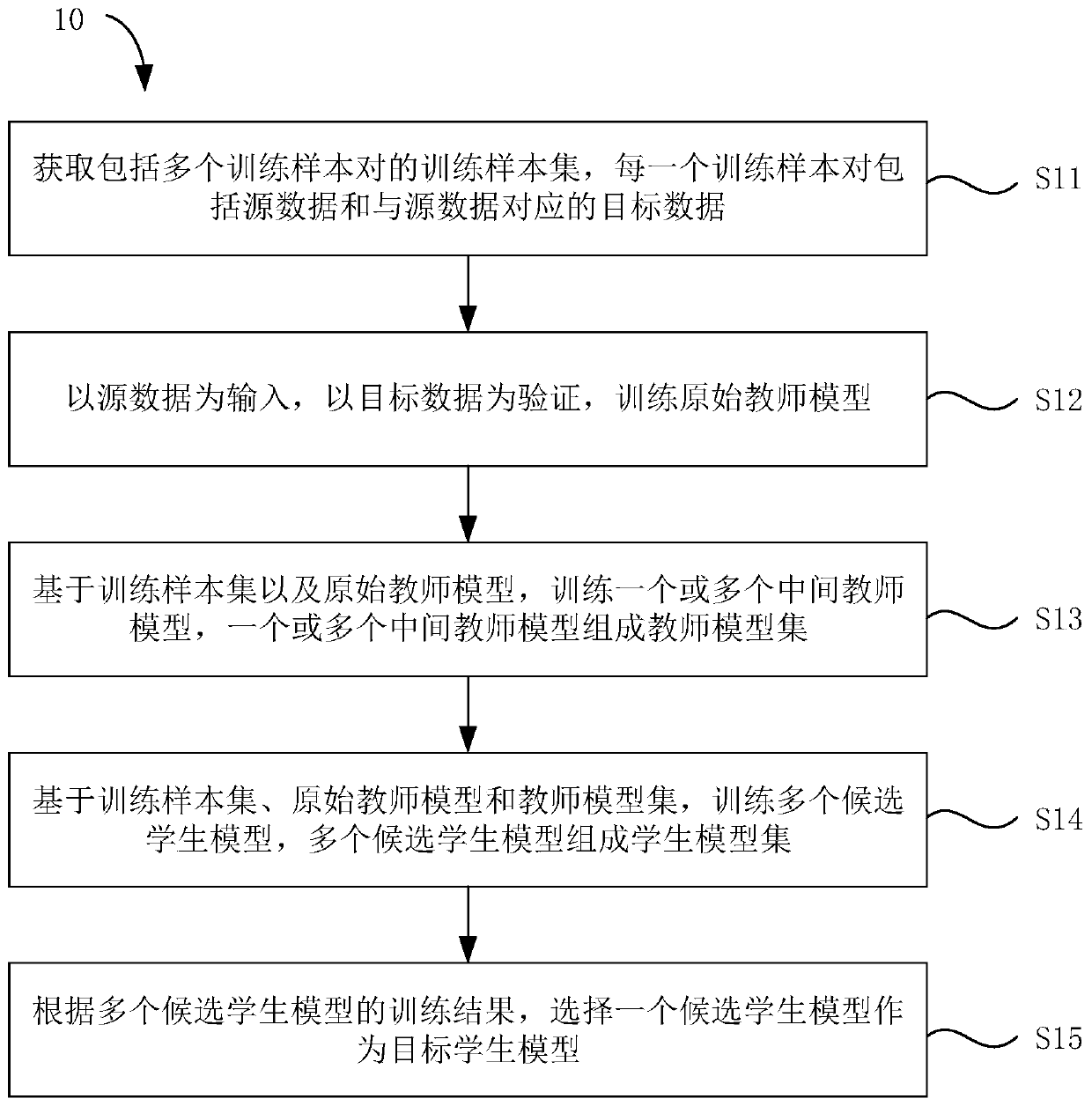

ActiveCN111159416AEffective migrationSpecial data processing applicationsNeural learning methodsLinguistic modelForward propagation

The invention provides a language task model training method and device, electronic equipment and a storage medium. The method comprises the steps of performing hierarchical pre-training in a languagemodel based on corpus samples of corresponding language tasks in a pre-training sample set; carrying out forward propagation on corpus samples corresponding to language tasks in a training sample setin the language task model; fixing parameters of the language model, and performing back propagation in the language task model to update the parameters of the task model; and performing forward propagation and reverse propagation on corpus samples corresponding to the language tasks in the training sample set in the language task model so as to update parameters of the language model and the task model. By means of the method and device, the catastrophic forgetting phenomenon of the language model can be prevented, and meanwhile it is guaranteed that the language model and the task model canachieve the training effect meeting the corresponding learning rate.

Owner:TENCENT TECH (SHENZHEN) CO LTD

Linear porous titanium dioxide material and preparation method and application thereof

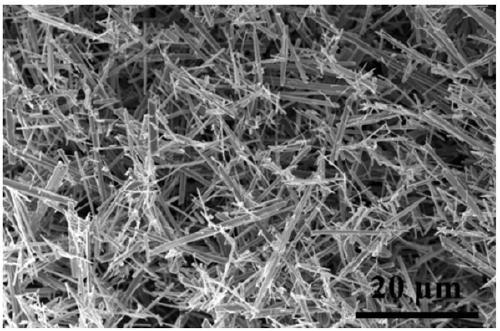

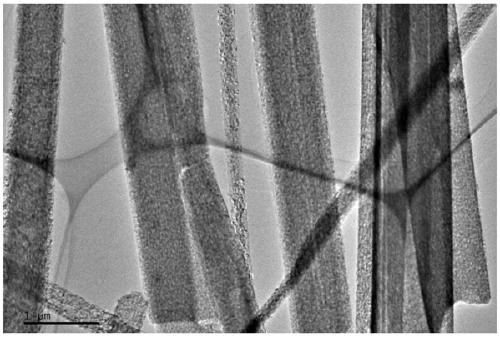

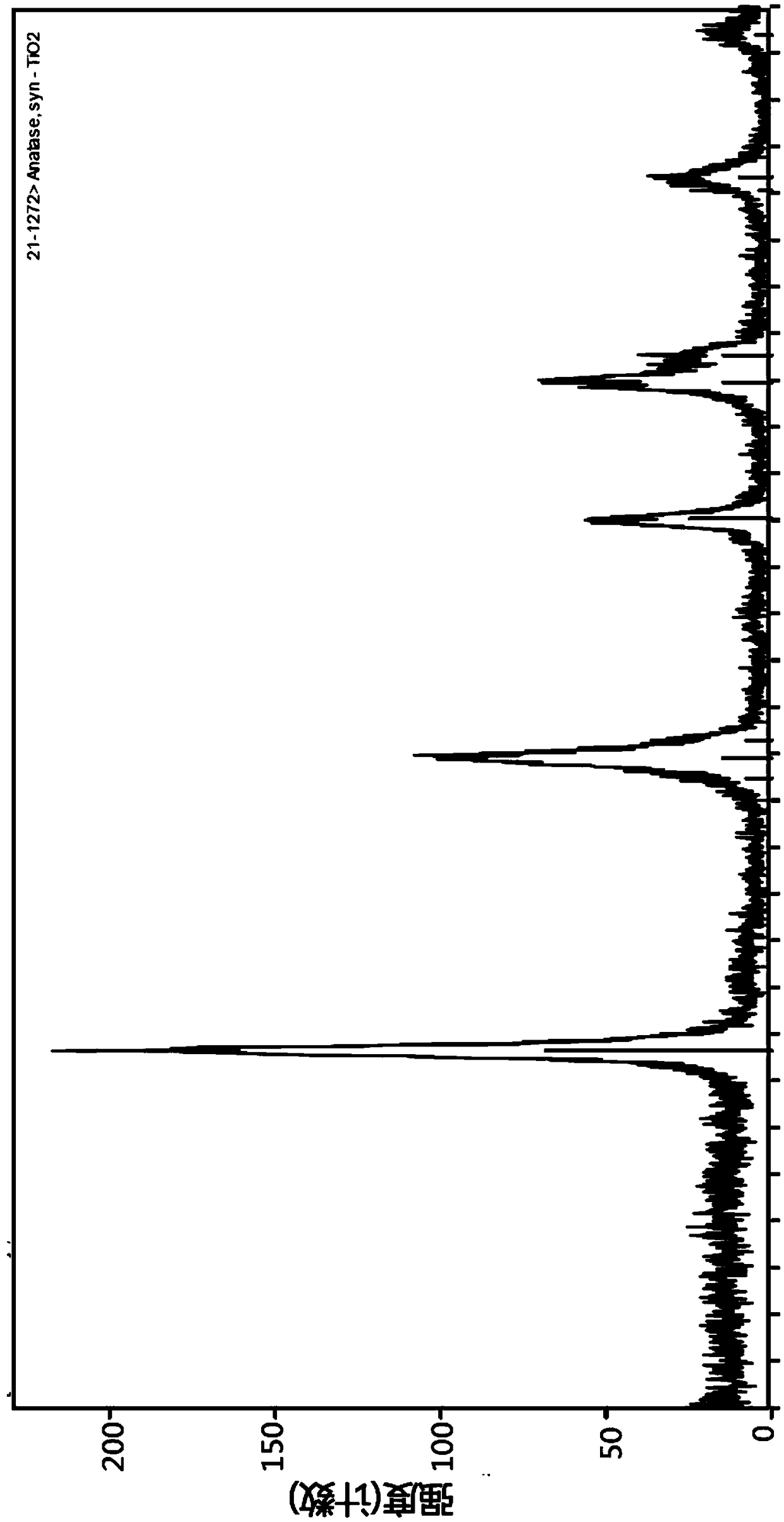

ActiveCN109319832ALarge specific surface areaGood application effectMaterial nanotechnologyAlkali titanatesElectrolytic agentNanowire

The invention provides a linear porous titanium dioxide material and a preparation method and application thereof. The linear porous titanium dioxide material is of an anatase-phase structure and a monocrystalline structure, and structurally consists of a plurality of particles; each particle has the fixed growth direction. The invention also provides the preparation method and application of thelinear porous titanium dioxide material. The titanium dioxide porous nanometer line has the advantages that the long axis of the structure is suitable for the effective transfer of electrons, so as tofacilitate the hydrogenation by photolysis of water, or degradation of organic pollutants by photocatalysis; the porous structure is suitable for the quick embedding-in and embedding-out process of lithium ions, sodium ions or potassium ions; the large specific surface area is suitable for the contact area between an electrolyte and an electrode, so that the current density is reduced, and the better battery quick charge and discharge property is realized.

Owner:PETROCHINA CO LTD

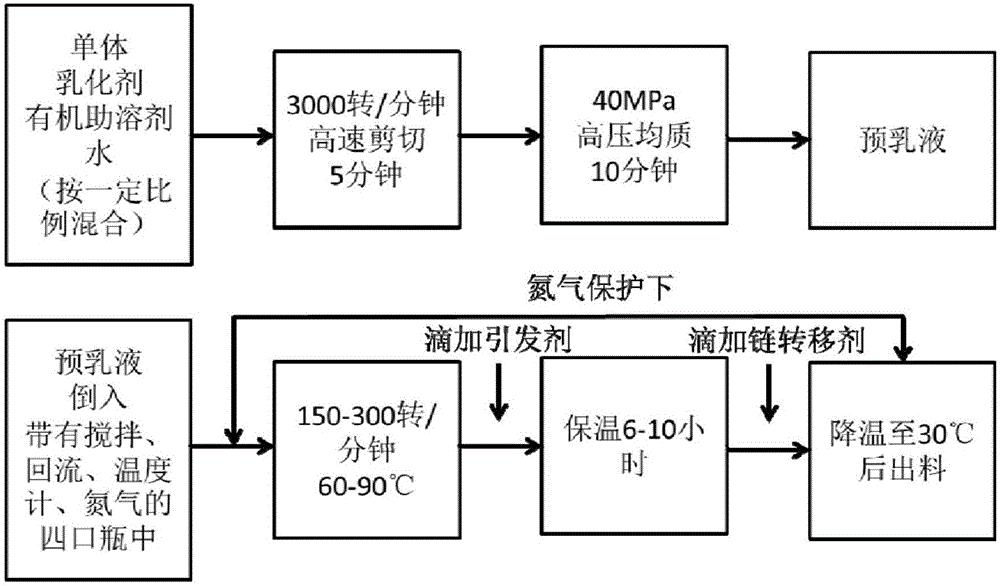

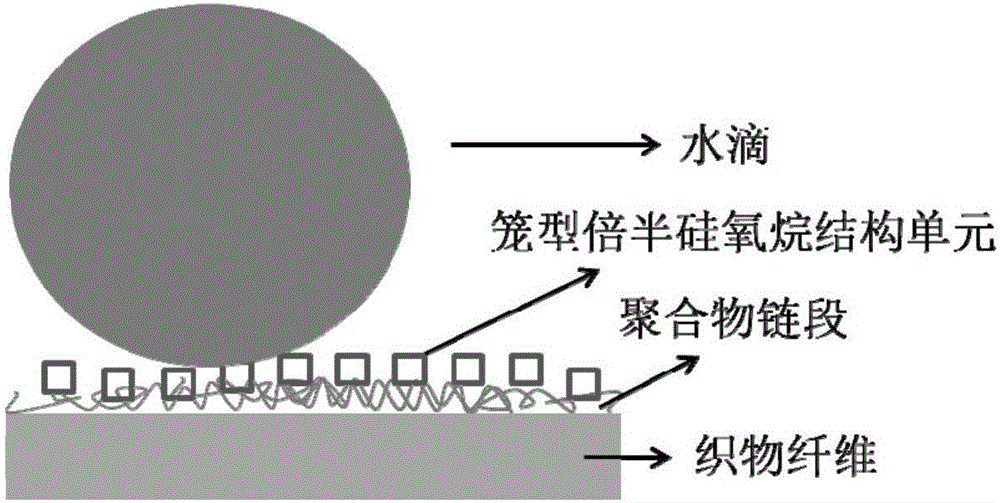

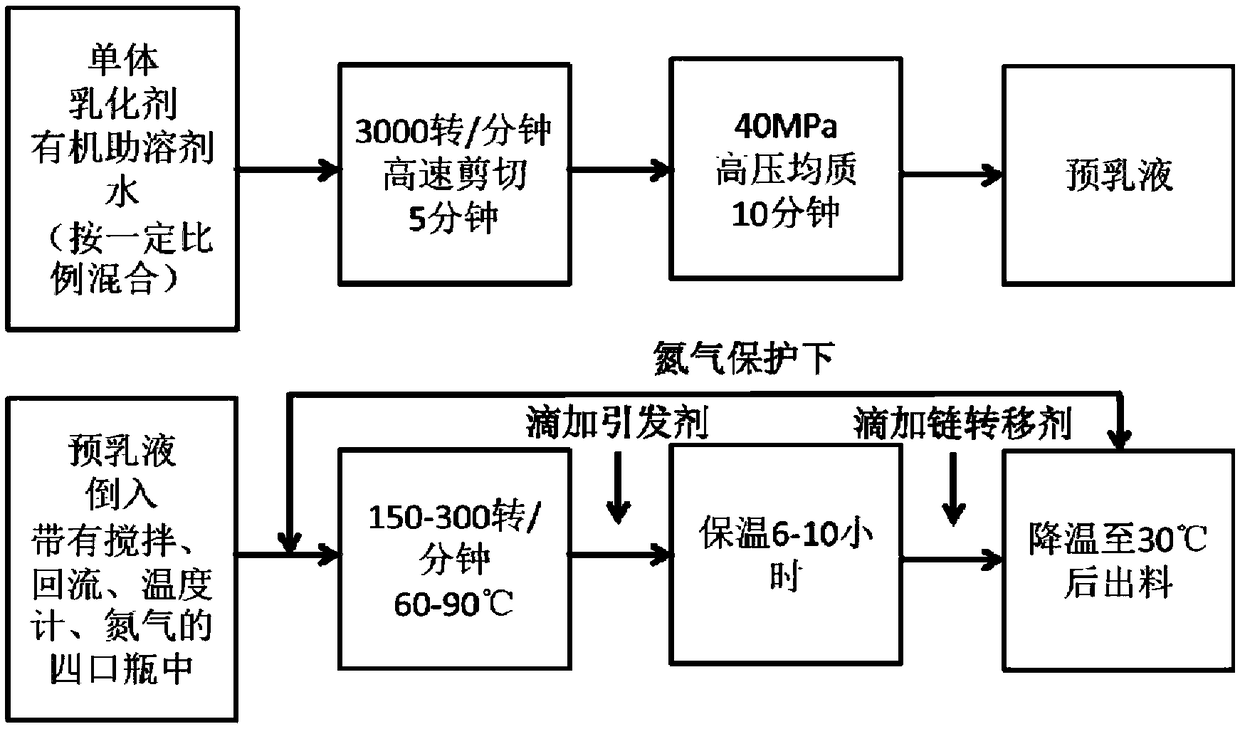

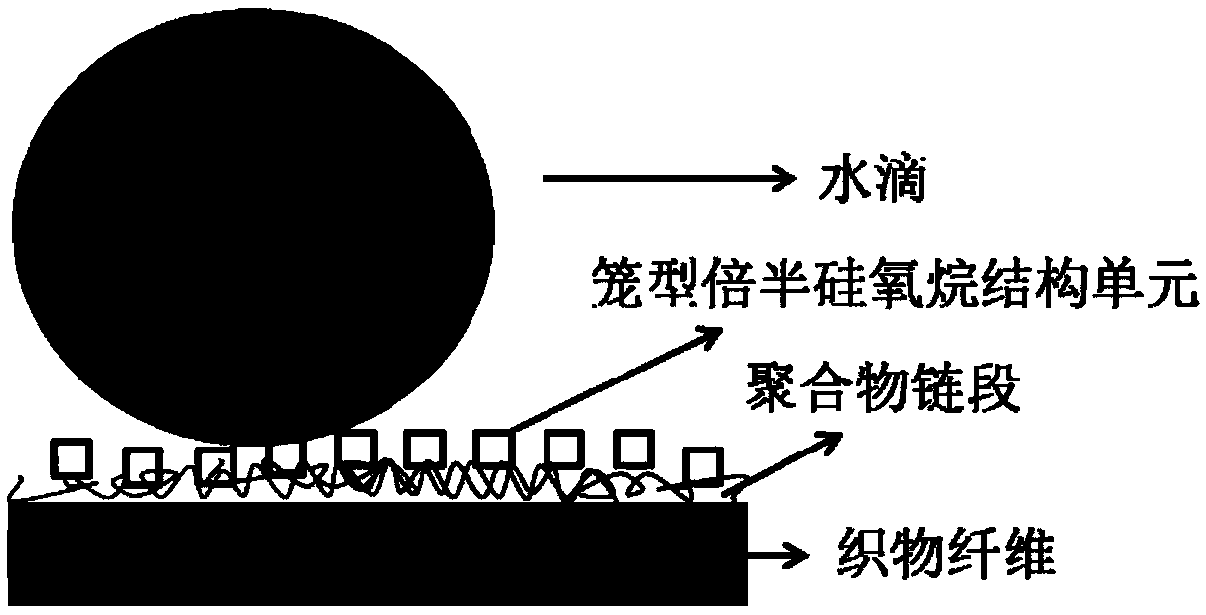

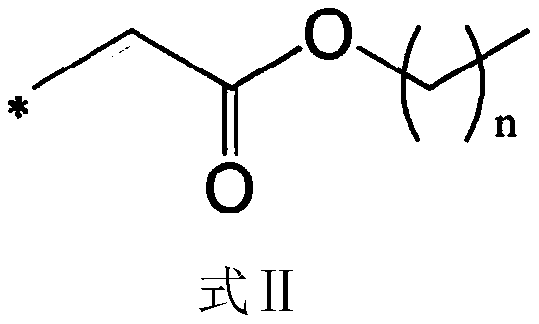

Fluoride-free waterproof agent with stereo silane structure and preparation method of fluoride-free waterproof agent

ActiveCN106810650AEffective migrationImprove waterproof performanceLiquid repellent fibresVegetal fibresFiberPolymer science

The invention discloses a fluoride-free waterproof agent with a stereo silane structure and a preparation method of the fluoride-free waterproof agent. In a formula I of a polymer, R1 refers to a long-chain acrylate structural chain segment, R2 refers to a polyhedral oligomeric silsesquioxane structural chain segment, R3 refers to a functional monomer structural chain segment, X refers to a natural number in a range of 1-150, and Y and Z refer to natural numbers in a range of 1-100. The fluoride-free waterproof agent is aqueous emulsion of the polymer shown as the formula I. By adoption of a polyhedral oligomeric silsesquioxane monomer with a vinyl structure for preparation of the fluoride-free waterproof agent through microemulsion polymerization, introduction of polyhedral oligomeric silsesquioxane with a stereo structure to a lateral group of a polymer long chain is realized, a low-surface-energy siloxane cubic structure can migrate to the fabric fiber surface more effectively in an emulsion film forming spread process to form continuous projections on the fabric fiber surfaces, and consequently waterproof effects are greatly improved. The fluoride-free waterproof agent is an environment-friendly waterproof agent, free of biotoxicity and nondegradability and harmless to organisms and environment.

