Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

202results about How to "Inhibition of phase transition" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for preparing lithium ion battery anode material doped with nanometer oxide

InactiveCN101719546AInitial reversible capacity improvement and enhancementIncreased initial reversible capacityCell electrodesCapacitanceLithium iron phosphate

The invention relates to a method for preparing a lithium ion battery anode material doped with a nanometer oxide, belonging to the technical field of manufacturing processes of lithium ion battery batteries. The method is characterized in that trace amount of nanometer oxide power is doped in the preparation process of lithium manganate, lithium cobaltoxide and lithium iron phosphate; the doping amount is 0.5-1.0 mol percent of lithium salts; and the nanometer oxide is selected from one or two of alumina, magnesia, titanium oxide, chromic oxide, nickel oxide, monox and zirconia and the nanometer oxide is subject to ball milling, drying, sieving, calcinating, crushing, grading and other processes to obtain the nanometer oxide doped or coated lithium ion battery anode material. The lithium ion battery anode material has reversible initial capacitance, and remarkably-improved attenuation property, charging-discharging properties, high-temperature circulating property and electrochemistry stability.

Owner:SHANGHAI UNIV

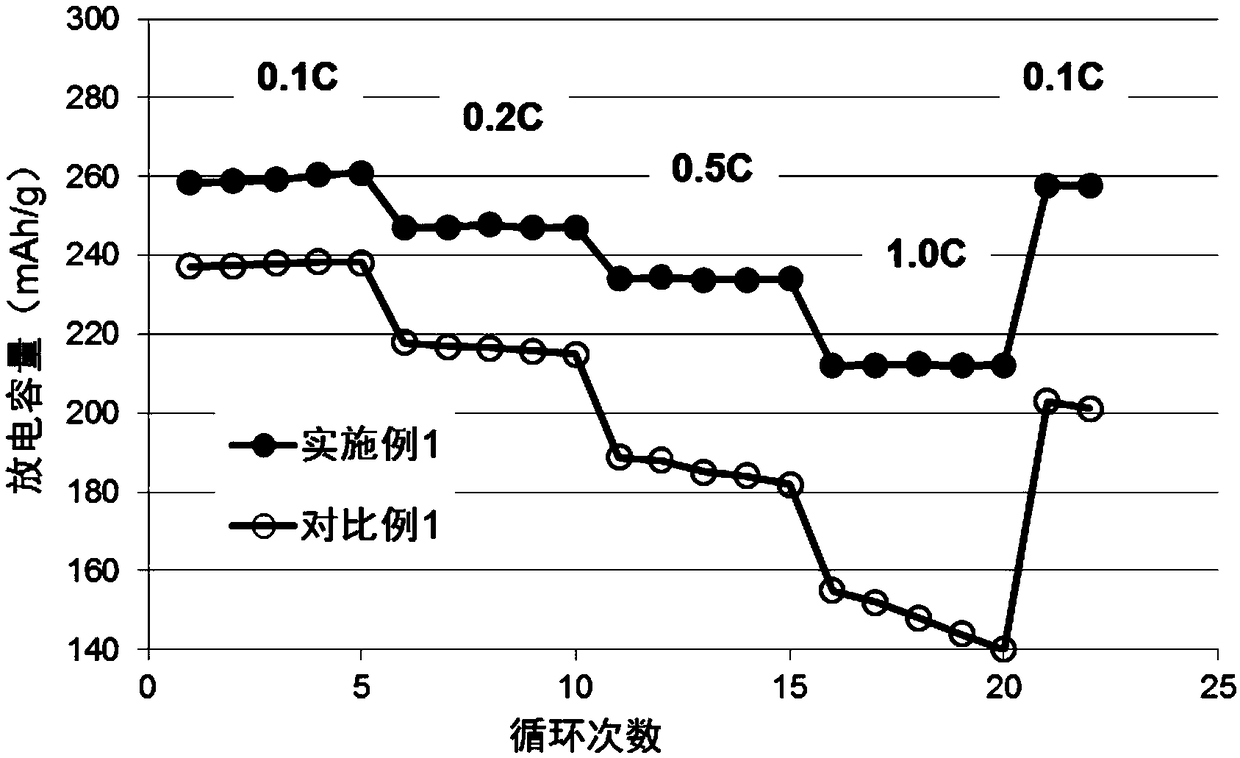

Preparation method of lithium-enriched magnesium-based anode material of lithium ion battery

InactiveCN102916172AIncrease energy densityInhibition of phase transitionCell electrodesCobalt oxideManganese oxide

The invention discloses a preparation method of a lithium-enriched magnesium-based anode material of a lithium ion battery. The preparation method comprises the steps of: depositing cobalt manganese oxide by using an electrodeposition method, and dissolving the cobalt manganese oxide and lithium chloride in a mixed way to obtain lithium cobalt manganese oxide powder; dissolving the lithium cobalt manganese oxide powder and the lithium chloride in a mixed way and heating to obtain lithium-enriched lithium cobalt manganese oxide powder; adding the lithium-enriched lithium cobalt manganese oxide powder into an aqueous solution of aluminum chloride, and standing to obtain aluminum-hydroxide-cladded aluminum-enriched lithium cobalt manganese oxide; sintering to obtain an alumina-cladded lithium-enriched lithium cobalt manganese oxide material; and preparing the anode material. According to the invention, by adoption the alumina-cladded lithium cobalt manganese oxide material as an anode active substance, while higher energy density is achieved, phase change of the anode material and the dissolution loss of important metal are inhibited, and the anode material has good cyclic stability, and is high in specific capacity, good cyclic performance and long service life when applied to the lithium ion battery.

