Lithium ion battery and preparation method thereof

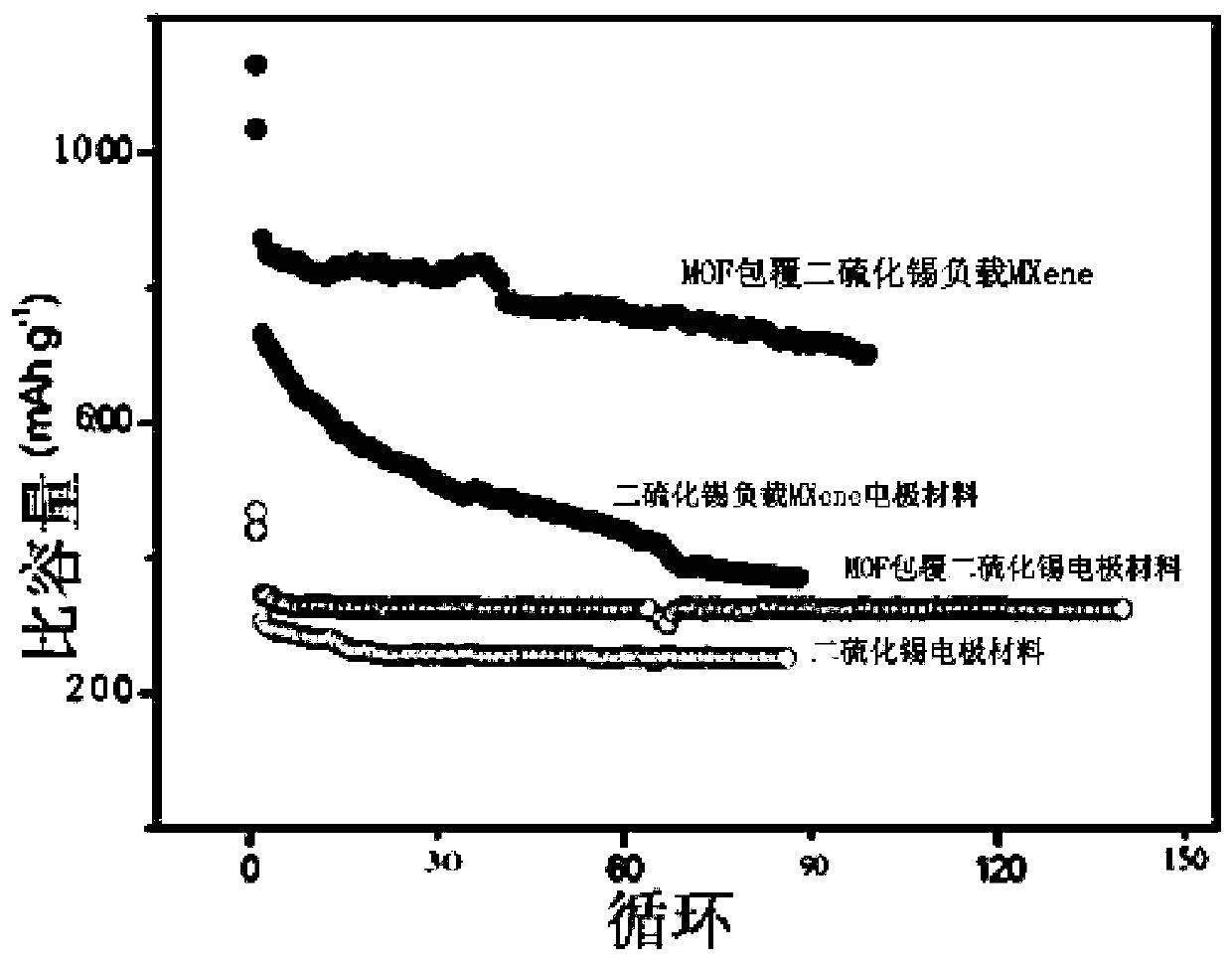

A lithium-ion battery and electrolyte technology, applied in the manufacture of electrolyte batteries, battery electrodes, secondary batteries, etc., can solve problems such as low specific capacity, low loading rate of tin disulfide, poor cycle stability, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

