Fluoride-free waterproof agent with stereo silane structure and preparation method of fluoride-free waterproof agent

A fluorine-free water repellent, structural chain technology, applied in the direction of repelling fibers, fiber types, textiles and papermaking to liquids, etc., can solve the problems of refractory degradation, low waterproof effect, and restricting the migration of silicon atoms.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0083] Embodiment 1, preparation fluorine-free waterproofing agent

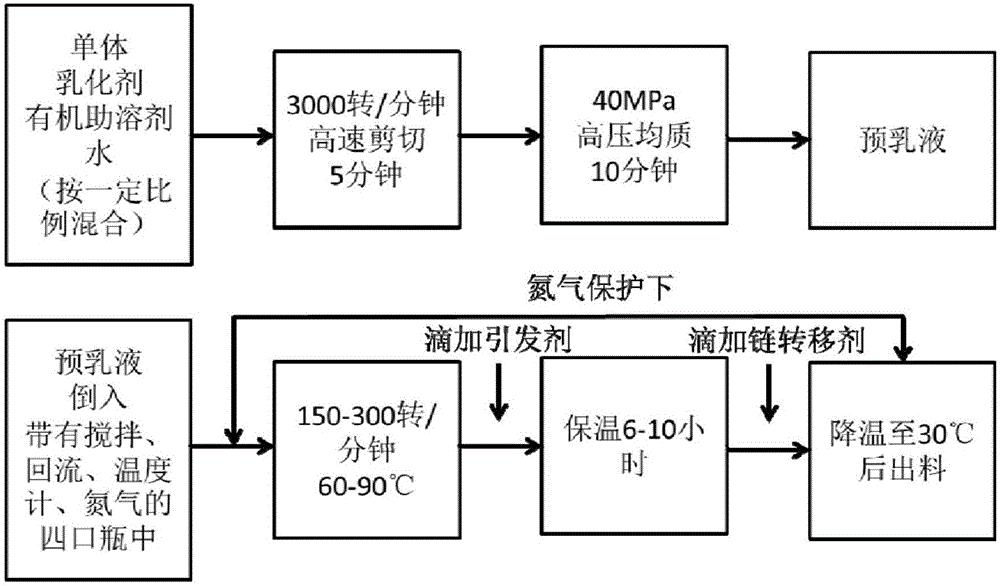

[0084] according to figure 1 The flow chart shown in the preparation of fluorine-free water repellent, the specific steps are as follows:

[0085] (1) Cetyl acrylate 50g, heptaisobutylacryloxypropyl cage silsesquioxane (heptaisobutylacrylate propyl cage silsesquioxane) 15g, hydroxyethyl acrylate 5g , cetyltrimethylammonium bromide 2g, polyoxyethylene sorbitan monoglyceride 2g, acetone 26g were added to 150g deionized water, mixed with a high-speed shear machine at 3000 rpm for 5 minutes, then added Homogenize for 10 minutes in a high-pressure homogenizer with a pressure of 40 MPa to obtain a stable oil-in-water pre-emulsion.

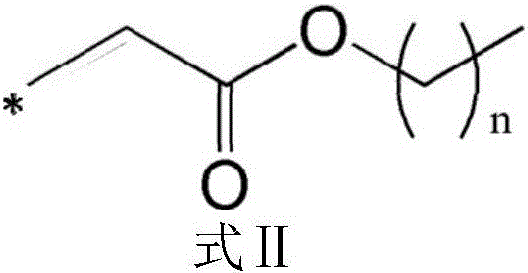

[0086] In the above-mentioned pre-emulsion, monomer I is hexadecyl acrylate, which accounts for 20% of the emulsion, and monomer II is heptaisobutylacryloyloxypropyl cage silsesquioxane (heptaisobutylacrylate propyl cage Type silsesquioxane), accounting for 6% of the emulsion, monome...

Embodiment 2

[0089] Embodiment 2, preparation fluorine-free waterproofing agent

[0090] according to figure 1 The flow chart shown in the preparation of fluorine-free water repellent, the specific steps are as follows:

[0091] (1) Cetyl acrylate 50g, heptaisobutylmethacryloxypropyl cage silsesquioxane (heptaisobutylmethacrylate propyl cage silsesquioxane) 15g, hydroxyethyl acrylate 2.5g g, N-methylolacrylamide 2.5g, octadecyltrimethylammonium bromide 4.2g, lauryl polyoxyethylene (10) ether 2.8g, methyl ethyl ketone 18g were added to 155g deionized After mixing in water with a high-speed shearer at 3000 rpm for 5 minutes, add it to a high-pressure homogenizer with a pressure of 40 MPa and homogenize for 10 minutes to obtain a stable oil-in-water pre-emulsion.

[0092]In the above-mentioned pre-emulsion, monomer I is hexadecyl acrylate, which accounts for 20% of the emulsion, and monomer II is heptaisobutylmethacryloxypropyl cage silsesquioxane (heptaisobutylmethacrylic acid propyl group...

Embodiment 3

[0095] Embodiment 3, preparation fluorine-free waterproofing agent

[0096] according to figure 1 The flow chart shown in the preparation of fluorine-free water repellent, the specific steps are as follows:

[0097] (1) 57.5g of octadecyl acrylate, 5g of heptaisobutylacryloxypropyl cage silsesquioxane (heptaisobutylacrylate propyl cage silsesquioxane), 5g of N-methylol Add 7.5g of methacrylamide, 2g of octadecyltrimethylammonium bromide, 3g of polyoxyethylene sorbitan monoglyceride, and 25g of dipropylene glycol into 150g of deionized water, and use a high-speed shear at 3000 rpm After cutting and mixing for 5 minutes, it was added to a high-pressure homogenizer with a pressure of 40 MPa and homogenized for 10 minutes to obtain a stable oil-in-water pre-emulsion.

[0098] In the above-mentioned pre-emulsion, monomer I is octadecyl acrylate, which accounts for 23% of the emulsion, and monomer II is heptaisobutylacryloyloxypropyl cage silsesquioxane (heptaisobutylacrylate prop...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com