Owner:SHANGHAI JINZHONG INFORMATION TECH

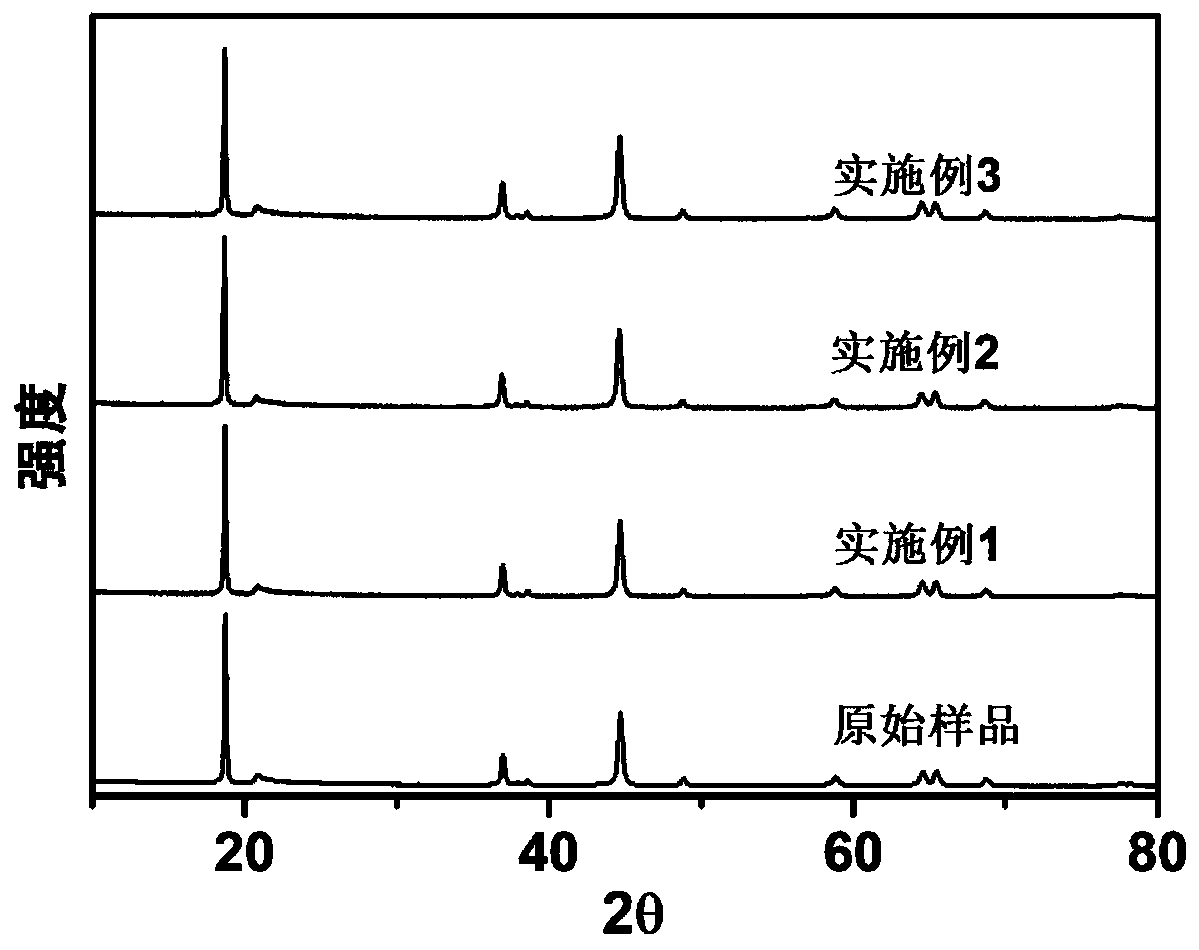

Lithium cobaltate positive electrode material and preparation method thereof, and lithium ion secondary battery

ActiveCN108123109AWithout sacrificing gram capacityWithout sacrificing energy densityCell electrodesSecondary cellsLithiumCompound structure

The present invention provides a high-voltage lithium cobaltate positive electrode material, which is a compound structure of a doped lithium cobaltate substrate and a surface coating layer, wherein the general formula of the doped lithium cobaltate substrate is Li1+zCo1-x-yMaxMbyO2, x is more than or equal to 0 and is less than or equal to 0.01, y is more than or equal to 0 and is less than or equal to 0.01, z is more than or equal to -0.05 and is less than or equal to 0.08, Ma is a doped element with unchanged valence, and is at least one selected from Al, Ga, Hf, Mg, Sn, Zn and Zr, Mb is adoped valence-changing element, and is at least one selected from Ni, Mn, V, Mo, Nb, Cu, Fe, In, W and Cr, and the surface coating layer is a high-voltage (more than 4.5 V) positive electrode material. According to the present invention, the element with unchanged valence is doped through substitution, such that the layered structure distortion caused by lithium removing can be minimized; the valence-changing element is subjected to gap doping, such that the Co<3+> oxidation is blended and delayed during the charging; and the surface coating layer has the stable structure at the voltage of more than 4.5 V, can separate the electrolytic solution from the lithium cobaltate substrate, can reduce the side reaction between the electrolytic solution and the lithium cobaltate substrate, can suppress the dissolution of the transition metal, and further can provide electrochemical energy.