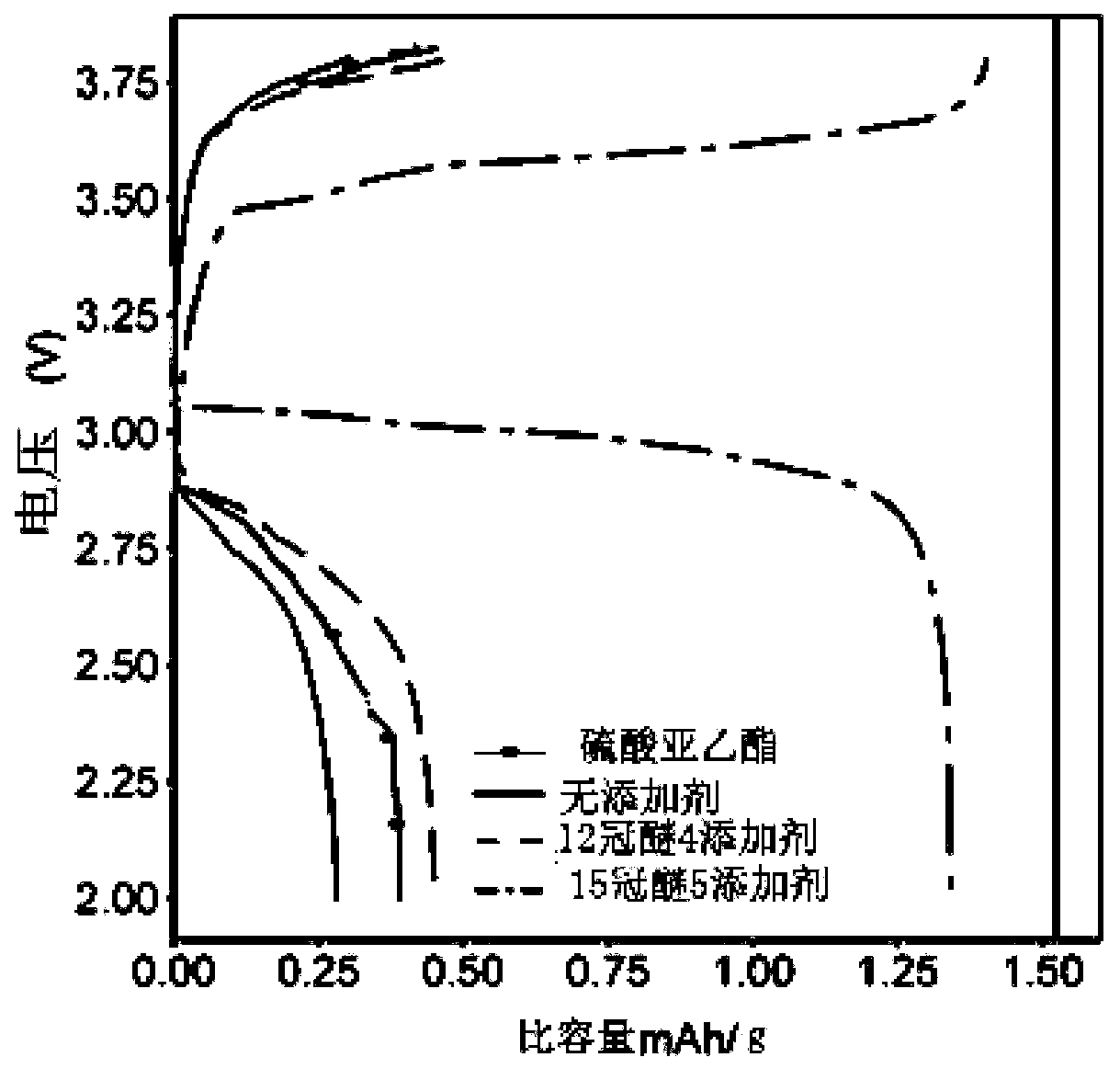

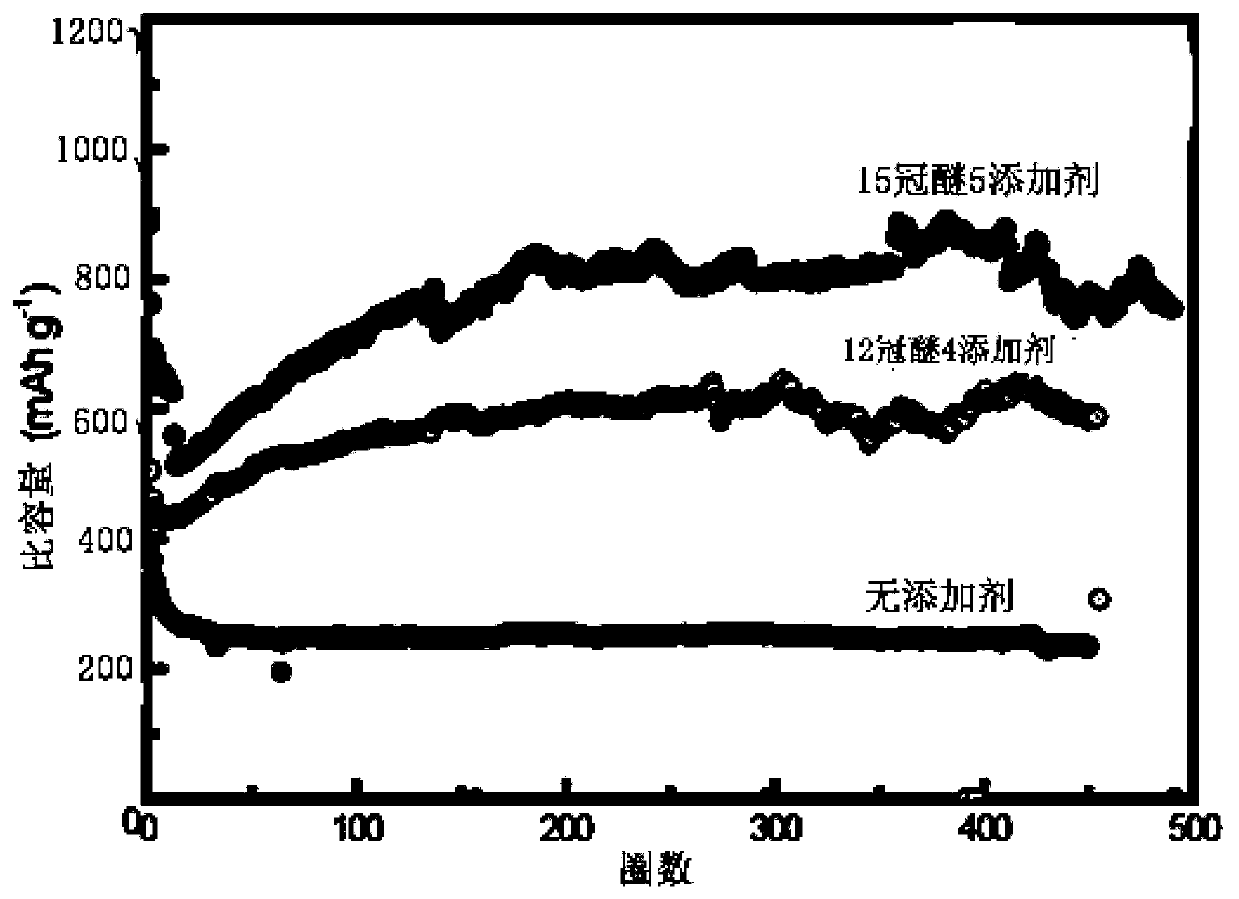

[0038] 1) Put 0.2g of Mxene two-dimensional carbon material into 0.1mol / l15-crown-5 electrolyte additive for pre-softening treatment, then disperse in 0.1mol / l hydrofluoric acid solution and stir for 12h; filter, wash, and dry;

[0039] 2) Put the product of step 1) in 50ml of alcohol solution, add 0.75mol / l cetyltrimethylamine bromide, and stir at constant temperature for 5h;

[0040] 3) Disperse the product of step 2) in ethanol and stir for 2 h, then add pentahydrate, tin chloride and thioacetamide and continue stirring for 2 h;

[0041]4) Heat the product in step 3) in a water bath for 3 h, wash with ethanol, and dry in a vacuum oven for 8-10 h, with the temperature controlled at 80 °C;

[0042] 5) Put the MOF precursor in the 15-crown-5 electrolyte additive with a concentration of 0.5mol / l and stir for 3 hours, then disperse in the alcohol solution, and then put the product of step 4) into the alcohol solution of the MOF precursor, the original bit synthesis of MOF;

[...

Embodiment 2

[0047] 1) Put 0.2g Mxene two-dimensional carbon material into 5mol / l 15-crown-5 electrolyte additive for pre-softening treatment, then disperse in 1.5mol / l hydrofluoric acid solution and stir for 12h; filter, wash, and dry;

[0048] 2) Put the product of step 1) in 50ml of alcohol solution, add 0.75mol / l cetyltrimethylamine bromide, and stir at constant temperature for 5h;

[0049] 3) Disperse the product of step 2) in ethanol and stir for 2 h, then add pentahydrate, tin chloride and thioacetamide and continue stirring for 2 h;