Owner:BEIJING CTA TEX CHEM

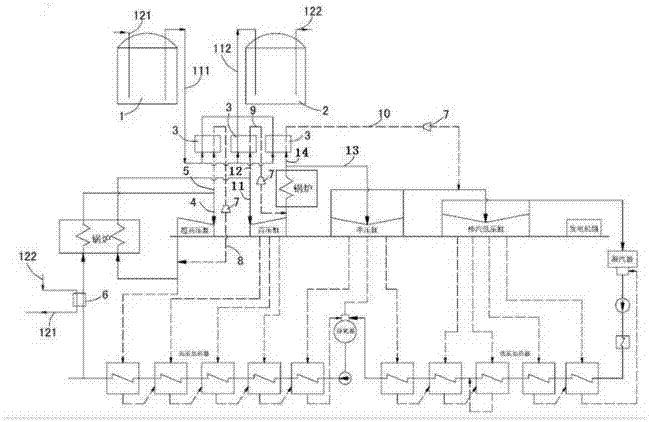

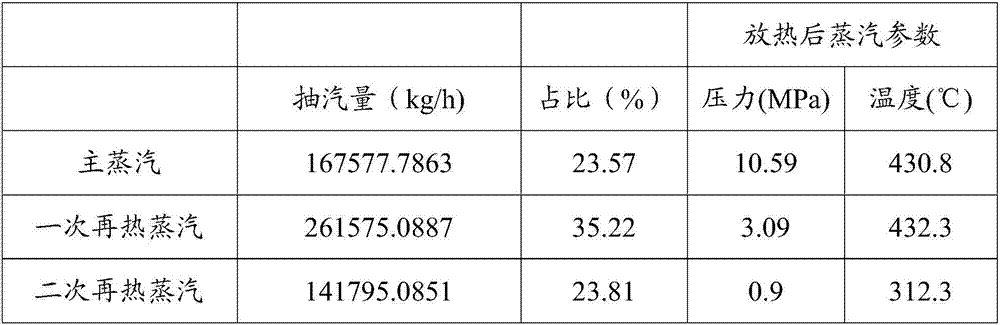

Liquid state energy storage system applicable to depth peak load regulation of heat power generating unit

PendingCN106885232AMeet the needs of low-load Internet accessRaise the inlet temperatureSteam engine plantsFeed-water heatersSteam pressureMolten salt

Owner:DONGFANG BOILER GROUP OF DONGFANG ELECTRIC CORP

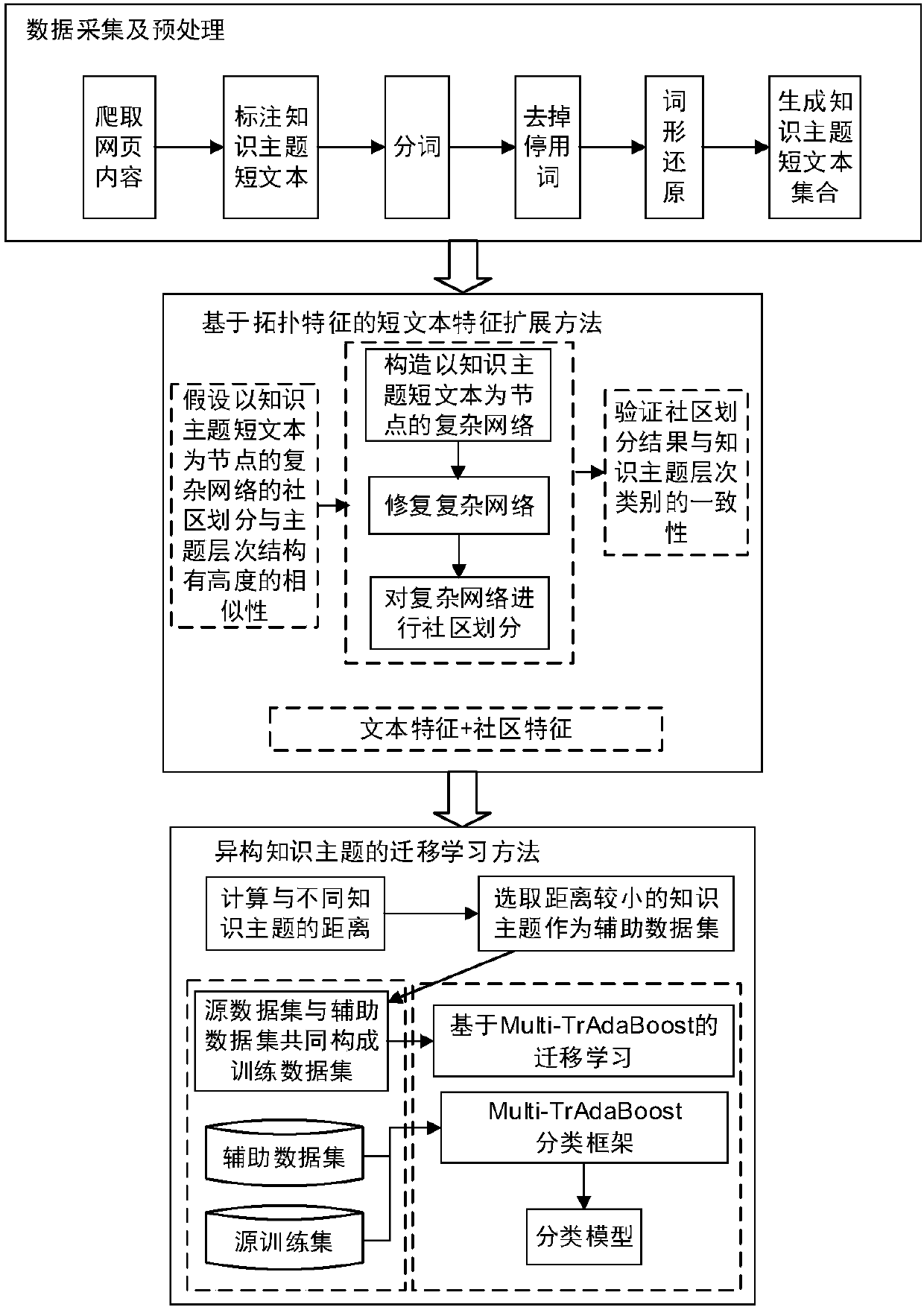

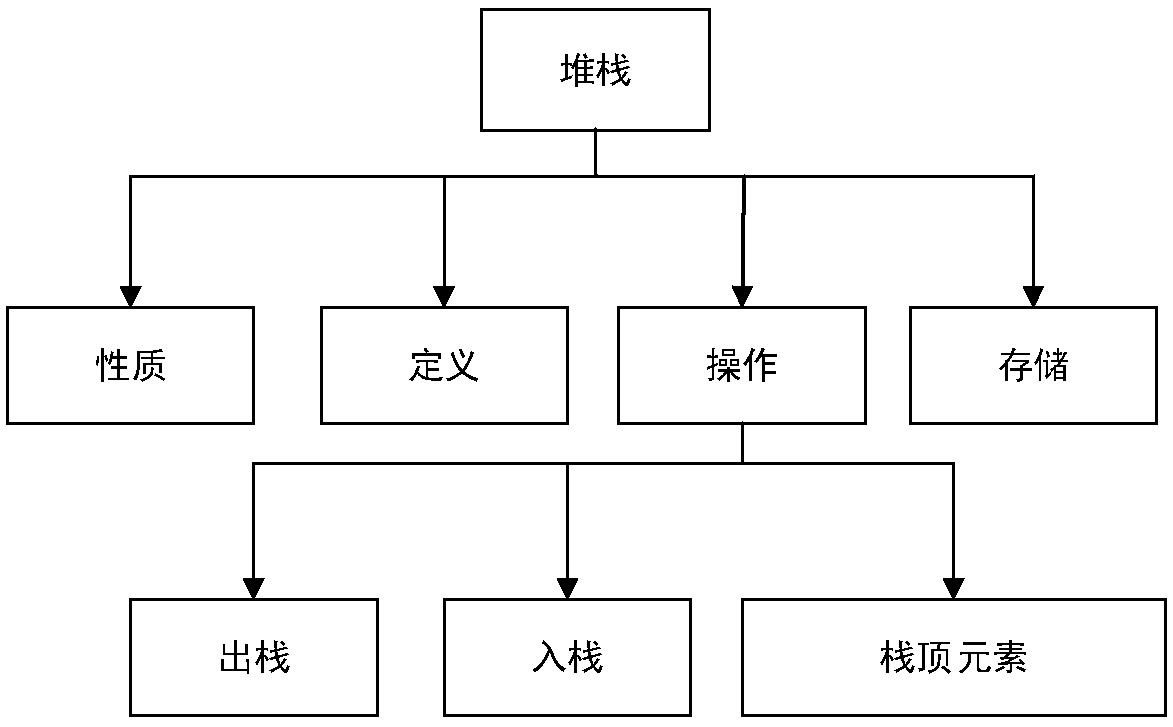

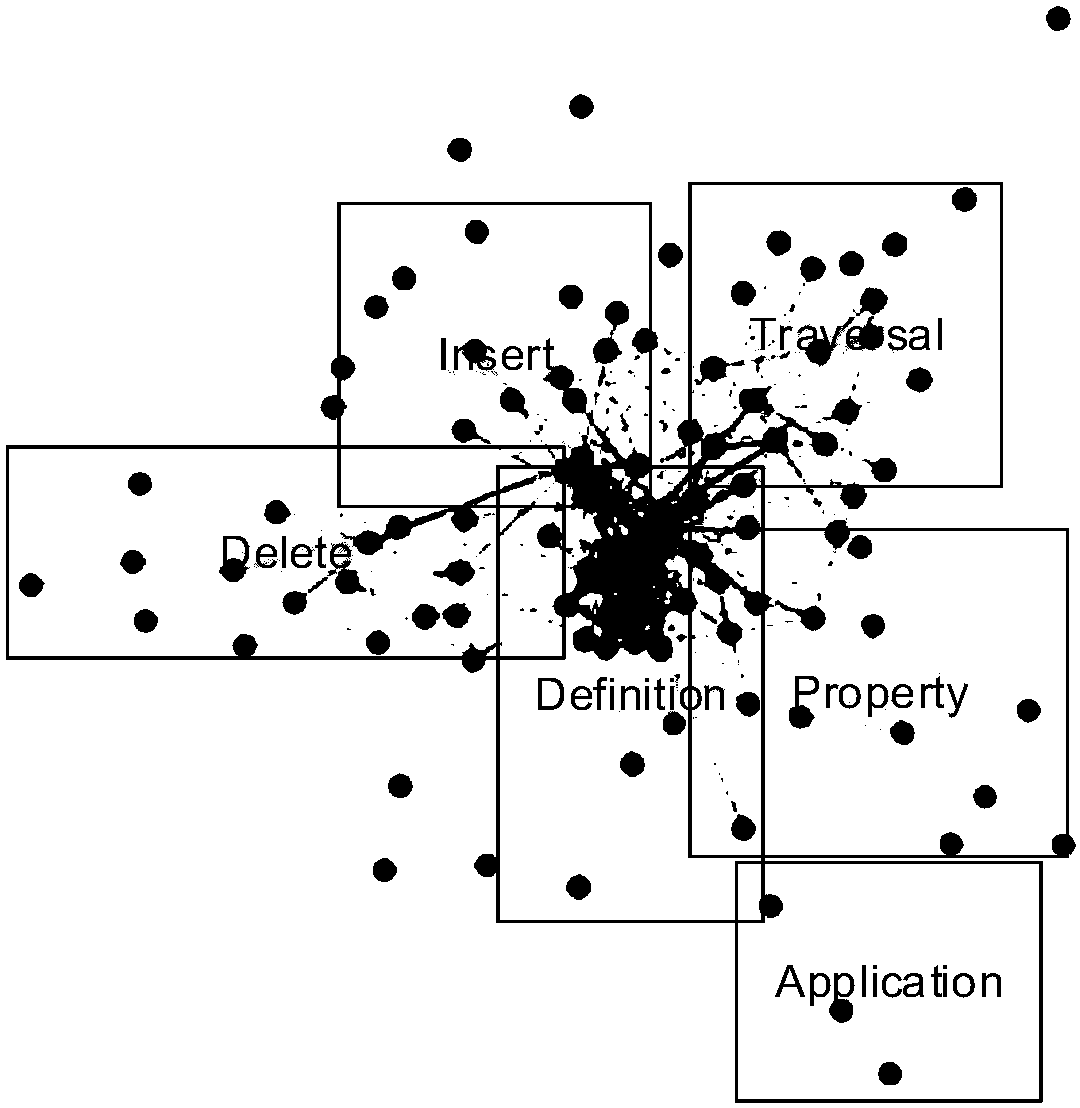

A knowledge topic short text hierarchical classification method based on topological characteristic extension

ActiveCN106991127AEasy to identifySpecify the degree of sparsitySpecial data processing applicationsCo-occurrenceThe Internet

The invention provides a knowledge topic short text hierarchical classification method based on topological characteristic extension. The method can effectively organize and manage knowledge topic short texts and solve the problem of information overload caused by mass knowledge short texts in the internet. The method comprises the steps of: 1) building of initial text characteristics; 2) topological characteristic-based short text characteristic extension; 3) transfer learning method among heterogeneous knowledge topics. By collecting the lengths of short texts corresponding to a plurality of knowledge topics and performing primary quantitative statistical analysis, the sparse degree of the characteristics of knowledge topic short texts becomes clear; a knowledge topic short text network is built and analyzed according to term co-occurrence conditions among short texts, and finally community characteristics are selected to effectively extend text characteristics. The difference of domains is measured by calculating the KL divergence among knowledge topics and further auxiliary data are selected; by converting hierarchical classification to multi-classification, the method can effectively organize and manage knowledge topic short texts.

Owner:XI AN JIAOTONG UNIV

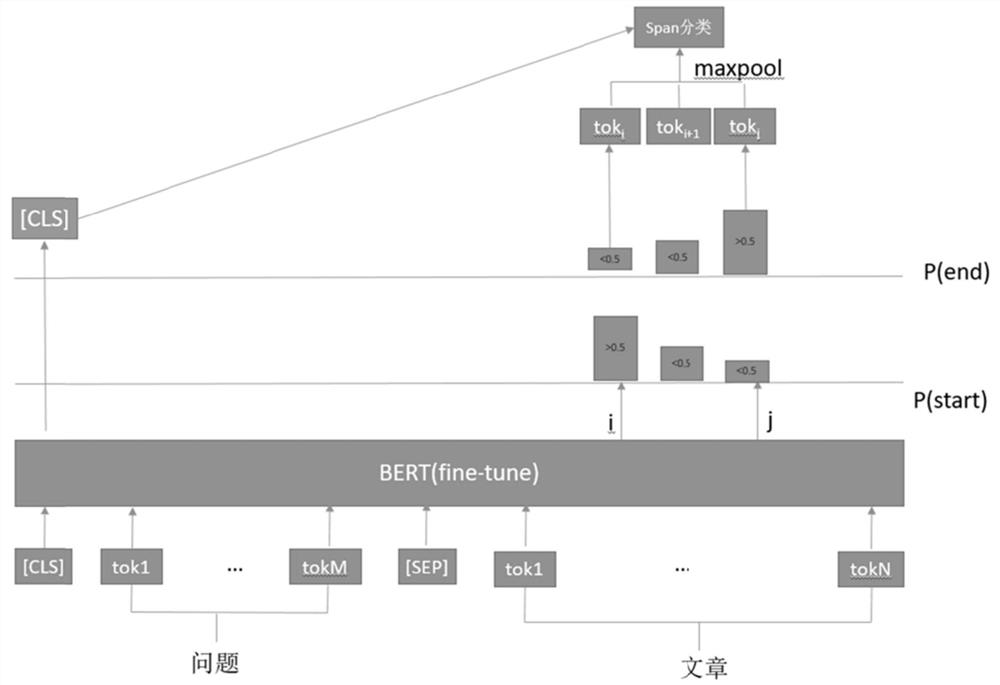

Application method in military equipment text entity extraction based on transfer learning

ActiveCN112215004AAvoid differencesReduce data labeling workCharacter and pattern recognitionNatural language data processingTask adaptationLinguistic model

The invention provides an application method for military equipment text entity extraction based on transfer learning, which comprises the following steps: step 1, establishing a network model for boundary extraction and text fragment classification as a skeleton model for text entity extraction, and effectively overcoming the difference of network structures caused by different types of extractedentities in different fields; 2, analyzing source domain data, constructing a source domain problem set, and realizing task adaptation; 3, realizing domain adaptation by using a mask-based language model; and step 4, applying the model completing the domain adaptation and the task adaptation to the target domain, and completing the extraction of the military equipment text information. Accordingto the method, the difference of network structures caused by different entity extraction types in different fields is effectively overcome; according to the method, the existing open source sequenceannotation data is fully utilized, the named entity recognition model is trained on the basis, learned knowledge is applied to the target field, and the data annotation work in the target field is effectively reduced.

