High-nickel ternary material with cobalt-rich surface layer and preparation method and application thereof

A high-nickel ternary material and surface layer technology, applied to electrical components, electrochemical generators, battery electrodes, etc., can solve problems such as poor cycle performance, unstable structure, short process, etc., to improve cycle performance and reduce grain size. The effect of cell volume change and short process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

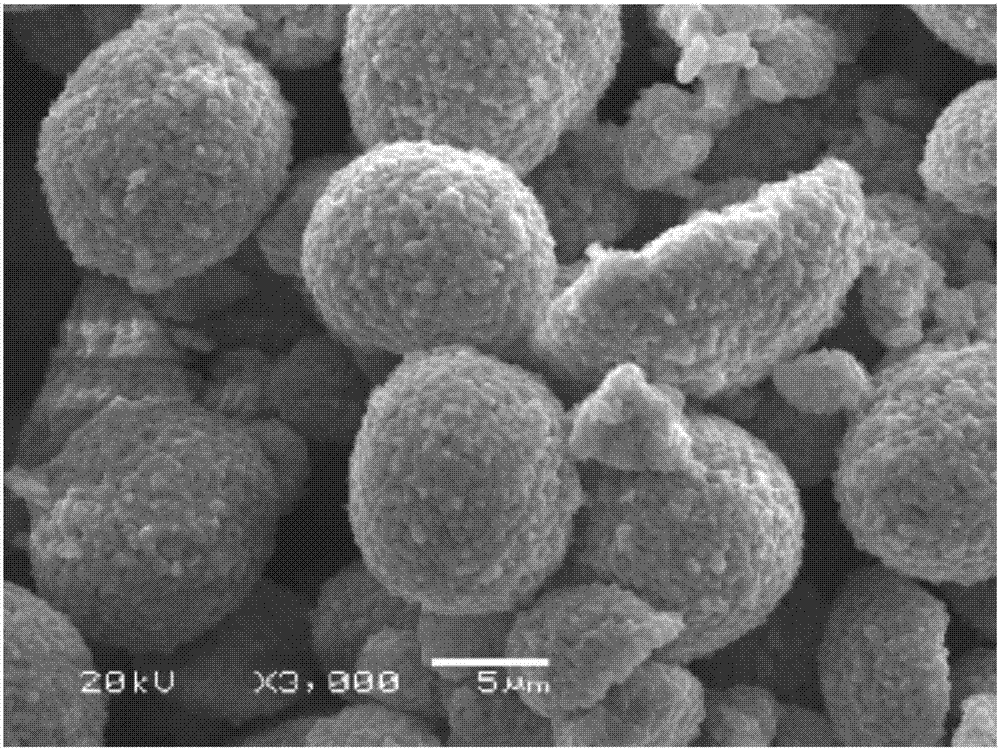

[0033] The high-nickel ternary material with cobalt-rich surface layer described in this embodiment is prepared by the following method:

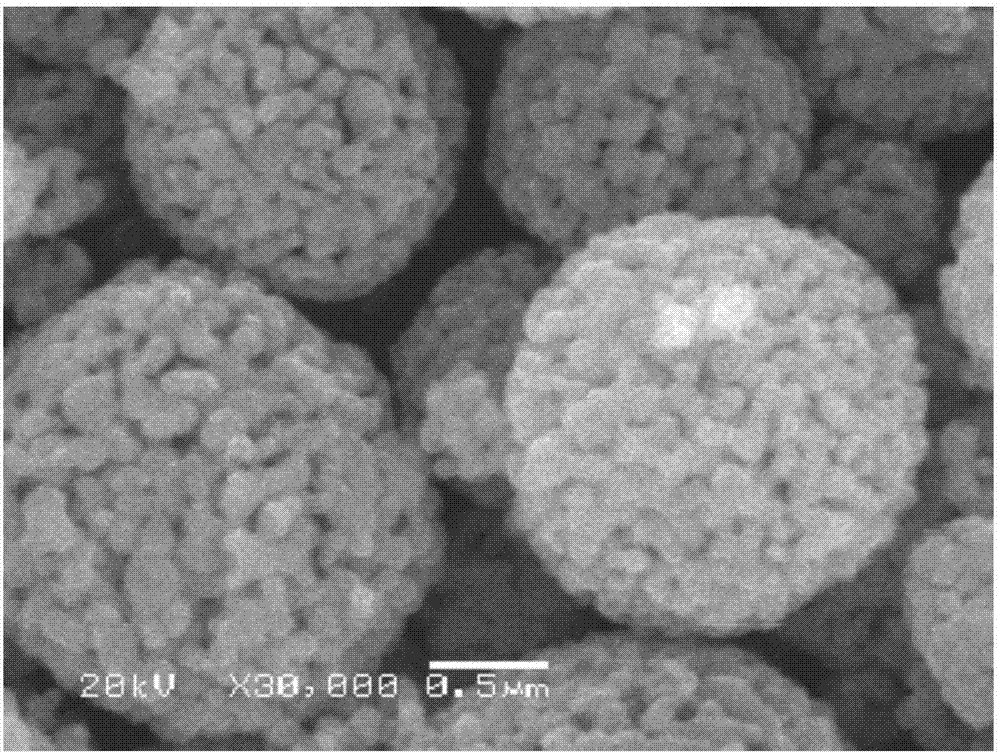

[0034] (1) Prepare a cobalt chloride solution with a concentration of 0.5mol / L, add it to the sprayer equipment, and perform spray pyrolysis at 750°C to obtain spherical Co 3 o 4 , wherein the carrier gas in the spray pyrolysis process is oxygen, the oxygen flow rate is 1L / min, and the sprayed solution flow rate is 1.5mL min;

[0035] (2) the porous spherical Co obtained in step (1) 3 o 4 With LiOH and high nickel ternary hydroxide precursor Ni 0.8 co 0.1 mn 0.1 (OH) 2 Mix well in the mortar, Ni 0.8 co 0.1 mn 0.1 (OH) 2 , porous spherical Co 3 o 4 The molar ratio of LiOH and LiOH is 100:5:110;

[0036] (3) Raise the temperature of the mixed material obtained in step (2) at a rate of 5°C / min, pre-sinter at 500°C for 6 hours, and then sinter at a high temperature of 780°C for 15 hours to obtain the cobalt-rich surface layer and h...

Embodiment 2

[0041] The cobalt-rich surface layer and high-nickel ternary material described in this example is prepared by the following method:

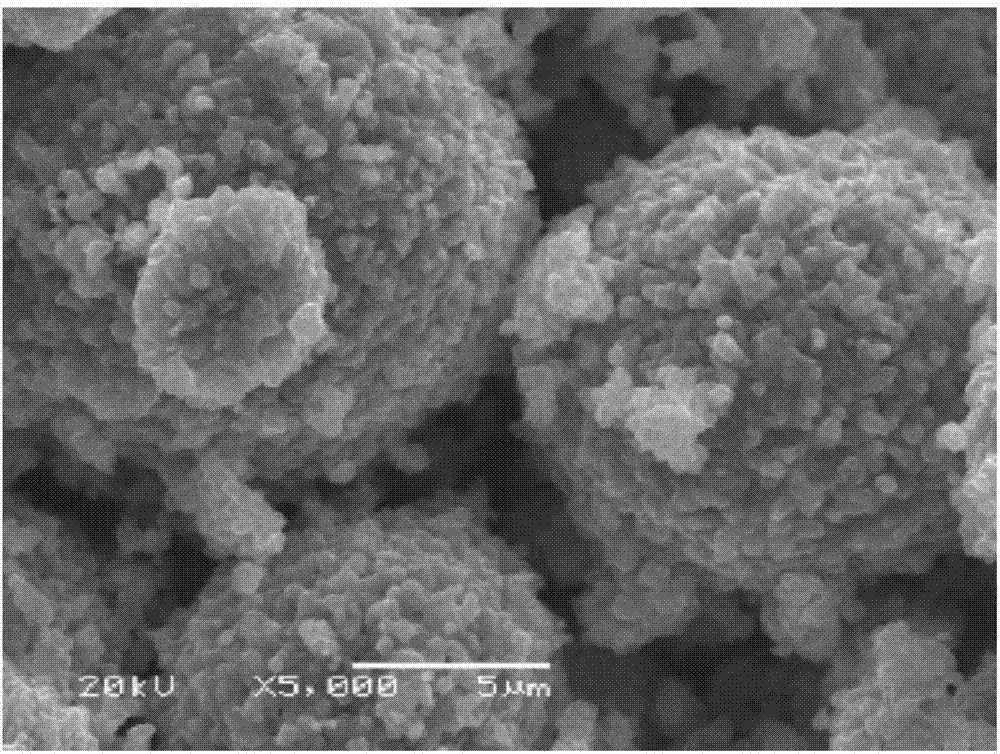

[0042] (1) Prepare a cobalt chloride solution with a concentration of 0.5mol / L, add it to the sprayer equipment, and spray and pyrolyze it at 750°C to obtain Co 3 o 4 , wherein the carrier gas in the spray pyrolysis process is oxygen, the oxygen flow rate is 2L / min, and the sprayed solution flow rate is 1.2mL / min;

[0043] (2) Co obtained in step (1) 3 o 4 With LiOH and high nickel ternary hydroxide precursor Ni 0.8 co 0.1 mn 0.1 (OH) 2 Mix well in the mortar, Ni 0.8 co 0.1 mn 0.1 o x , spherical Co 3 o 4 The molar ratio of LiOH and LiOH is 100:10:115;

[0044] (3) Raise the temperature of the mixed material obtained in step (2) at a rate of 8°C / min, pre-sinter at 450°C for 6 hours, and sinter at 800°C for 12 hours to obtain the cobalt-rich surface layer and high-nickel ternary material described in this example . According to IC...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com