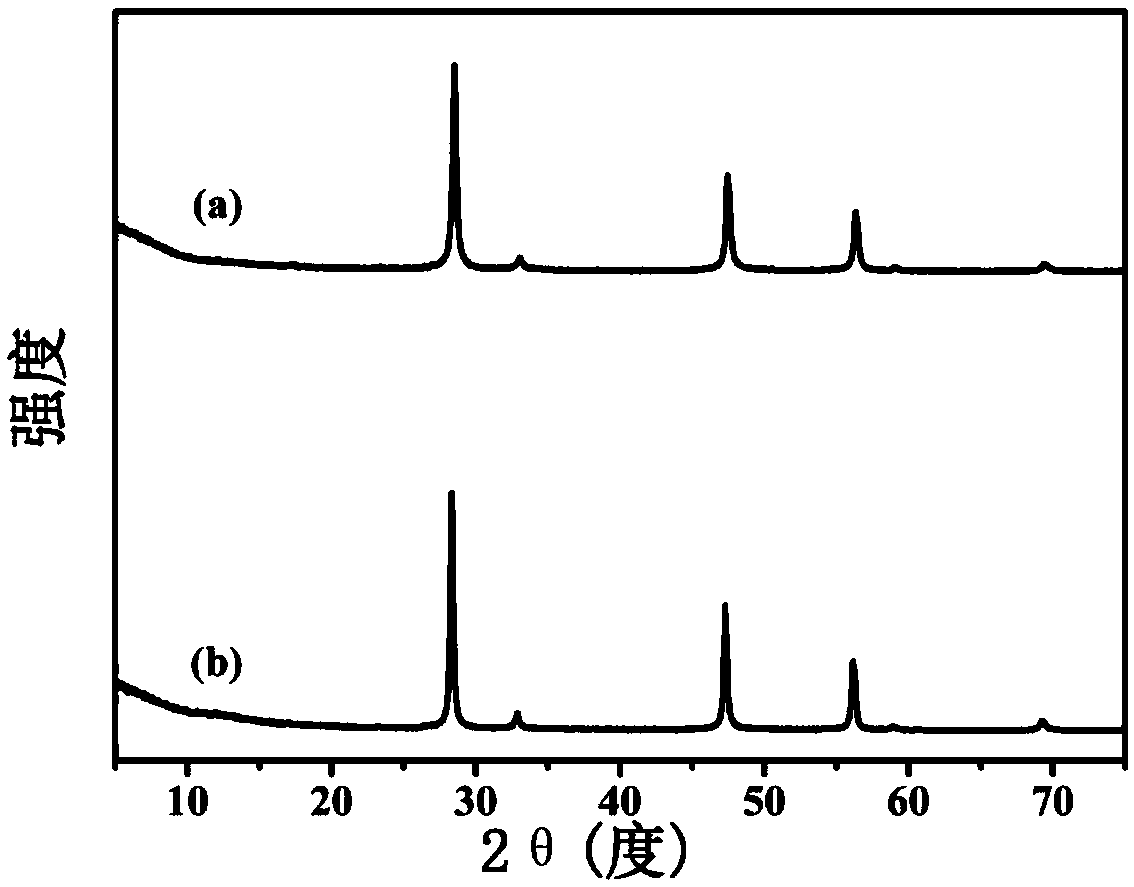

Graphene/ZnS-MoS2 nano solid solution photocatalyst having visible light catalytic activity