Owner:THE 28TH RES INST OF CHINA ELECTRONICS TECH GROUP CORP

Neural network model compression method, corpus translation method and devices thereof

ActiveCN110826344AQuality improvementEffective migrationNatural language translationSemantic analysisMachine learningSource data

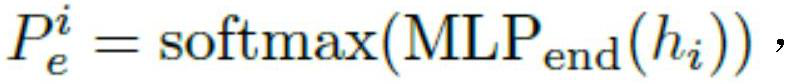

The invention relates to a neural network model compression method, a corpus translation method and devices thereof. The neural network model compression method comprises the steps of acquiring a training sample set comprising a plurality of training sample pairs, wherein each training sample pair comprises source data and target data corresponding to the source data; training an original teachermodel by taking the source data as input and taking the target data as verification; training an intermediate teacher model based on the training sample set and the original teacher model, and forminga teacher model set by one or more intermediate teacher models; training a plurality of candidate student models based on the training sample set, the original teacher model and the teacher model set, and forming a student model set by the plurality of candidate student models; and according to the training results of the plurality of candidate student models, selecting one candidate student model as a target student model. By introducing a plurality of teacher models, multistage guidance of student model training is realized, so that the quality of the student model is improved.

Owner:BEIJING XIAOMI INTELLIGENT TECH CO LTD

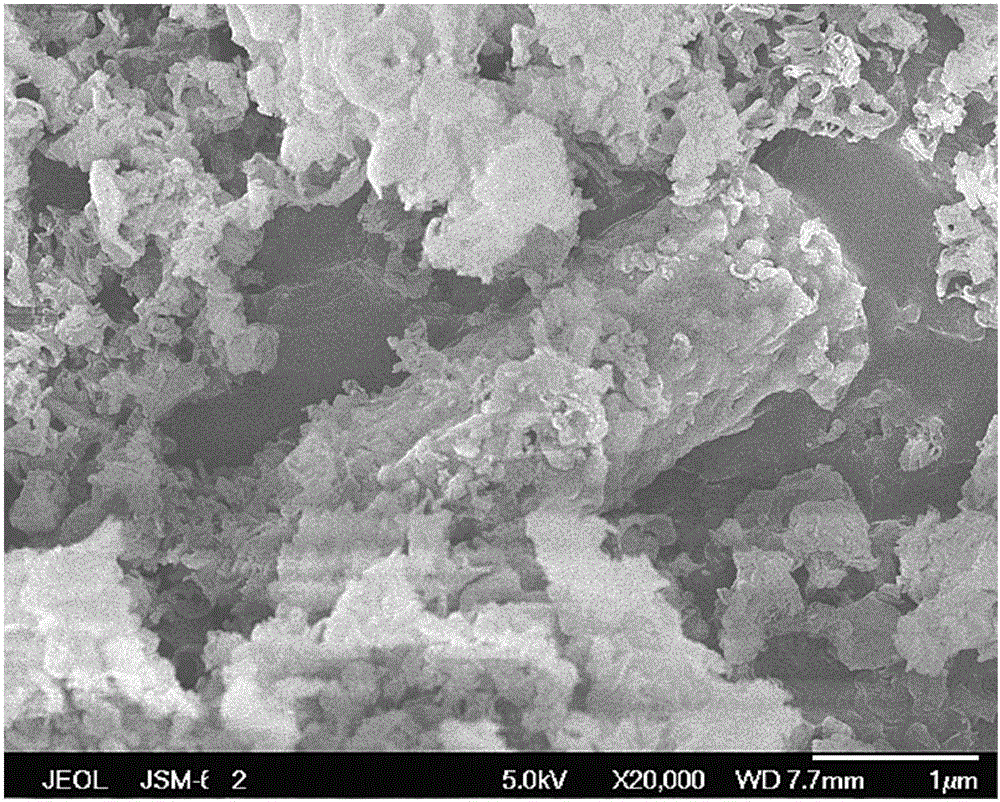

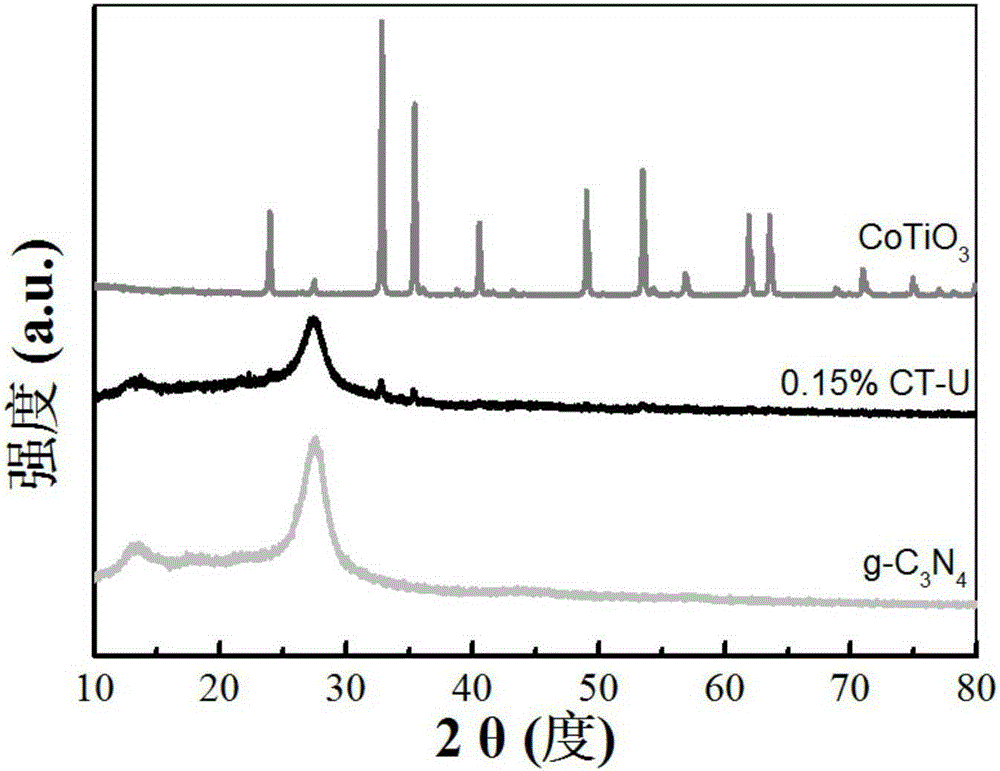

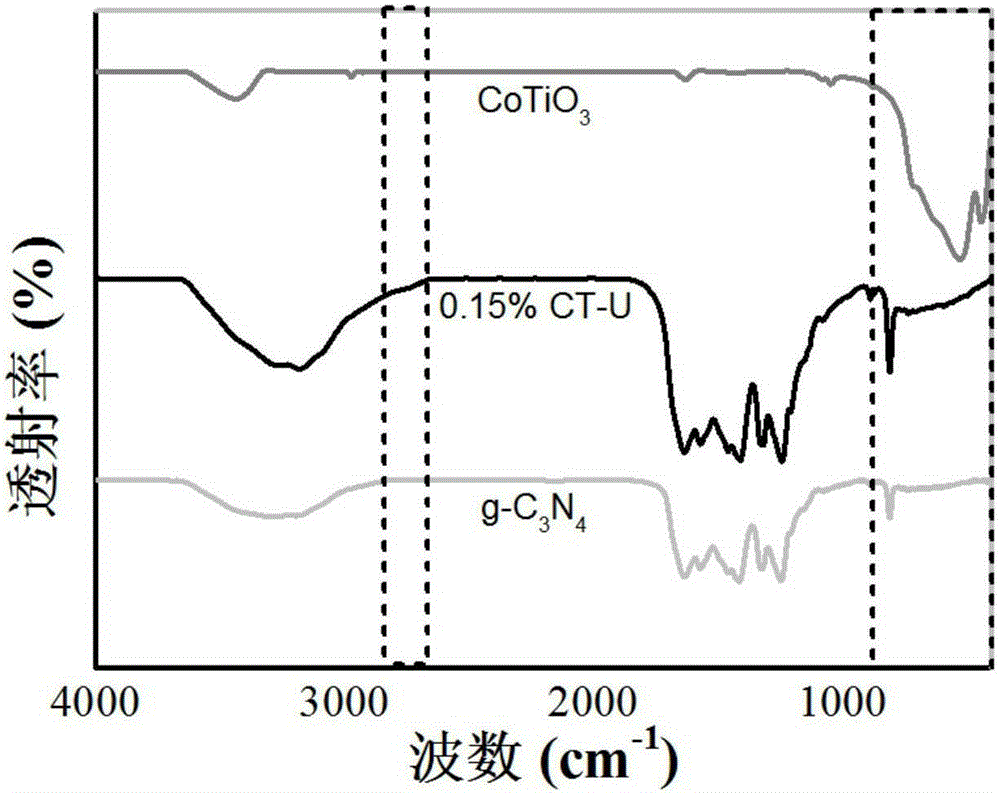

Perovskite material/organic polymer compound photocatalyst, preparation and application

ActiveCN105170173AEasy to prepareEasy to operateOrganic-compounds/hydrides/coordination-complexes catalystsHydrogen productionValence bandCarbon nitride

The invention discloses a perovskite material / organic polymer compound photocatalyst, preparation and application, and belongs to the field of perovskite material / organic polymer compound photocatalyst. Rolled-piece-shaped carbon nitride is successfully dispersed on the surface of cobalt titanate, through compounding of electrons on a cobalt titanate conduction band and holes in a carbon nitride valence band, holes in a cobalt titanate valence band and electrons on a carbon nitride conduction band are separated, and therefore the photocatalytic performance is greatly improved. The material is applied to the field of water photolysis hydrogen production, and the hydrogen production rate is substantially increased compared with pure carbon nitride.

Owner:BEIJING UNIV OF CHEM TECH

Method for manufacturing shallow trench isolation

InactiveCN102867774AReduce roughnessEffective migrationSemiconductor/solid-state device manufacturingHydrogen atmosphereEngineering

The invention provides a method for manufacturing shallow trench isolation. After being etched to form a shallow trench, a substrate is subject to an annealing process under a certain condition of hydrogen atmosphere, so that element atoms of the substrate are promoted to make thermal motion migration under a high temperature, side walls of the rough shallow trench and square corners of the shallow trench become smooth, the leakage current of a semiconductor device employing the shallow trench isolation is reduced, and the performances of the semiconductor device and an integrated circuit are improved.

