Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

69results about How to "Lamellar structure is stable" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

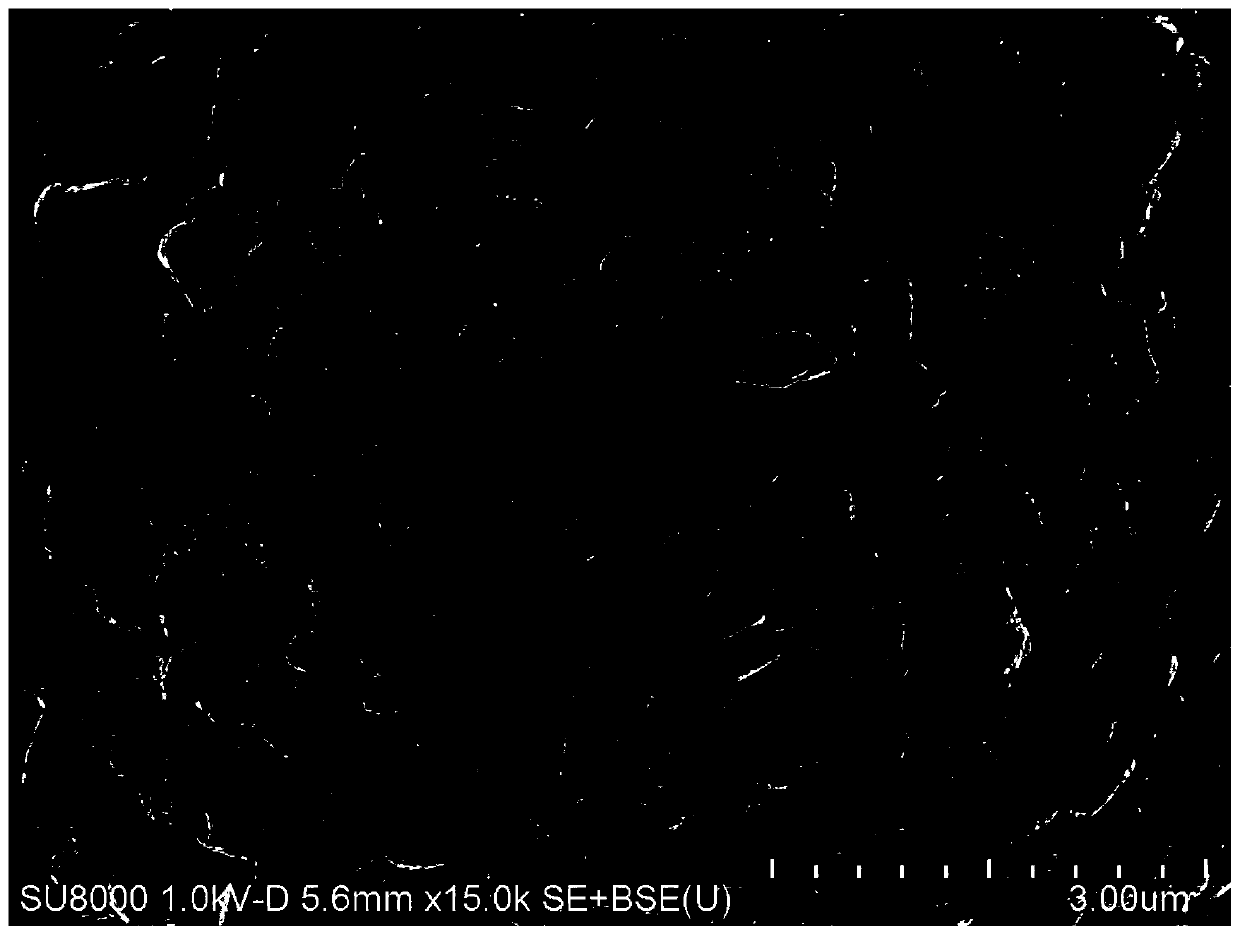

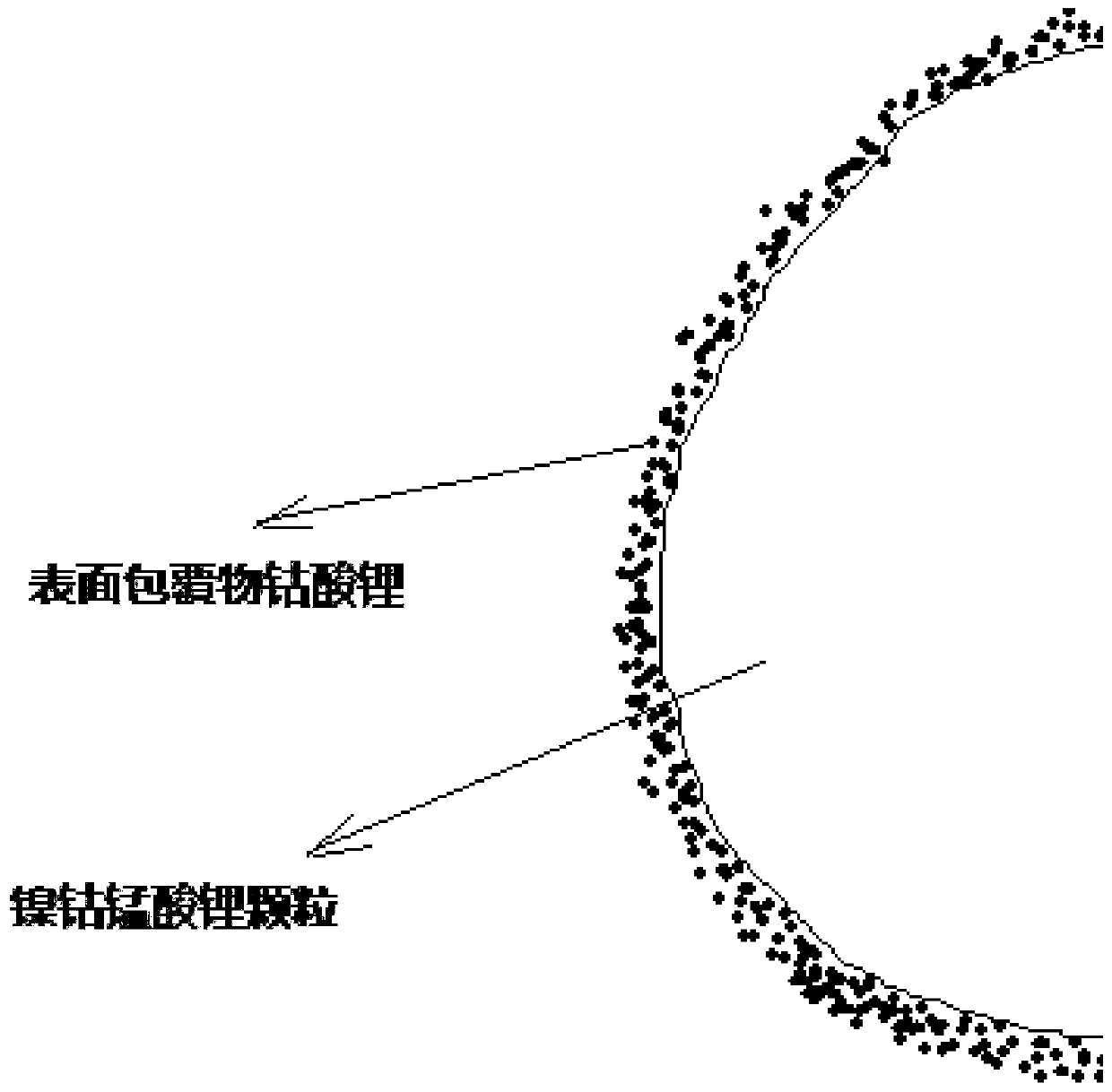

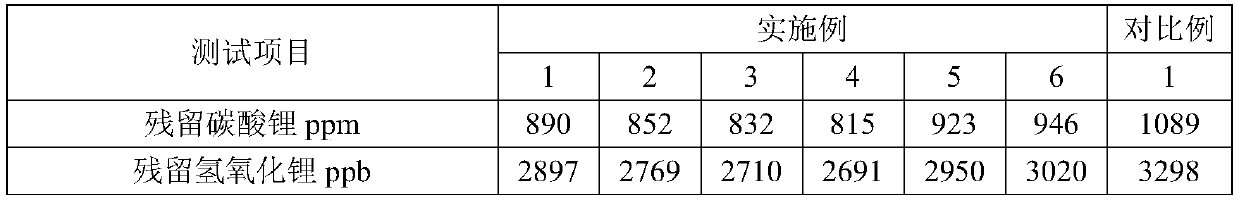

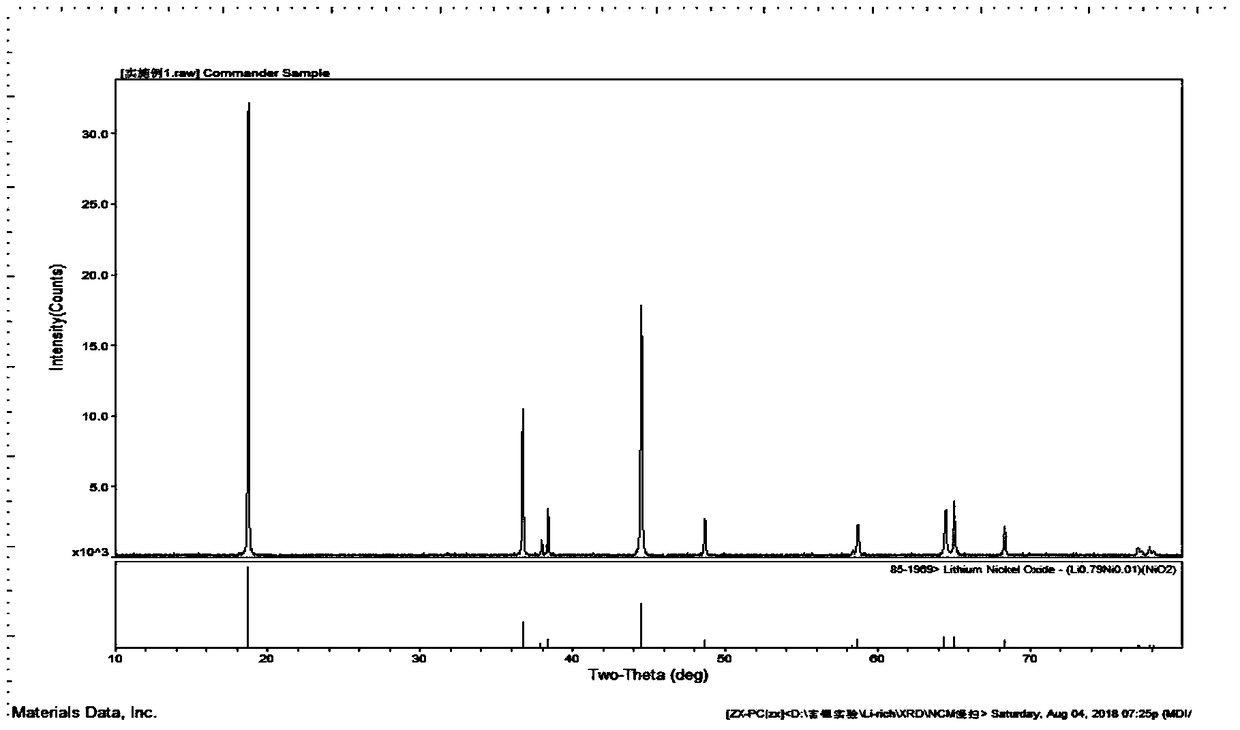

Lithium cobaltate-coated high-nickel ternary positive electrode material and preparation method thereof

InactiveCN110247031AAvoid direct contact with airReduce surface residual alkaliCell electrodesLithium carbonateChemistry

The invention relates to a lithium cobaltate-coated high-nickel ternary positive electrode material and a preparation method thereof. The preparation method comprises the following steps of: mixing a high-nickel ternary precursor, nano cobaltosic oxide, and a lithium source, and calcining the mixture at 750-820 degrees centigrade to obtain the lithium cobaltate-coated high-nickel ternary positive electrode material, wherein the mass ratio of the nano cobaltosic oxide to the high-nickel ternary precursor is 0.05 to 0.2:1. The surface of the high-nickel ternary positive electrode material is uniformly coated with a layer of lithium cobaltate material, thereby protecting the reticular structure of the high-nickel ternary positive electrode material, reducing the nickel-lithium ion mixing, improving the electronic conduction, the cycle performance and the rate performance of the material, additionally avoiding direct contact between the surface of high-nickel ternary positive electrode material and the air, reducing the water absorption of the material and the formation of surface lithium hydroxide and lithium carbonate, reducing residual alkali on the surface of the material, and optimizing the processing properties of the material.

Owner:RUYUAN DONGYANGGUANG MAGNETIC MATERIAL

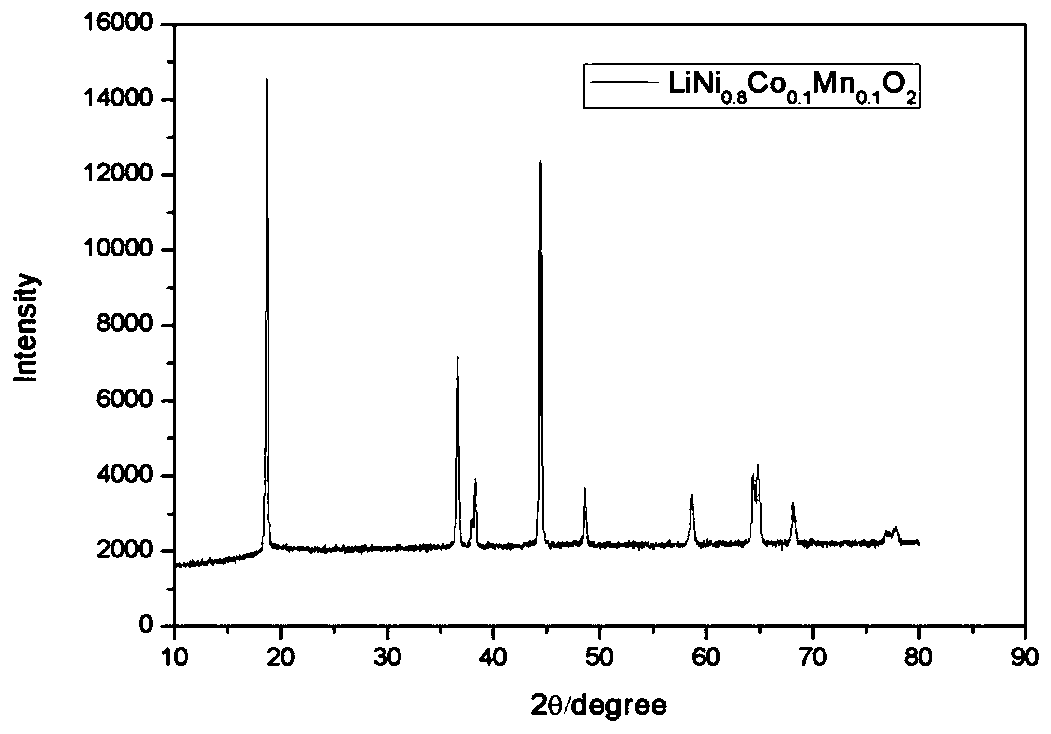

A co-doped modified high-nickel ternary material and a preparation method thereof

ActiveCN109119628ALow mixingLamellar structure is stableCell electrodesSecondary cellsChemistryCyclic stability

The invention provides a high-nickel ternary cathode material and a preparation method thereof, wherein the general chemical formula is LiNixCoyMnzM<1>M<2>O<2+d>, M1 is one of alkali metal elements Li, Na or K; and M2 is one of the nonmetallic elements B, P, Si, or S. The preparation method includes mixing ternary precursor powder with a lithium-containing compound, a compound containing M1and a compound containing M2 at a temperature 1 for a period of time, further heating to a temperature 2, uniformly diffusing M and M' ions into the material, and obtaining a co-doped modified high-nickel ternary material. After the high-nickel ternary material of the invention is modified by co-doping, the mixed arrangement degree of Ni2+ and Li+ t is low, the layer spacing is enlarged, the structure is stable, and the ternary material has excellent electrochemical activity, rate performance and cycle stability; and the method of the invention is simple in synthesis process and is suitable for industrialized production.