Owner:HUAWEI TECH CO LTD

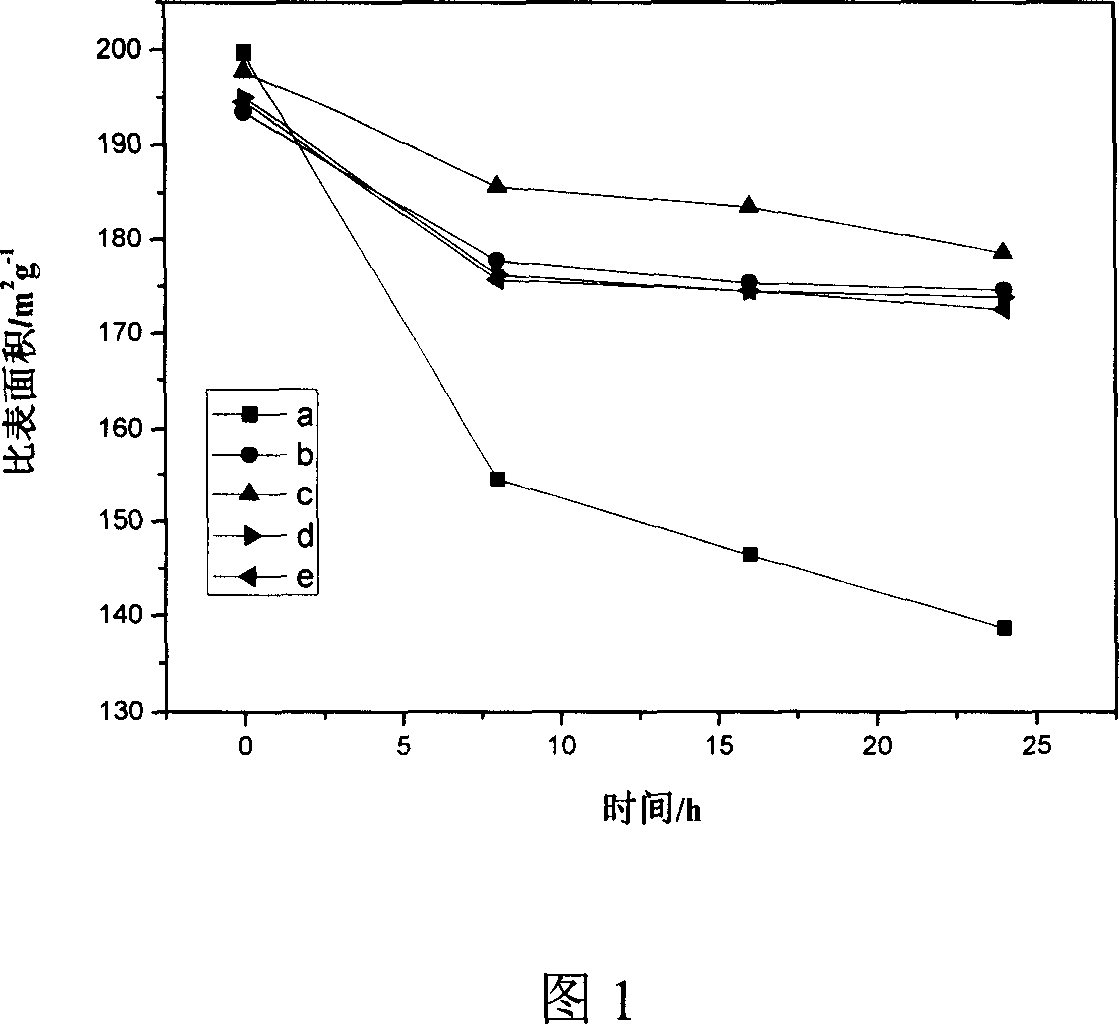

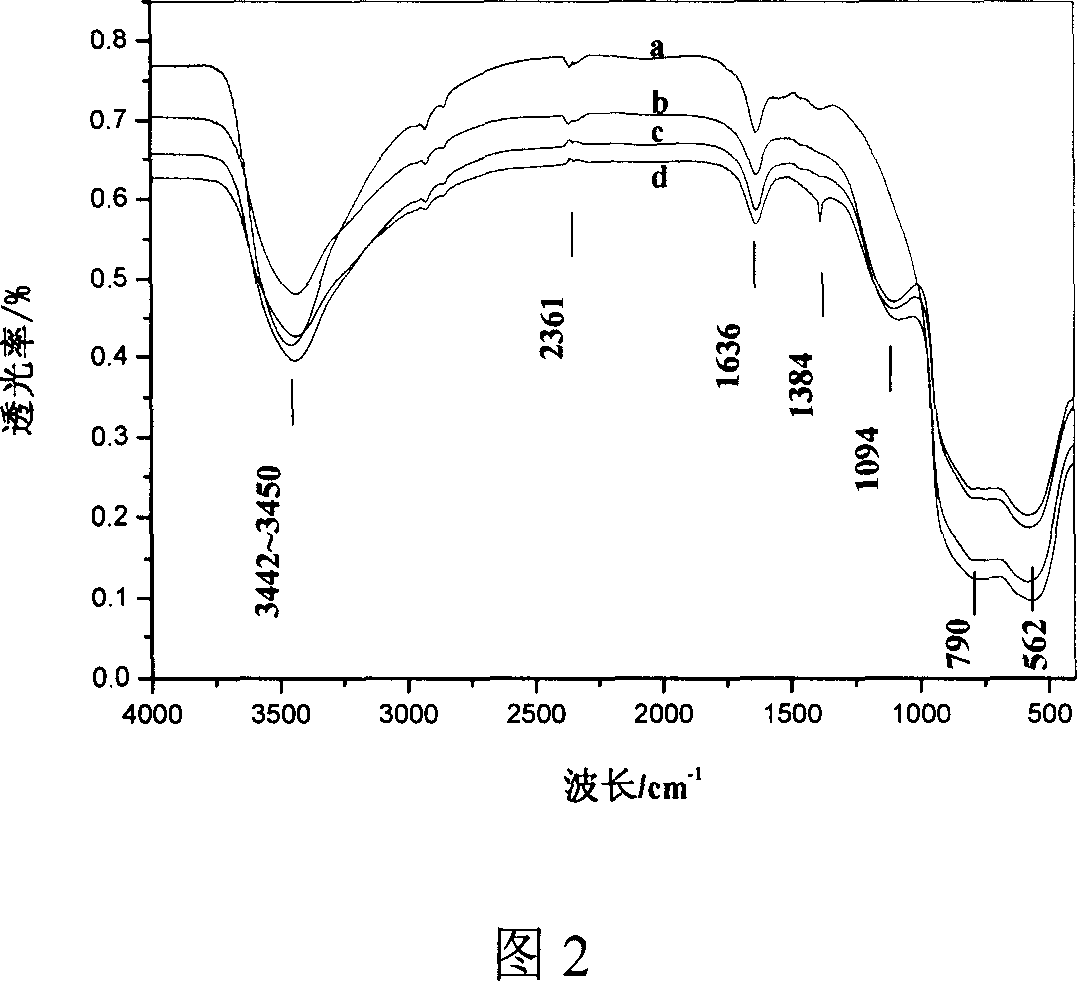

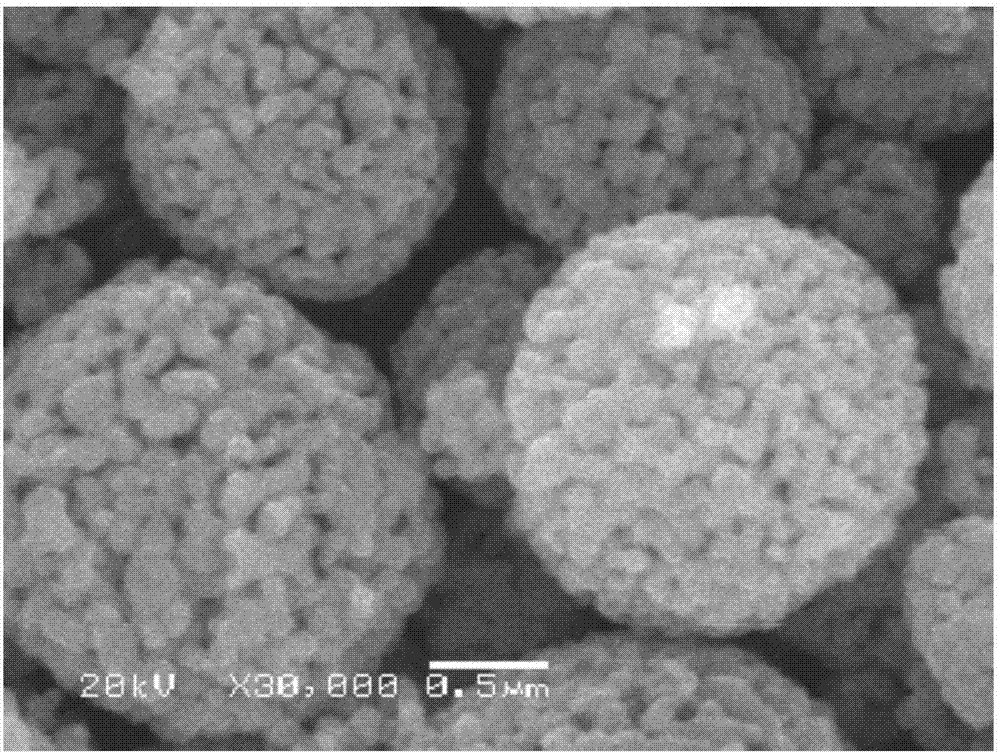

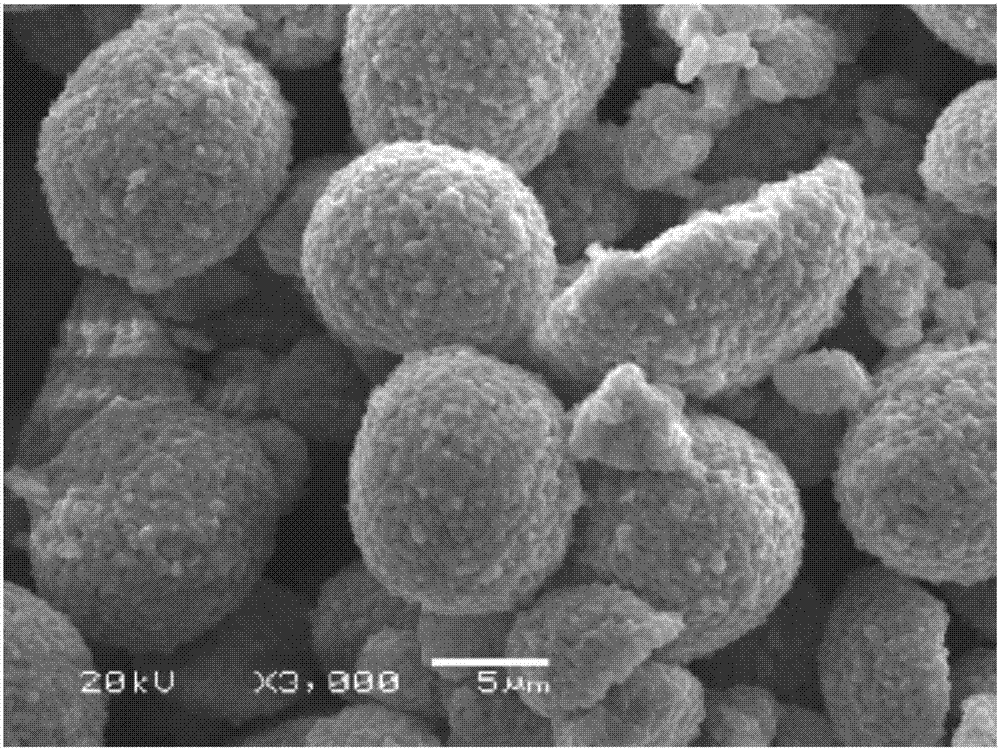

Alumina in high hydrothermal stability, and preparation method

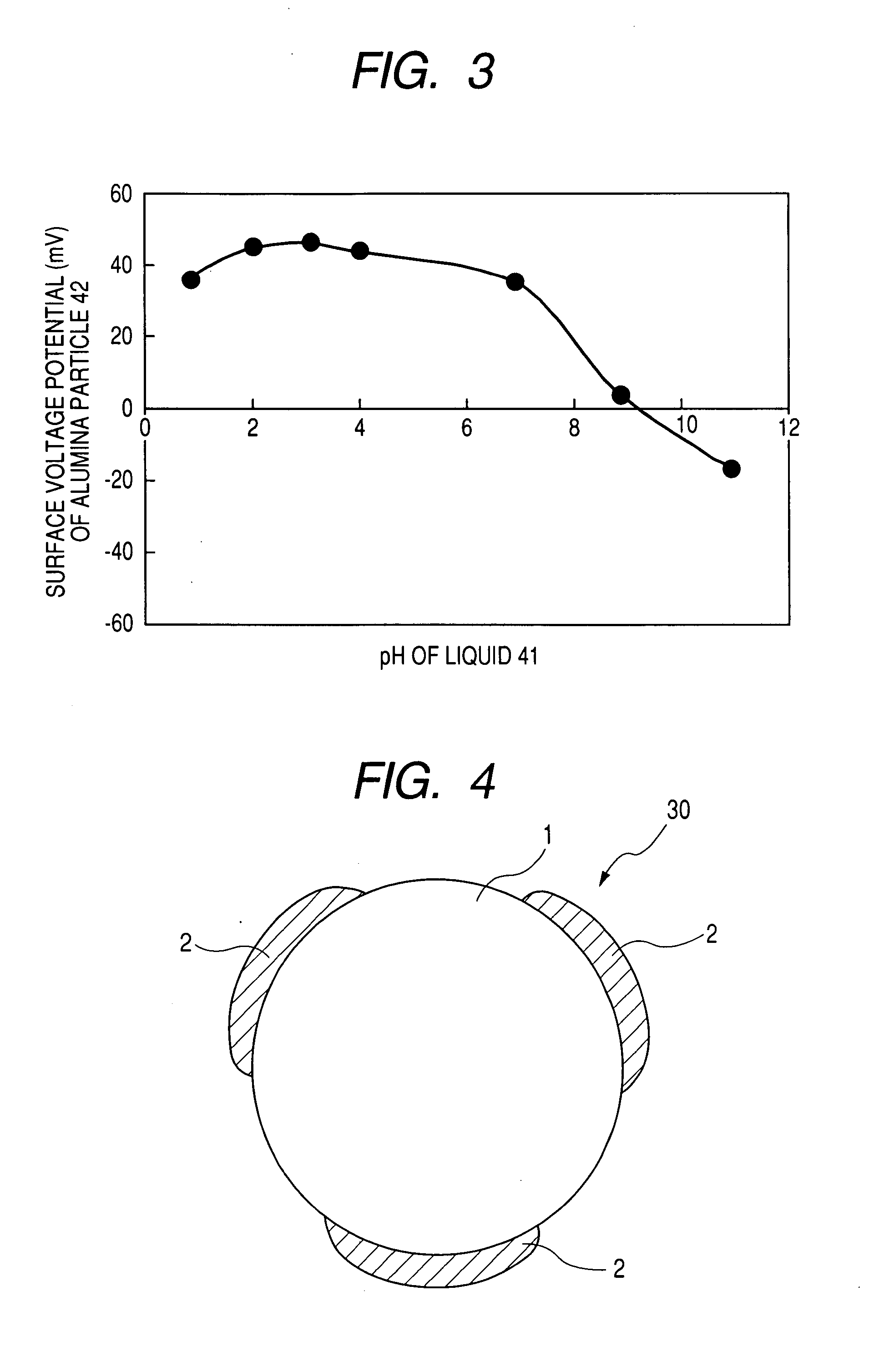

InactiveCN1958456AHigh hydrothermal stabilityPrevent sinteringAluminium oxide/hydroxide preparationAluminium oxides/hydroxidesPhosphate ionPetrochemical

This invention provides a method for preparing spherical Al2O3 with high hydrothermal stability. Based on the mechanisms of Al2O3 sintering and phase change, the method introduces phosphate ions, which can react with OH groups on the pore walls to reduce the quantity of OH groups and change the surface acidity of Al2O3. The method can prevent the sintering and phase change of Al2O3 pore channels, thus can improve the hydrothermal stability of spherical Al2O3 carrier. The hydrothermal stability of modified spherical Al2O3 is much higher than that of unmodified spherical Al2O3. The specific surface area of modified spherical Al2O3 is 190-200 m2 / g, the pore volume is 0.85-1.25 mL / g, the particle diameters are 0.5-5 mm, the packing density is 0.3-0.55 g / cm3, and the weight content of P2O5 is 0.5-5%. The spherical Al2O3 can be used as catalyst or catalyst carrier for petrochemicals and fine chemicals.