Owner:SEMICON MFG INT (SHANGHAI) CORP

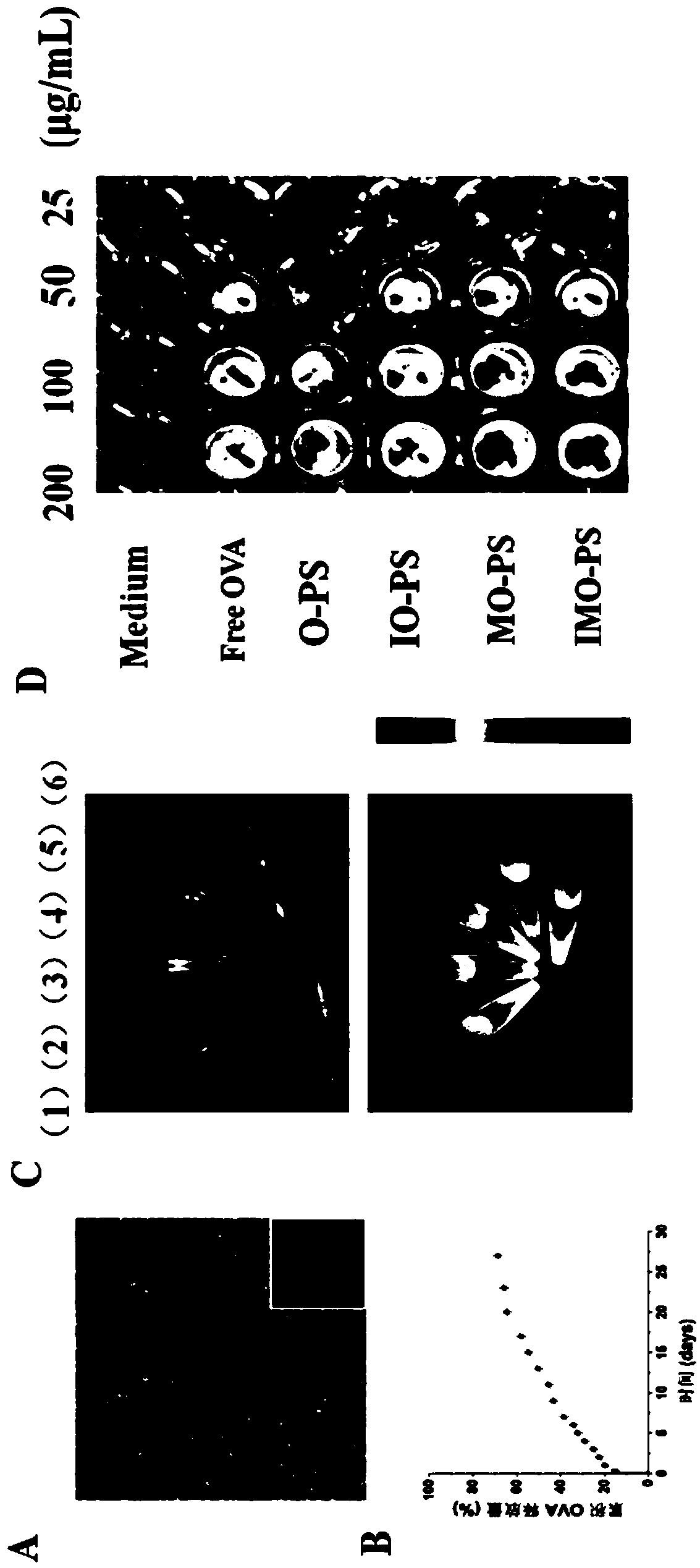

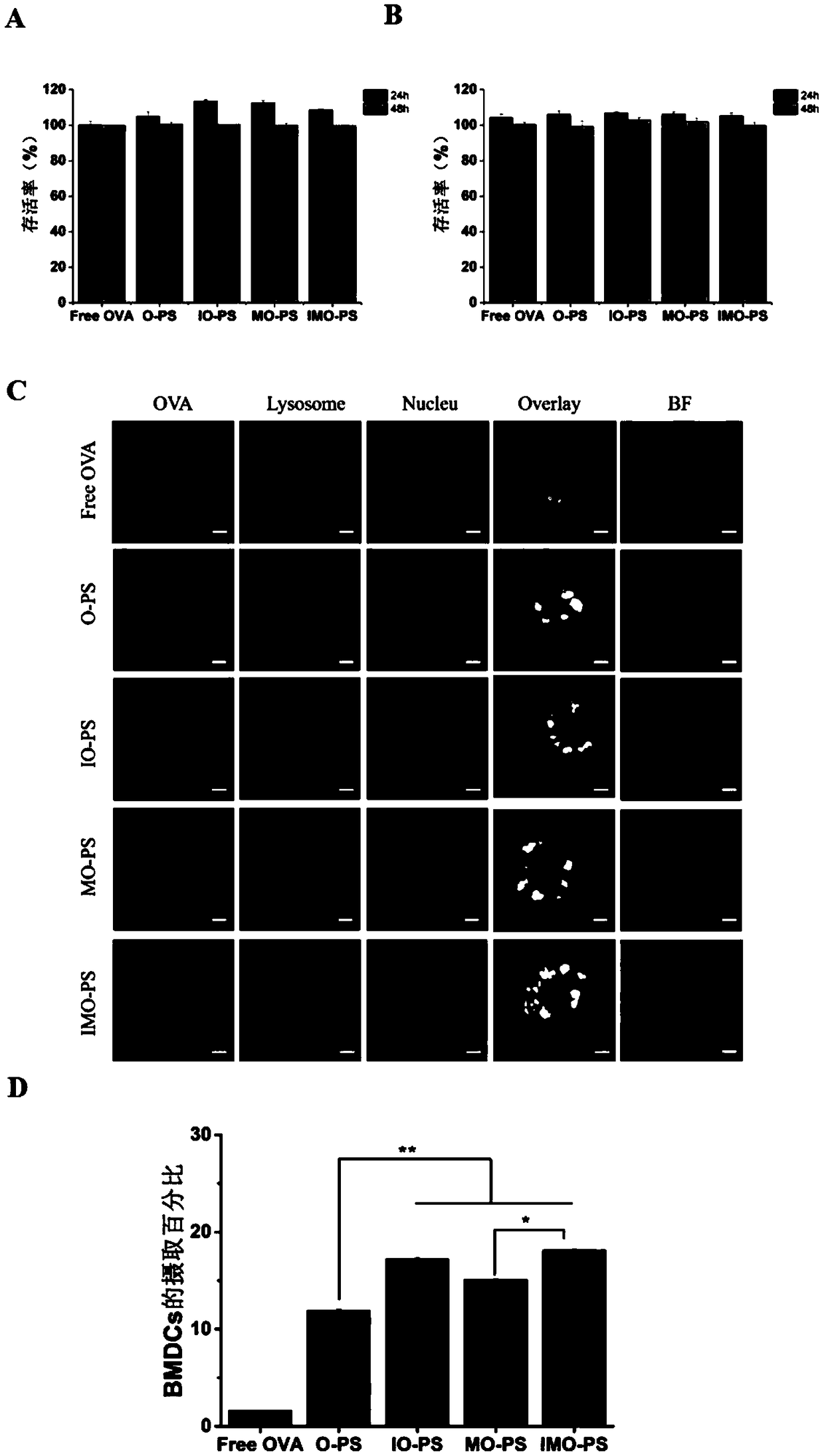

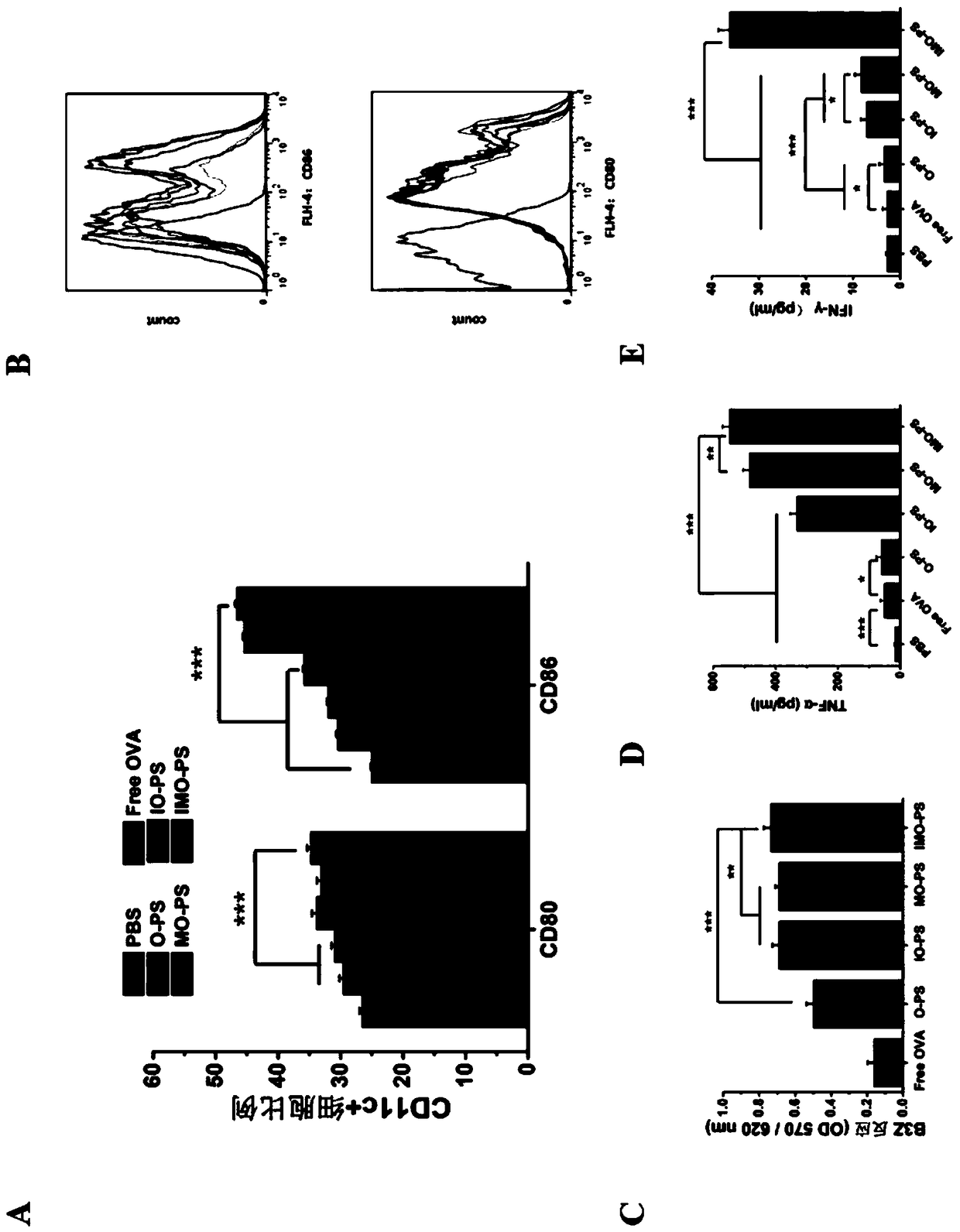

DCs vaccine based on phospholipid hybrid polymersome jointly encapsulating antigen and dual immunoagonists and preparation method and application thereof

ActiveCN108938568AMaximize Targeting EffectAchieving ImmunotherapyCancer antigen ingredientsPharmaceutical non-active ingredientsT lymphocyteBiological activation

The invention relates to a DCs vaccine based on phospholipid hybrid polymersome jointly encapsulating an antigen and dual immunoagonists, a preparation method and application thereof. The phospholipidhybrid polymersome which can jointly load a model antigen OVA and two types of TLR agonists (TLR7 / 8 and TLR4) is used for stimulation in vitro of the DCs so as to realize the effective phagocytosis of DCs cells. The rapid and long-term immunostimulatory effect on the DCs is achieved by the internal and external co-loading of the OVA antigen. The synergistic effect of the two types of TLR agonistssignificantly enhances the immune response after antigen stimulation; the phospholipid hybrid polymersome which jointly encapsulates the antigen and the dual immunoagonists can effectively promote the activation and maturation of the DCs, increases the level of cross-presentation, promotes the migration of the DC vaccine to secondary lymphoid organs, and produces a strong specific cytotoxic T lymphocytes (CTLs) killing effect, thereby effectively killing tumor cells and realizing the immunotherapy of the DCs vaccine on tumors.

Owner:INST OF BIOMEDICAL ENG CHINESE ACAD OF MEDICAL SCI

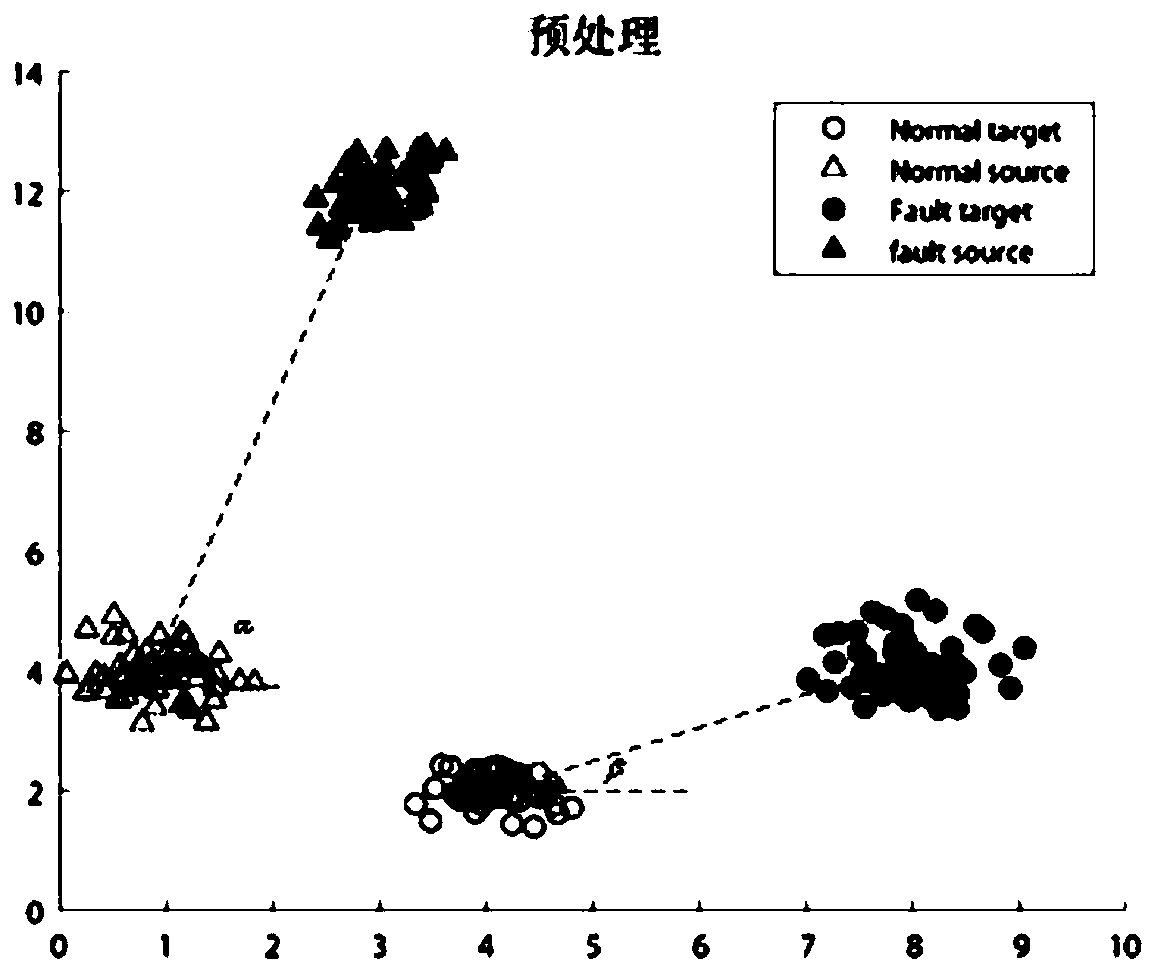

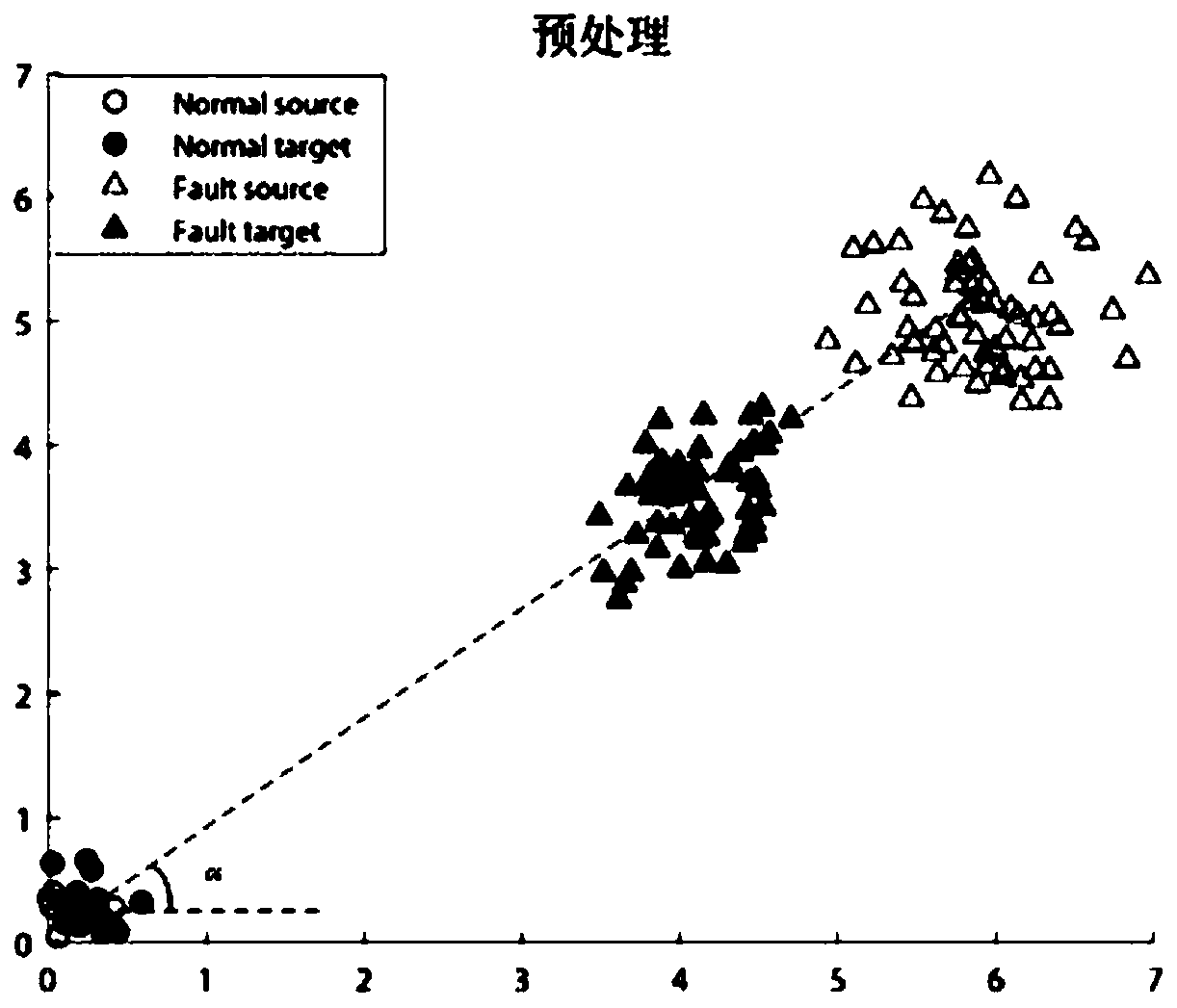

Seawater pump fault monitoring device and diagnosis method based on multi-source information fusion

ActiveCN111259990AFacilitate pre-diagnosis of faultsExtended maintenance cycleMeasurement devicesCharacter and pattern recognitionSeawaterReliability engineering

The invention belongs to the technical field of fault diagnosis, and particularly relates to a fault monitoring device and diagnosis method based on multi-source signal fusion, and the device comprises a vibration signal collection unit A, a current signal collection unit B, and a signal processing unit C; the signal acquisition units A and B use sensors to acquire vibration and current data of the seawater cooling pump; the signal processing unit C carries out fast Fourier transform (FFT) processing on the signals to obtain frequency domain information, and the fault monitoring device can monitor the time-frequency domain states of vibration signals and current signals of the sea water pump in real time and is used as data preparation for fault diagnosis. According to the seawater pump fault diagnosis method based on multi-source information fusion, the migration kernel locality preserving projection algorithm is used as a model, multi-source signal information obtained by a fault monitoring device is used as input, Acc and F1-score are used as evaluation indexes, and a trained classifier is used for classifying and identifying unknown fault data, so that fault information can bequickly obtained, the generalization ability is enhanced, and the diagnosis accuracy is improved.

Owner:JIANGSU UNIV OF SCI & TECH

Method and apparatus for preparing high-purity gallium

ActiveCN104711438AEffective migrationStabilize the solid-liquid interface regionLiquid stateLiquid metal

The present invention discloses a method and an apparatus for preparing high-purity gallium. According to the method, liquid-state high-purity gallium is placed on the bottom portion of a container and is cooled as a seed crystal, the liquid-state metal gallium is poured into the cooling container to cool and crystallize, a thermal source coil is opened after complete crystallization, the temperature and the movement speed of the thermal source coil are controlled, the thermal source coil moves from bottom to top, the stable solid-liquid interface during the solidification process is ensured, the solidification interception ratio is 70-90%, and the metal gallium can be purified to achieve more than or equal to 6N. The apparatus comprises the cooling container, a constant temperature cold source, the thermal source coil and a control device, wherein the bottom portion of the cooling container is provided with the constant temperature cold source, the upper portion of the cooling container is provided with a dust preventing cover, the thermal source coil sleeves on the outer side of the cooling container, and the thermal source coil is connected with the control device through a conducting wire so as to make the temperature and the movement speed of the thermal source coil be controlled by the control device. According to the present invention, characteristics of simple apparatus mechanism, easy method operation, convenient specification quantifying, good product stability and the like are provided.