Owner:CENT SOUTH UNIV +1

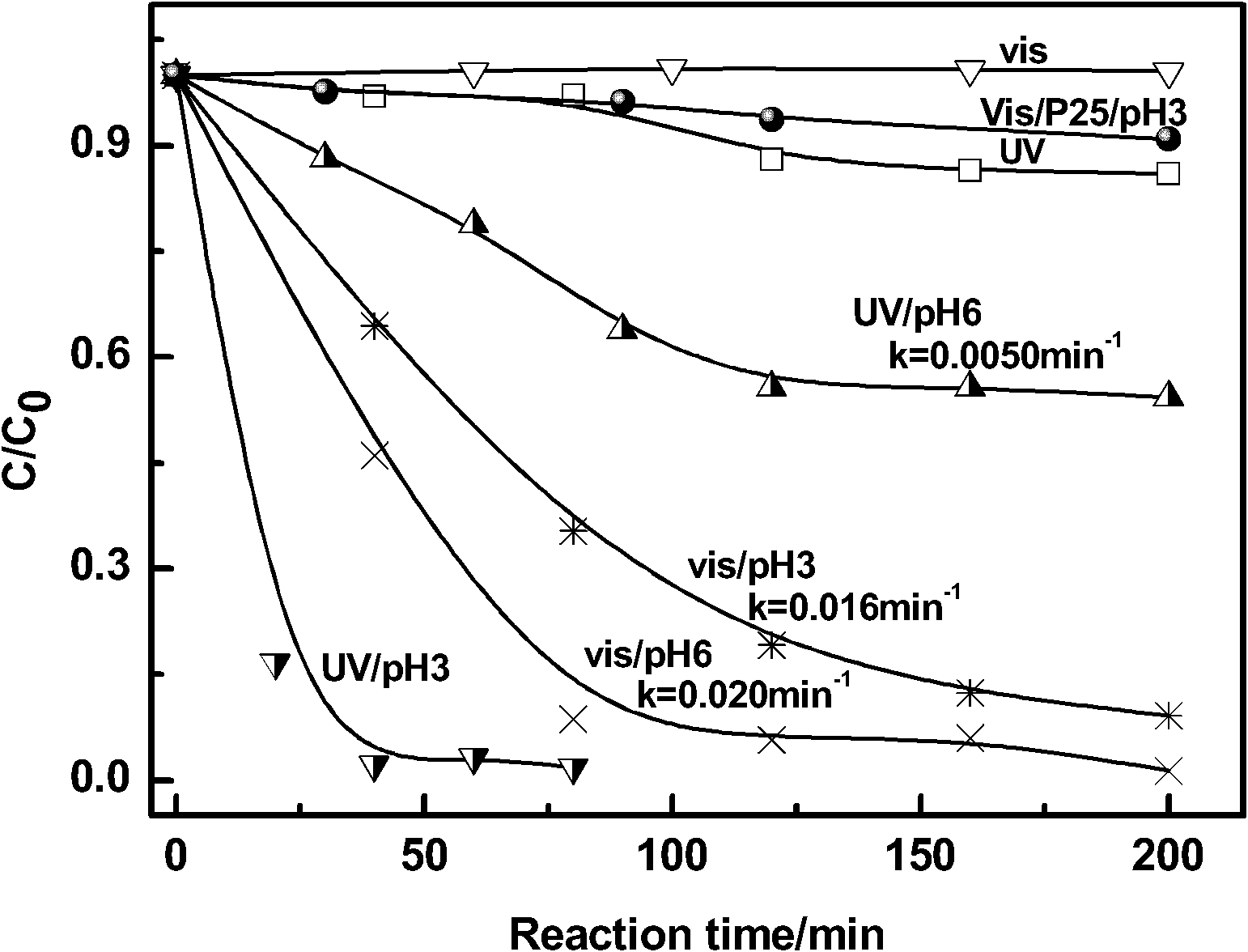

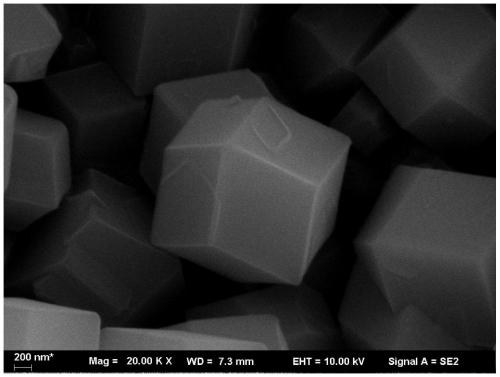

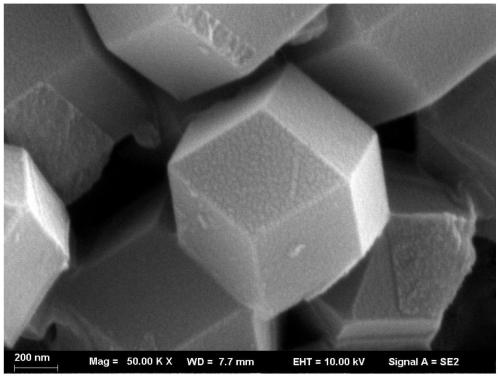

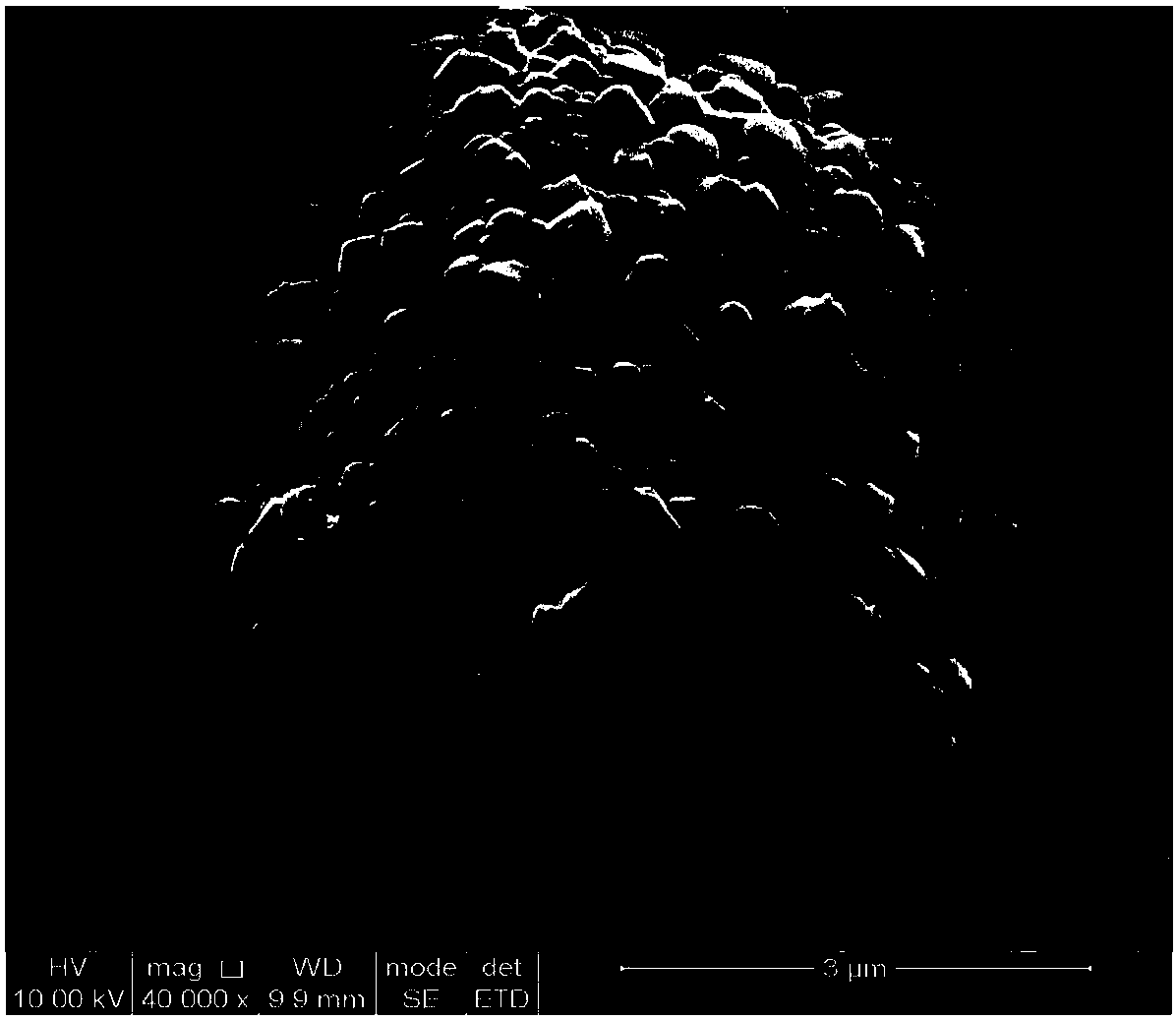

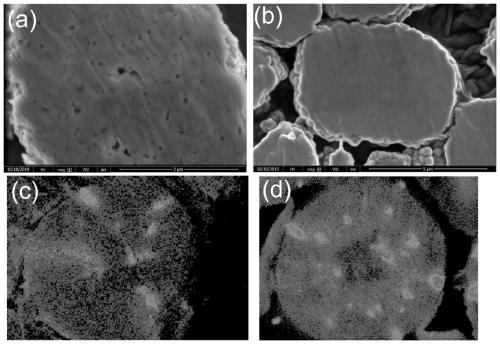

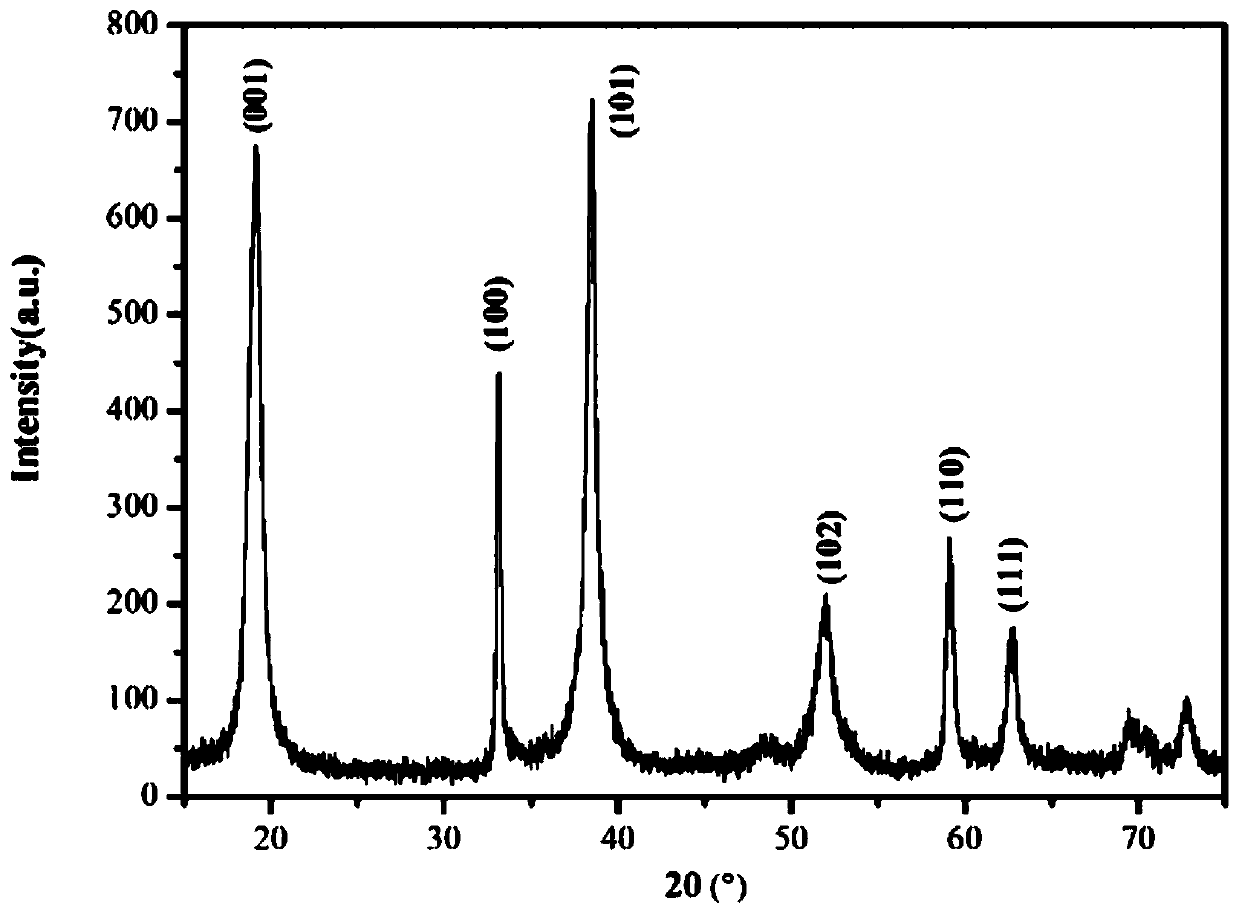

Preparation method of bismuth oxybromide photocatalyst

InactiveCN101786006AHigh crystallinityHigh specific surface areaPhysical/chemical process catalystsWater/sewage treatment by irradiationLight ActivityBismuth oxybromide

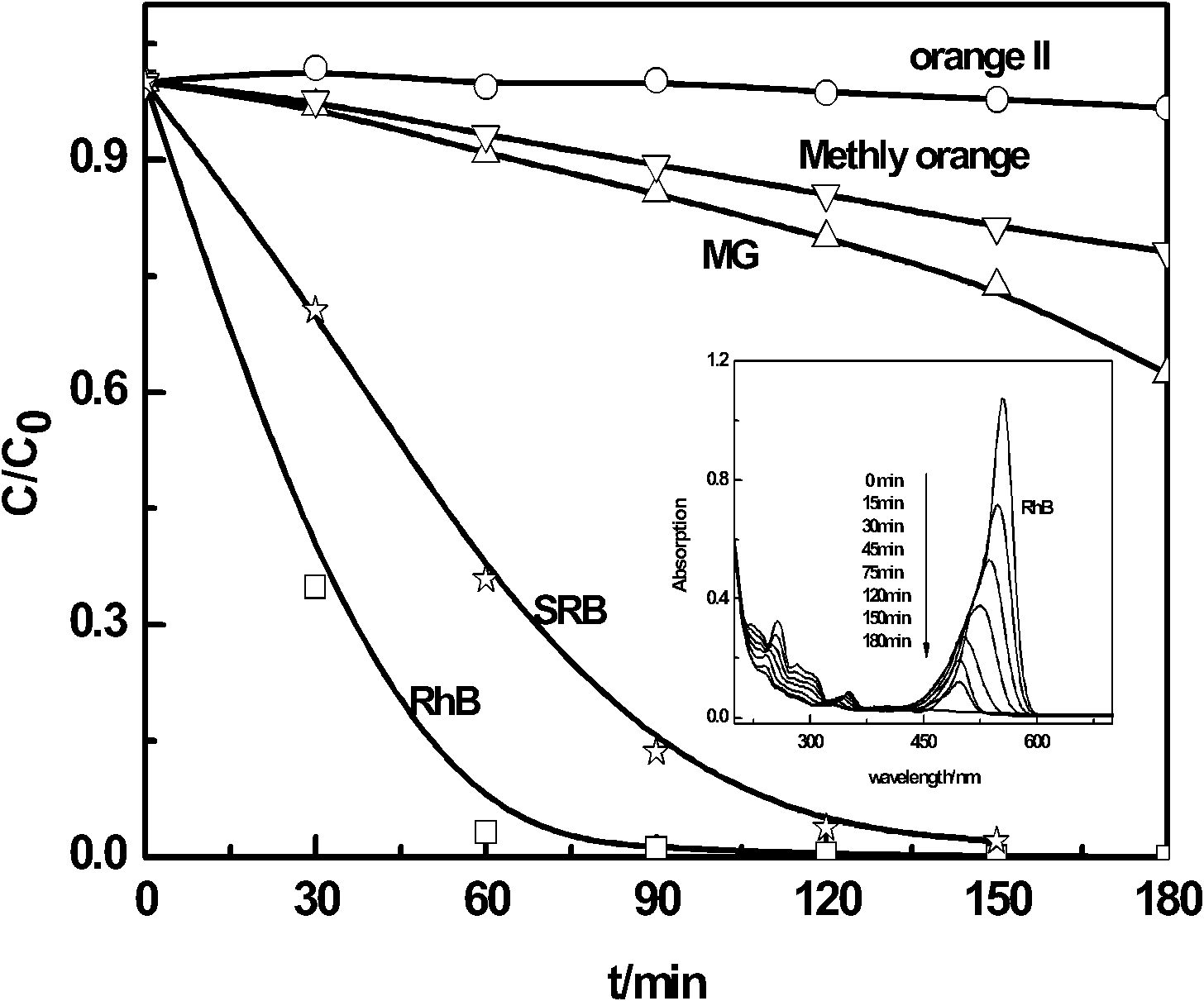

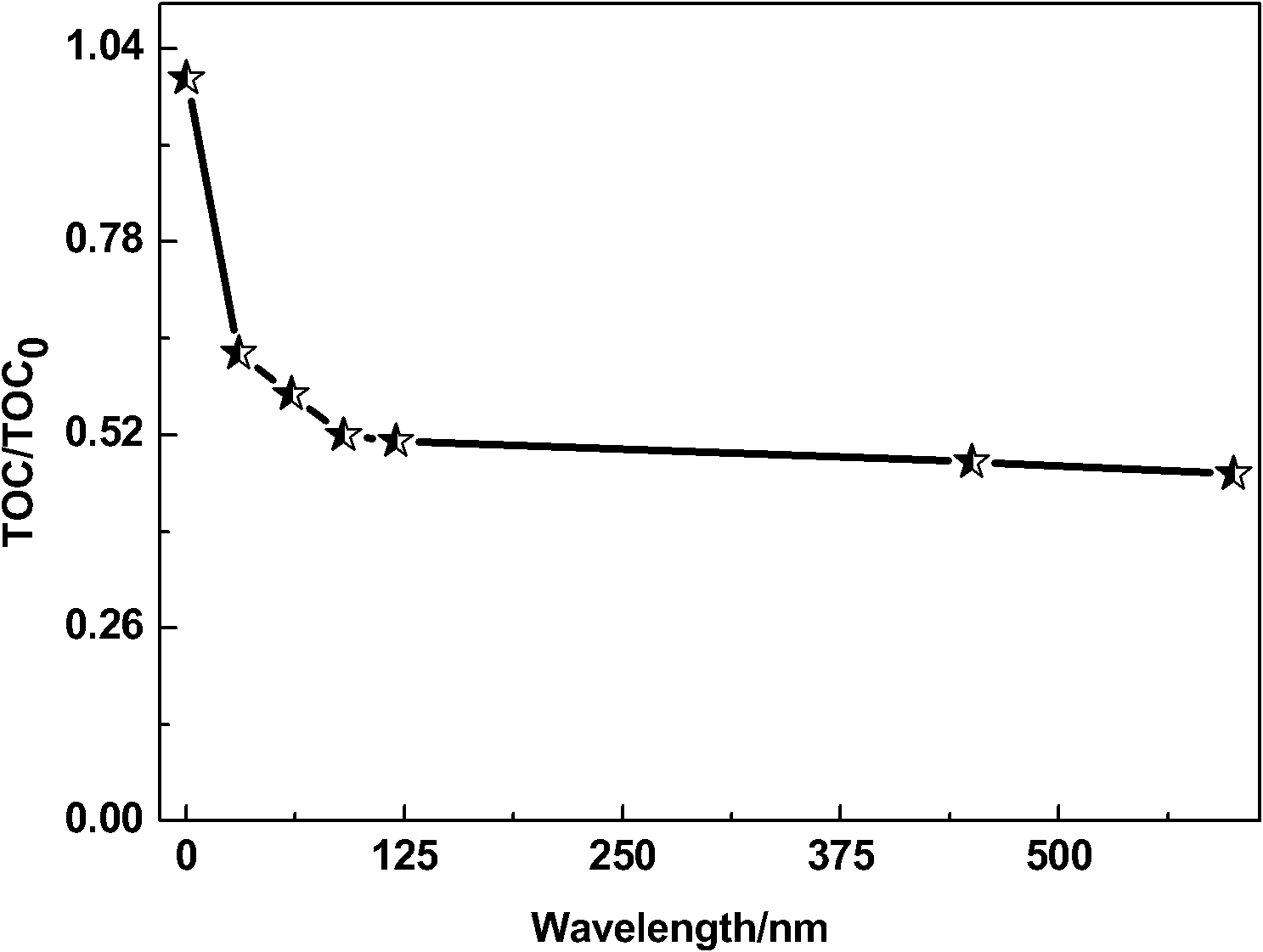

A preparation method of bismuth oxybromide with high-efficient visible light activities adopts cetyl pyridine bromide as raw material, the surfactant has the functions of providing bromine source and structure template agent simultaneously, and the bismuth oxybromide with stable structure and performance and high activity can be obtained. Dilute nitric acid solution dissolved with Bi(NO3)3 is dripped into the cetyl pyridine bromide solution to produce faint yellow precipitate, and then the pH value needs to be adjusted to 7; and the mass ratio of the two raw materials meets nBi: nBr=1: 1.5. The bismuth oxybromide synthesized by the method is faint yellow solid powder and has no special smell. The bismuth oxybromide has quadrangular crystal form detected by an instrument, the specific surface area is large, the surface aperture is small, the band gap is 2.62eV, the crystallinity is 98.3% of layer crystal, the product purity is more than 99.9%, the visible light activity of the prepared bismuth oxybromide is high, and various organic dyes and microcystic toxins can be degraded effectively in a short time.

Owner:INST OF MOUNTAIN HAZARDS & ENVIRONMENT CHINESE ACADEMY OF SCI

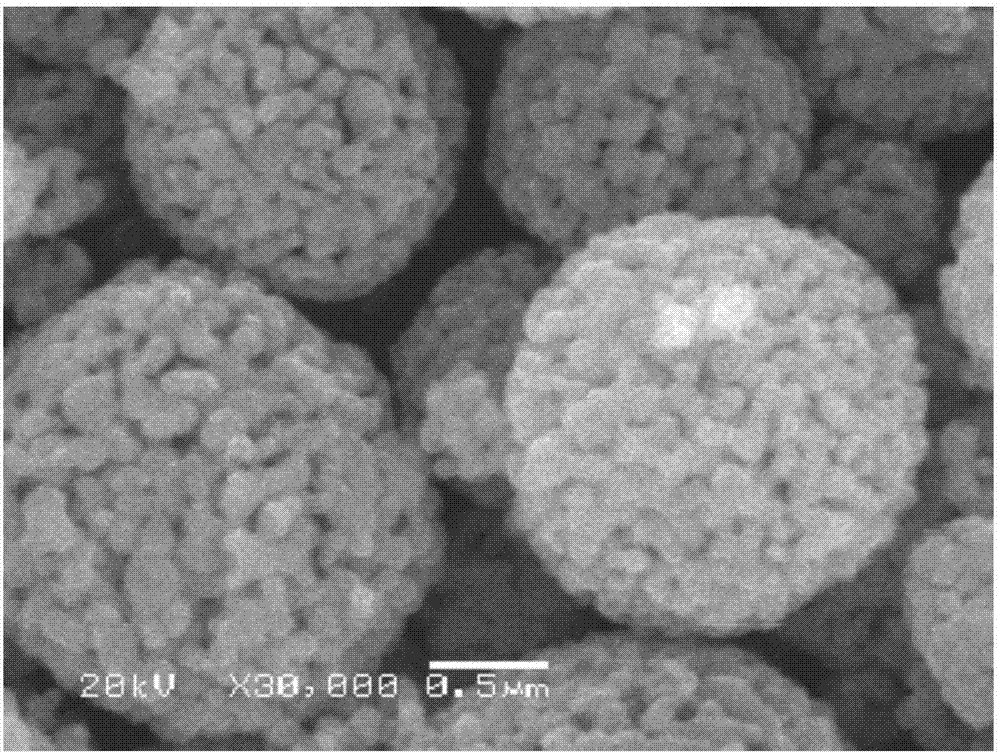

Preparation method of ternary compound potassium ion battery plus plate material

ActiveCN1956242AAvoid local overconcentrationIncrease contactElectrode manufacturing processesLithium compoundsLithium compoundSolvent

A method for preparing positive electrode material of ternary composite Li ion cell includes mixing soluble compound of Ni and Mn as well as Co to be transition metal soluble, filling certain amount of ammonia water in reactor then adding transition metal solution into reactor by ejecting gun and pumping mixed liquid of ammonia and sodium hydroxide into reactor by precipitation then wet-mixing it with Li compound, sintering mixture of presoma and Li compound with high temperature under oxygen atmosphere then grinding sintered material to obtain positive electrode material.