[0050] 4) Heat the product in step 3) in a water bath for 3 h, wash with ethanol, and dry in a vacuum oven for 8-10 h, with the temperature controlled at 80 °C;

[0051] 5) Put the MOF precursor in the 12-crown-4 electrolyte additive and stir for 3 hours, then disperse it in the alcohol solution, then put the product of step 4) into the alcohol solution of the MOF precursor, and synthesize MOF in situ;

[0052] 6) Heat the product of step 5) to 100°C...

Embodiment 3

[0056] 1) Put 0.2g of Mxene two-dimensional carbon material into 12-crown-4 electrolyte additive for pre-softening treatment, then disperse in 3mol / l hydrofluoric acid solution and stir for 12h; filter, wash and dry;

[0057] 2) Put the product of step 1) in 50ml of alcohol solution, add 0.75mol / l cetyltrimethylamine bromide, and stir at constant temperature for 5h;

[0058] 3) Disperse the product of step 2) in ethanol and stir for 2 h, then add pentahydrate, tin chloride and thioacetamide and continue stirring for 2 h;

[0059] 4) Heat the product in step 3) in a water bath for 3 h, wash with ethanol, and dry in a vacuum oven for 8-10 h, with the temperature controlled at 80 °C;

[0060] 5) Put the MOF precursor in 2mol / l 15-crown-5 electrolyte additive and stir for 3 hours, then disperse in the alcohol solution, then put the product of step 4) into the alcohol solution of the MOF precursor, and synthesize MOF in situ ;

[0061] 6) Heat the product of step 5) to 100°C with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com