Owner:NORTHEASTERN UNIV

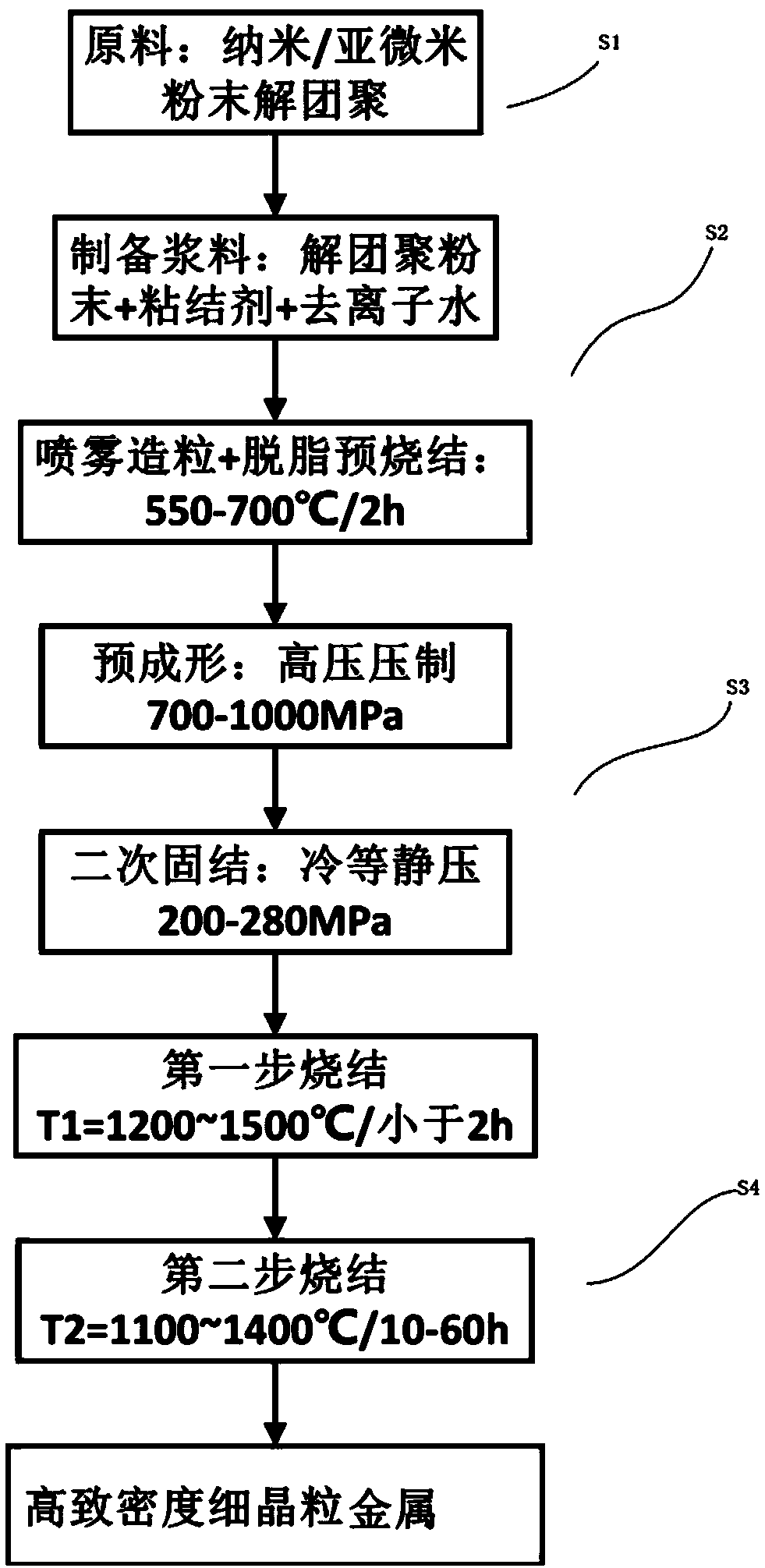

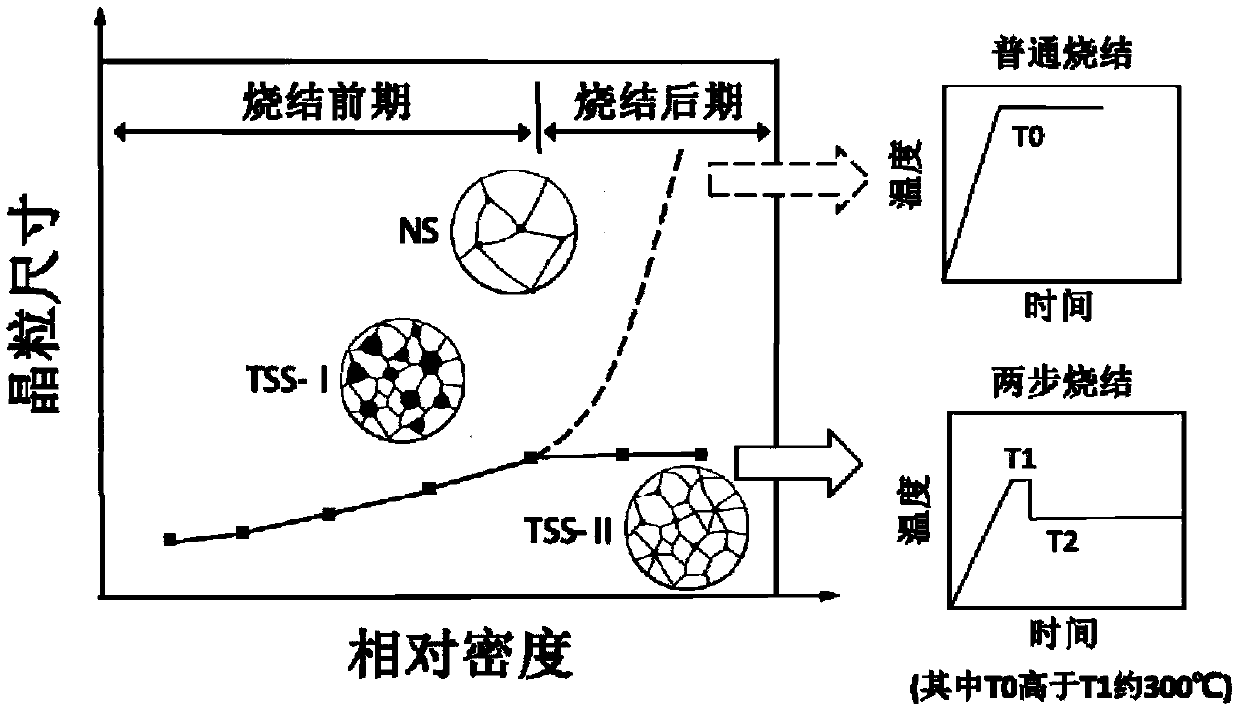

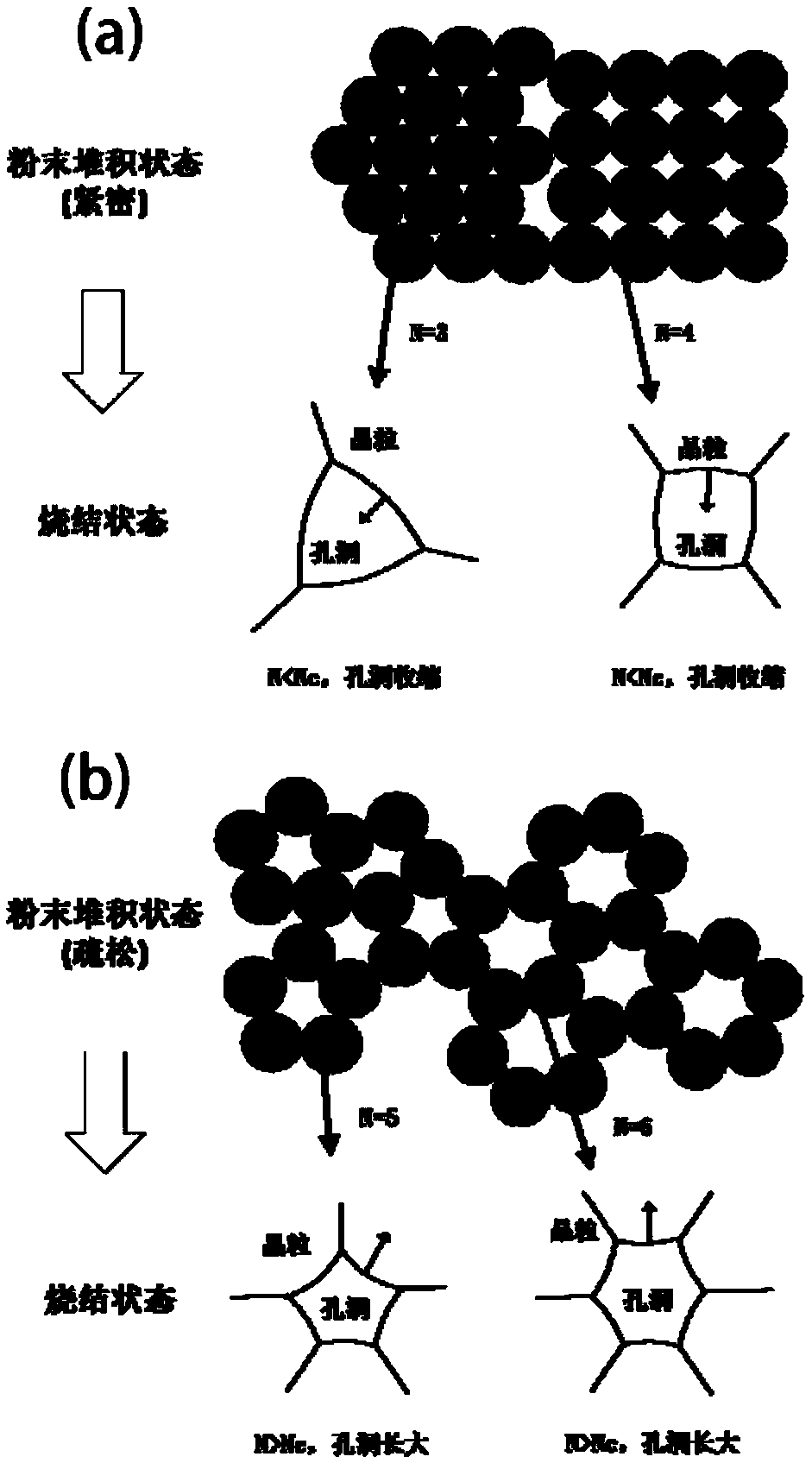

Method for controlling sintering densification and grain sizes of metal materials

ActiveCN109676124AReduce abnormal growthNarrow particle size distributionTransportation and packagingMetal-working apparatusSpray GranulationDispersity

The invention provides a method for controlling sintering densification and grain sizes of metal materials. The method includes the steps that firstly, raw material powder is deagglomerated, and deagglomerated powder with good dispersity is obtained. The deagglomerated powder is subjected to spray granulation, so that the flow performance of the powder and the density uniformity of a pressing blank are improved. The granulated powder is subjected to high-pressure pressing and cold isostatic forming. After the pressing blank is subjected to two steps of pressureless sintering, high-density fine-grain refractory metal is obtained. According to the first step of sintering, the pressing blank is rapidly heated to the temperature T1, heat preservation is carried out, the density is controlled at 75-85%, then the pressing blank is reduced to the temperature T2, then time heat preservation is carried out, and residual holes are further eliminated. By means of the two steps of sintering, the sintering temperature can be greatly reduced, almost full densification of the metal blank can be achieved at low temperature, rapid growth of grains in the densification later period in the conventional sintering process can be effectively restrained, the prepared refractory metal product is almost fully dense, the grains are fine, the grain sizes are evenly distributed, and the mechanical performance is excellent.

Owner:UNIV OF SCI & TECH BEIJING

Compound oil-displacing agent for high temperature reservoir and compound oil-displacing system

ActiveCN105038752AImprove long-term thermal stabilityEasy injectionDrilling compositionEmulsionOil water

The invention discloses a compound oil-displacing agent for a high temperature reservoir and a compound oil-displacing system. The compound oil-displacing agent is prepared from the following components in parts by mass: 5-15 parts of polymer, 40-100 parts of negative and non-ionic compound surfactant and 50-200 parts of NaCl. After the compound oil-displacing agent is mixed with water, the compound oil-displacing system capable of forming micro emulsion in a high temperature reservoir is formed; the compound oil-displacing system can act with crude oil to form stable micro emulsion and has the characteristics of strong oil-water solubilizing capability and ultra-low interface tension; the oil-displacing system is capable of resisting temperature of 105 DEG C, has good long-term thermal stability and good injectivity, and can obviously improve the recovery efficiency; and the oil-displacing agent is suitable for a high temperature reservoir of which the reservoir temperature is 80-105 DEG C, the permeability rate is equal to or higher than 200*10<-3>mu m<2> and the salinity is 0-100000mg / L, and the crude oil recovery ratio is improved.

Owner:CHINA PETROLEUM & CHEM CORP +1

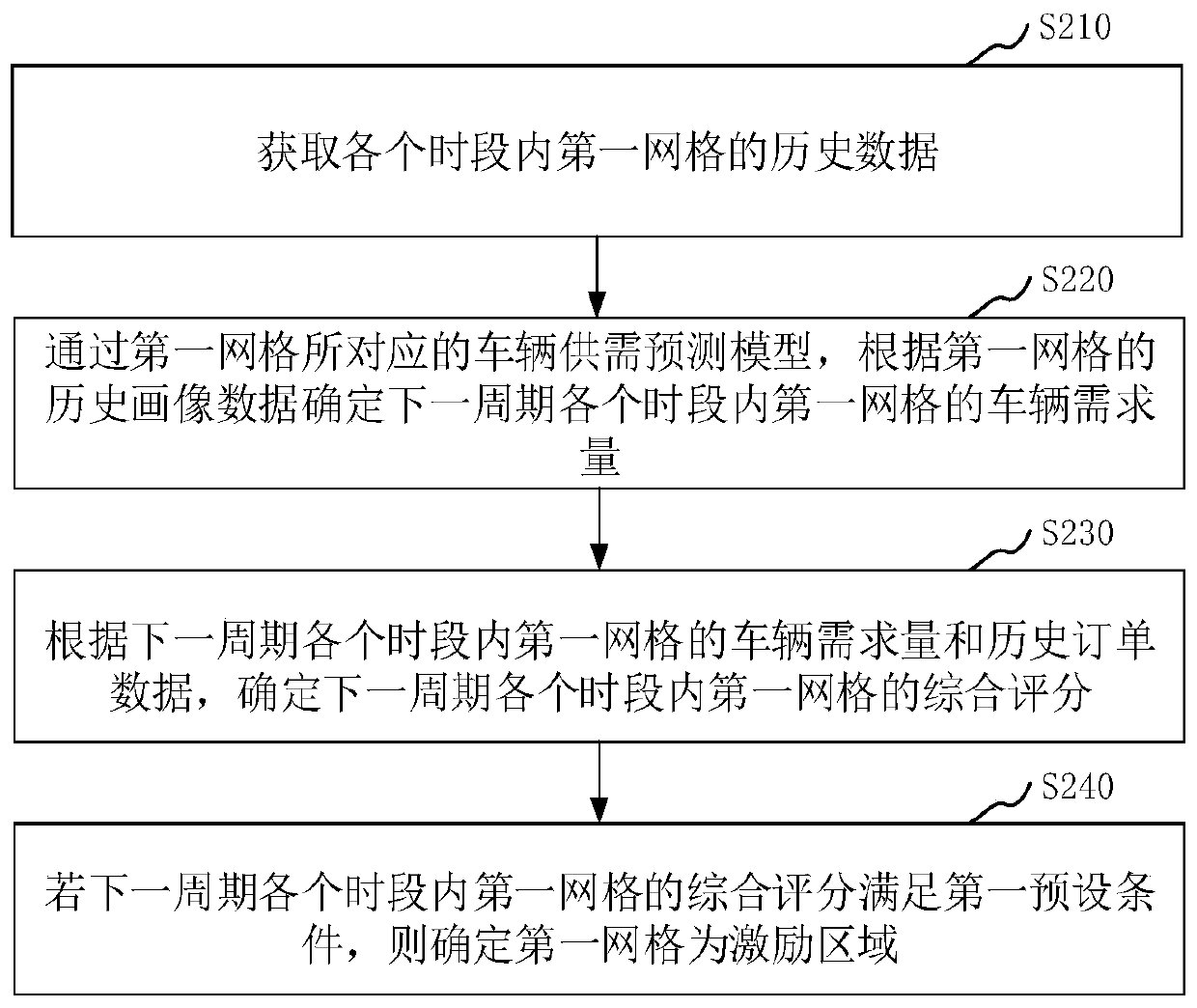

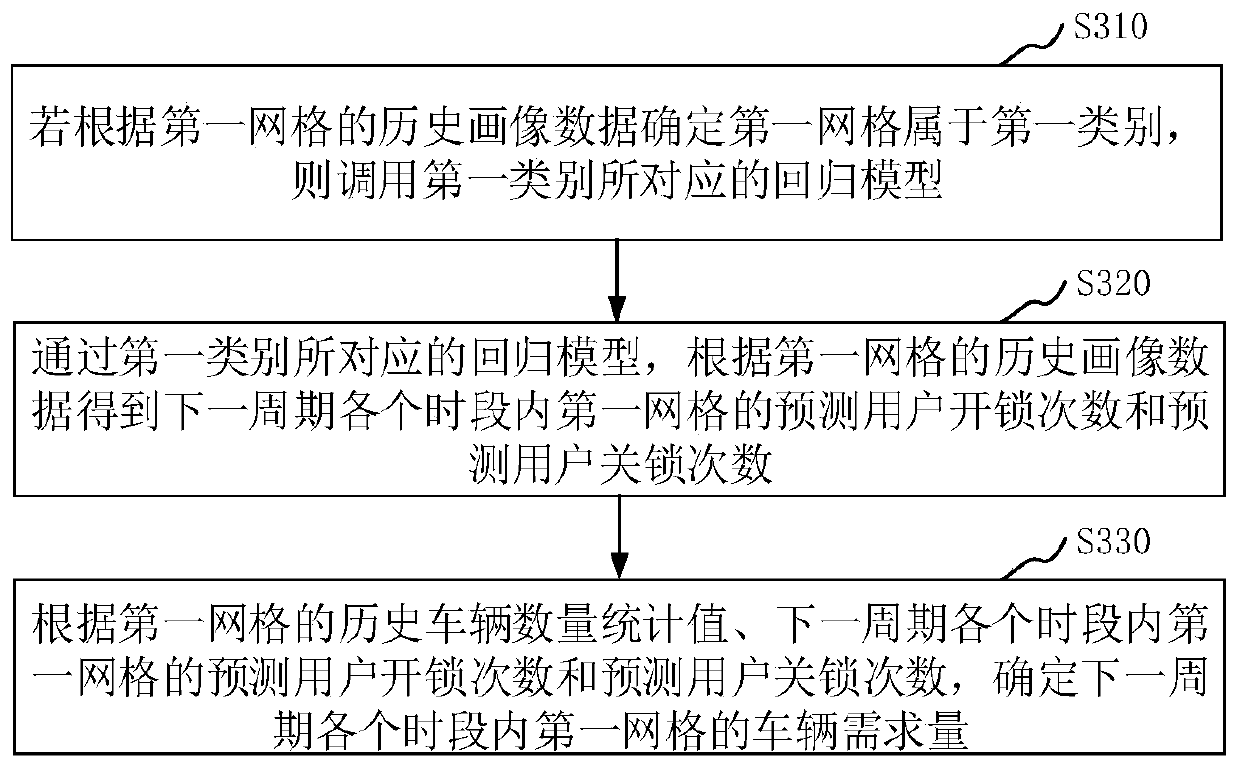

Excitation area setting method and device, computer equipment and storage medium

InactiveCN110796496AEffective migrationIncrease usageBuying/selling/leasing transactionsResourcesData packSimulation

The invention relates to a shared vehicle excitation area setting method and device, computer equipment and a storage medium. The method comprises the steps of obtaining historical data of a first grid in each time period; wherein the first grid is obtained by dividing an operation area of the shared vehicle, and the historical data comprises historical portrait data and historical order data; through a vehicle supply and demand prediction model corresponding to the first grid, determining the vehicle demand of the first grid in each time period of the next period according to the historical portrait data of the first grid; determining a comprehensive score of the first grid in each time period of the next period according to the vehicle demand and the historical order data of the first grid in each time period of the next period; and if the comprehensive score of the first grid in each time period of the next period meets a first preset condition, determining that the first grid is anexcitation region. Effective migration of the shared vehicles can be guaranteed, the utilization rate of the shared vehicles is increased, and the technical problem that in the prior art, the vehicleutilization rate is insufficient is solved.