Owner:BYD CO LTD

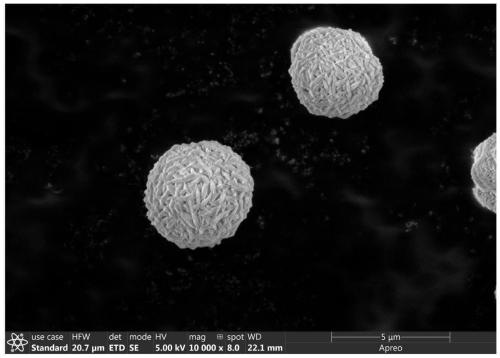

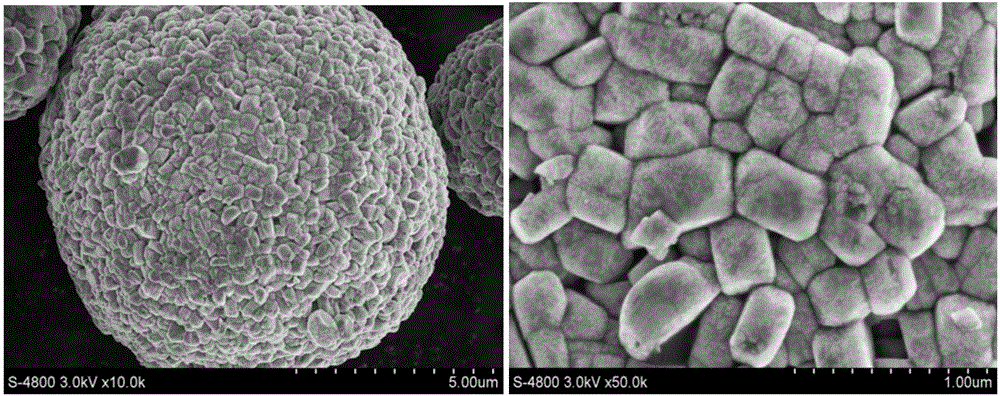

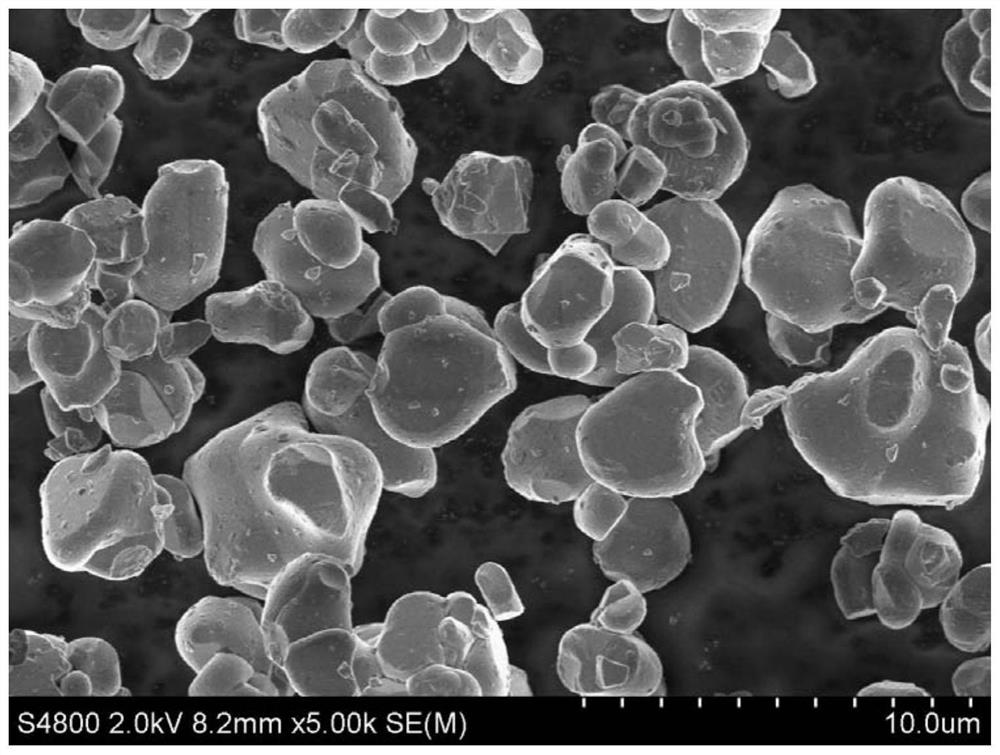

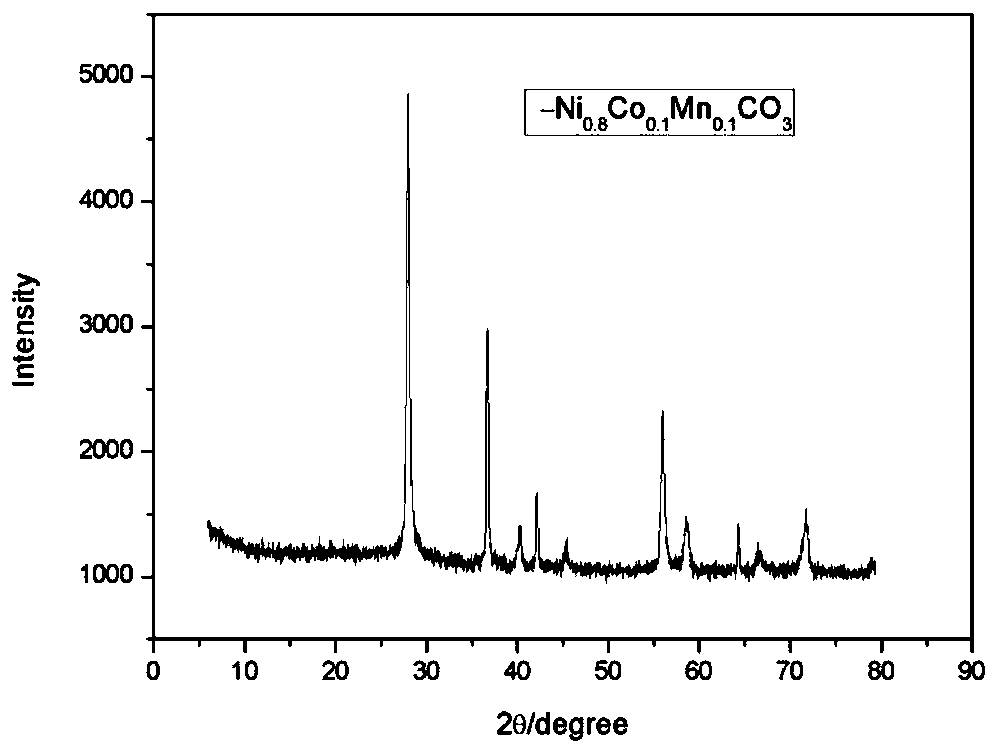

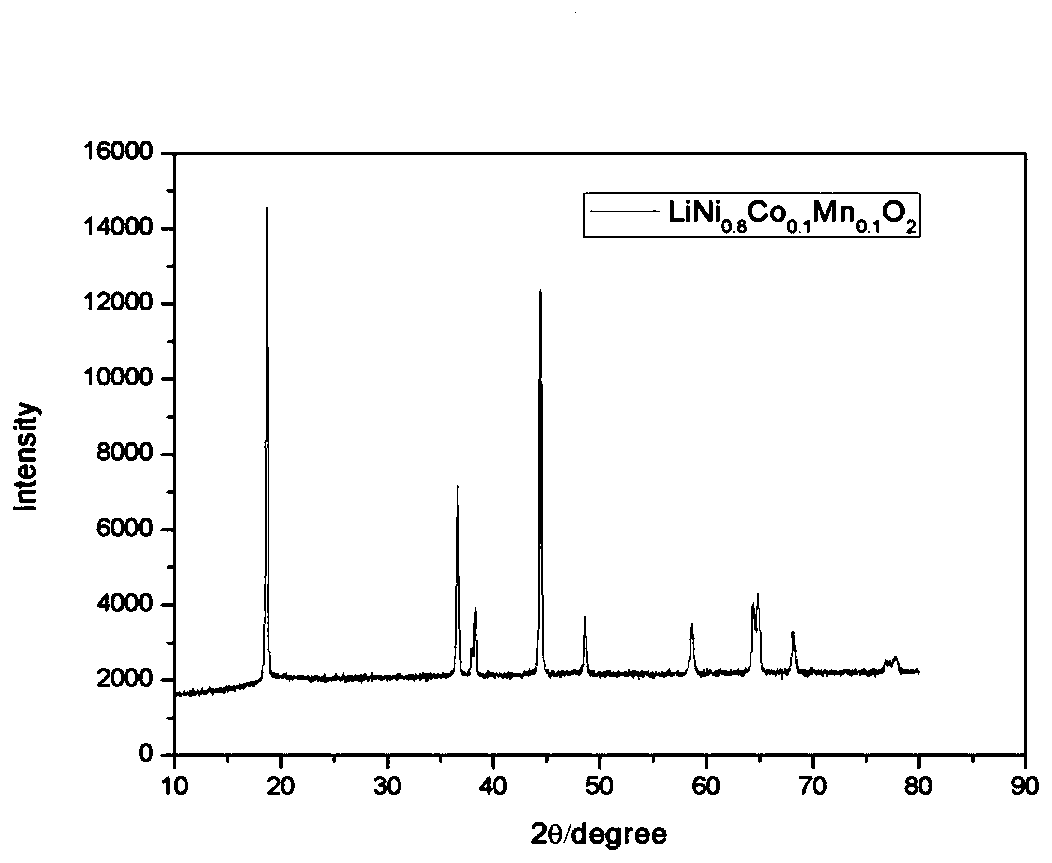

High-nickel ternary precursor with core-shell structure, preparation method of high-nickel ternary precursor, and hollow doped high-nickel ternary positive electrode material

ActiveCN111525113ATailorableHave diversityCell electrodesSecondary cellsOctahedronMetal-organic framework

The invention relates to the field of lithium ion battery materials, in particular to a high-nickel ternary precursor with a core-shell structure, a preparation method of the high-nickel ternary precursor and a hollow doped high-nickel ternary positive electrode material. The precursor is of a core-shell structure, an inner core is of a boron-doped octahedral structure Zn-MOF, and an outer shell is of a nickel-rich ternary precursor NixCoyMnz(OH)2. The preparation method comprises the following two steps: step 1, synthesizing octahedral structure Zn-MOF (metal organic framework) through coprecipitation, and soaking the octahedral structure Zn-MOF in a boric acid solution to obtain boron-doped MOF; and step 2, coating a high-nickel ternary precursor material on the basis to form the high-nickel ternary precursor with the core-shell structure. The high-nickel ternary precursor with the core-shell structure is prepared by adopting a simple and efficient method, and a foundation is laid for a cathode material prepared in the later period to have higher initial capacity and cycling stability; the product synthesized by adopting a coprecipitation method is uniform in component, good in sphericity degree and good in reproducibility, and has good economic value and application prospect.

Owner:ZHUJI PAWA NEW ENERGY

Quad-element lithium ion battery anode material and preparing method

InactiveCN108288711AImprove stability and securityImprove cycle stabilityCell electrodesSecondary cellsNickel saltFiltration

The invention discloses a quad-element lithium ion battery anode material and a preparing method. The molecular formula of the quad-element lithium ion battery material is LiNi0.6Co0.1Mn0.1Fe0.1O2. The preparing method of the battery anode material includes the following steps of weighing soluble nickel salt, soluble cobalt salt, soluble manganese salt and soluble iron salt, adding the salts to deionized water at the same time to be dissolved to prepare a mixed solution, adding a precipitant to the deionized water to be dissolved to prepare a precipitant solution, dropwise adding the mixed solution to the precipitant solution to be stirred and mixed, conducting coprecipitation, suction filtration, washing and drying to obtain a precursor for standing and ageing, evenly mixing the nickel-cobalt-manganese-iron four-element material precursor and a lithium source, and conducting presintering, grinding and secondary calcinating to obtain the nickel-cobalt-manganese-iron four-element anodematerial. By introducing the fourth element, namely iron, to a three-element material, since the radius and electronegativity of an introduced ion are close to those of a replaced element, damage cannot happen after introduction, the layer structure of the material can be stabilized, and the circulation stability of the material is improved.

Owner:CHENGDU UNIVERSITY OF TECHNOLOGY

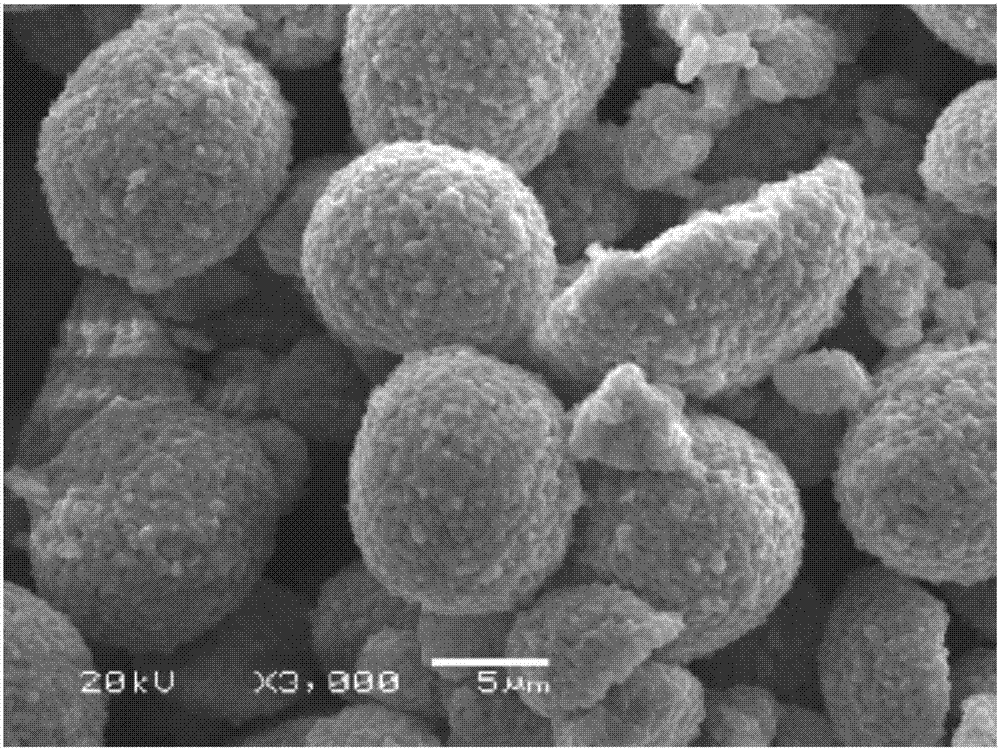

High-nickel ternary material with cobalt-rich surface layer and preparation method and application thereof

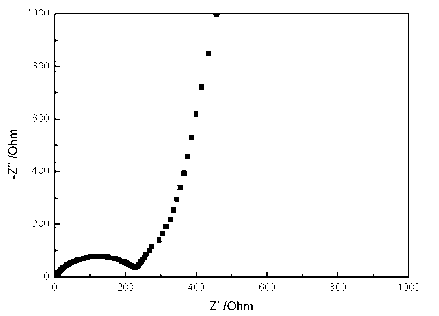

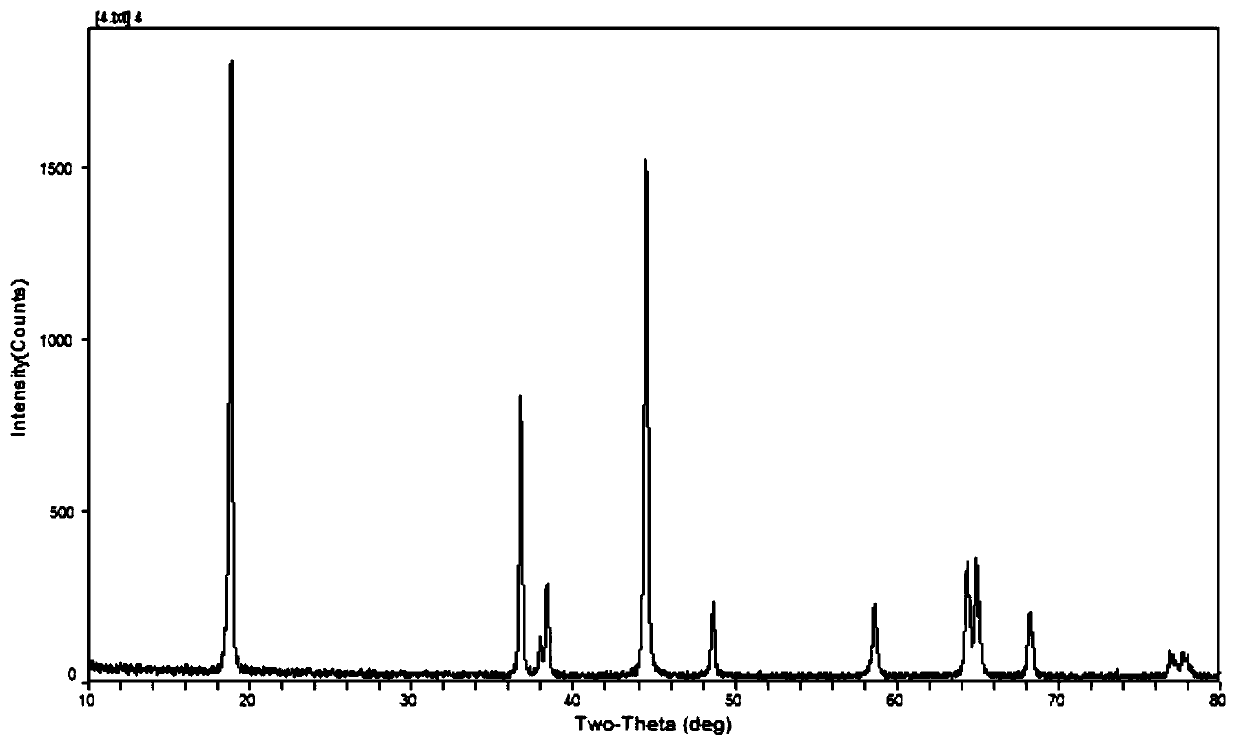

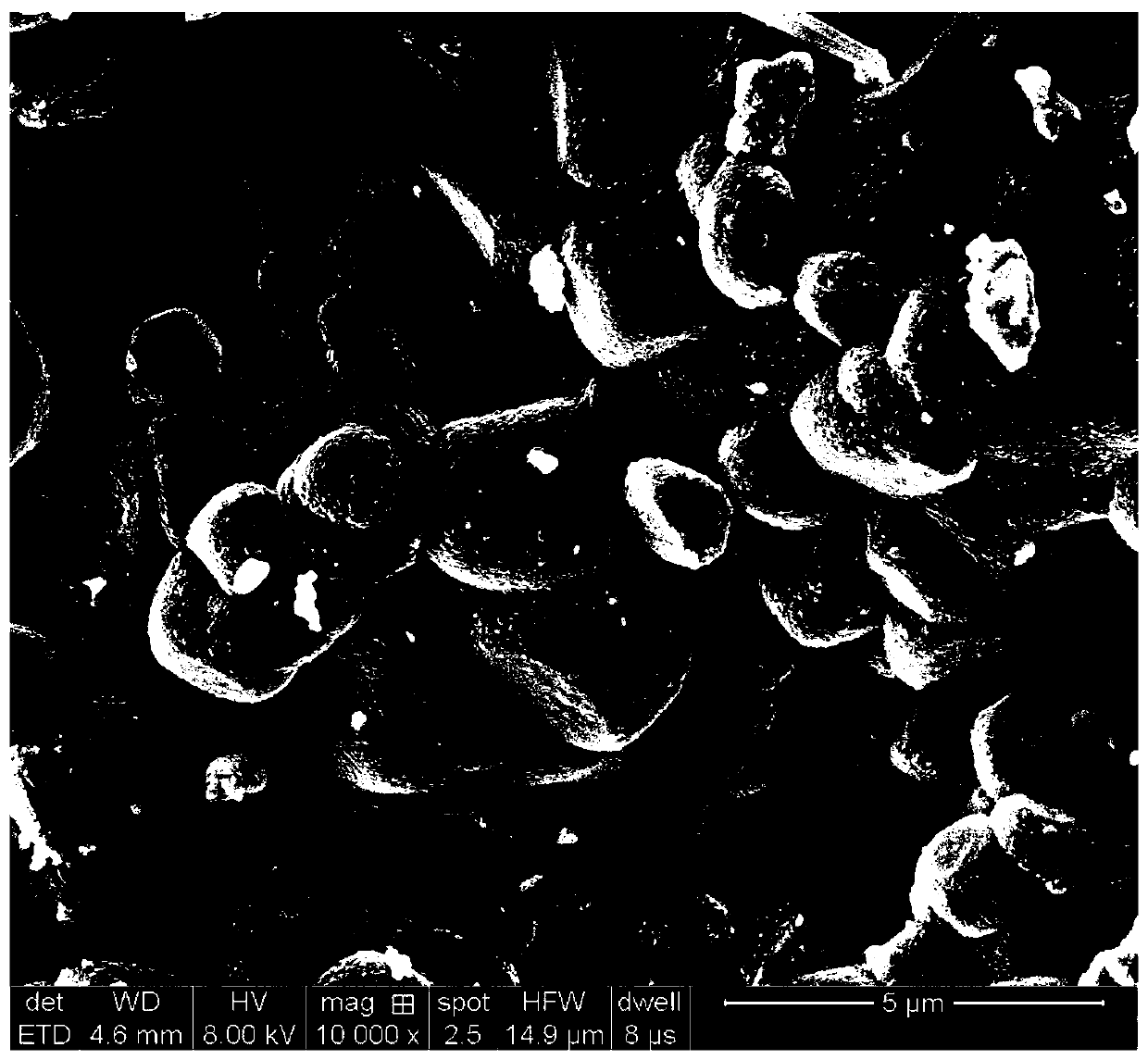

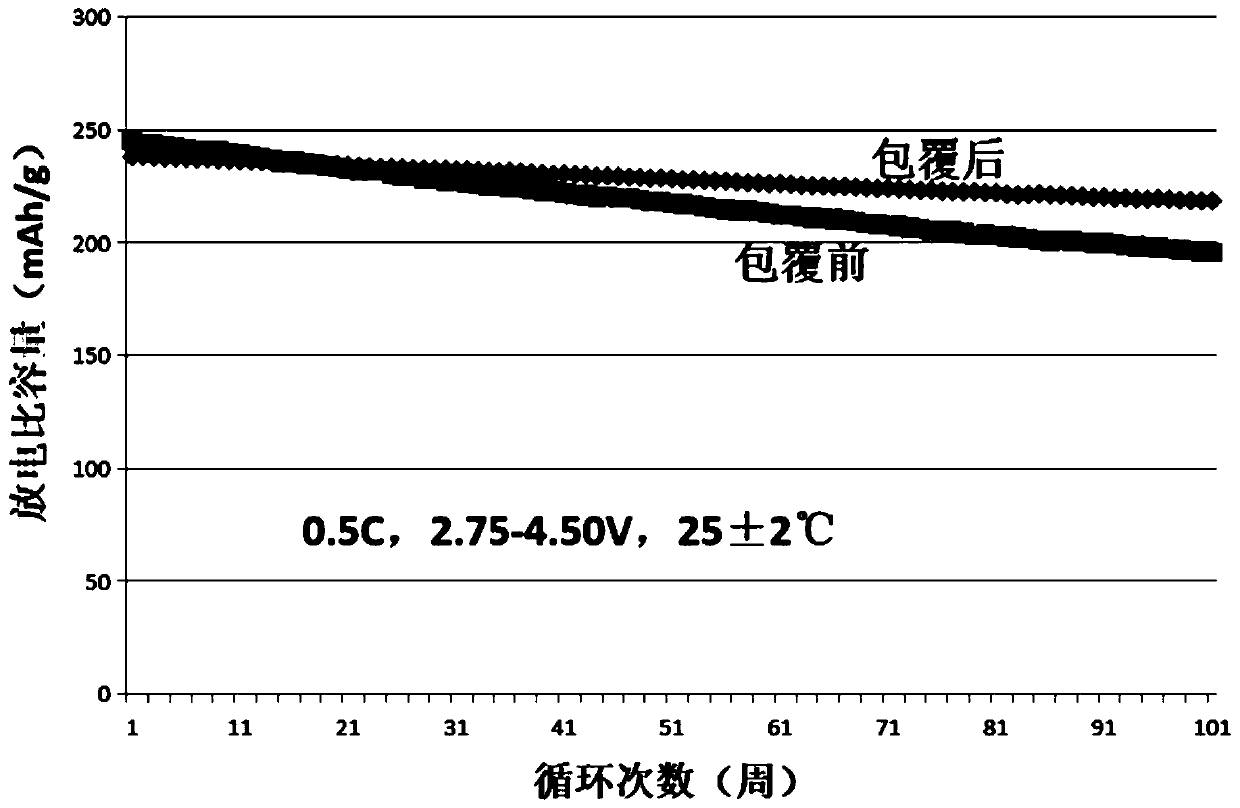

ActiveCN106898751ALamellar structure is stableSmall volume changeCell electrodesSecondary cellsElectrolyteNickel based

The invention discloses a high-nickel ternary material with a cobalt-rich surface layer and a preparation method thereof. The method comprises the following steps: (1) preparing a cobalt chloride solution by spray pyrolysis to obtain porous spherical Co3O4; (2) uniformly mixing the porous spherical Co3O4 with a high-nickel ternary hydroxide precursor and lithium salt, and then sintering the mixture to obtain a nickel-based ternary anode material with the cobalt-rich surface layer. The surface of the anode material has a uniform cobalt-rich coating layer, and reaction of Ni4+ and electrolyte at the position of an interface is reduced. Meanwhile, phase change of H2-H3 is inhibited in charging and discharging processes of the material, volume change of unit cells due to phase change is reduced, therefore, a layer structure of the material is stable, and the cycle performance is improved. The raw materials used in the preparation method are simple and easy to obtain, the process is simple, and the technological process is short.