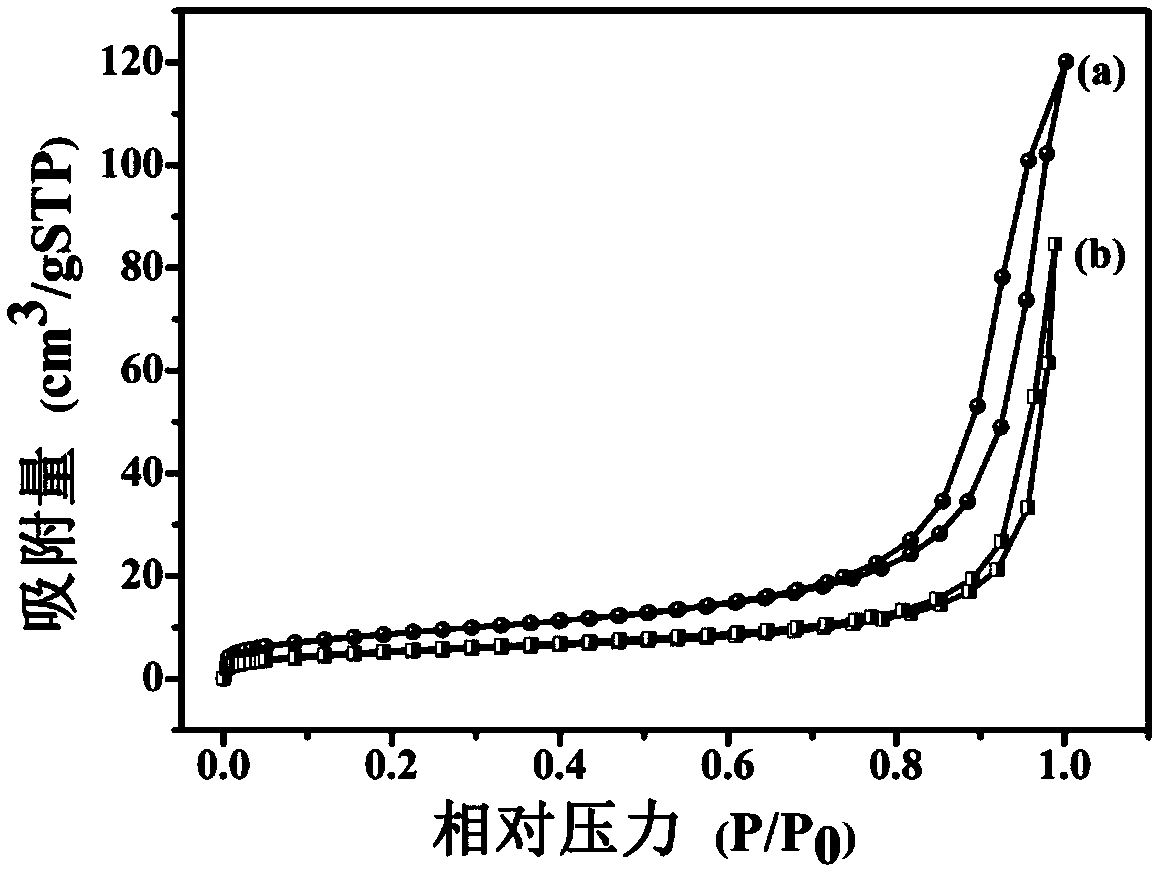

A catalytic activity and photocatalyst technology, which is applied in physical/chemical process catalysts, chemical/physical processes, light water/sewage treatment, etc., can solve the problems of few reactive sites, limited pollutant molecules, small specific surface area, etc. Achieve the effects of strong light absorption and photocatalytic ability, high stability and regeneration performance, and large specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] (1) Using graphite powder as raw material, graphene oxide was synthesized by the Hummers method, and then 0.06787 g of graphene oxide was put into 10 mL of N,N-dimethylformamide solution, and ultrasonicated for 30 minutes for later use.

[0031] (2) Add 6.0mmol of zinc acetate, 0.2mmol of sodium molybdate, and 13.3mmol of thioacetamide into 40mL of N,N-dimethylformamide solution and stir until the solution is transparent, then add the above graphene solution.

[0032] (3) Transfer the solution to a 100mL reaction kettle at 210°C for 24 hours.

[0033] (4) The reacted sample was centrifuged and washed several times with deionized water and ethanol, and the obtained sample was vacuum-dried at 60° C. for 12 hours and then ground. The obtained product is rGO / ZnS-MoS 2 Nano solid solution photocatalyst.

Embodiment 2

[0035] (1) Using graphite powder as raw material, graphene oxide was synthesized by the Hummers method, and then 0.04936 g of graphite oxide was weighed into 10 mL of ethylene glycol solution, and ultrasonicated for 40 min for later use.

[0036] (2) Add 6.0mmol of zinc chloride, 0.2mmol of sodium molybdate, and 13.3mmol of thioacetamide into 40mL of ethylene glycol solution and stir until the solution is transparent, then add the above-mentioned graphene solution.

[0037] (3) Transfer the solution to a 100mL reaction kettle at 200°C for a reaction time of 24 hours.

[0038] (4) The reacted sample was centrifuged and washed several times with deionized water and ethanol, and the obtained sample was vacuum-dried at 60° C. for 12 hours and then ground. The obtained product is rGO / ZnS-MoS 2 Nano solid solution photocatalyst.

Embodiment 3

[0040] (1) Using graphite powder as raw material, graphene oxide was synthesized by the Hummers method, and then 0.06787 g of graphene oxide was dispersed into 10 mL of ethanol solution, and ultrasonicated for 60 min for later use.

[0041] (2) Add 5.0mmol of zinc nitrate, 0.25mmol of sodium molybdate, and 11.5mmol of sodium sulfide into 40mL of ethanol solution and stir until the solution is transparent, then add the above-mentioned graphene solution.

[0042] (3) Transfer the solution to a 100mL reaction kettle at 220°C for a reaction time of 24 hours.

[0043] (4) The reacted sample was centrifuged and washed several times with deionized water and ethanol, and the obtained sample was vacuum-dried at 60° C. for 12 hours and then ground. The obtained product is rGO / ZnS-MoS 2 Nano solid solution photocatalyst.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com