Owner:SHANGHAI JUNZHENG NETWORK TECH CO LTD

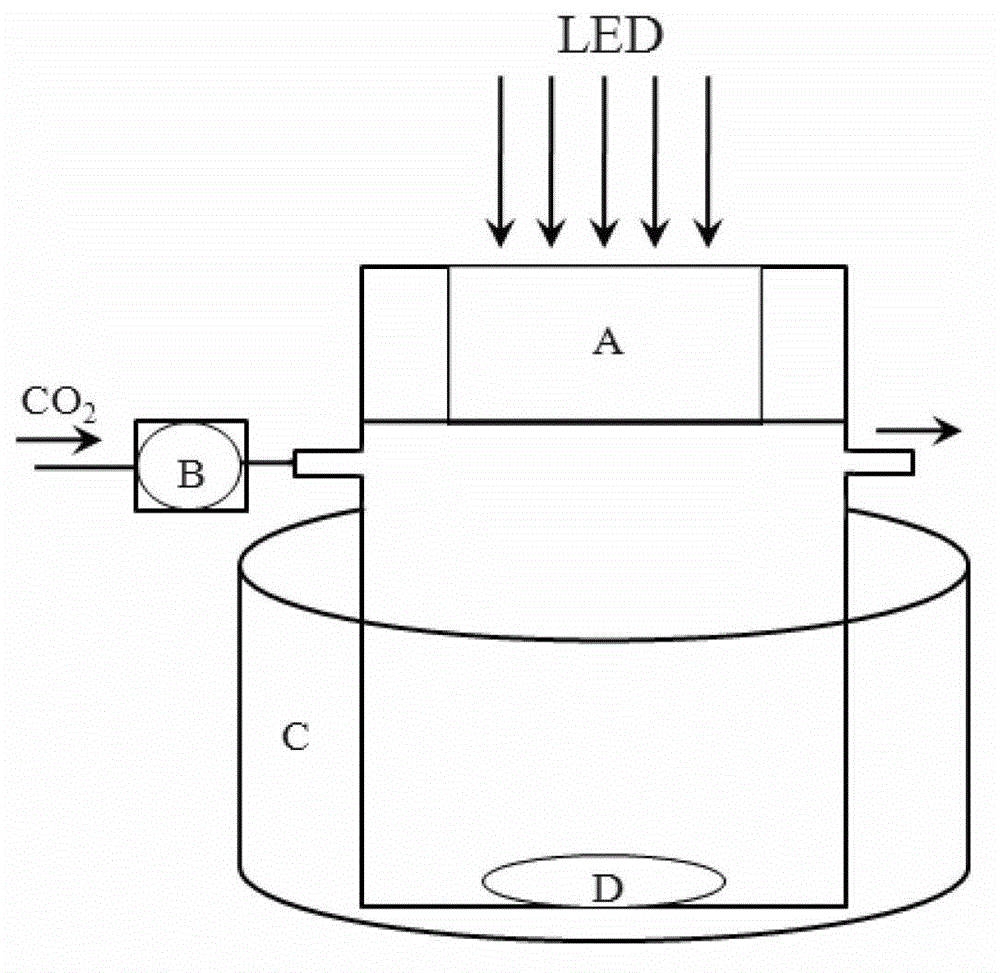

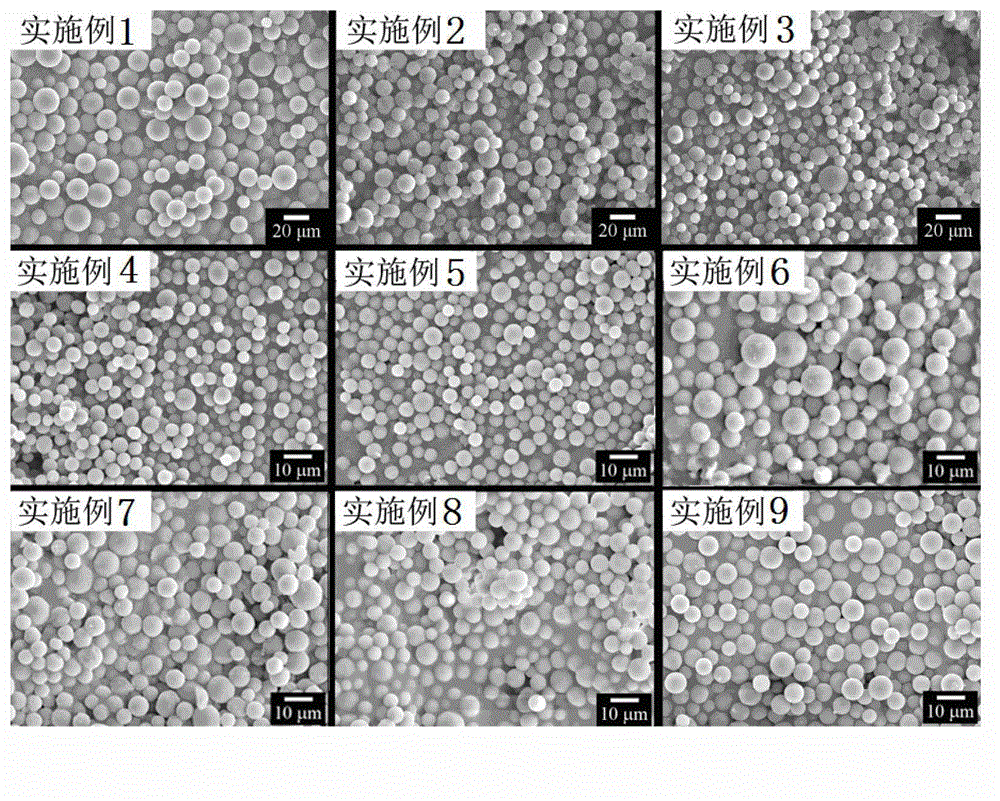

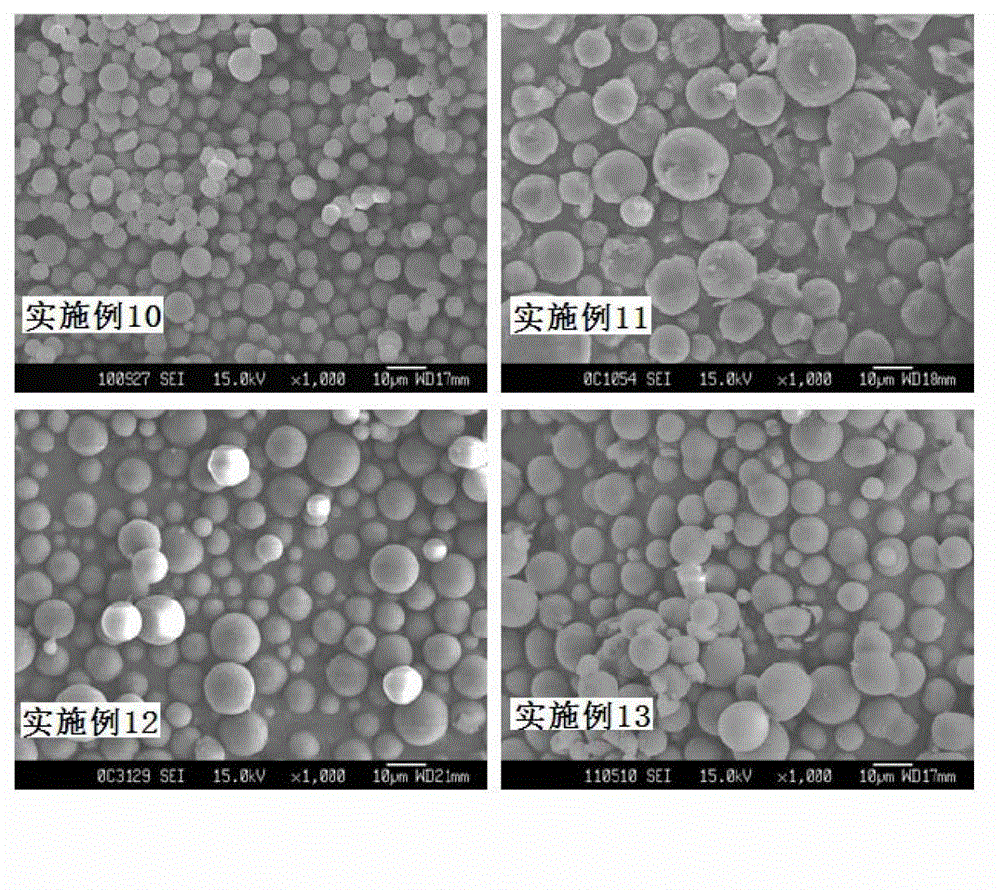

Preparation method of polymer microsphere with liquid carbon dioxide as medium

The invention discloses a preparation method of a polymer microsphere with liquid carbon dioxide as a medium. The method includes the steps of: adding a polymerization monomer, a photoinitiator and a stable dispersant into a reaction kettle, introducing a carbon dioxide gas to conduct emptying, then injecting liquid carbon dioxide, when the temperature and pressure in the reaction kettle become constant, irradiating the inside of the reaction kettle by an initiating light source, letting a reaction to undergo under a temperature ranging from -20 to 30DEG C and a pressure of 20-70bar for 0.5-5h; at the end of the reaction, bringing the temperature back to room temperature, washing the polymer precipitated to the bottom of the reaction kettle by liquid carbon dioxide, and removing the residual polymerization monomer, thus obtaining the polymer microsphere. The method provided in the invention introduces a photo-initiation technology into dispersion polymerization with carbon dioxide as the medium, greatly reduces the carbon dioxide system pressure, and shortens the time of polymerization reaction, thereby significantly reducing the cost of high-pressure reaction equipment and improving the production efficiency. The prepared microsphere has good hydrophobic property and low surface energy, and can be effectively enriched on a coating surface in coating application.

Owner:SHANGHAI WEIKAI CHEM +1

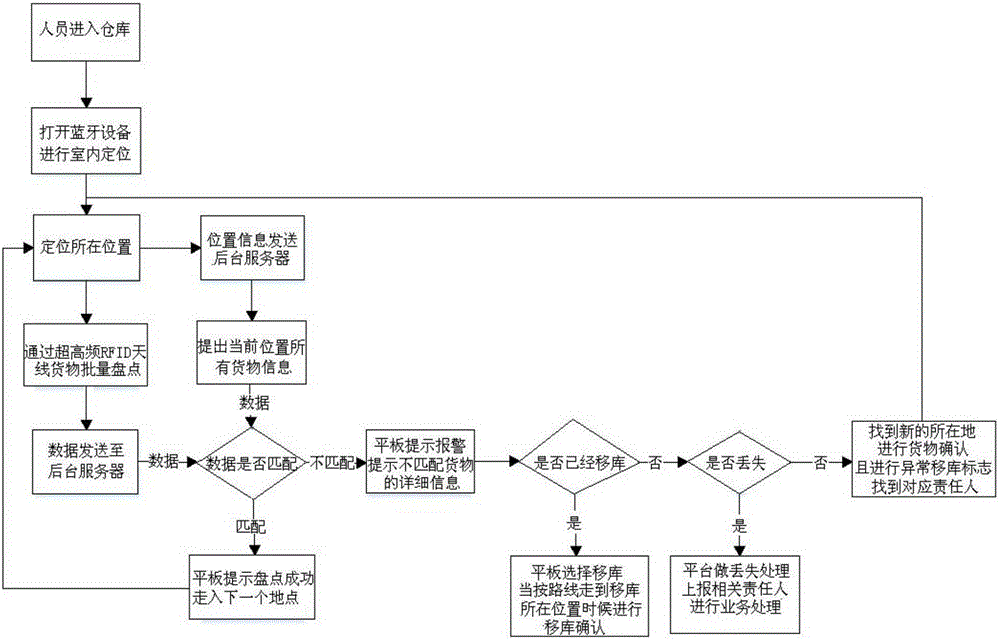

On-line checking method based on Bluetooth positioning and RFID

InactiveCN105279628AEffective migrationReduce the likelihood of a mismatchLogisticsLocation information based serviceWorkloadBluetooth

The invention discloses an on-line checking method based on Bluetooth positioning and an RFID, and the method enables the Bluetooth indoor positioning and cargo checking to be combined for use. A conventional warehouse application environment is diversified, and the input / output of cargos is relatively large. Cargos usually need to be checked, and a background usually needs to carry out checking for correcting data of cargos. The checking process needs a large amount of manpower in the prior art, and the internal position where the cargos are located is unclear. Through the cooperation of Bluetooth positioning and an ultrahigh frequency RFID, the method can iron out various defects in a full-automatic manner that the workload is large and the data correction is tedious in current cargo checking, and can effectively improve the working efficiency of a checker.

Owner:HANGZHOU ZIYUE TECH CO LTD

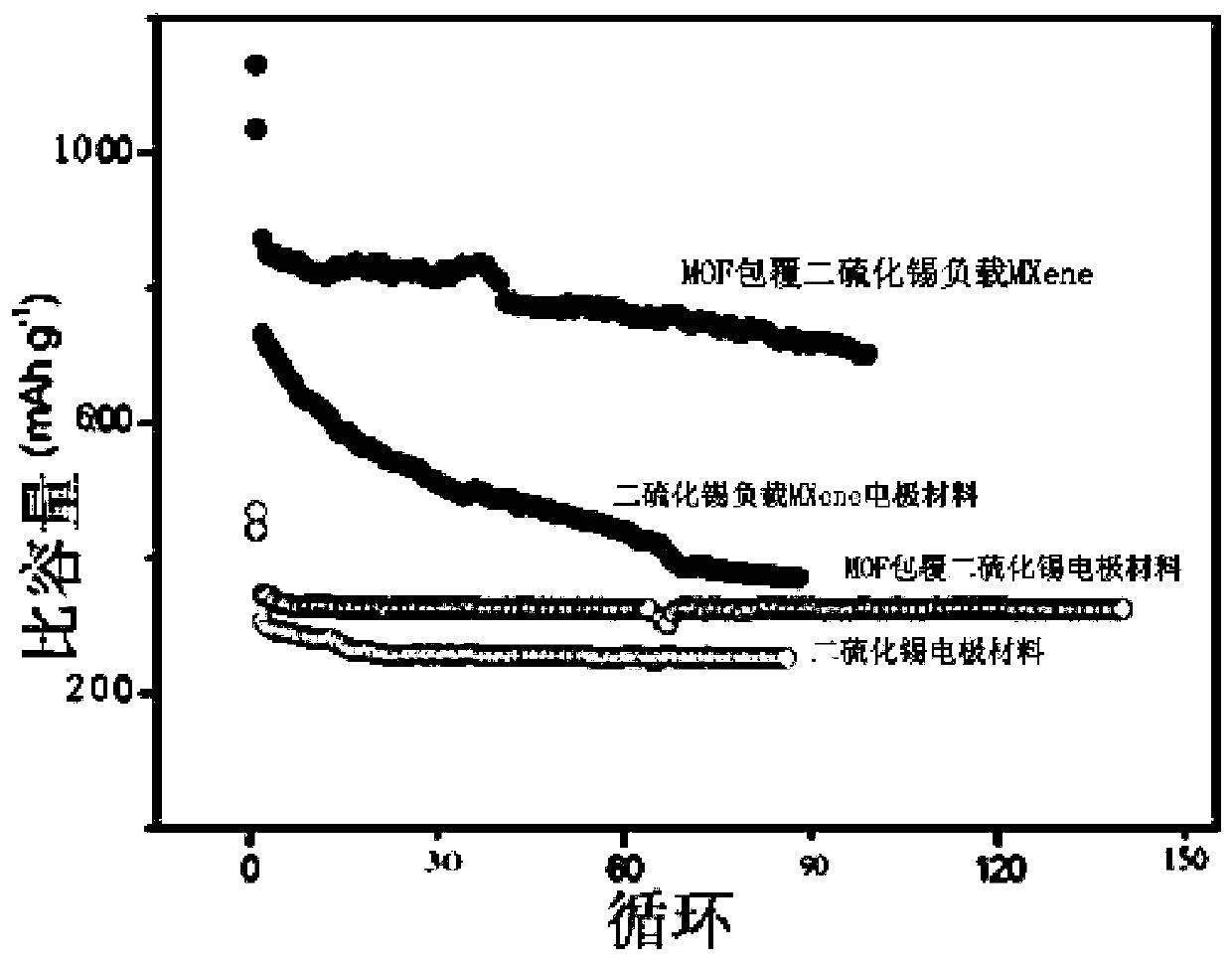

Lithium ion battery and preparation method thereof

ActiveCN111384387AEasy to controlGood synergyFinal product manufactureNegative electrodesPhysical chemistryBattery cell

The invention relates to a lithium ion battery and a preparation method thereof. The lithium ion battery negative electrode active material is an MOF-coated tin disulfide-loaded Mxene composite material, wherein MOF is a metal carbon framework, and Mxene is a material with a two-dimensional layered structure; the MOF and tin disulfide loaded Mxene are compounded to form a double-carbon framework material, and a more stable lithium ion de-intercalation carrier is formed; the MOF is used as a shell frame to provide a lithium ion transmission channel and provide a skeleton supporting effect, tindisulfide is prevented from volume collapse and pulverization in the charging and discharging process, the layered structure has more excellent stability, tin disulfide loading is facilitated, the Li+de-intercalation number is increased, and the specific capacity of tin disulfide can be greatly improved.

Owner:HANGZHOU DEBIAO NEW ENERGY TECH CO LTD

Graphene/ZnS-MoS2 nano solid solution photocatalyst having visible light catalytic activity

ActiveCN108686681ALarge specific surface areaStrong light absorption and photocatalytic abilityPhysical/chemical process catalystsWater/sewage treatment by irradiationCvd grapheneElectron hole

The invention discloses a synthesis method of a graphene / ZnS-MoS2 nano solid solution photocatalyst having visible light catalytic activity. The method includes steps of: preparing graphene oxide (GO)through an improved Hummers method, then dispersing the GO in organic solvent and performing ultrasonic treatment to form a homogenous solution; with inorganic zinc salt, inorganic molybdenum salt and sulfur source as raw materials, successively dissolving the raw materials in an organic solution, and adding the graphene solution prepared before; performing a reaction at 180-220 DEG C so that thenano solid solution ZnS-MoS2 is uniformly adhered to the graphene thin film to form the rGO ZnS-MoS2 nano solid solution photocatalyst combined with chemical bonds. The photocatalyst, when the content of graphene is 5-14%, has excellent visible light catalytic performance. The photocatalyst has large specific surface area, narrow and continuously-adjustable energy gap, can effectively promote separation and migration of photo-induced electron-hole, and has excellent photo-absorption and photo-catalytic activity under visible light.

Owner:NANCHANG HANGKONG UNIVERSITY

Preparation method of ZnO/g-C3N4 composite photocatalyst

InactiveCN102950016BHigh crystallinityGood dispersionPhysical/chemical process catalystsWastewaterSolvent

The invention relates to a preparation method of a ZnO / g-C3N4 composite photocatalyst. A two-stage solvent thermal / ultrasonic dispersing method is employed to prepare the ZnO / g-C3N4 composite photocatalyst. After the two-stage solvent thermal treatment, porous ZnO nano crystalline with high dispersion grown on the g-C3N4 can be obtained, and the ZnO nanocrystalline and the g-C3N4 can form a good composite structure; the ultrasonic treatment reduces agglomeration among the ZnO / g-C3N4 composite particles, and improves dispersion of the composite catalyst; and the nano composite particles with high dispersion strengthen effective utilization of sun light by the catalyst, and improve activity of the catalyst. The preparation method provided by the invention has the advantages of cheap raw materials and simple process; and the prepared composite photocatalyst has a broad application prospects in the fields of wastewater treatment and gas purification.