Owner:CENT SOUTH UNIV

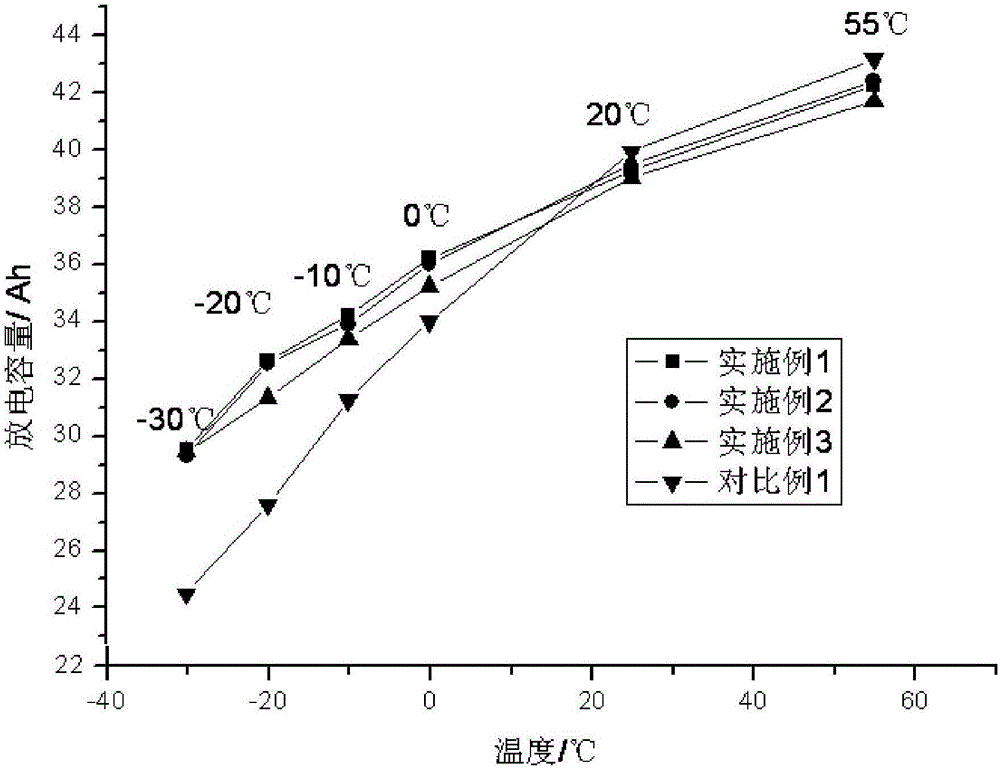

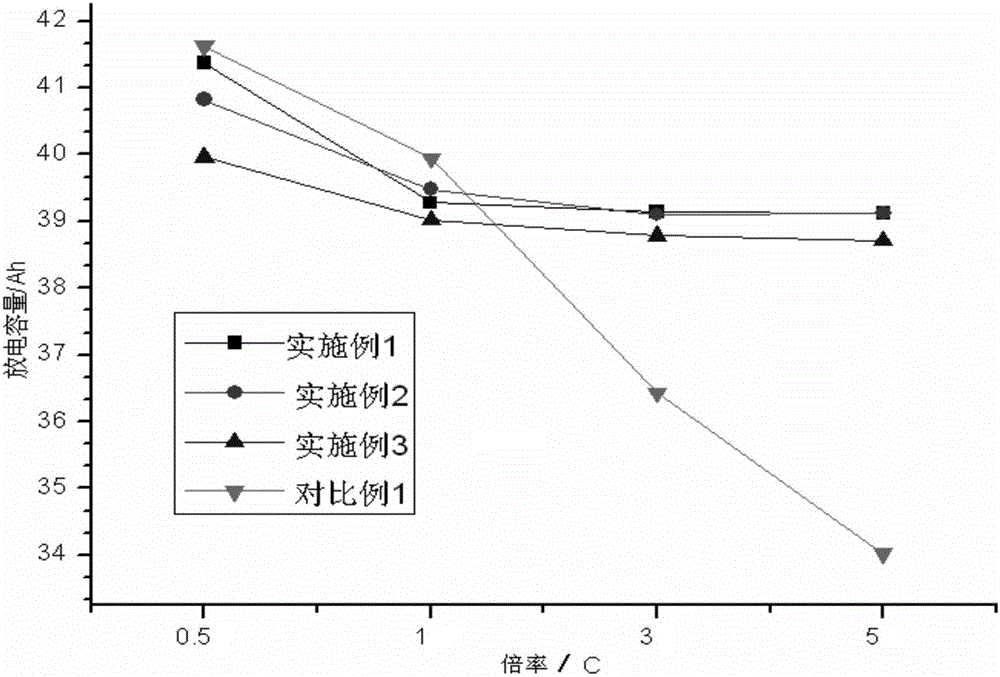

Preparation method for power NCM523 material capable of improving high-and-low-temperature performance

ActiveCN106450273AImprove ion conduction conductivityImprove surface conditionCell electrodesSecondary cellsType transformationLithium-ion battery

The invention relates to a preparation method for a power NCM523 material capable of improving high-and-low-temperature performance, and belongs to the technical field of a positive electrode material of a lithium ion battery. The preparation method comprises the following steps of 1, preparation of an NCM523 precursor, including the sub steps of 1) solution preparation: preparing a mixed solution of Ni, Co, Mn and Y salt; preparing an NaOH alkali solution, adding Al(NO<3>)<3>.9H<2>O, and adding ammonium hydroxide to form an aluminum-containing ammonia alkali solution; 2) parallel flow reaction: performing a parallel flow reaction on the Ni, Co, Mn and Y salt solution and the aluminum-containing ammonia alkali solution in a reaction kettle to form a sky blue turbid liquid; 3) aging: regulating the ph value of the solution to perform aging and crystal type transformation; 4) performing pressing and filtering, washing and drying; and 5) performing demagnetizing; 2, lithium preparing and sintering: enabling a lithium salt to be mixed with a precursor material, and performing sintering and smashing on the mixture to obtain the positive electrode material; and 3, performing liquid phase coating of a lithium rapid ion conductor: enabling Li<3>PO<4>-Al(OH)<3> to be mixed with the positive electrode material, and performing spraying and drying, and sintering. The preparation method has the advantages of simple process, convenient operation, and capability of remarkably improving the high-and-low-temperature performance, and the like.

Owner:CHINA ELECTRONIC TECH GRP CORP NO 18 RES INST

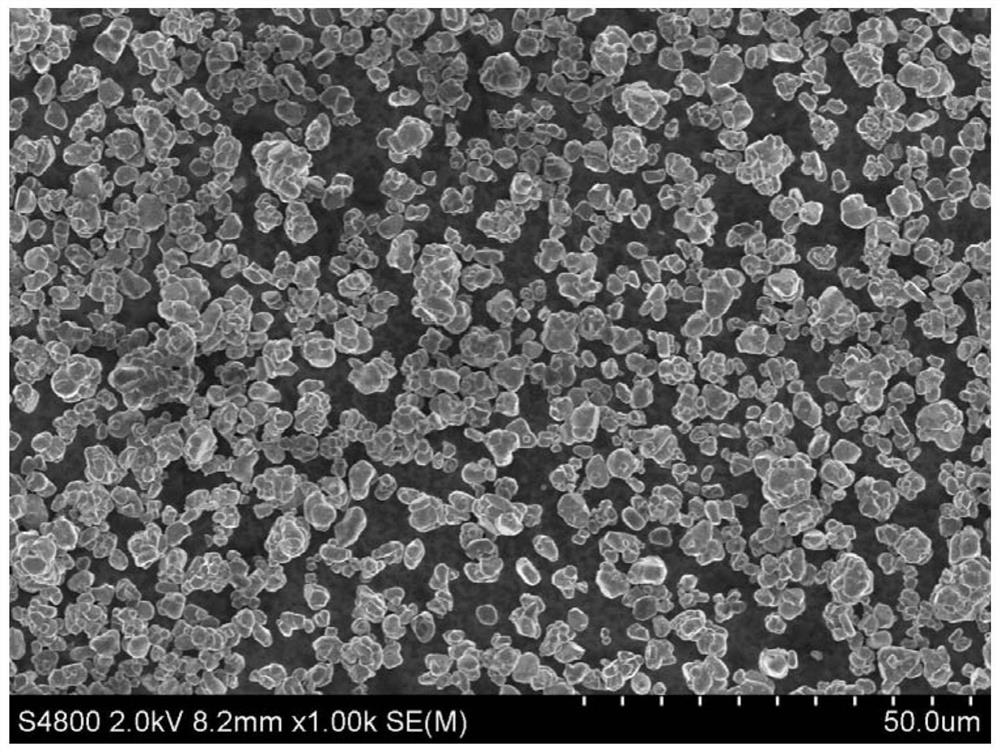

Ultrahigh nickel single crystal positive electrode material, preparation method and application

InactiveCN112310389AHigh crystallinityIncreased dispersionPolycrystalline material growthCell electrodesLithium hydroxideSingle crystal

The invention discloses a preparation method of an ultrahigh nickel single crystal positive electrode material, which comprises the following steps of S1, mixing a ternary precursor and lithium hydroxide according to a lithium-metal molar ratio of 1.01-1.10: 1, adding a doping agent, and calcining in an oxygen atmosphere to obtain a primary calcined material, S2, performing coarse crushing, fine crushing, sieving and demagnetizing on the primary calcined material to obtain a crushed material, S3, adding the crushed material and water into a reaction kettle according to a water-material ratio of 0.5: 1-5: 1, controlling the temperature of the reaction kettle, adding a reagent for reaction, and drying after the reaction is finished to obtain a mixed material, and S4, mixing the mixture witha modified coating agent, placing the mixture in an atmosphere furnace for secondary calcination, and then performing coarse crushing, fine crushing, sieving and demagnetizing to obtain the ternary positive electrode material. The ultrahigh nickel single crystal is subjected to optimization treatment by different calcining processes and is coated and modified by the modified coating agent, so thatthe obtained single crystal positive electrode material has the characteristics of extremely low residual alkali level and less single crystal particle agglomeration state, and the soft package battery assembled by the single crystal material has the characteristics of good thermal stability, low gas expansion rate and excellent cycle performance; compared with a conventional high-nickel secondary ball with the same nickel content, the material has obvious performance advantages.

Owner:ZHEJIANG MEIDU HITRANS LITHIUM BATTERY TECHNOLOGY CO LTD

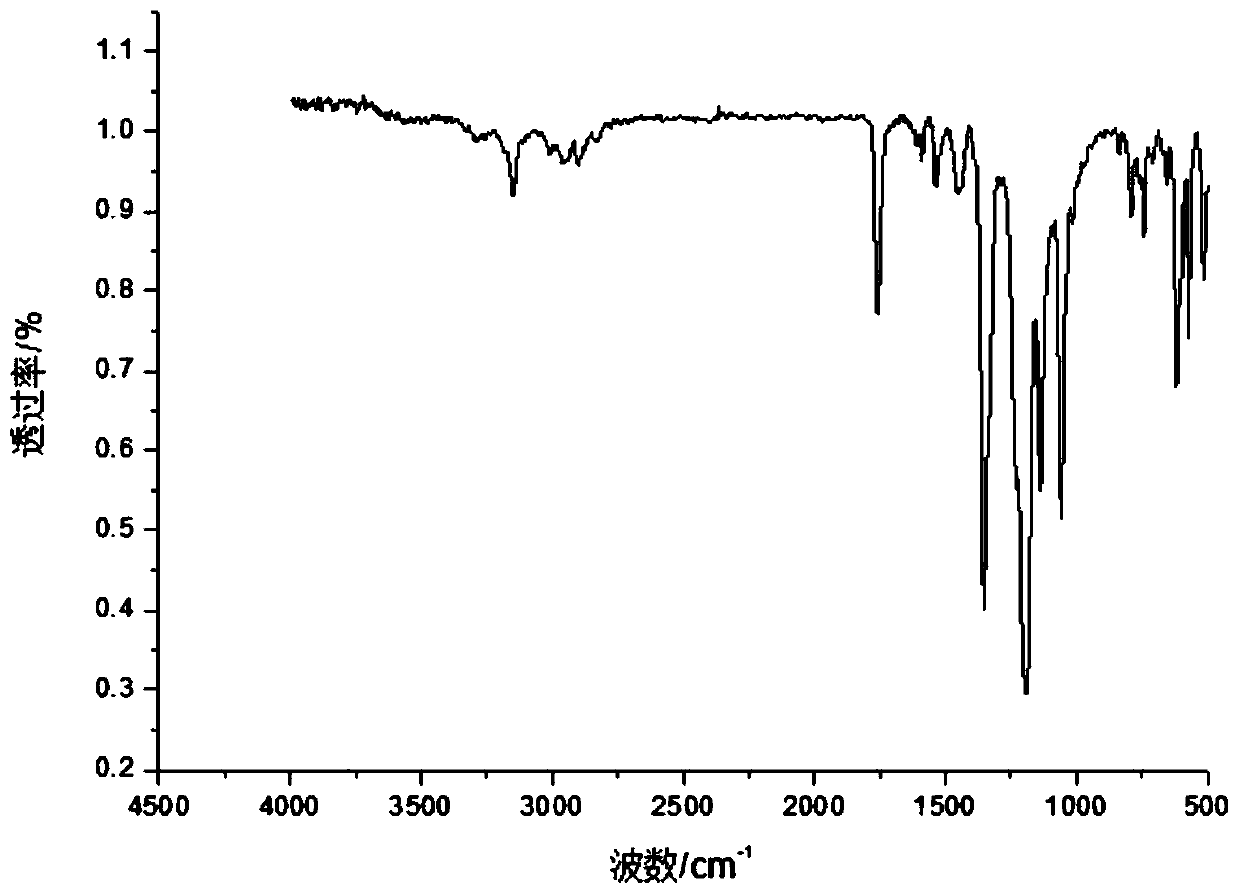

Method for improving electrochemical performance of high nickel ternary cathode material through silicon dioxide/sodium collaborative modification

InactiveCN109980203AImprove lithium ion conductivityIncrease speedCell electrodesSecondary cellsFurnace temperatureHigh rate

The invention discloses a method for improving electrochemical performance of a high nickel ternary cathode material through silicon dioxide / sodium collaborative modification. The method comprises thesteps of (1) respectively dissolving nickel, cobalt and manganese sources and urea in distilled water, transferring the solutions to a reactor after sufficient dissolution, then placing the reactor in an oven for reaction to obtain milky yellow powder of a high nickel ternary precursor; (2) sufficiently grinding the precursor, a lithium source and a sodium source to obtain a mixture, carrying outtwo-stage high temperature sintering on the mixture in an oxygen atmosphere in a tubular furnace, and cooling to the room temperature along with the furnace temperature to obtain Li<0.9>Na<0.1>Ni<0.8>Co<0.1>Mn<0.1>O2; and (3) mixing ethyl orthosilicate and water, then adding the mixture to Li<0.9>Na<0.1>Ni<0.8>Co<0.1>Mn<0.1>O2, stirring, drying, adding a small amount of absolute ethyl alcohol, grinding and then preserving the temperature for a period of time in a Muffle furnace to obtain an SiO2 / Li<0.9>Na<0.1>Ni<0.8>Co<0.1>Mn<0.1>O2 composite material. The method has the advantages of simpleprocess and low cost and prepares the silicon dioxide coated SiO2 / Li<0.9>Na<0.1>Ni<0.8>Co<0.1>Mn<0.1>O2 composite material with good electrochemical performance such as high rate performance and cycle performance.

Owner:GUILIN UNIVERSITY OF TECHNOLOGY

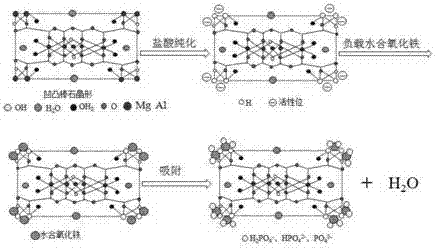

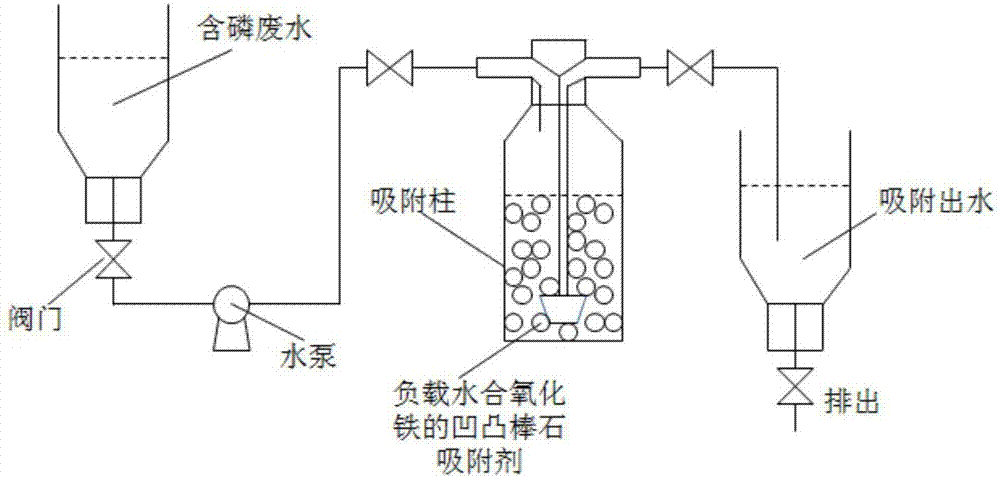

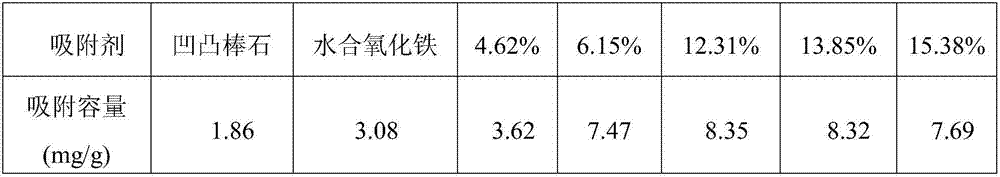

Method for deep adsorption dephosphorization through ferric oxide hydrate-carrying attapulgite

ActiveCN107265548AImprove adsorption performanceIncrease totalOther chemical processesWater contaminantsChemistryIron oxide

The invention discloses a method for deep adsorption dephosphorization through ferric oxide hydrate-carrying attapulgite. The method comprises (1) preparing a ferric oxide hydrate-carrying attapulgite adsorbent with particle diameters of 2 to 6 mm through attapulgite purification, modification and granulation, and (2) filling an adsorption device with the adsorbent particles, making phosphorus-containing wastewater flow through a dephosphorization device, adjusting and controlling inlet and outlet water amounts to ensure standing time so that the adsorbent fully contacts with the phosphorus-containing wastewater and phosphorus is adsorbed and fixed to the surface of the adsorbent, and when the adsorbing capacity is saturated, carrying out soaking in a sodium hydroxide solution so that the adsorbent is regenerated. The adsorption synthesis process is simple and has strong operability. The adsorption device is simple and easy and realizes wastewater self-flowing treatment. The treated product water has a phosphorus concentration less than 0.1ppm. Under phosphorus removal total amount quantification, the wastewater discharge capability is increased. The adsorbent can be regenerated and recycled so that requirements of environmental protection are satisfied and a treatment cost is effectively reduced.

Owner:盛隆资源再生(无锡)有限公司

Doped high-nickel high-voltage NCM positive electrode material and preparation method thereof

PendingCN110797529AReduce consumptionIncrease profitCell electrodesSecondary cellsHigh energyManganese

The invention discloses a doped high-nickel high-voltage NCM positive electrode material and a preparation method thereof, and belongs to the field of lithium ion batteries. The preparation method comprises the following steps: simultaneously doping manganese and cobalt to obtain an NCM precursor; and adding a dopant M into the precursor, and sintering the precursor in a high-pressure oxygen atmosphere to obtain a lithium ion battery positive electrode material. The positive electrode material has very high specific discharge capacity and excellent cycling stability, can meet the high-rate charging and discharging requirement, and can achieve long-life safe cycling under high voltage. The positive electrode material is prepared by combining four-solution parallel-flow co-precipitation witha high-pressure solid-phase synthesis method, and the prepared product has the advantages of high purity, high crystallization quality, high particle density, uniform distribution of particles, excellent electrochemical performance and low manufacturing cost, is an ideal positive electrode material with high energy density, and has a wide application prospect.

Owner:SICHUAN FUHUA NEW ENERGY HIGH TECH CO LTD

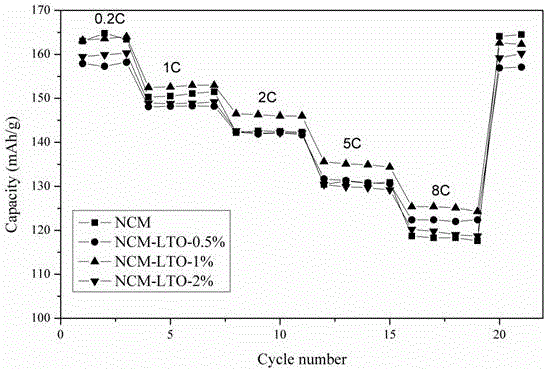

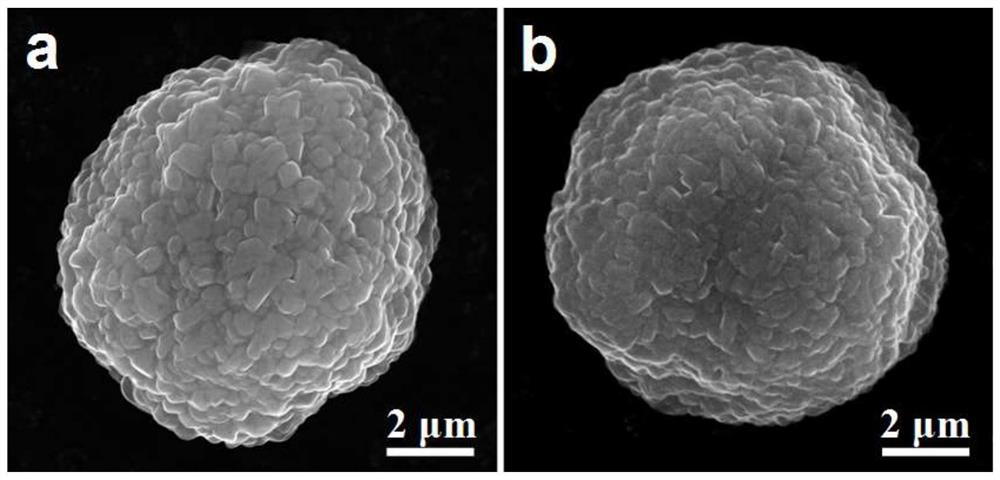

Preparation method of lithium titanate coated lithium ion battery nickel cobalt manganese cathode material

InactiveCN105789606AImprove cycle stabilityImproved magnification performanceCell electrodesBatteriesManganeseCobalt

The invention relates to the technical field of battery materials, in particular to a preparation method of the lithium titanate coated lithium ion battery nickel cobalt manganese cathode material. According to the method, the existing preparation process of the lithium ion battery cathode material is improved, a lithium titanate nanomaterial is synthesized via a sol-gel method and then dipped on a nickel cobalt manganese ternary material via a solution method, so that the composite material high in safety, good in cycling stability and high in initial coulomb efficiency is obtained. The method is simple, feasible, high in production efficiency and suitable for large-scale production, production procedures are reduced, sintering temperature is lowered, sintering time is shortened, and production cost is saved.