Owner:BEIJING UNIV OF CHEM TECH

Selective catalytic reduction (SCR) catalyst and preparation method thereof

InactiveCN103623808AImprove thermal stabilityInhibition of phase transitionCatalyst carriersMetal/metal-oxides/metal-hydroxide catalystsActive componentHeat stability

The invention provides a selective catalytic reduction (SCR) catalyst and a preparation method thereof. The SCR catalyst comprises a TiO2-SiO2 composite oxide carrier, a metal oxide solid acid, V2O5 and CeO2. Compared with the existing SCR catalyst, the SCR catalyst has the advantages that SiO2 is added, so phase change of TiO2 at high temperature can be inhibited and the heat stability of the catalyst is enhanced; the SiO2 has more specific surface area than that of the TiO2, so the specific surface area of the catalyst can be increased, active components are dispersed well, and the activity of the catalyst is further improved through the interaction of the metal and the carrier; the SiO2 has excellent heat stability, so the using temperature window of the SCR catalyst can be widened by inhibiting the phase change of the carrier at high temperature and inhibiting reduction of the specific surface area; and the active components such as the CeO2 are added, so the catalytic activity of the catalyst at a lower temperature can be improved by enhancing the oxidizing capacity at a low temperature.

Owner:柳景惠

Tailored blank laser welding method for hot-formed steel with Al-Si plating

ActiveCN106392328AInhibits the formation of intermetallic compounds and affects the austenite transformationSimple methodWelding/cutting media/materialsSoldering mediaMetalWelding joint

The invention provides a tailored blank laser welding method for hot-formed steel with Al-Si plating. The method comprises steps as follows: tailored welding is performed on a hot-formed steel plate with the Al-Si plating under the condition of shielding gas by laser welding equipment; and the shielding gas includes mixed gas of one or two of oxygen and carbon dioxide and inert gas. In the tailored welding process, the mixed gas of one or two of the oxygen and the carbon dioxide and the inert gas is used as the shielding gas, the oxygen partial pressure in a welding pool is increased, Al and O elements entering the welding pool are combined to form Al2O3 which does not affect the strength and toughness of a weld joint, Al and Fe elements are inhibited from forming an intermetallic compound and affecting austenitic phase transformation, a weld joint zone with the all slat martensitic structure is obtained finally, and the strength of the weld joint reaches the level of base metal. With the method, welding wires are not required to be added, plating removal before welding is also not required, the method is simple, the production efficiency is improved, and the production cost is reduced.