Owner:EAST CHINA UNIV OF SCI & TECH +1

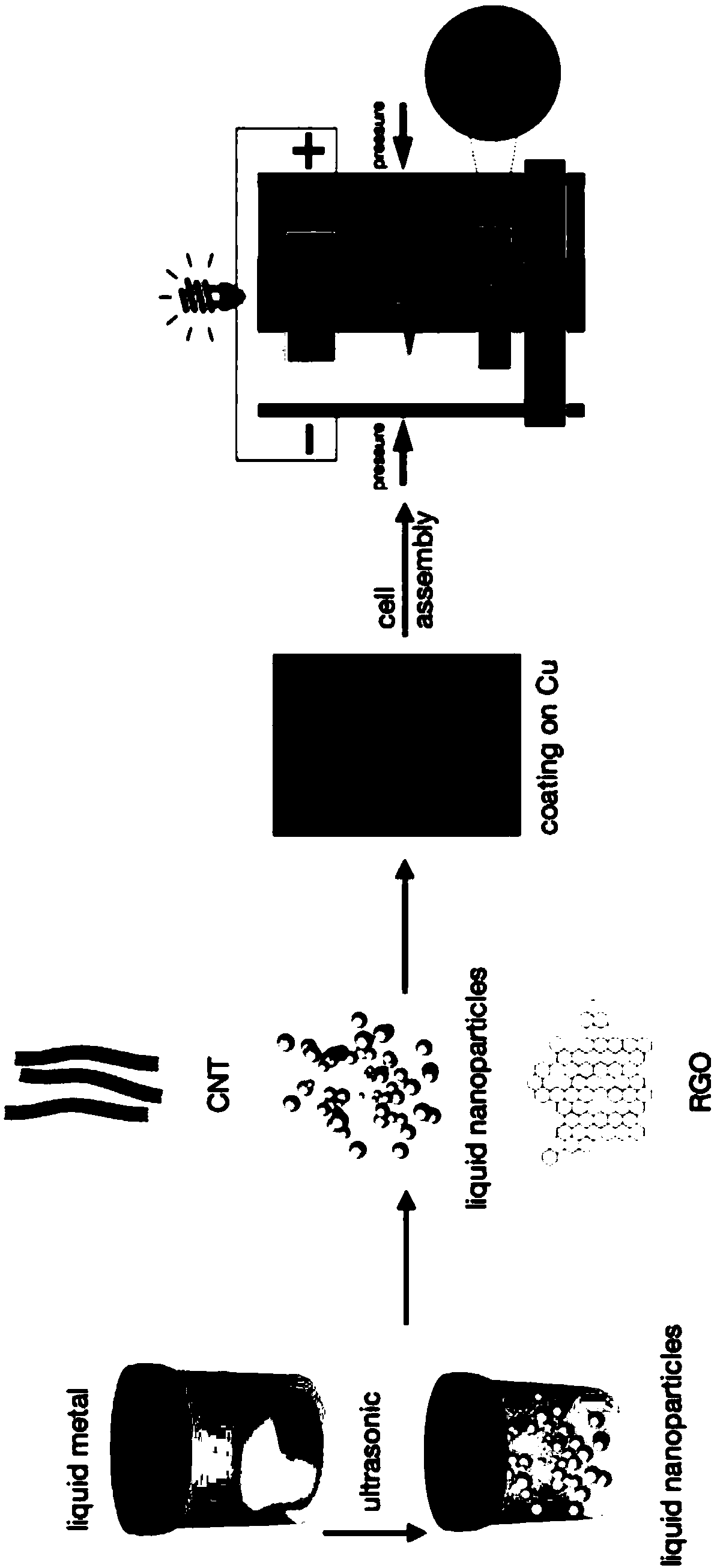

Preparation method of high-capacity high-safety solid-state lithium battery

InactiveCN108493485AImprove ionic conductivityIncrease energy densityFinal product manufactureLi-accumulatorsSolid state electrolyteHigh energy

The invention relates to a preparation method of a high-capacity high-safety solid-state lithium battery. The high-capacity high-safety solid-state lithium battery is prepared by taking a liquid metalcomplex prepared from liquid metal nanoparticles, carbon nanotubes and graphene as a negative active substance and taking solid electrolyte as an electrolyte. The negative active substance of the solid-state lithium battery adopts liquid metals, the carbon nanotubes and the graphene, wherein liquid metals tin and gallium have high energy density, can provide high capacity for the solid-state lithium battery, and thereby are ideal materials for a lithium battery with high energy density; the carbon nanotubes and the graphene are added to construct a three-dimensional frame which enables the lithium battery to have higher ionic conductivity; in addition, the three-dimensional frame has a complex structure and good mechanical properties, so that lithium dendrites formed on the surface of anode metal lithium can be inhibited, and the safety performance of the battery is improved; the cycle life of the battery is prolonged and the and the stability of the battery is improved; by adopting the solid electrolyte, the interface resistance can be greatly reduced to a great extent.

Owner:武汉新能源研究院有限公司

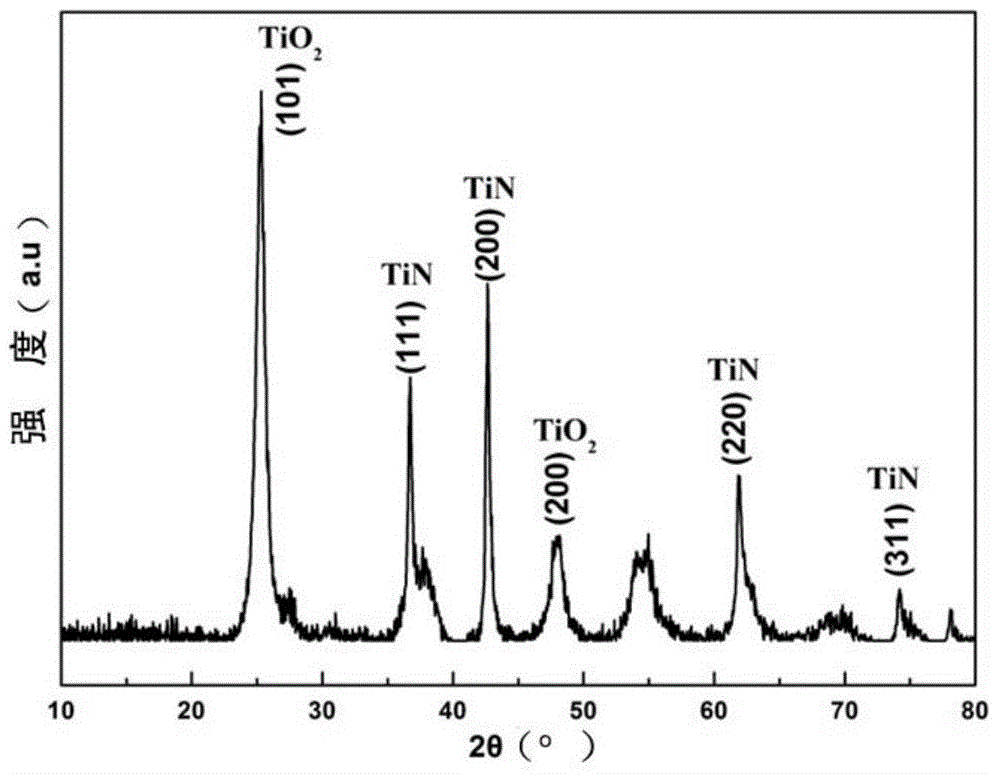

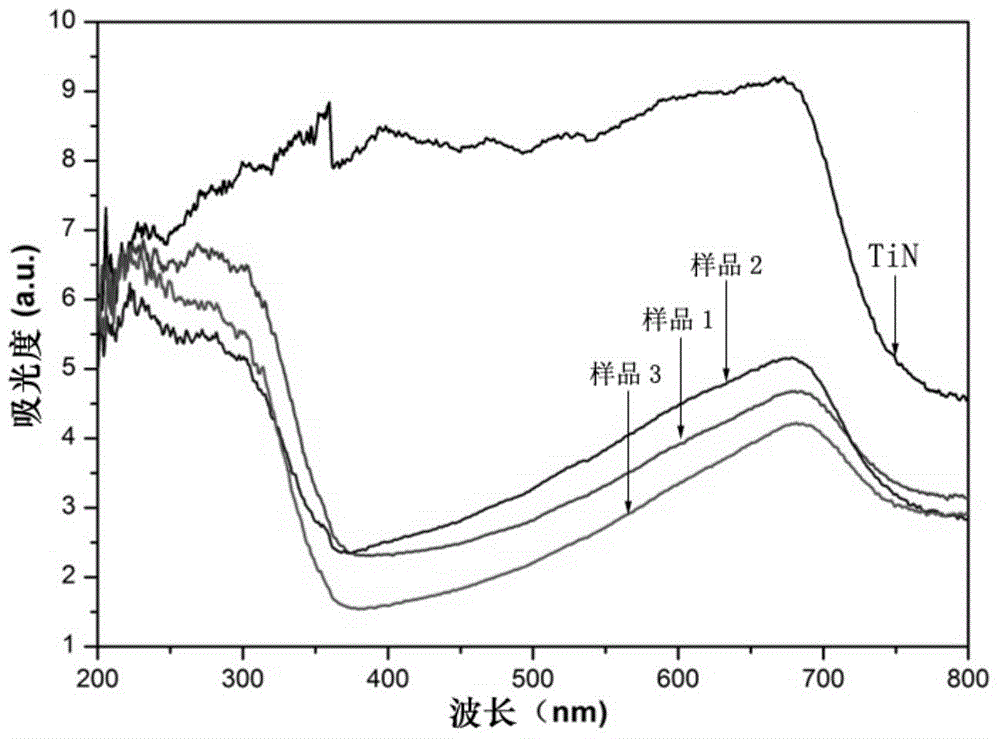

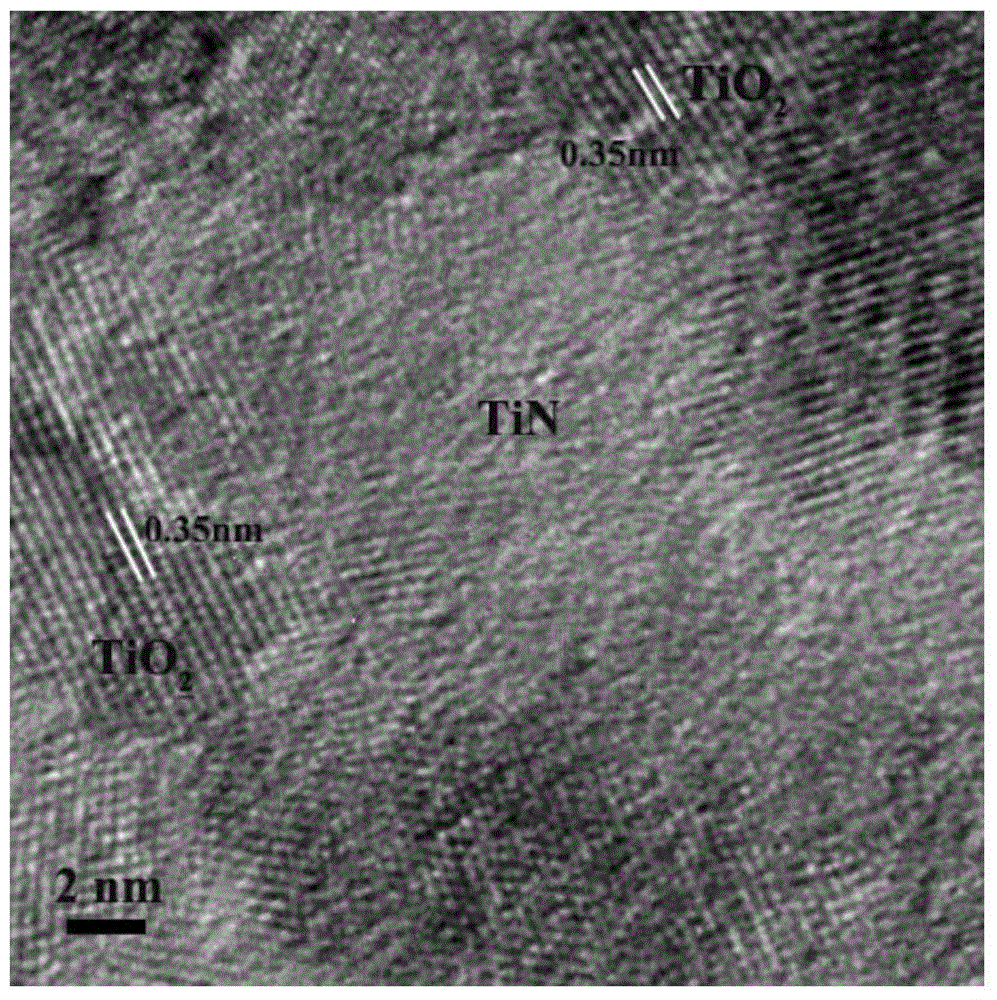

Nano titanium nitride-based composite photocatalytic material as well as preparation method and application thereof

InactiveCN106268896APromote migrationFacilitated DiffusionPhysical/chemical process catalystsWater/sewage treatment by irradiationMaterials preparationSurface oxidation

The invention discloses a nano titanium nitride-based composite photocatalytic material as well as a preparation method and application thereof, belonging to the technical fields of inorganic non-metallic nano material preparation, environmental protection technologies and solar energy utilization. According to the nano titanium nitride-based composite photocatalytic material, controllable surface oxidation is carried out on nanoscale titanium nitride particles, so that a composite photocatalytic material which takes nano titanium nitride as a core and titanium dioxide as a shell is formed. The nano titanium nitride-based composite photocatalytic material has adjustable optical adsorption property, thus being directly used for solving the problems of decomposition of organic matters under visible light, inactivation of microbial pathogens and efficient utilization of solar energy, and especially solving the problem of low photocatalytic efficiency of single-component photocatalytic materials.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

A kind of fluorine-free waterproofing agent with three-dimensional silane structure and preparation method thereof

ActiveCN106810650BEffective migrationImprove waterproof performanceLiquid repellent fibresVegetal fibresFiberPolymer science

The invention discloses a fluoride-free waterproof agent with a stereo silane structure and a preparation method of the fluoride-free waterproof agent. In a formula I of a polymer, R1 refers to a long-chain acrylate structural chain segment, R2 refers to a polyhedral oligomeric silsesquioxane structural chain segment, R3 refers to a functional monomer structural chain segment, X refers to a natural number in a range of 1-150, and Y and Z refer to natural numbers in a range of 1-100. The fluoride-free waterproof agent is aqueous emulsion of the polymer shown as the formula I. By adoption of a polyhedral oligomeric silsesquioxane monomer with a vinyl structure for preparation of the fluoride-free waterproof agent through microemulsion polymerization, introduction of polyhedral oligomeric silsesquioxane with a stereo structure to a lateral group of a polymer long chain is realized, a low-surface-energy siloxane cubic structure can migrate to the fabric fiber surface more effectively in an emulsion film forming spread process to form continuous projections on the fabric fiber surfaces, and consequently waterproof effects are greatly improved. The fluoride-free waterproof agent is an environment-friendly waterproof agent, free of biotoxicity and nondegradability and harmless to organisms and environment.