Owner:SHANDONG YUHUANG NEW ENERGY TECH

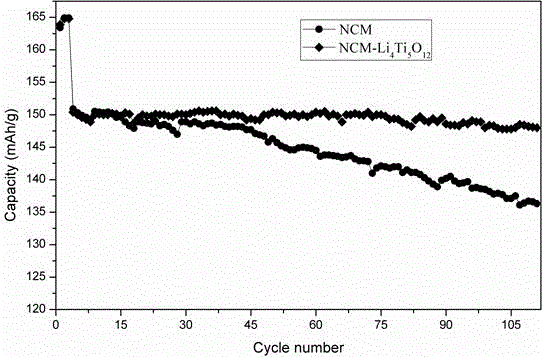

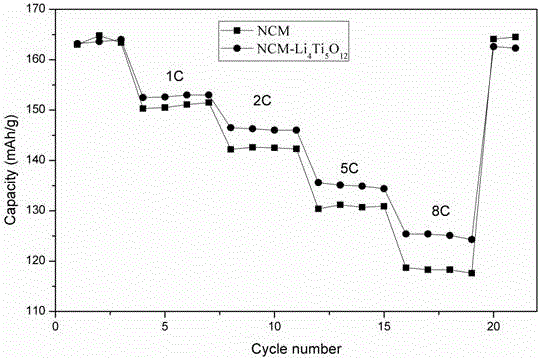

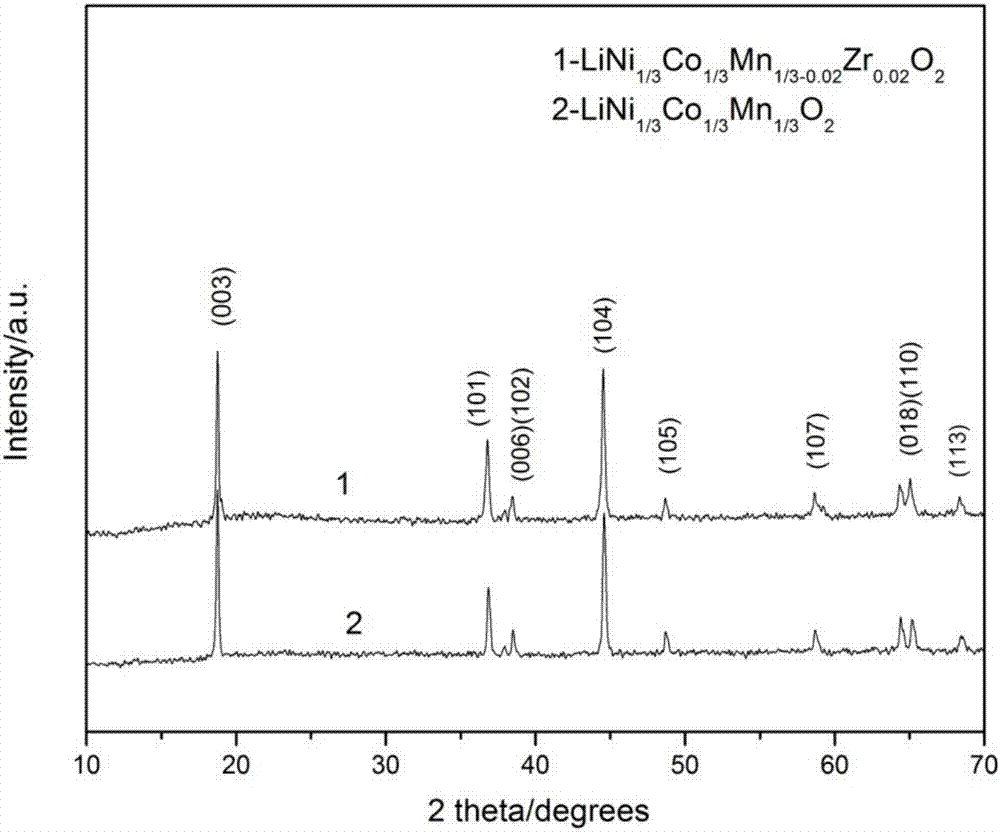

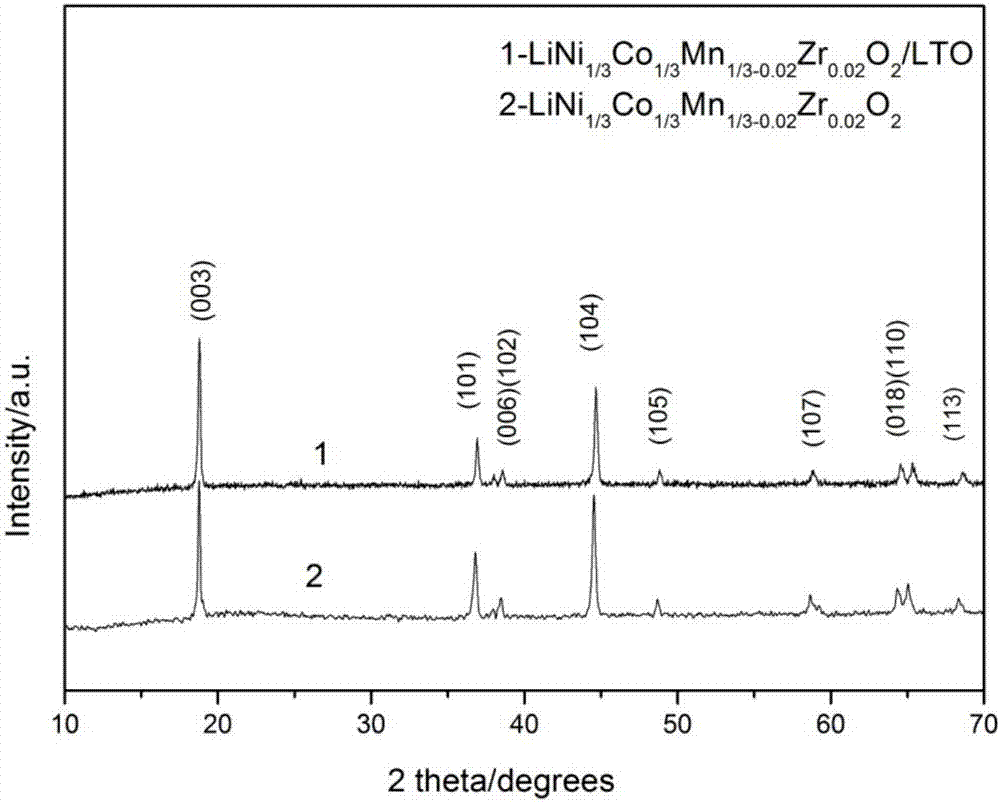

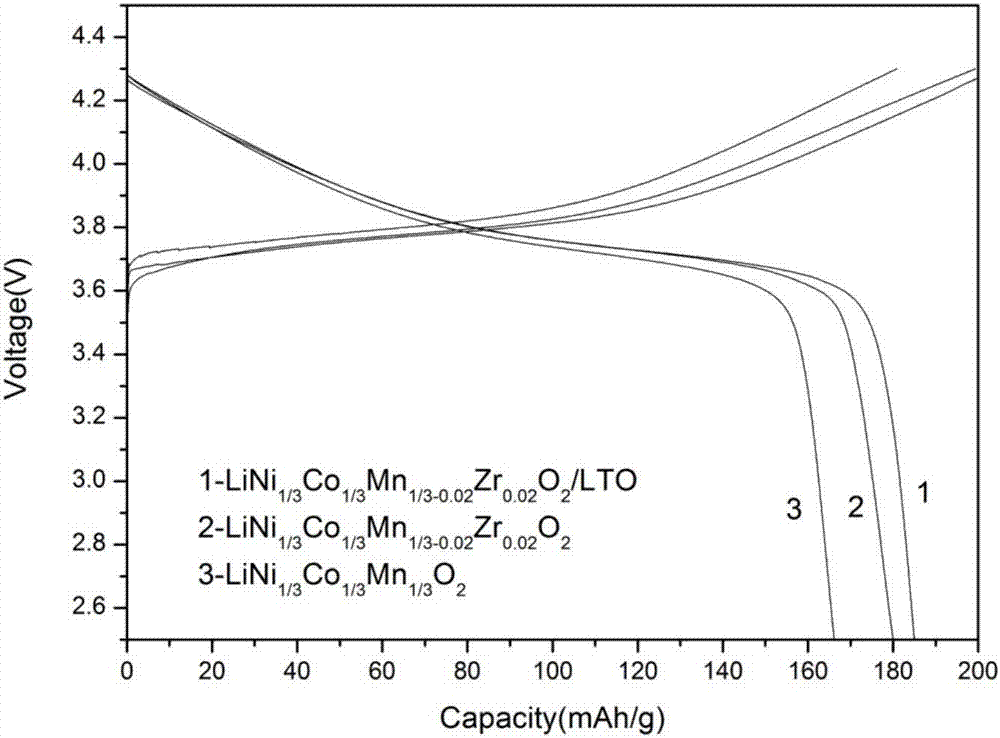

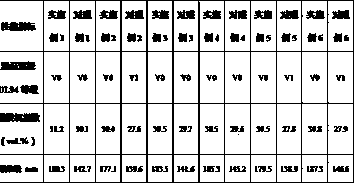

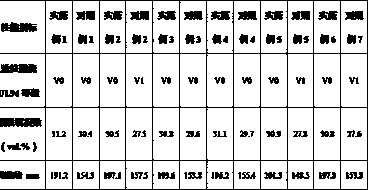

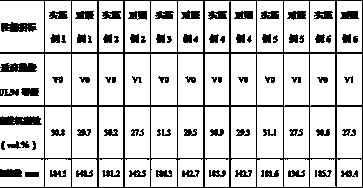

Zirconium-doped modified nickel cobalt manganese lithium oxide/lithium titanate composite cathode material

InactiveCN107204426AHigh specific capacityImproved magnification performanceElectrode thermal treatmentImpregnation manufacturingLithium oxideManganese

The invention discloses a zirconium-doped modified nickel cobalt manganese lithium oxide / lithium titanate composite cathode material. According to the cathode material, a zirconium-doped modified nickel cobalt manganese lithium oxide cathode material is synthesized by a coprecipitation method at first, and then a trinary material is coated by a lithium titanate active electrode material. On one hand, electronic conductivity and ionic conductivity are improved, the output power density of a cell is improved, and further structure stability of the trinary material is improved; on the other hand, advantages of the two materials can be combined through coating; thus, the composite cathode material having better circulation, higher cyclicity and larger energy density is obtained.

Owner:HEFEI UNIV OF TECH +1

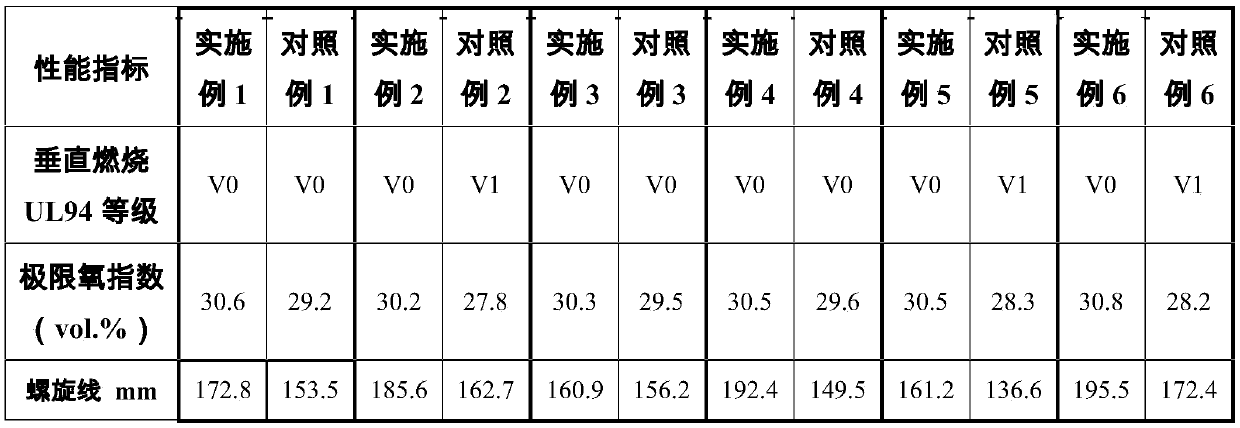

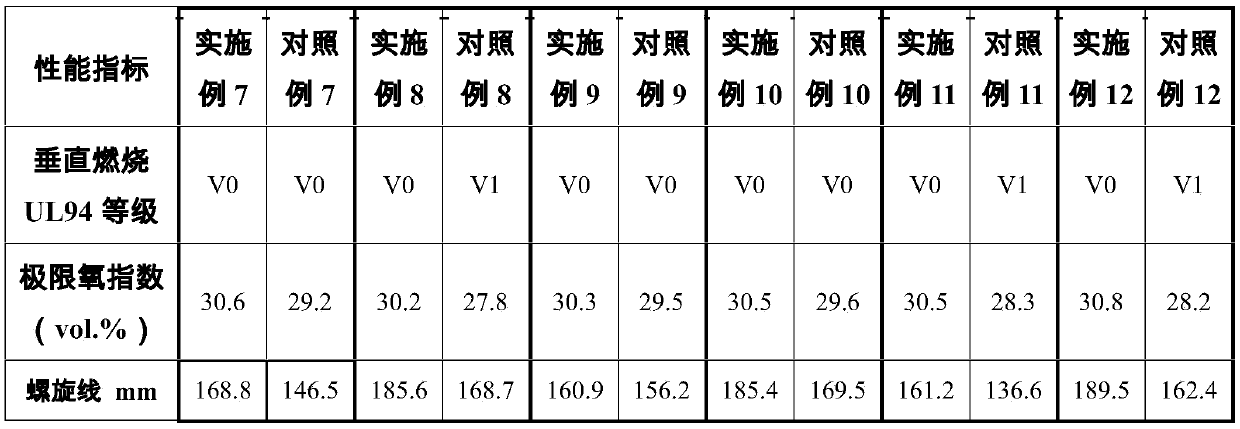

Special halogen-free flame-retardant synergistic masterbatch for modification of nylon resin and preparation method of halogen-free flame-retardant synergistic masterbatch

ActiveCN110591341AEffective protectionImprove thermal protection performanceAcrylonitrilePolytetrafluoroethylene

The invention relates to the technical field of modification and processing of plastics, in particular to special halogen-free flame-retardant synergistic masterbatch for modification of nylon resin and a preparation method of the halogen-free flame-retardant synergistic masterbatch. Multiple-compounded coated aluminum diethylphosphinate is adopted as a phosphorous-based flame retardant of the functional masterbatch, and the functional masterbatch comprises the compositions: in percent by mass, 55.0-65.0% of multiple-compounded coated aluminum diethylphosphinate, 20.0-30.0% of anhydrous zinc borate, 8.0-10.0% of nylon 6 resin, 3.0-5.0% of star-shaped nylon, 0.5-1.0% of styrene-acrylonitrile copolymer-coated polytetrafluoroethylene, 0.5-1.0% of a dispersant and 0.3-0.5% of a lubricant. Whenthe prepared functional masterbatch is compared with traditional flame-retardant functional masterbatch, the heat resistance and thermal stability of aluminum diethylphosphinate are improved significantly, aluminum diethylphosphinate is adaptive to a high processing temperature of nylon resin, so that the flame retardant effect of aluminum diethylphophinate on nylon resin is improved more effectively.

Owner:江苏万纳普新材料科技有限公司

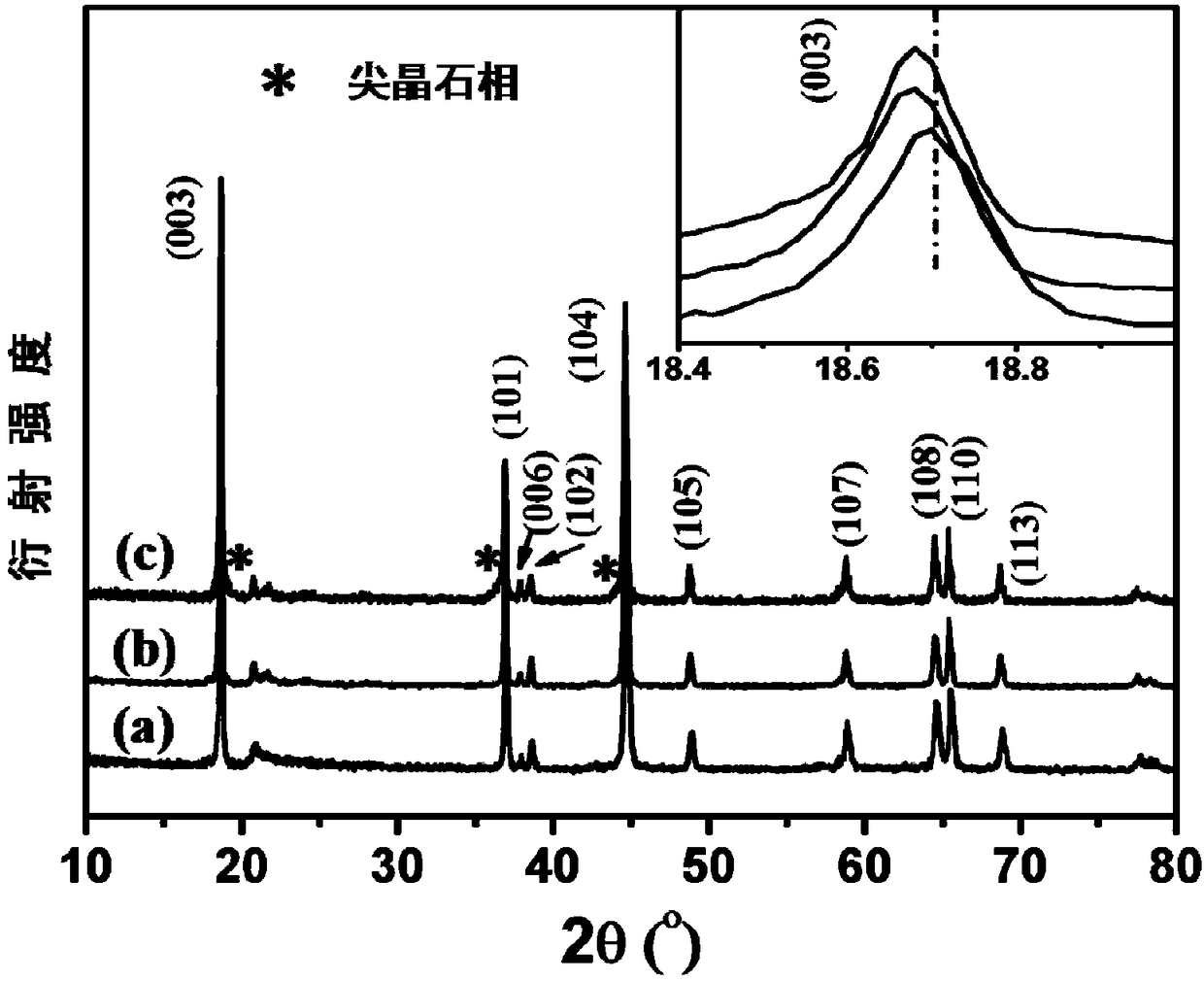

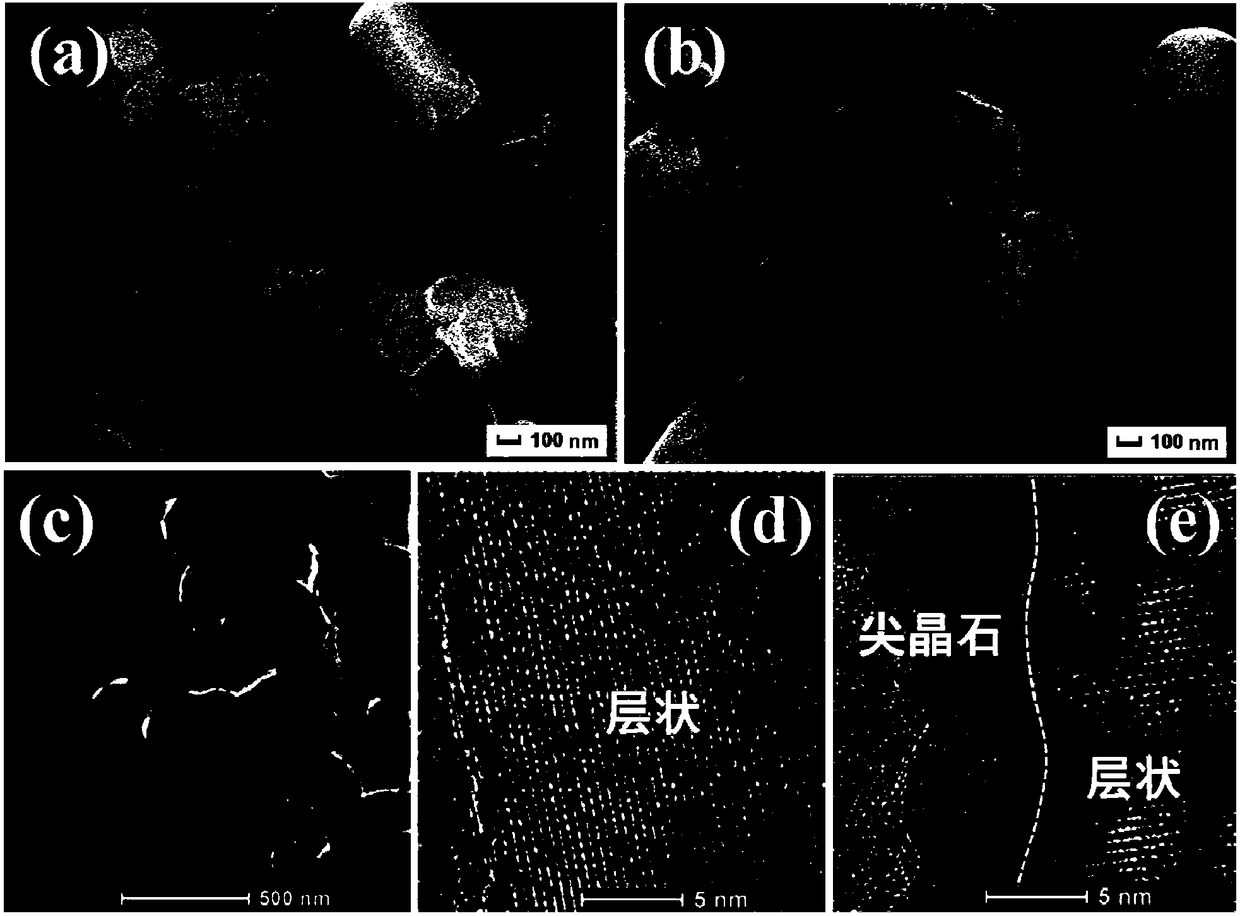

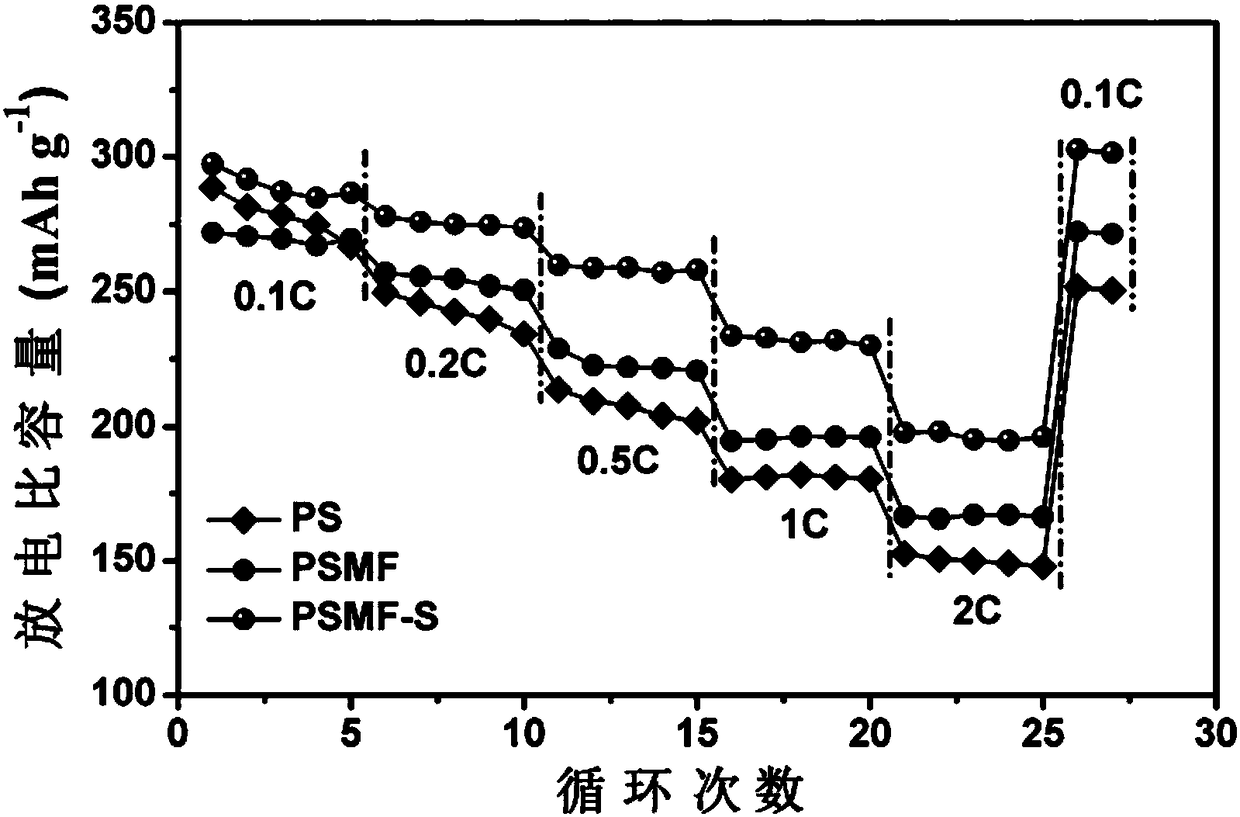

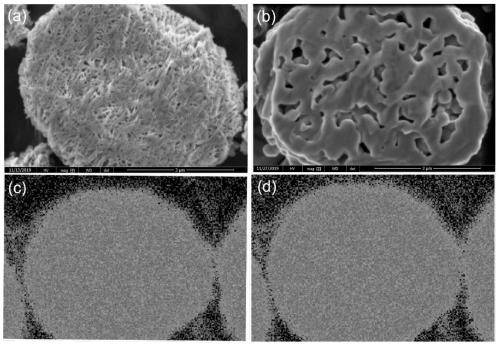

Lithium-rich positive electrode material co-doped by molybdenum and fluorine and coated by spinel in situ, and preparation method thereof

