Perovskite material/organic polymer compound photocatalyst, preparation and application

A perovskite material and compound light technology, applied in the direction of organic compound/hydride/coordination complex catalyst, physical/chemical process catalyst, chemical/physical process, etc., can solve the problems that have not been introduced reasonably and effectively, Achieve the effects of promoting effective migration, improving light utilization, and efficient photolysis of water to produce hydrogen

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] (1) Preparation of cobalt titanate:

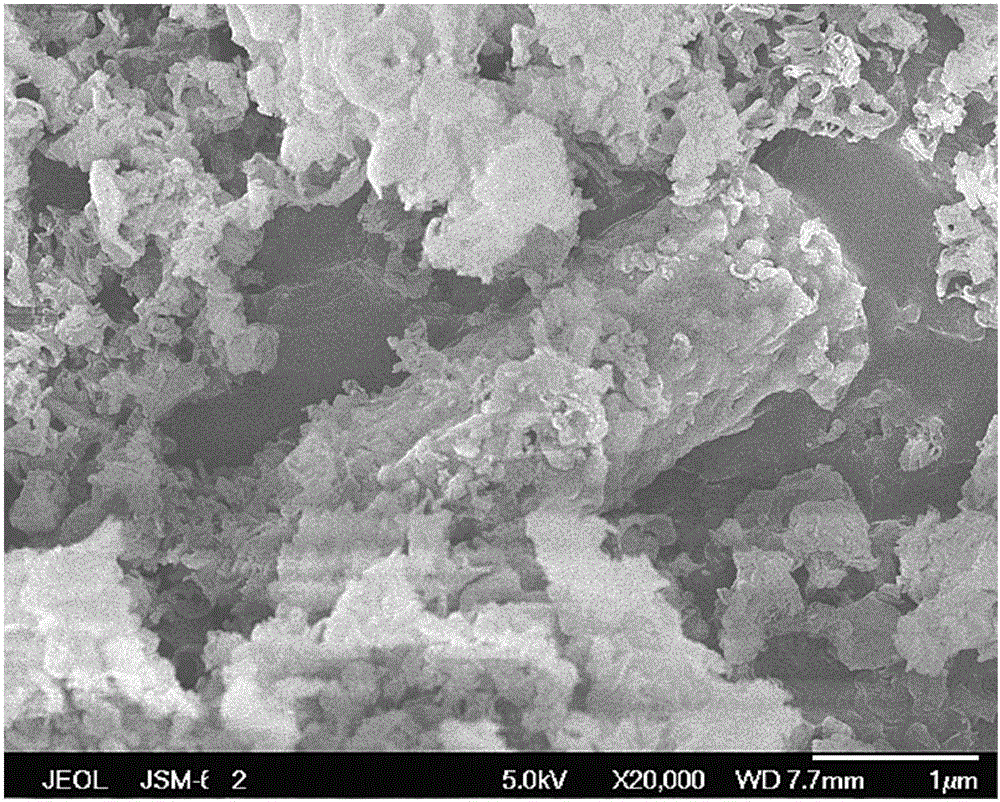

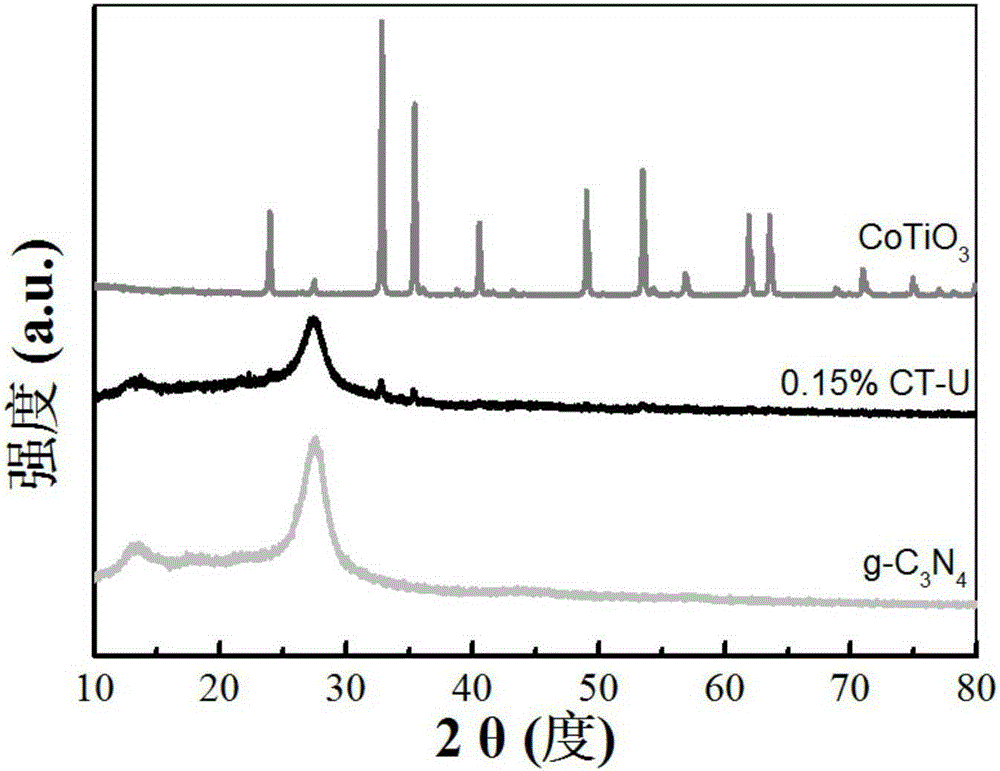

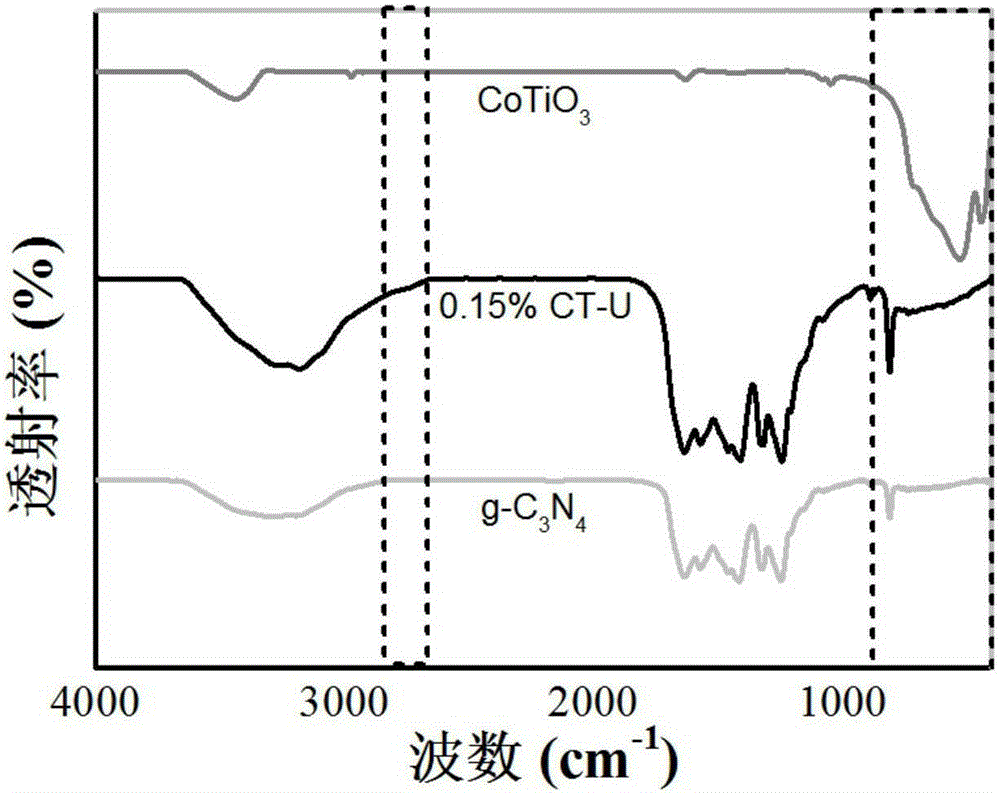

[0034] Co(CH 3 COO) 2 4H 2 O and tetrabutyl titanate were dissolved in 60ml of ethylene glycol at a mass ratio of 1:1 to form a dark red solution, which was stirred at room temperature for 5 hours to fully react and the solution turned into light pink. Centrifugal washing with ethanol three times, vacuum drying for 6 hours, and calcination at 700° C. for 4 hours to obtain nanorod-shaped cobalt titanate.

[0035] (2) Preparation of carbon nitride:

[0036] Prepared by thermal decomposition polymerization method, take 10g of urea in a 50ml crucible, calcinate in a semi-closed state in air at 520°C for 4 hours, 20°C / min, wash with water and ethanol, and dry in vacuum at 60°C to obtain light yellow carbon nitride powder .

[0037] (3) Preparation of cobalt titanate / carbon nitride composite photocatalyst (expressed as CT-U):

[0038]Grind 10-30 mg of cobalt titanate and 10 g of urea for 30 min, place in a 50 ml crucible, and calcin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com