Owner:BEIJING CTA TEX CHEM

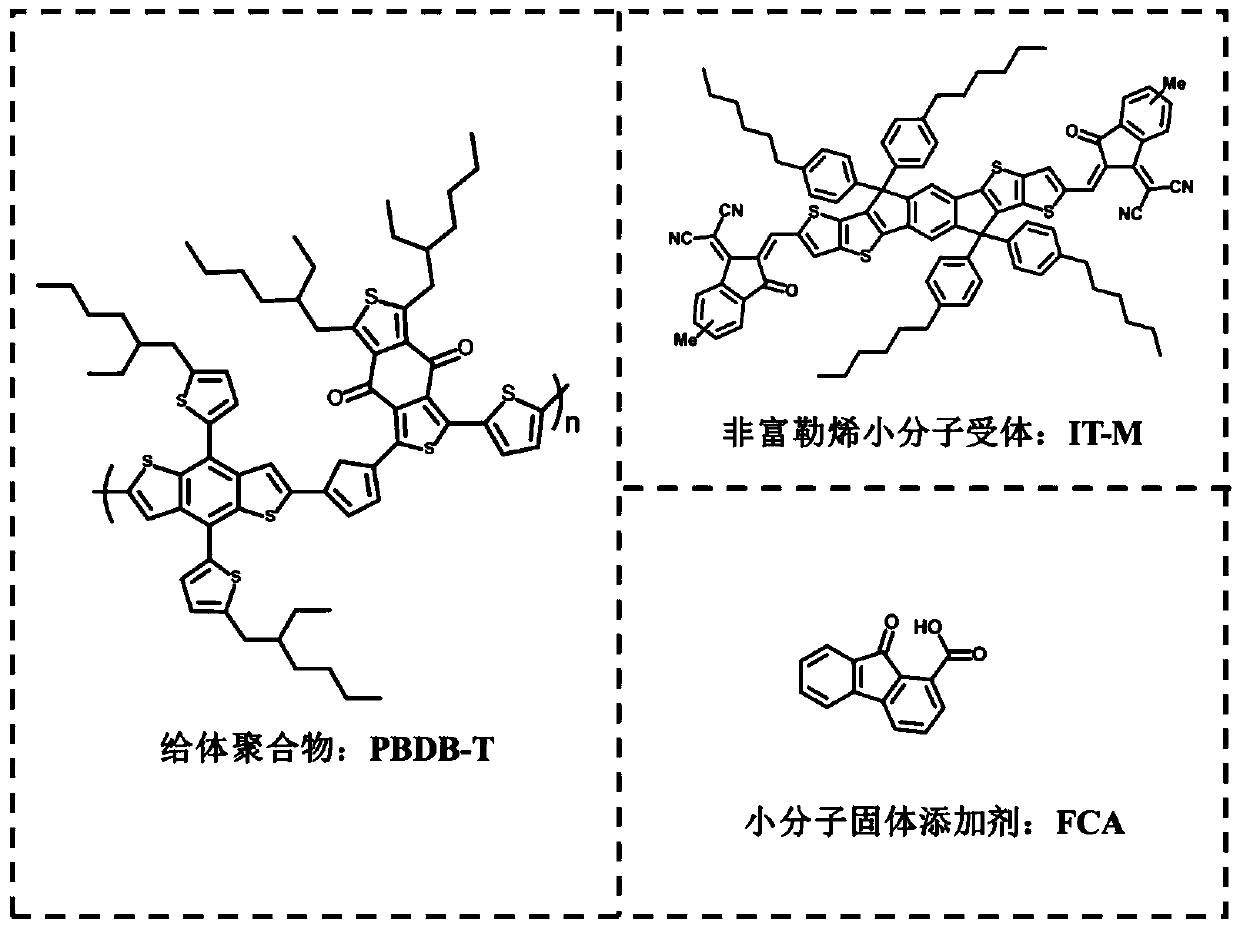

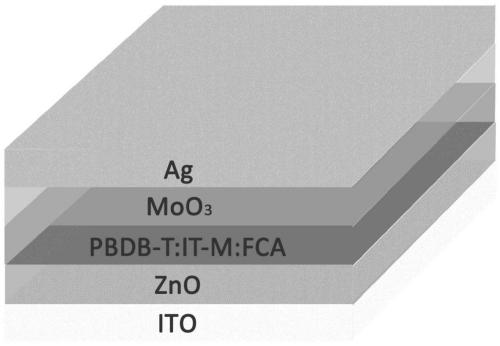

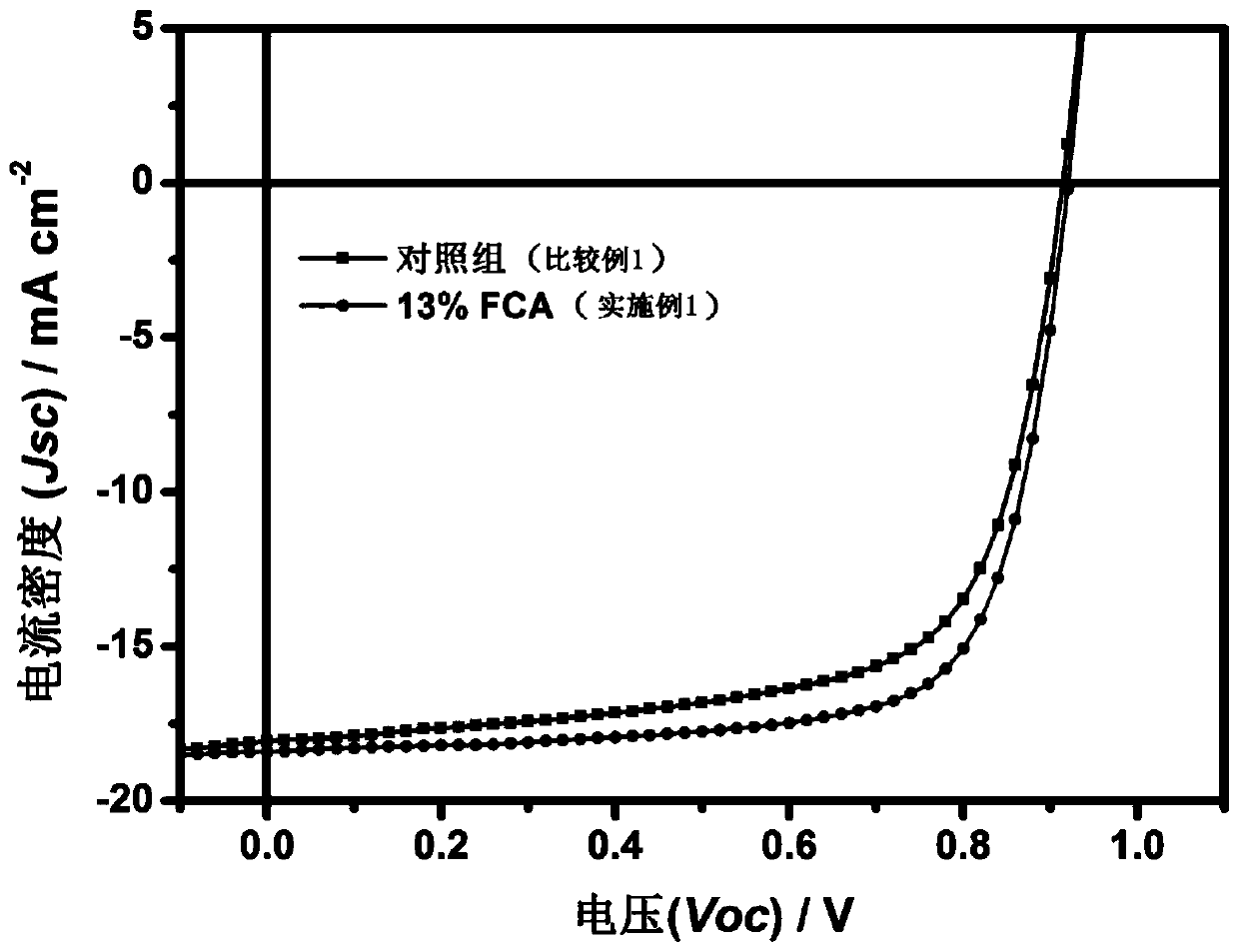

Solid additive for organic polymer solar cell

ActiveCN111326656AExtend your lifeImprove separation efficiencySolid-state devicesSemiconductor/solid-state device manufacturingElectron donorHole transport layer

The invention relates to a solid additive for an organic polymer solar cell, which is characterized in that the solid additive is an aromatic substance containing a carbonyl, a carboxyl, an aldehyde group or an ester group, and the molecular weight of the solid additive is 100-500g / mol. The invention further relates to an organic polymer solar cell device. The organic polymer solar cell device ischaracterized by sequentially comprising a transparent electrode, an electron transport / hole barrier layer, an active layer, an electron barrier / hole transport layer and a metal electrode, wherein theactive layer comprises a wide band gap conjugated polymer electron donor, a non-fullerene small molecule electron acceptor and the solid additive. The solid additive disclosed by the invention can prolong the service life of receptor excitons, so that the excitons can be effectively migrated to an electron donor-receptor interface, the exciton separation efficiency is improved, and the short-circuit current density, the filling factor and the photoelectric conversion efficiency of a solar cell device are further improved.

Owner:BEIJING NORMAL UNIVERSITY

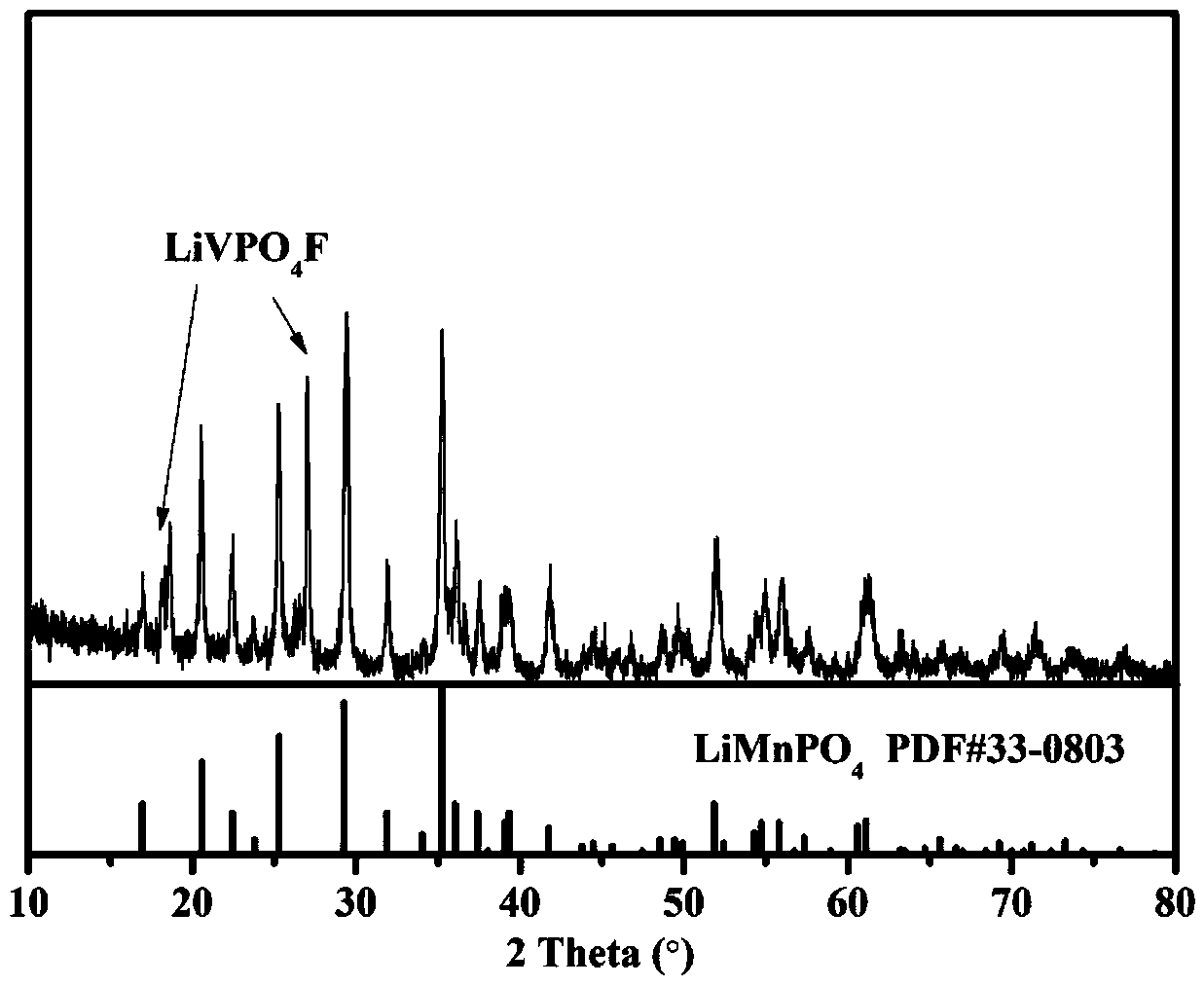

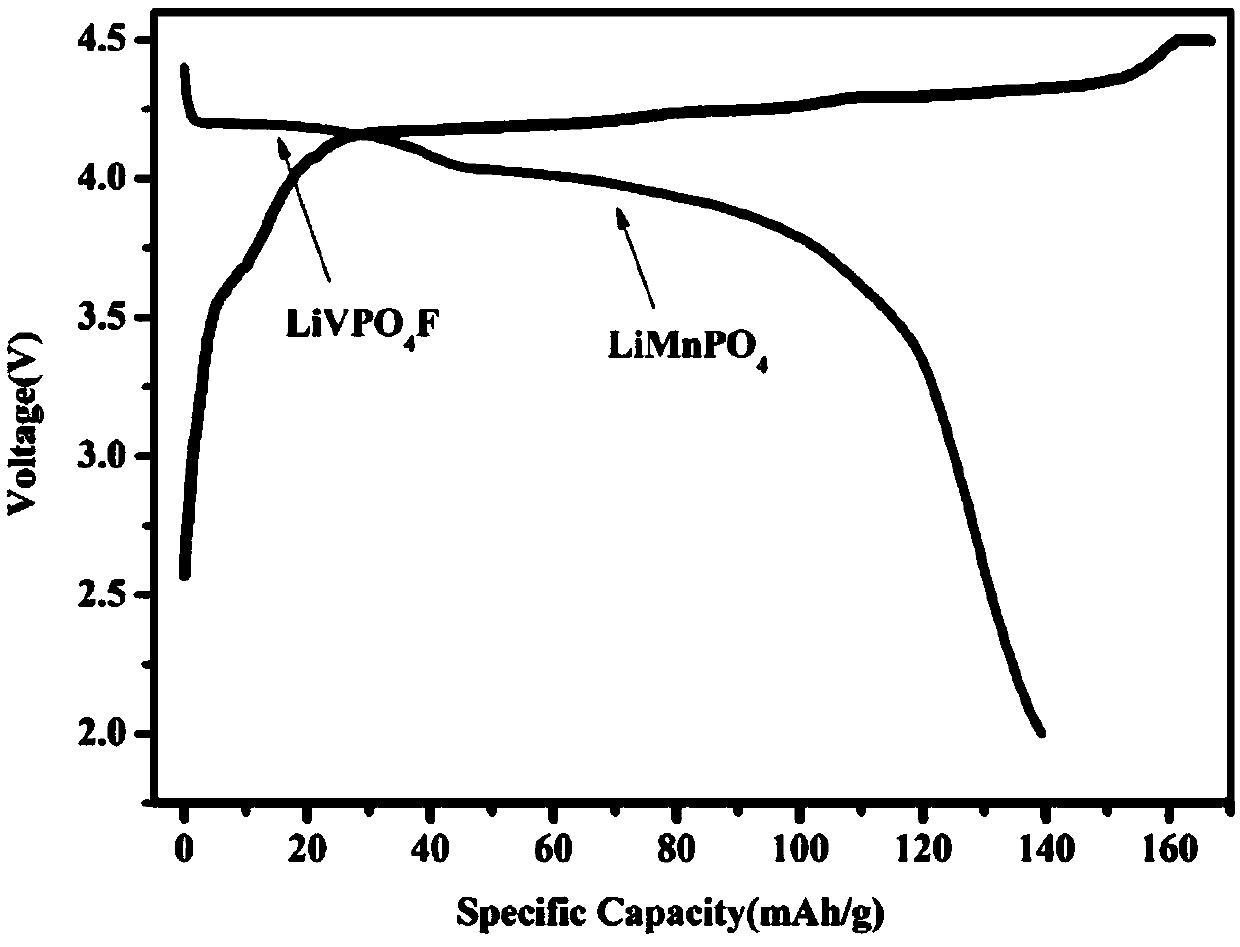

Manganese phosphate lithium/lithium vanadium fluorophosphate/carbon composite anode material and preparation method thereof

ActiveCN108682811AHigh specific capacityExcellent rate performanceCell electrodesSecondary cellsCarbon compositesElectrical resistivity and conductivity

The invention discloses a manganese phosphate lithium / lithium vanadium fluorophosphate / carbon composite anode material and a preparation method thereof, and aims to improve the ion eclectic conductivity and the circulation stability of manganese phosphate lithium and thus overcome defects that a manganese phosphate lithium anode material is poor in rate capability and poor in circulation stability. The composite material disclosed by the invention has a nominal molecular formula of (1-x)LiMnPO4*xLiVPO4F / C, and in the formula, x is greater than 0 and less than or equal to 0.3. The synthetic composite material has primary particles of 60-100nm in size, and the surfaces of the particles are coated by a layer of a uniform carbon source. The preparation method disclosed by the invention is simple in process and easy to control, and due to synergetic functions of the components, the prepared (1-x)LiMnPO4*xLiVPO4F / C composite anode material has the characteristics of being high in energy density, stable in circulation and good in rate capability.

Owner:CENT SOUTH UNIV

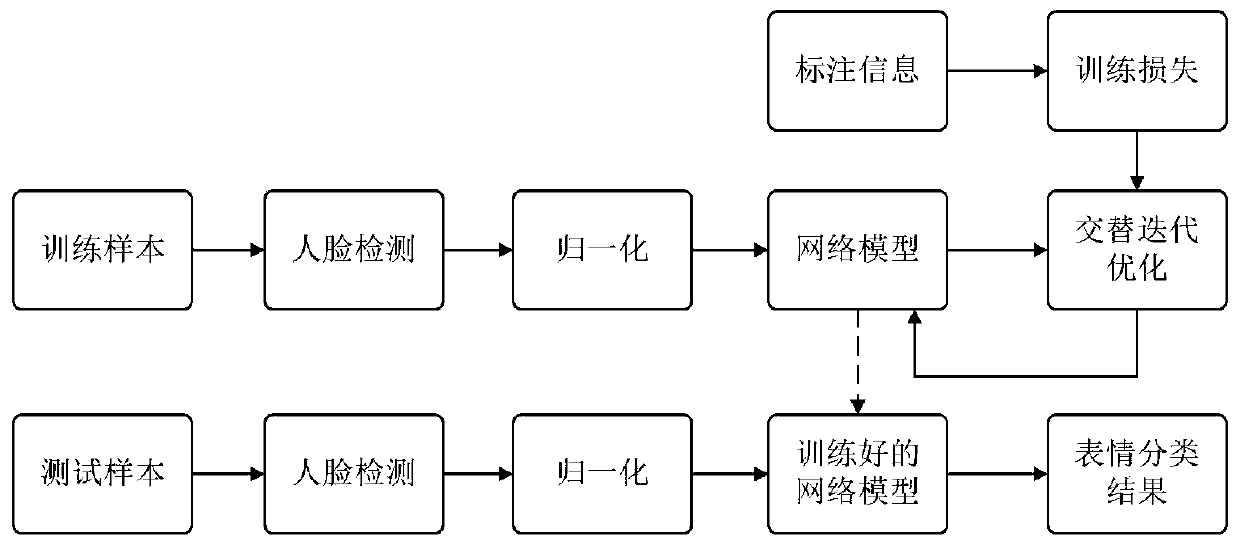

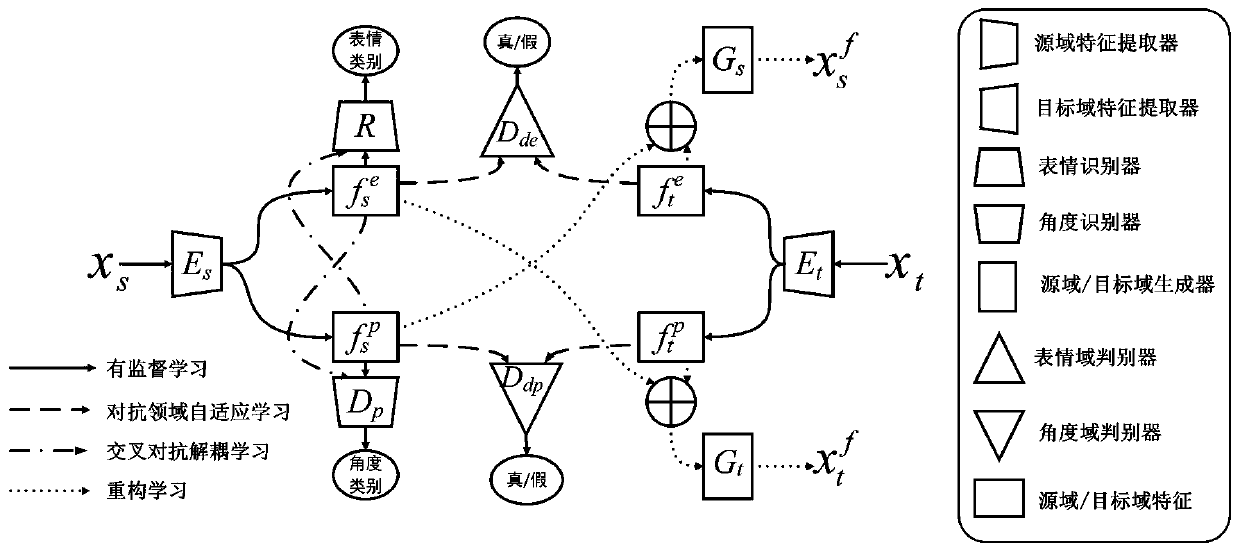

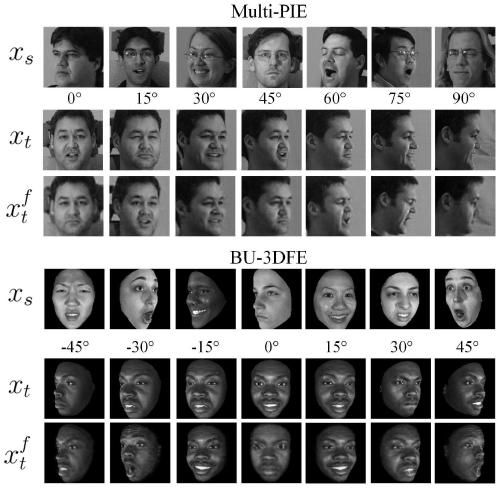

Angle robust personalized facial expression recognition method based on adversarial learning

ActiveCN111382684AEffective migrationMake up for the defect that is limited by the small number of samples in the target domainNeural architecturesAcquiring/recognising facial featuresPattern recognitionNetwork model

The invention discloses an angle robust personalized facial expression recognition method based on adversarial learning. The angle robust personalized facial expression recognition method comprises the steps of: 1, performing image preprocessing on a database containing N types of facial expression images; 2, constructing a feature decoupling and domain adaptive network model based on adversariallearning; 3, training the constructed network model by using an alternate iterative optimization mode; and 4, predicting a to-be-detected face image by using the trained model to realize classification and recognition of the face expressions. According to the angle robust personalized facial expression recognition method, the negative influence of angles and individual difference in facial expression recognition on the facial expression recognition effect can be overcome at the same time, so that the precise recognition of the facial expression is realized.

Owner:UNIV OF SCI & TECH OF CHINA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com