ActiveCN108336318AStable bulk structureImprove surface/interface physical and chemical propertiesCell electrodesLithium-ion batteryMaterials science

The invention discloses a lithium-rich positive electrode material co-doped by molybdenum and fluorine and coated by spinel in situ, and a preparation method thereof, belonging to the technical fieldof lithium ion battery materials. The lithium-rich positive electrode material comprises a molybdenum / fluorine co-doped lithium-rich material nuclear body and a spinel coating formed on the surface ofthe nuclear body in situ. The molybdenum / fluorine co-doped lithium-rich material nuclear body has the molecular formula of Li<1.2-delta>MnNi<b-lambda>Co<c>Mo<lambda>O<2-delta>F<delta>. The preparation method for the material comprises the following steps: firstly, preparing a molybdenum / fluorine co-doped lithium-rich material; then subjecting the molybdenum / fluorine co-doped lithium-rich material to surface treatment with reducing organic acid under certain conditions; and carrying out subsequent sintering to allow the spinel coating to be formed on the surface of the nuclear body in situso as to prepare the lithium-rich positive electrode material with excellent electrochemical properties. The preparation method provided by the invention is simple and easy to control, and can preparethe nano-scale high-performance lithium-rich positive electrode material with good consistency.

Owner:TIANNENG SAFT ENERGY JOINT CO

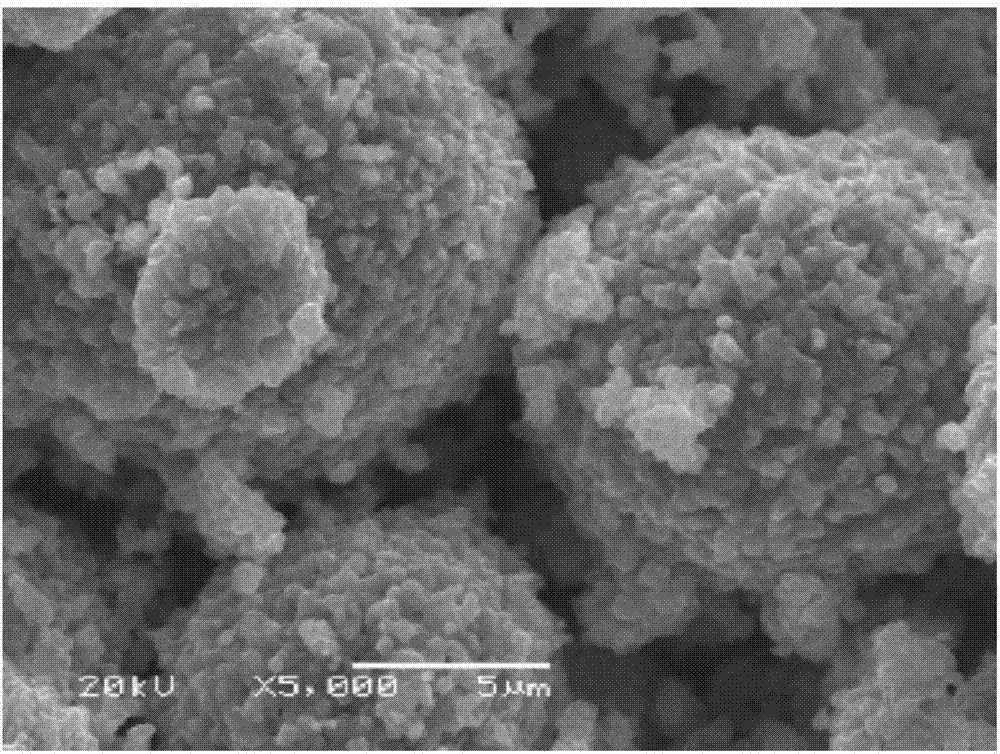

Cerium-zirconium co-doped porous structure positive electrode material and preparation method thereof

ActiveCN111276688AEvenly distributedLamellar structure is stableSecondary cellsPositive electrodesElectrical batteryPhysical chemistry

The invention provides a cerium-zirconium co-doped porous structure positive electrode material and a preparation method thereof. The method comprises the following steps: (1) preparing a ternary solution, a cerium-zirconium blended salt solution, a precipitant solution and a complexing agent solution for later use; (2) preparing a base solution and stirring; (3) injecting the ternary solution, the mixed solution of the cerium salt and the zirconium salt, the precipitant solution and the complexing agent solution into the base solution, carrying out reaction of the stage I and the stage II, and stopping feeding until the reaction reaches the target particle size; (4) centrifugally washing, drying, screening and deironing the reacted slurry to obtain a precursor; and (5) mixing the precursor with a lithium source, and sintering to obtain the positive electrode material. According to the preparation method, the blended cerium-zirconium salt solution is doped into the ternary solution byutilizing liquid-phase doping, so that doped elements are uniformly distributed, and the battery cycle performance of the material is improved by utilizing the synergistic effect of the doped elements; the positive electrode material with a pore structure, high purity and good performance is prepared through process control in different reaction stages.

Owner:JINGMEN GEM NEW MATERIAL +1

Method for improving electrochemical performance of high-nickel ternary positive electrode material by magnesium fluoride/sodium synergic modification

InactiveCN110048100AImprove lithium ion conductivityIncrease speedCell electrodesSecondary cellsLithiumAlcohol

The invention discloses a method for improving electrochemical performance of a high-nickel ternary positive electrode material by magnesium fluoride / sodium synergic modification. The method comprisesthe steps of (1) fully grinding a precursor, a lithium source and a sodium source to obtain a mixture, performing two-segment high-temperature calcination on the mixture in a tubular furnace under anoxygen atmosphere, and cooling with the furnace to a room temperature, thereby obtaining Li<0.9>Na<0.1>Ni<0.8>Co<0.1>Mn<0.1>O2; and (2) adding Li<0.9>Na<0.1>Ni<0.8>Co<0.1>Mn<0.1>O2 after magnesium nitrate and ammonium fluoride are mixed in absolute ethyl alcohol, performing stirring and drying, adding a few amount of absolute ethyl alcohol, performing heat preservation in the tubular furnace under an argon atmosphere for a certain time after grinding, thereby obtaining a MgF2 / Li<0.9>Na<0.1>Ni<0.8>Co<0.1>Mn<0.1>O2 composite material. The method is simple in process and low in cost, and the sodium ion-doped and magnesium fluoride-coated MgF2 / Li<0.9>Na<0.1>Ni<0.8>Co<0.1>Mn<0.1>O2 composite material having favorable electrochemical performance such as large rate performance and cycle propertyis prepared.

Owner:GUILIN UNIVERSITY OF TECHNOLOGY

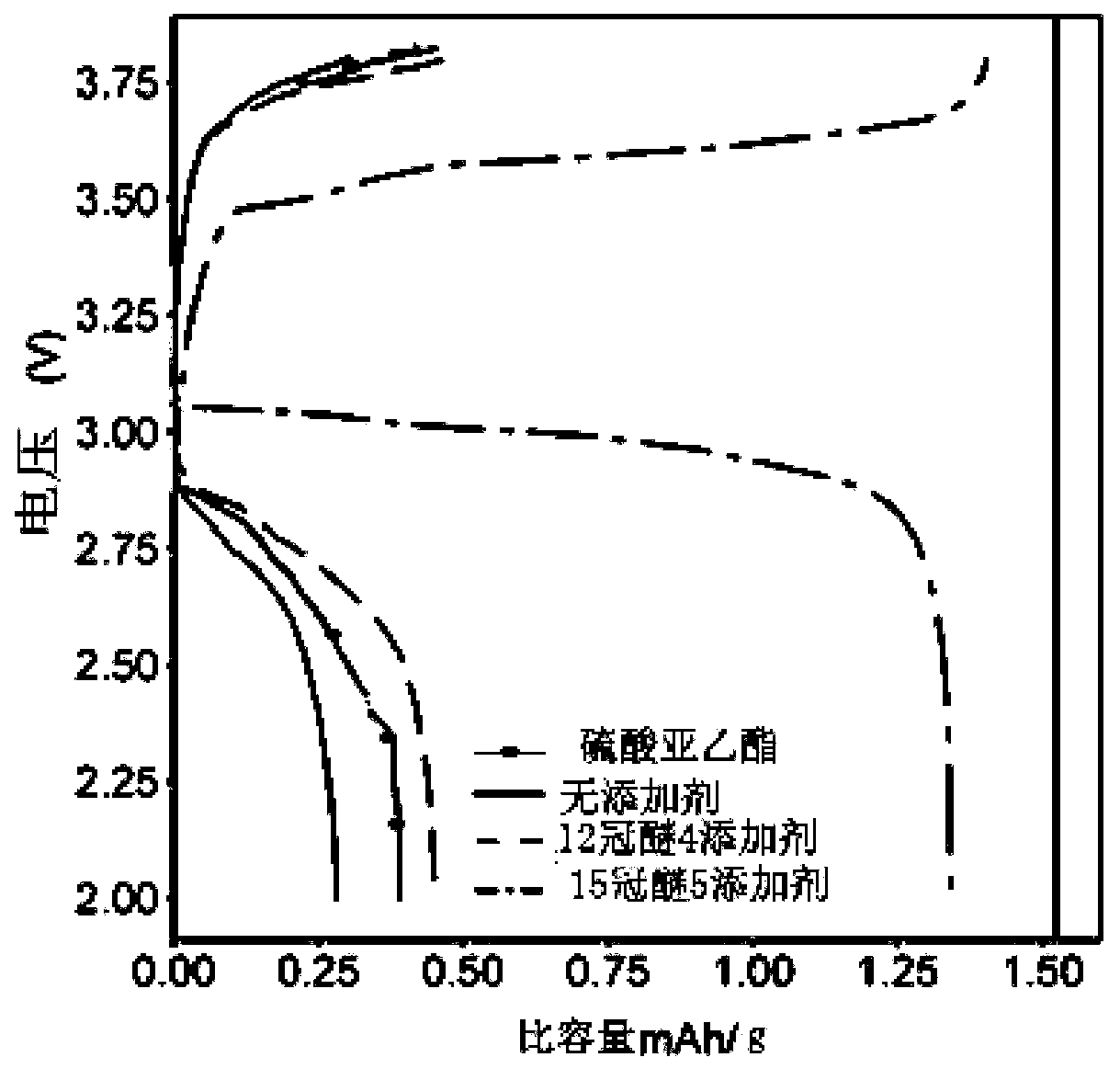

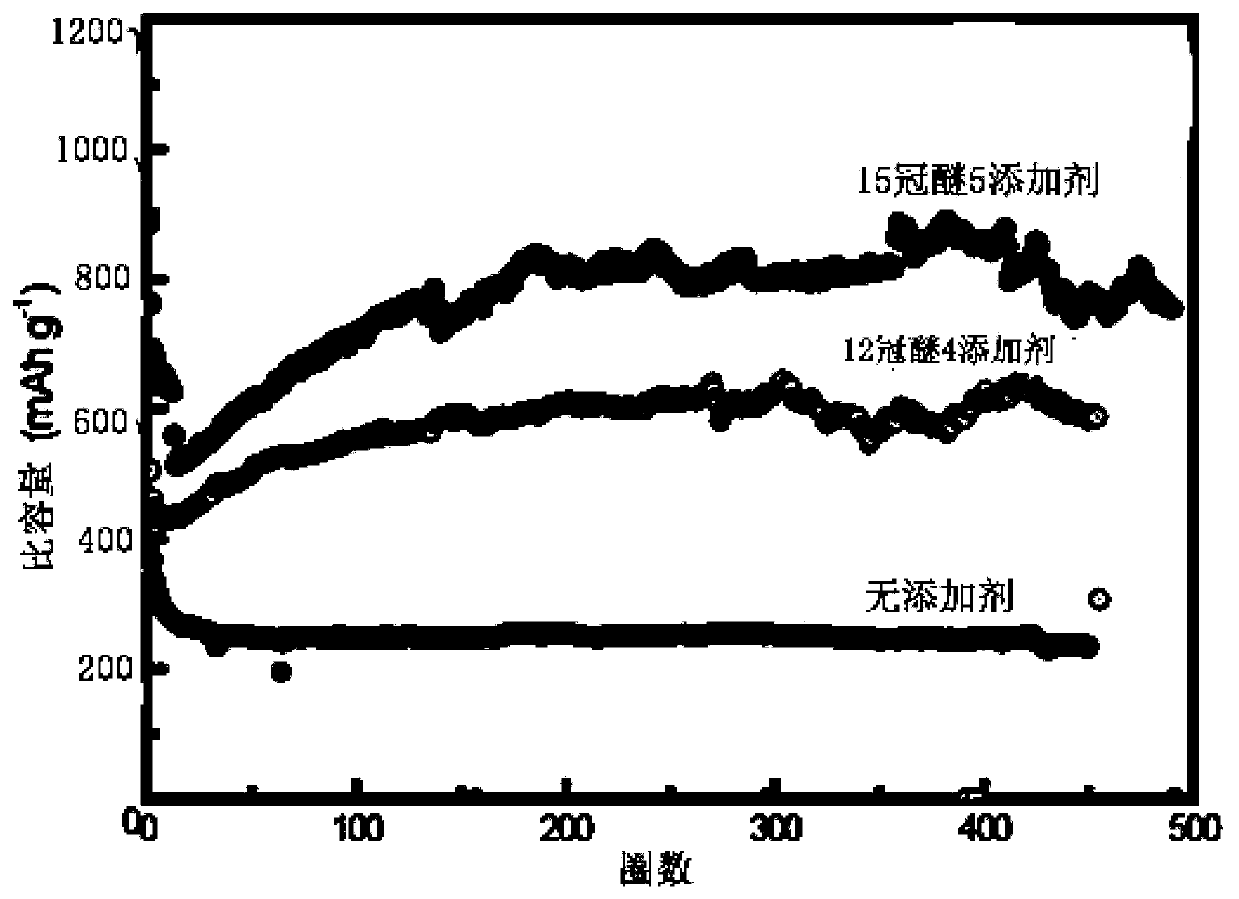

High-capacity imidazole ionic liquid as well as preparation method and application thereof

PendingCN111233772AEnhanced electrochemical windowImprove electrochemical stabilityOrganic chemistrySecondary cellsEtherLithium electrode

The invention relates to high-capacity imidazole ionic liquid as well as a preparation method and an application thereof. The structural formula of the ionic liquid is shown in the specification, in the formula, R1 is CH2(CH2)aO(CH2)bCH3, a is 0 or 1, and b is 0 or 1; R2 is CH2(CH2)cCOO(CH2)dCH3, c is 0 or 1, and d is 0 or 1; Y<-> is BF4<->, PF6<->, TFSI<->, FSI<-> or N(CN) 2<->. In the preparation of the imidazole ionic liquid, through ternary substitution, ether groups are introduced to the N-1 site of an imidazole ring, so that the viscosity of the ionic liquid is reduced; an ester group isintroduced to the N-3 site of the imidazole ring, so that the electrochemical window and the electrochemical stability of the ionic liquid are improved. The imidazole ionic liquid is used as an electrolyte additive, is applied to a lithium ion battery taking a ternary material (NCM523) as a positive electrode material, and has good safety performance and electrochemical performance.

Owner:HEBEI UNIV OF TECH

Single-crystal ternary cathode material containing microelements

InactiveCN110699744AImprove conductivityIncrease discharge voltagePolycrystalline material growthFrom solid stateMetallurgyElectrical battery

The invention belongs to the field of lithium ion battery materials, and provides a single-crystal ternary cathode material containing microelements and a preparation method thereof. A general formulaof the cathode material is LiNixCoyMn1-x-y(M+N)zO2, wherein 0.3 <=x<=0.75, 0.15<=y<=0.3, 0<=z<=0.1, and the M and N elements are respectively at least one selected from the group consisting of Mg, Ti, Al, Zr, La, Y, W, Mn and Ba, and the average particle size of the single-crystal ternary cathode material is 3.0-8.0 [mu]m. According to the cathode material, through compound doping and coating ofone or more of microelement compounds, lithium-nickel disordering of a ternary cathode can be effectively reduced, so that the cycle performance, discharge voltage and rate performance of the materialcan be further improved, and the advantages of high charging voltage and a high compaction density of the single-crystal ternary material are maintained.

Owner:LONG POWER SYST SUZHOU

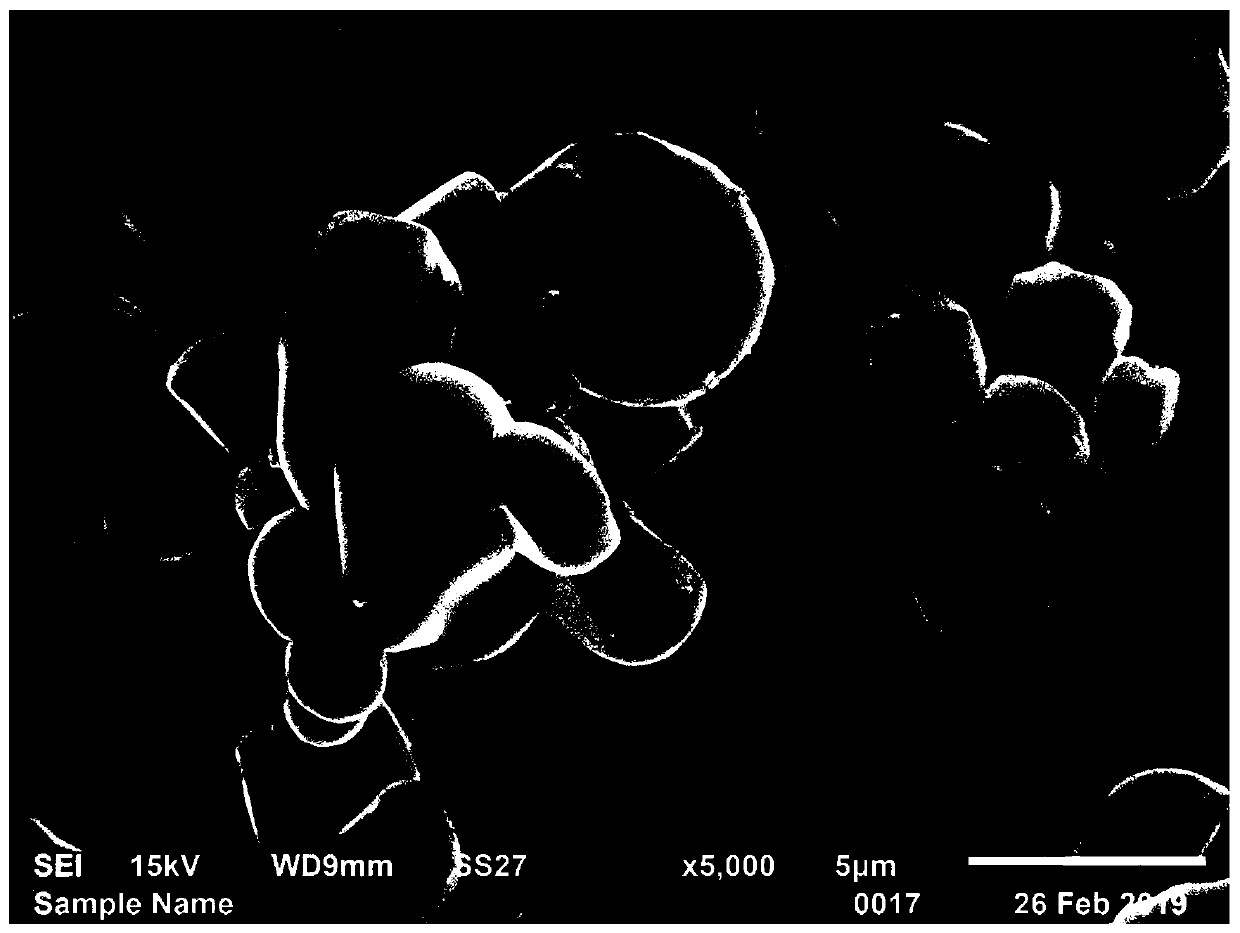

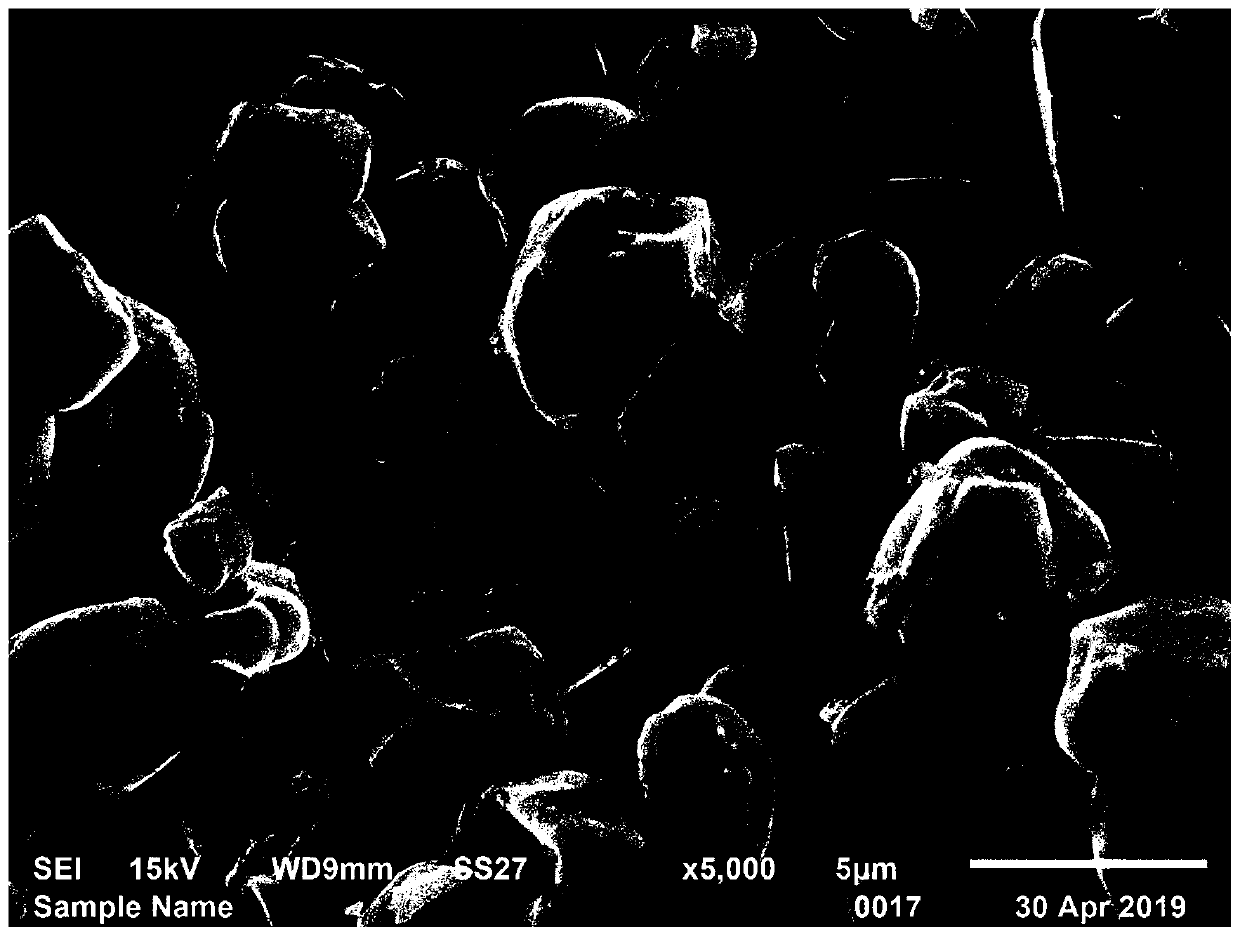

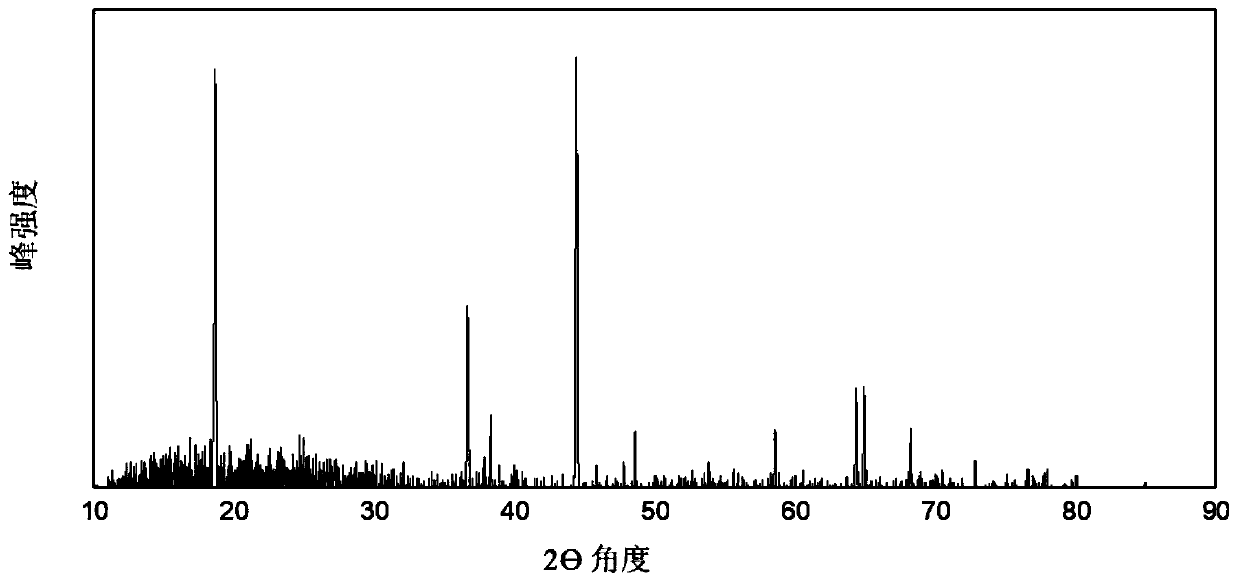

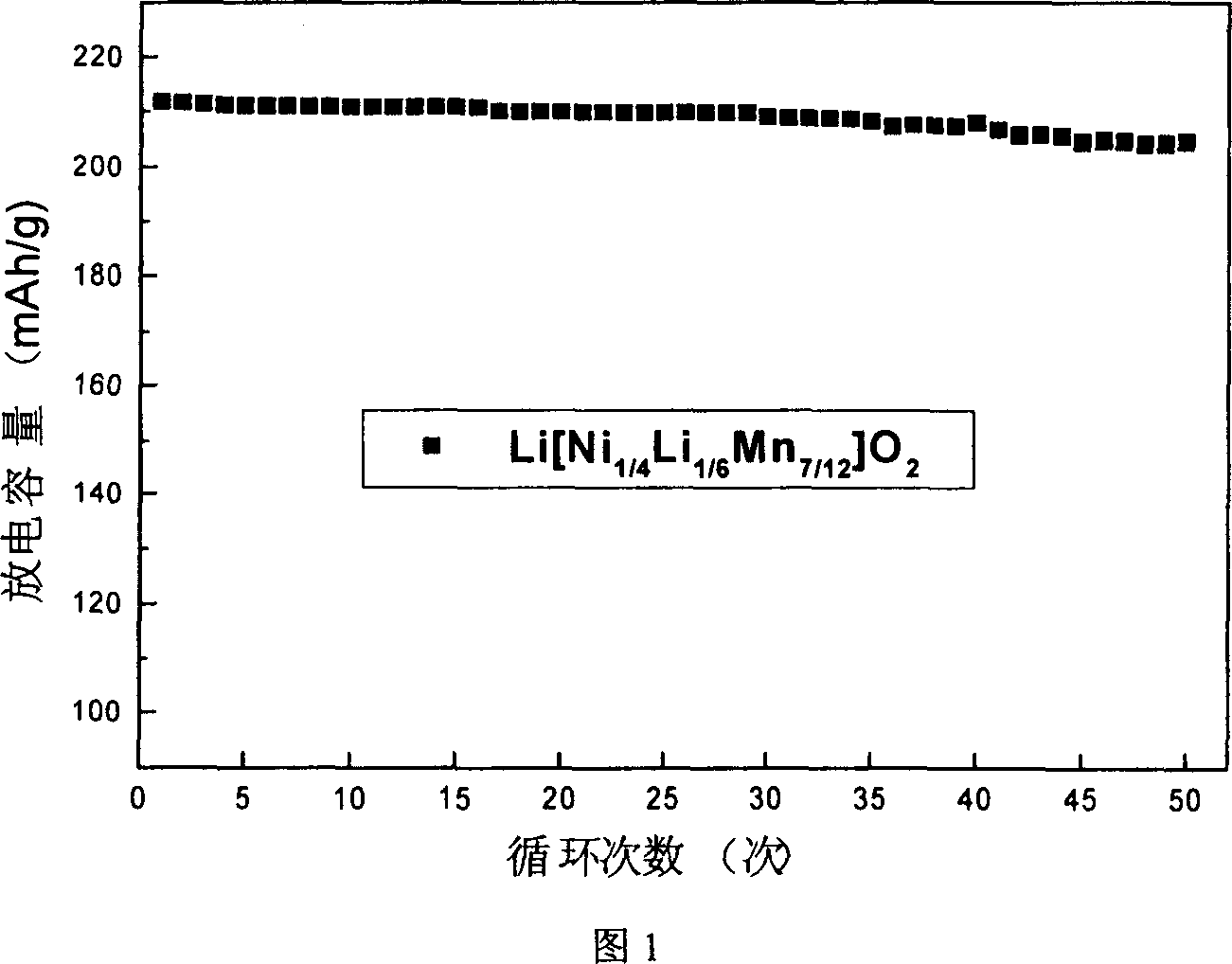

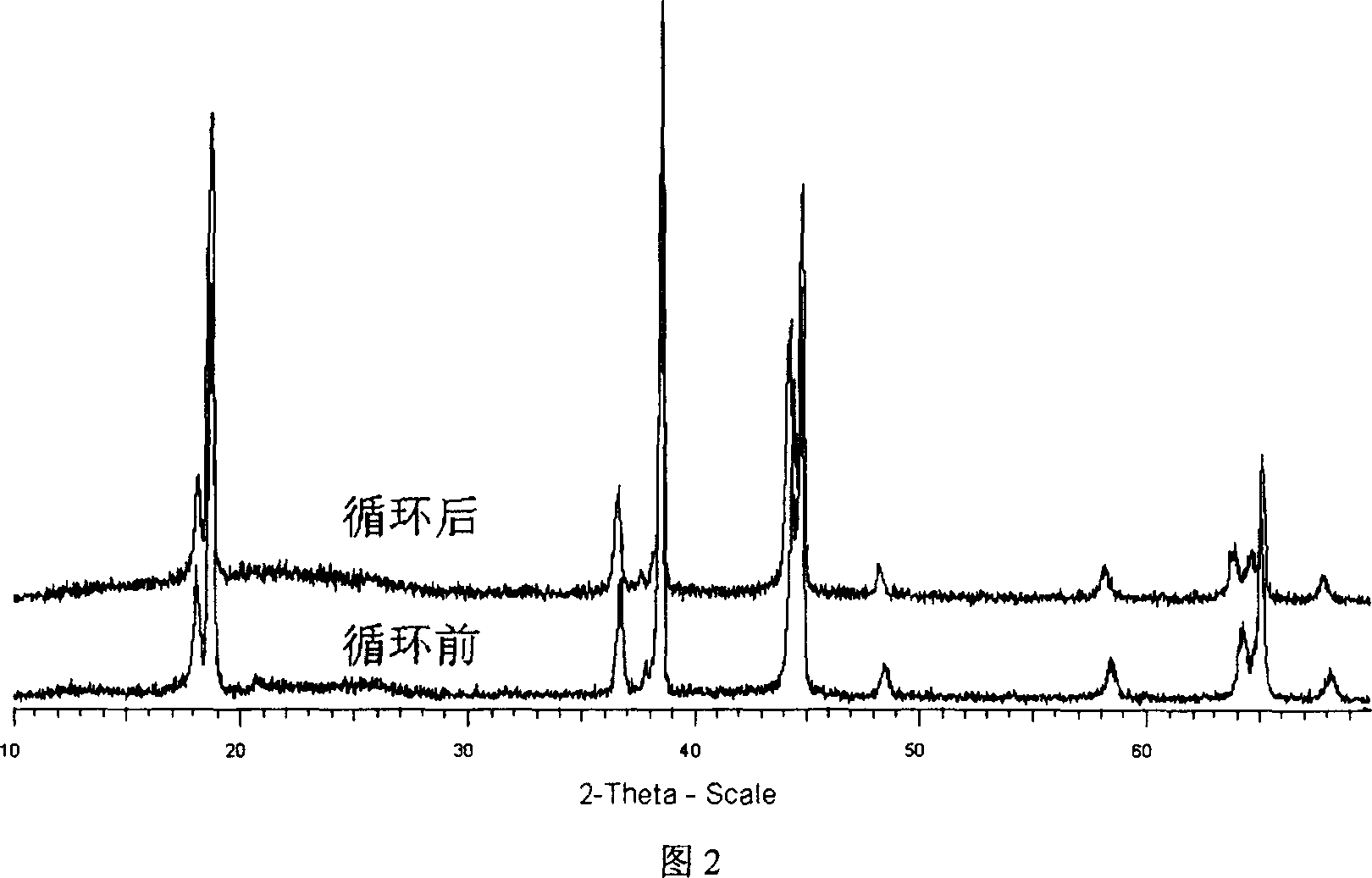

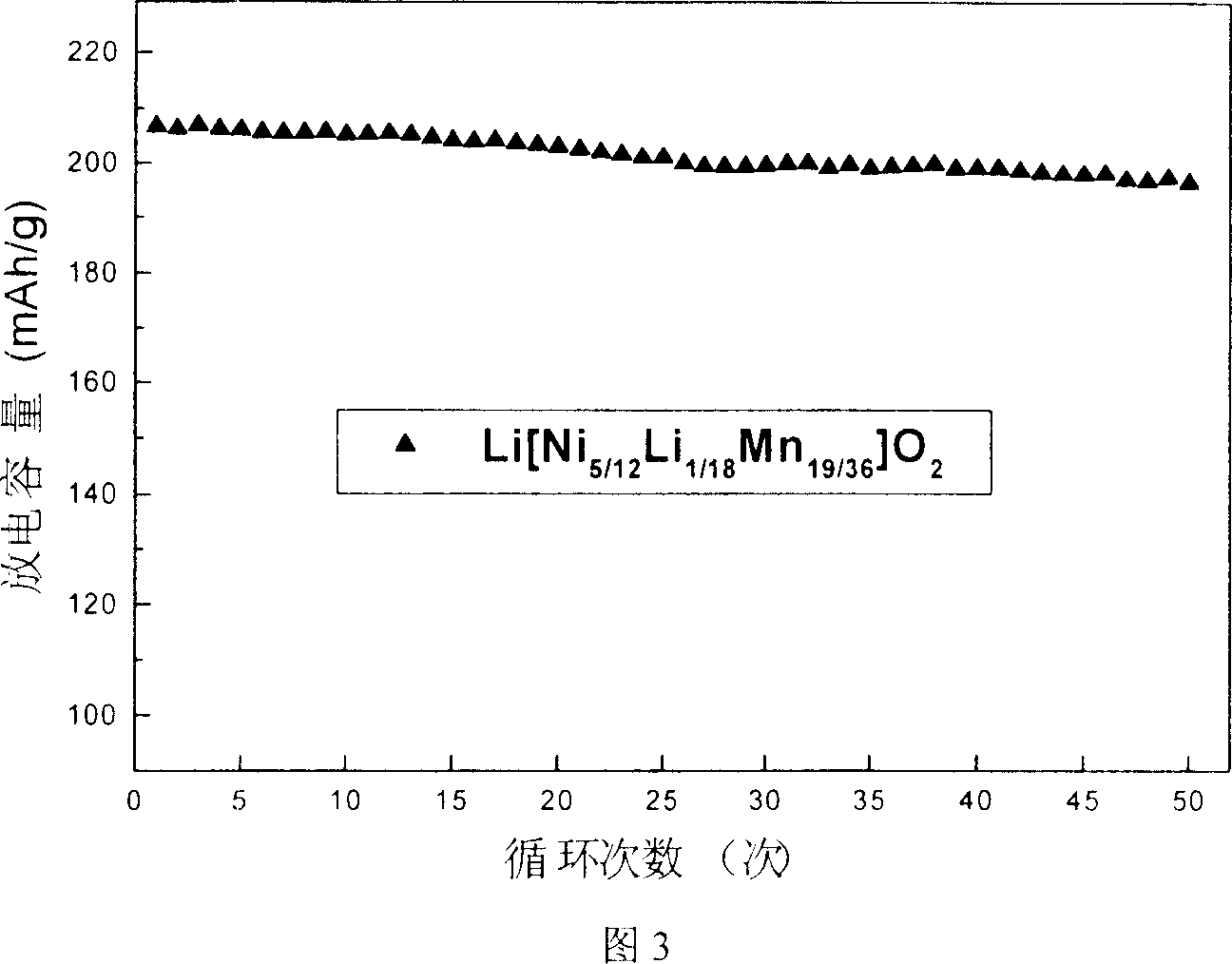

Stable laminated structure positive electrode material of lithium ion battery and its preparing method

InactiveCN1945877ALamellar structure is stableReduce loss rateElectrode manufacturing processesLithium compoundsAir atmosphereManganese

This invention relates to a positive material of a stable sandwich used in Li ionic cells and its preparation method, in which, the formula of said material is Li[N1Xli1 / 3-2X / 3Mn2 / 3-X / 3]O2, and 0<X<1 / 2, which takes nitrate or sulfate of Ni and Mn as the raw material, carbonate as the precipitator to prepare co-precipitator with the pH value in the sphere of 8-11, the precursor-the co-precipitation product is pre-processed under 300-700deg.C and the powder mixed with Li salt is sintered under the normal air atmosphere and cooled in the oven.

Owner:UNIV OF SCI & TECH BEIJING

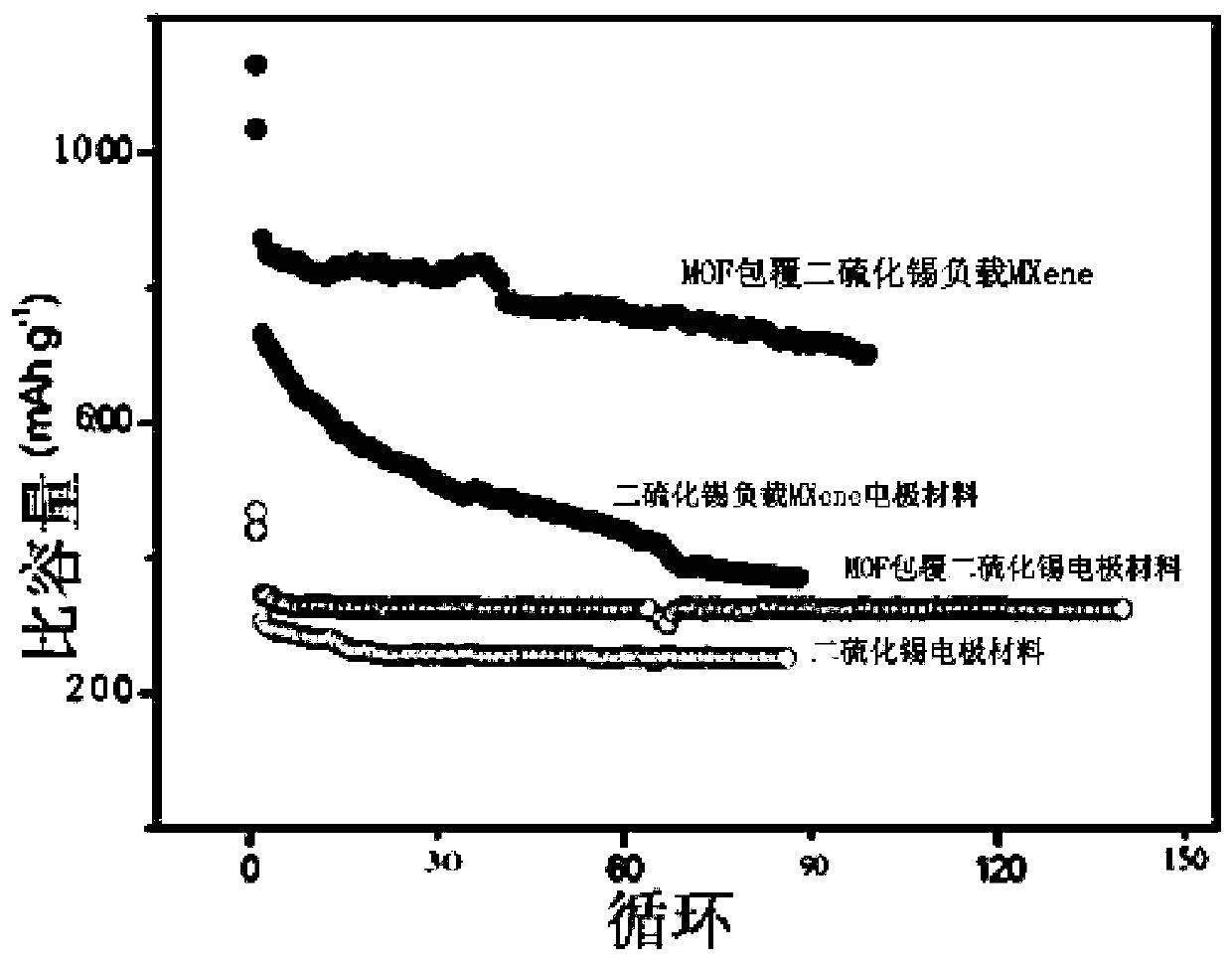

Lithium ion battery and preparation method thereof

ActiveCN111384387AEasy to controlGood synergyFinal product manufactureNegative electrodesPhysical chemistryBattery cell

The invention relates to a lithium ion battery and a preparation method thereof. The lithium ion battery negative electrode active material is an MOF-coated tin disulfide-loaded Mxene composite material, wherein MOF is a metal carbon framework, and Mxene is a material with a two-dimensional layered structure; the MOF and tin disulfide loaded Mxene are compounded to form a double-carbon framework material, and a more stable lithium ion de-intercalation carrier is formed; the MOF is used as a shell frame to provide a lithium ion transmission channel and provide a skeleton supporting effect, tindisulfide is prevented from volume collapse and pulverization in the charging and discharging process, the layered structure has more excellent stability, tin disulfide loading is facilitated, the Li+de-intercalation number is increased, and the specific capacity of tin disulfide can be greatly improved.

Owner:HANGZHOU DEBIAO NEW ENERGY TECH CO LTD

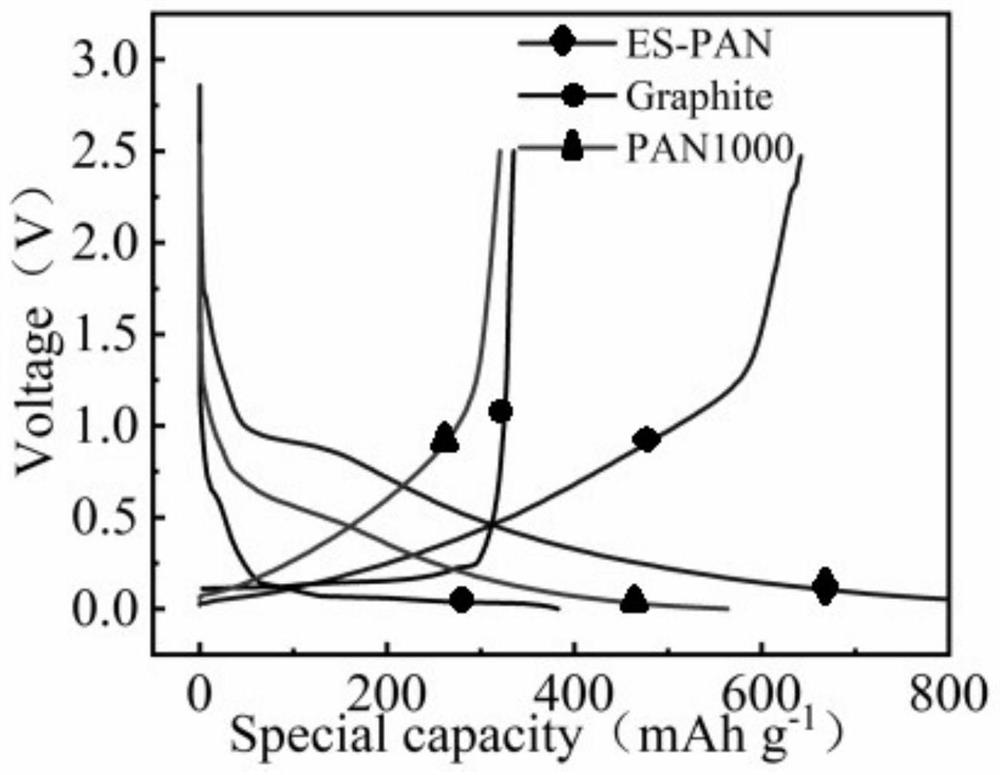

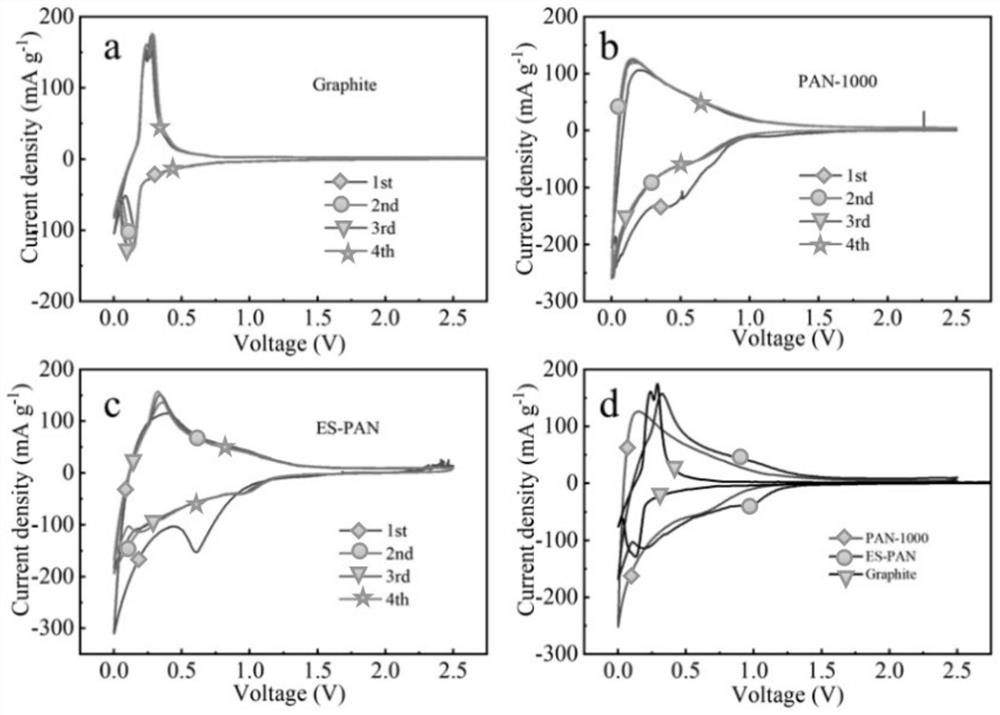

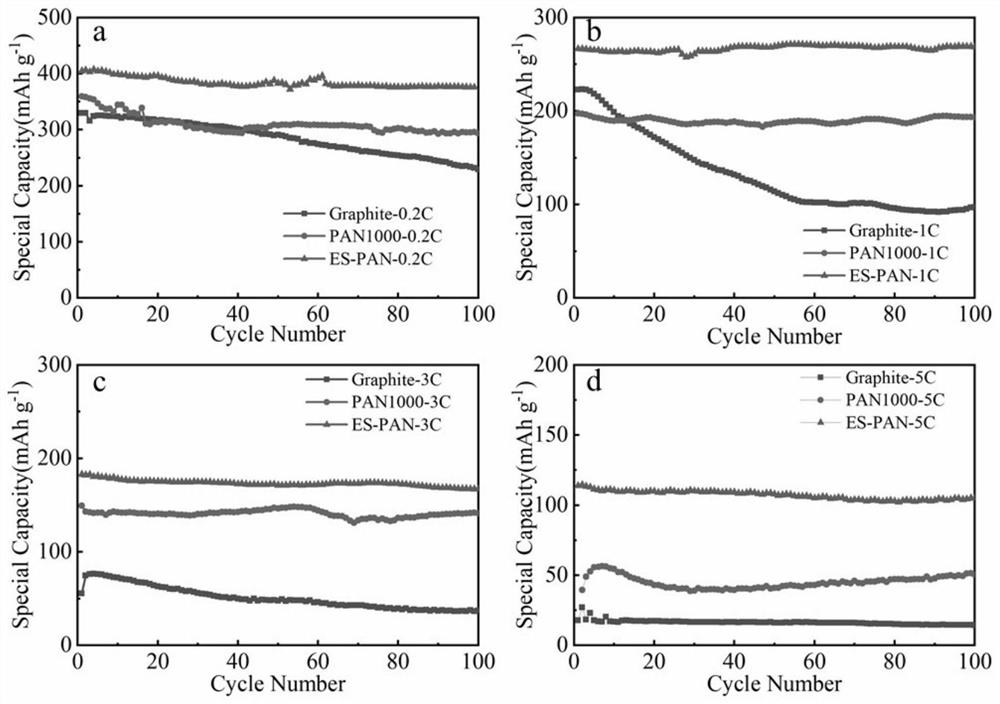

High-performance lithium ion battery polyacrylonitrile carbon fiber negative electrode material and preparation method thereof

InactiveCN113224292AGuaranteed cycle stabilityImprove charge and discharge performanceMaterial nanotechnologyCell electrodesPolymer scienceCarbon fibers

The invention discloses a preparation method of a high-performance lithium ion battery polyacrylonitrile carbon fiber negative electrode material. The preparation method comprises the following steps of: dissolving polyacrylonitrile in a DMF solvent, and fully stirring to obtain a spinning solution; spinning the spinning solution to obtain stable nanofiber filaments, and continuously spinning to obtain polyacrylonitrile protofilaments; placing the polyacrylonitrile protofilaments in a porcelain boat, performing heating and pre-oxidizingin a tubular furnace under an oxygen atmosphere, and cooling to room temperature to obtain pre-oxidized fibers; carbonizing the pre-oxidized fibers in the tubular furnace in a nitrogen atmosphere, and naturally cooling the carbonized pre-oxidized fibers to room temperature to obtain polyacrylonitrile carbon fibers; fully grinding the carbonized polyacrylonitrile carbon fibers in an agate mortar, and drying an obtained substance to obtain the superfine electrostatically-spun polyacrylonitrile carbon fiber material. The lithium ion battery polyacrylonitrile carbon fiber negative electrode material has the advantages of high performance, high capacity, high cycling stability, high charging specific capacity and long cycle life.

Owner:JIANGXI UNIV OF SCI & TECH

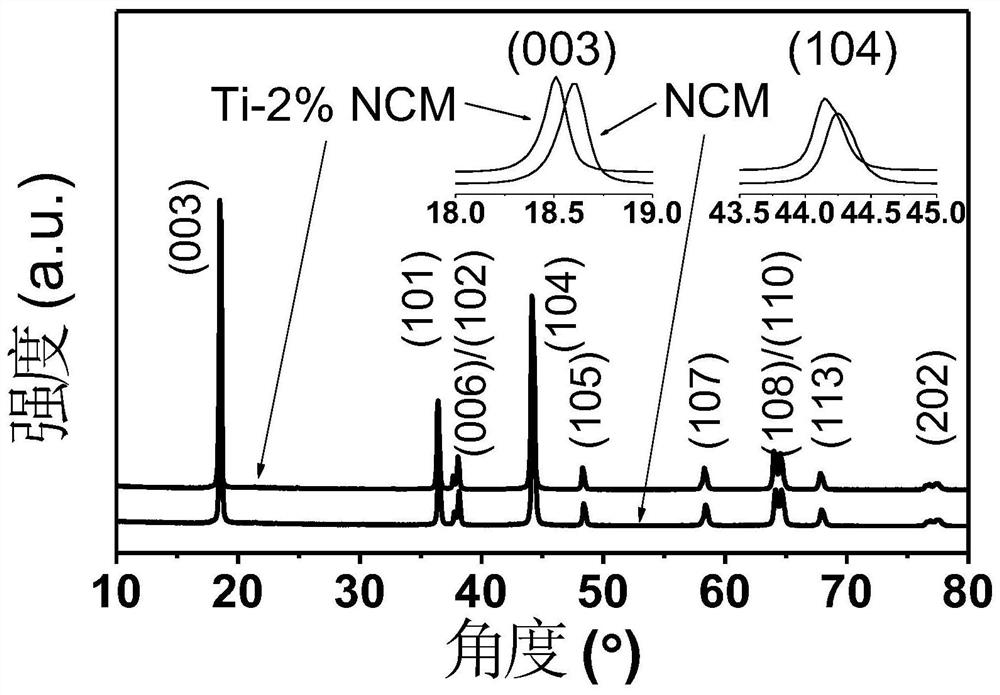

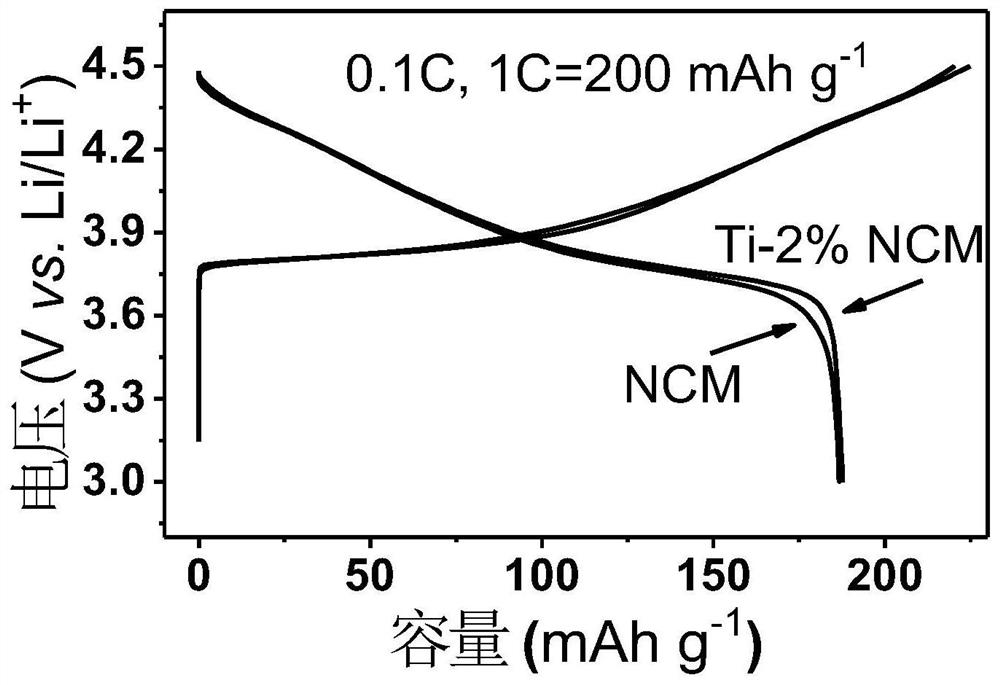

Cation-doped and modified ternary positive electrode material for lithium ion battery and preparation method of positive ion doped and modified ternary positive electrode material

InactiveCN113410458AExcellent rate performanceImprove cycle stabilitySecondary cellsPositive electrodesElectrical batteryPhysical chemistry

The invention discloses a cation-doped and modified ternary positive electrode material for a lithium ion battery and a preparation method of the ternary positive electrode material, and relates to the technical field of positive electrode materials for lithium ion batteries. The cation-doped and modified ternary positive electrode material is obtained by uniformly mixing nanoscale metal oxide particles with a ternary material precursor and lithium salt and then roasting at high temperature. The invention also discloses a preparation method of the cation-doped and modified ternary positive electrode material for the lithium ion battery, which comprises the following steps: stirring and mixing the nano-scale metal oxide and the ternary positive electrode material precursor in a solvent to obtain a precursor material uniformly coated with the nano-scale metal oxide; and drying, uniformly mixing with a lithium salt, and roasting to obtain the modified ternary positive electrode material with uniformly doped cations. The ternary positive electrode material obtained by the method shows more excellent cycling stability and rate capability than those of an undoped modified material under the high voltage of 4.5 V, plays an important role in inhibiting cation mixing, collapse of a layered structure and lattice oxygen release, and can greatly improve the electrochemical performance of the material.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

W compound-coated lithium ion secondary battery positive electrode material and preparation method thereof

InactiveCN110137487AWell mixedEasy to controlCell electrodesSecondary cellsLithiumPhysical chemistry

The invention relates to a W compound-coated lithium ion secondary battery positive electrode material and a preparation method thereof. The W compound-coated lithium ion secondary battery positive electrode material comprises a positive electrode material and a W compound coated on the positive electrode material. The positive electrode material is composed of primary particles or secondary particles formed by aggregation of the primary particles or the mixed particles of the primary particles and the secondary particles. The preparation method comprises the following steps: (1) sintering (2)surface treatment (3) drying and sieving treatment. The binary precursor A2 is obtained by continuous co-precipitation reaction, the elements are mixed uniformly, the reaction is sufficient, the control of morphology is facilitated, continuous production is performed, the production efficiency is improved and the particle size is more consistent. The structure of the binary high nickel material is stabilized by doping appropriate elements, the alkali content is controlled by water washing and coating of the W compound is realized in the process of water washing so that the electrochemical performance of the battery can be enhanced and the safety and the high temperature performance of the battery material can be enhanced.

Owner:LONG POWER SYST NANTONG CO LTD

Preparation method of cathode material Li2Mn1-x-yCoxNiySiO4 for lithium ion battery

The invention relates to a preparation method of a cathode material Li2Mn1-x-yCoxNiySiO4 for a lithium ion battery. The method comprises the steps of mixing a lithium salt, a manganese salt, a cobalt salt, a nickel salt and tetraethyl orthosilicate in a homogeneous medium; adding a catalyst; stirring; transferring the mixture into a polytetrafluoroethylene jar; reacting to obtain a wet gel; drying the wet gel to obtain a xerogel; grinding the xerogel to obtain a reaction precursor; and calcining the reaction precursor to obtain the cathode material Li2Mn1-x-yCoxNiySiO4 for the lithium ion battery. The method has the advantages of simple preparation process, low cost, good dispersibility of the obtained material, etc. The cathode material Li2Mn1-x-yCoxNiySiO4 for the lithium ion battery becomes a novel generation cathode material for the lithium-ion battery having great developmental potential, because the material has the advantages of high theoretical capacity, outstanding safety performance, stable crystal framework structure, flexible and controllable charging and discharging voltage platform, and the like. At the same time, Co<2+> can stabilize a layered structure; Ni<2+> can increase the capacity of the material; and Mn<2+> can not only reduce the cost of the material but also improve security and stability.

Owner:SHANGHAI NAT ENG RES CENT FORNANOTECH

Stable lithium ion battery with high capacitance

InactiveCN103606666AImprove high-magnification performanceImprove power densityCell electrodesSecondary cellsCapacitanceLithium electrode

The invention discloses a stable lithium ion battery with high capacitance. Two poles are respectively prepared from a composite carbon cathode material and a ternary composite anode material. By adopting the stable lithium ion battery, the high magnification performance and the power density of the lithium ion battery can be effectively improved. The stable lithium ion battery has high-magnification charge and discharge properties. Three transition metals such as nickel, manganese and cobalt are evenly mixed, so that a layered structure of the material is stabilized by synergistic effects of the nickel, manganese and cobalt, and the charge and discharge capacities, the cycle performance and the overcharging tolerance of the material are improved.

Owner:JIANGSU TENPOWER LITHIUM

Doped lithium ion battery high-voltage NCA positive electrode material and preparation method thereof

InactiveCN110790321AImprove thermal stabilityImprove cycle lifeSecondary cellsPositive electrodesDopantElectrical battery

The invention discloses a doped lithium ion battery high-voltage NCA positive electrode material and a preparation method thereof, and belongs to the field of lithium ion batteries. The preparation method comprises the following steps: simultaneously doping trivalent element aluminum and divalent element cobalt to replace element nickel in a positive electrode material to obtain an NCA precursor,adding a dopant M into the precursor, and sintering in a high-pressure oxygen atmosphere to obtain the lithium ion battery positive electrode material. The positive electrode material disclosed by theinvention has very high specific discharge capacity and excellent cycle stability, can meet the high-rate charge and discharge requirements, and can be safely cycled for a long time under high voltage; the positive electrode material is prepared by combining four solution parallel-flow coprecipitation with a high-pressure solid-phase synthesis method, and the prepared product is high in purity, high in crystallization quality, high in product particle density, uniform in distribution, excellent in electrochemical performance and low in manufacturing cost, is an ideal positive electrode material with high energy density and has a wide application prospect.

Owner:SICHUAN FUHUA NEW ENERGY HIGH TECH CO LTD

Special halogen-free flame-retardant synergistic functional masterbatch for polyolefin resin modification and preparation method thereof

The invention relates to the technical field of plastic modification processing, in particular to special halogen-free flame-retardant synergistic functional masterbatch for polyolefin resin modification and a preparation method thereof. According to the functional masterbatch, multiple composite coated ammonium polyphosphate is used as a phosphorus-based flame retardant; the functional masterbatch is prepared from the following components in percentage by mass: 55.0-65.0 wt.% of the multiple composite coated ammonium polyphosphate, 25.0-35.0 wt.% of a nitrogen flame retardant, 7.0-11.0 wt.% of carrier resin, 0.5-1.0 wt.% of styrene-acrylonitrile copolymer coated polytetrafluoroethylene, 0.5-1.0 wt.% of a dispersing agent and 0.3-0.5 wt.% of a lubricating agent. Compared with the traditional flame-retardant functional masterbatch, the functional masterbatch prepared by the invention has the advantages that the thermal stability of ammonium polyphosphate is remarkably improved, and thewater resistance of the ammonium polyphosphate is enhanced, so that the flame-retardant effect of the ammonium polyphosphate on polyolefin resin is more effectively improved.

Owner:江苏万纳普新材料科技有限公司

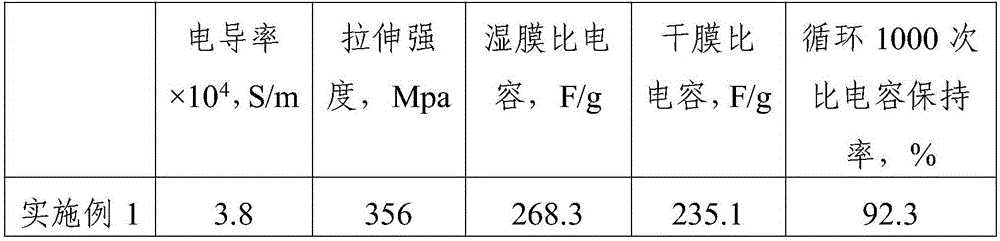

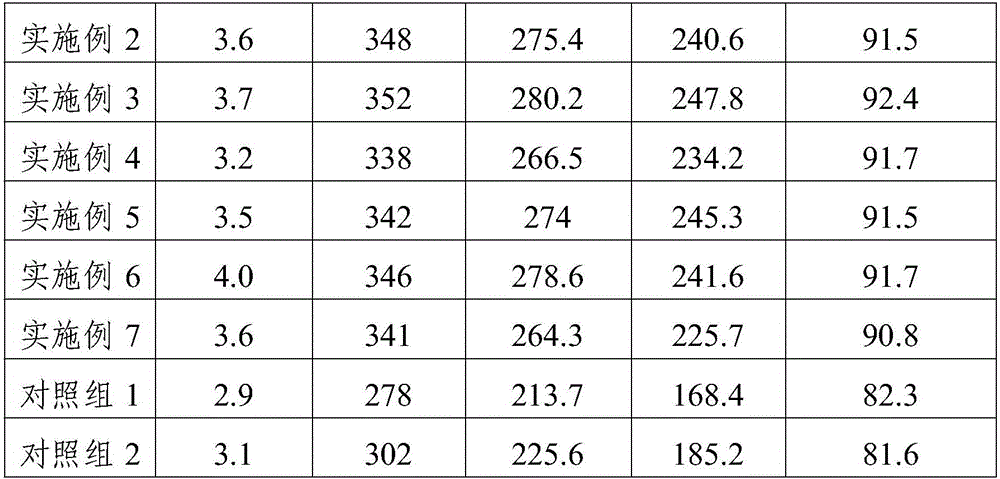

Preparation method and application of nitrogen-doped graphene oxide film

ActiveCN106335899ALamellar structure is stableHigh mechanical strengthElectrode carriers/collectorsGraphenePolyvinyl alcoholNitrogen doped graphene

The invention provides a preparation method and application of a nitrogen-doped graphene oxide film. The preparation method comprises the steps of preparation of a graphene oxide film, treatment of the graphene oxide film, nitrogen doping of the graphene oxide film and the like, and particularly comprises the steps: vacuum-filtering a graphene oxide suspension, soaking the filter cake in a mixed solution of a cross-linking agent, polyvinyl alcohol and polyaniline, carrying out drying treatment to obtain the graphene oxide film, and then mixing the graphene oxide film with a nitrogen source, to obtain a nitrogen-doped graphene oxide film precursor; and then carrying out heating, drying, heat treatment and other steps to obtain the nitrogen-doped graphene oxide film. The prepared nitrogen-doped graphene oxide film has the advantages of good stability, high electric conductivity, and strong mechanical properties; a supercapacitor with the nitrogen-doped graphene oxide film as a current collector has the advantages of large energy storage capacity and long service life.

Owner:ANHUI NINGGUO TIANCHENG ELECTRICAL APPLIANCES

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com