Owner:SUZHOU UNIV

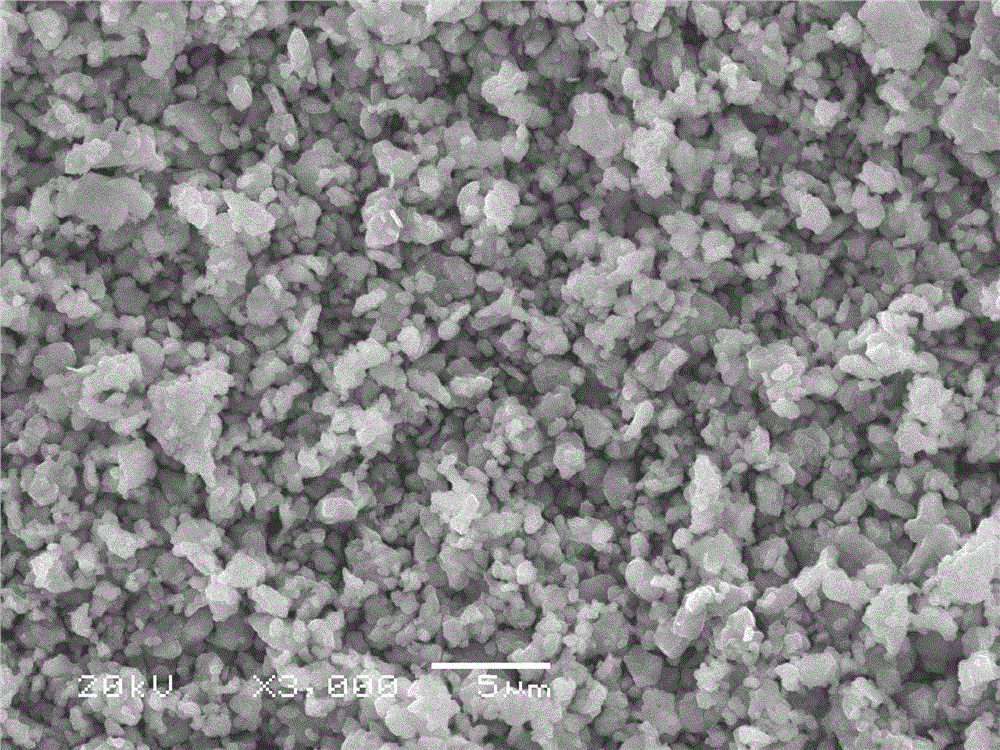

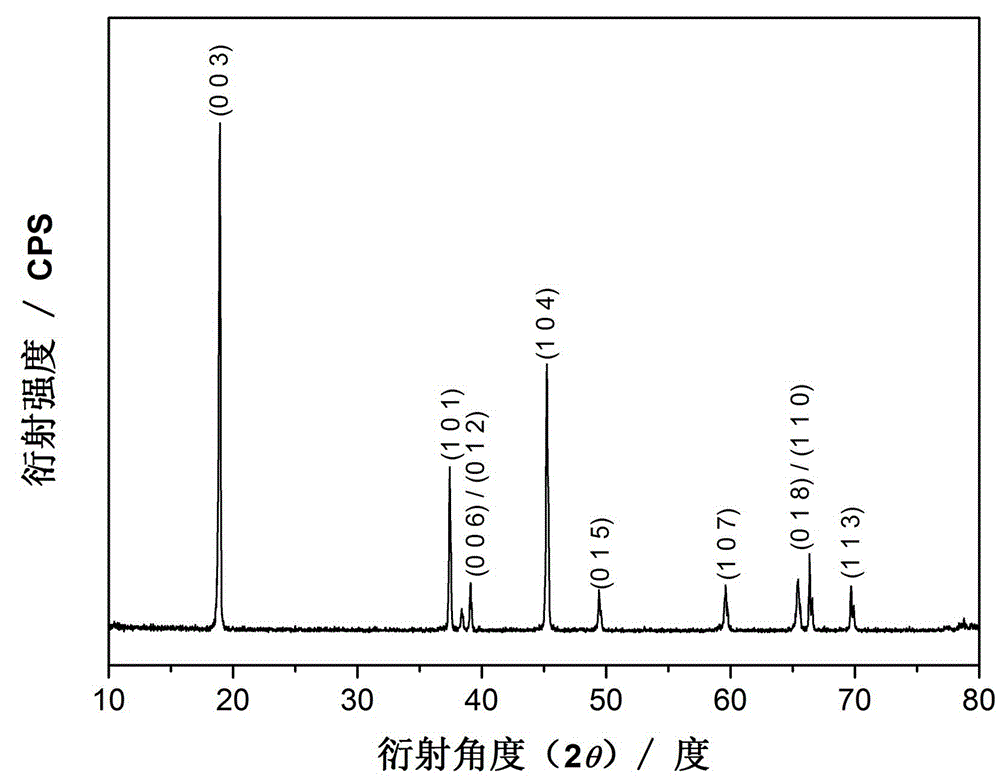

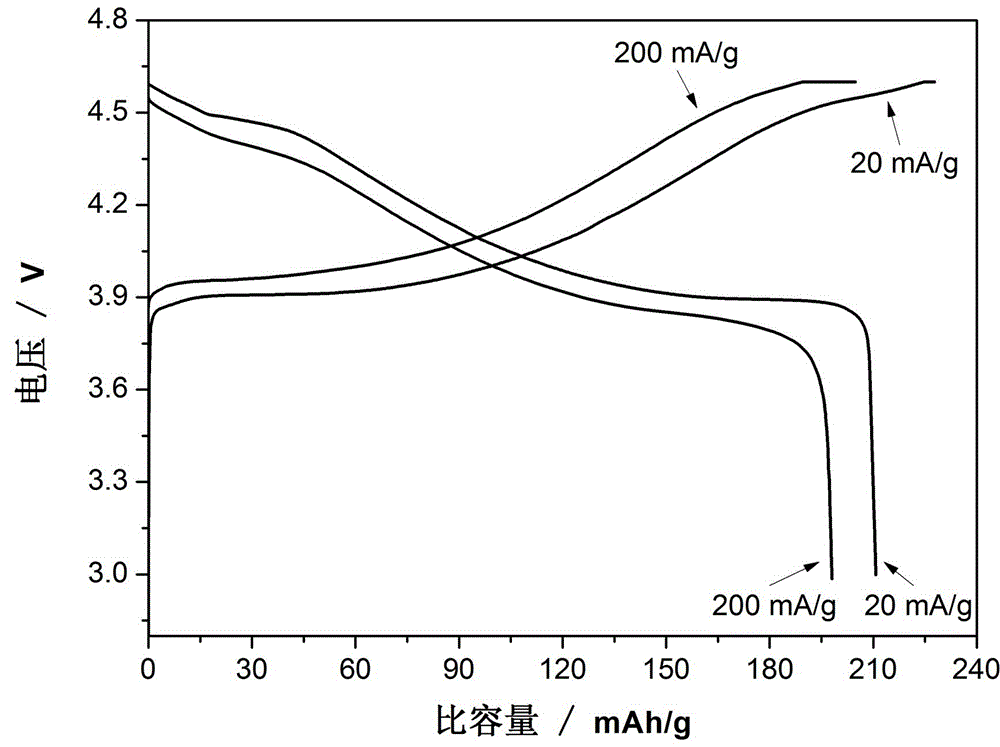

Li2MnO3 and LiCoO2 composite anode material

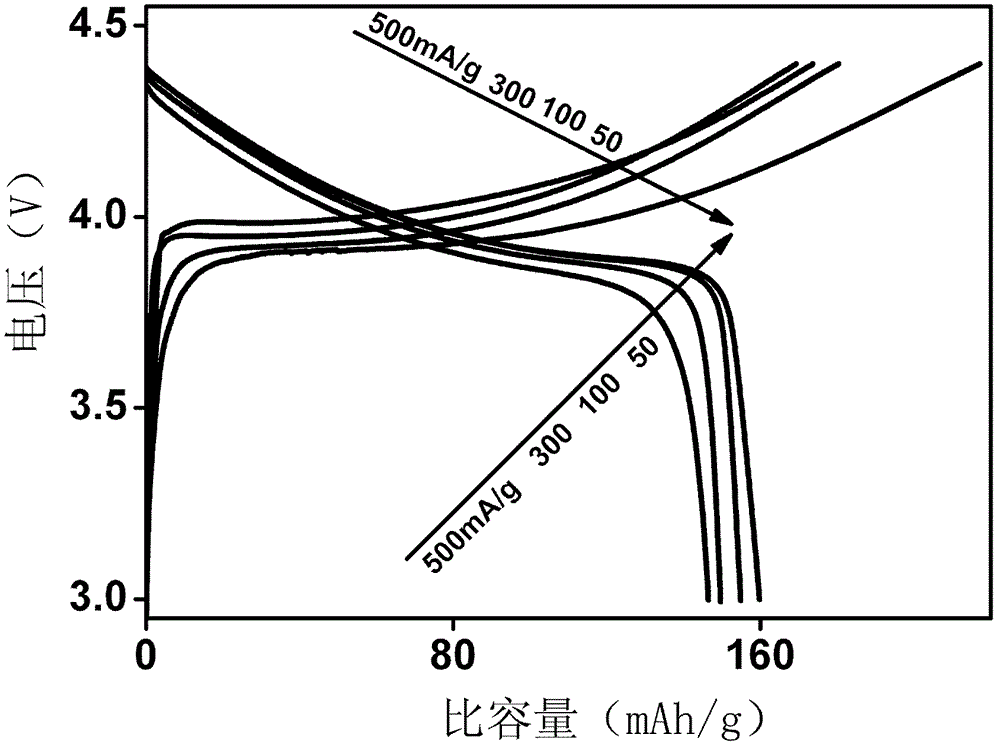

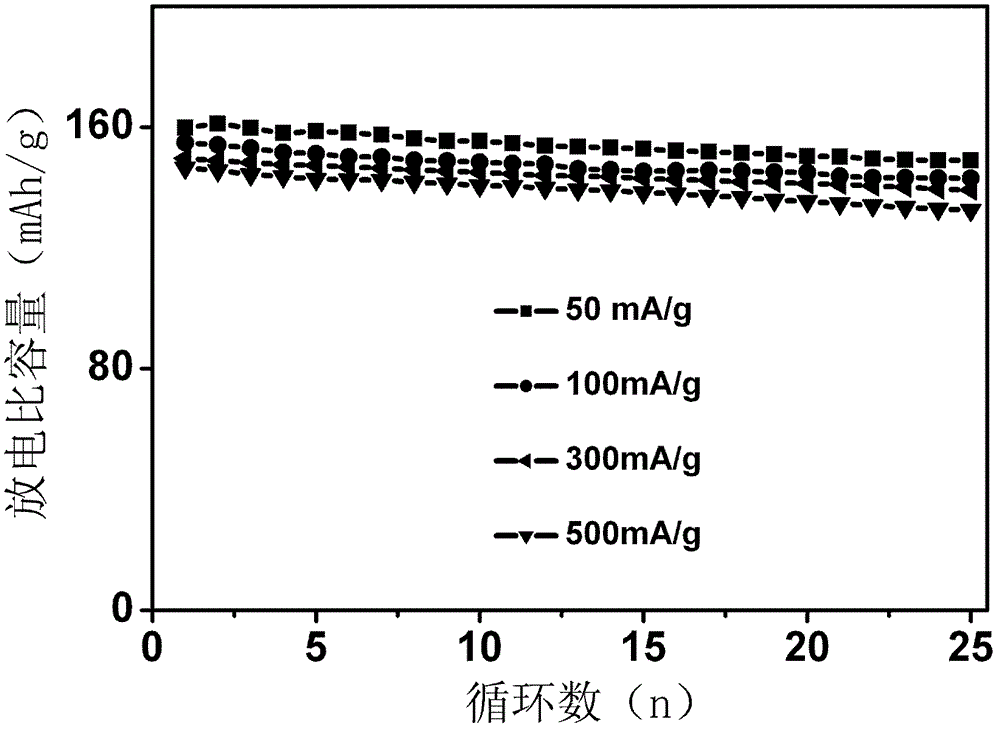

InactiveCN102751481AInhibition of phase transitionImprove electrochemical performanceCell electrodesHigh rateComposite oxide

The present invention discloses a Li2MnO3 and LiCoO2 composite anode material, which is a Li2MnO3 and LiCoO2 composite oxide meeting a stoichiometric ratio of xLi2MnO3.yLiCoO2, wherein x is more than or equal to 0.025 and is less than or equal to 0.15, and x plus y equals 1. The Li2MnO3 and LiCoO2 composite anode material of the present invention has characteristics of high specific capacity and high cycle life, and further has excellent performances under conditions of high rate, high temperature, low temperature, and the like.

Owner:FUJIAN INST OF RES ON THE STRUCTURE OF MATTER CHINESE ACAD OF SCI

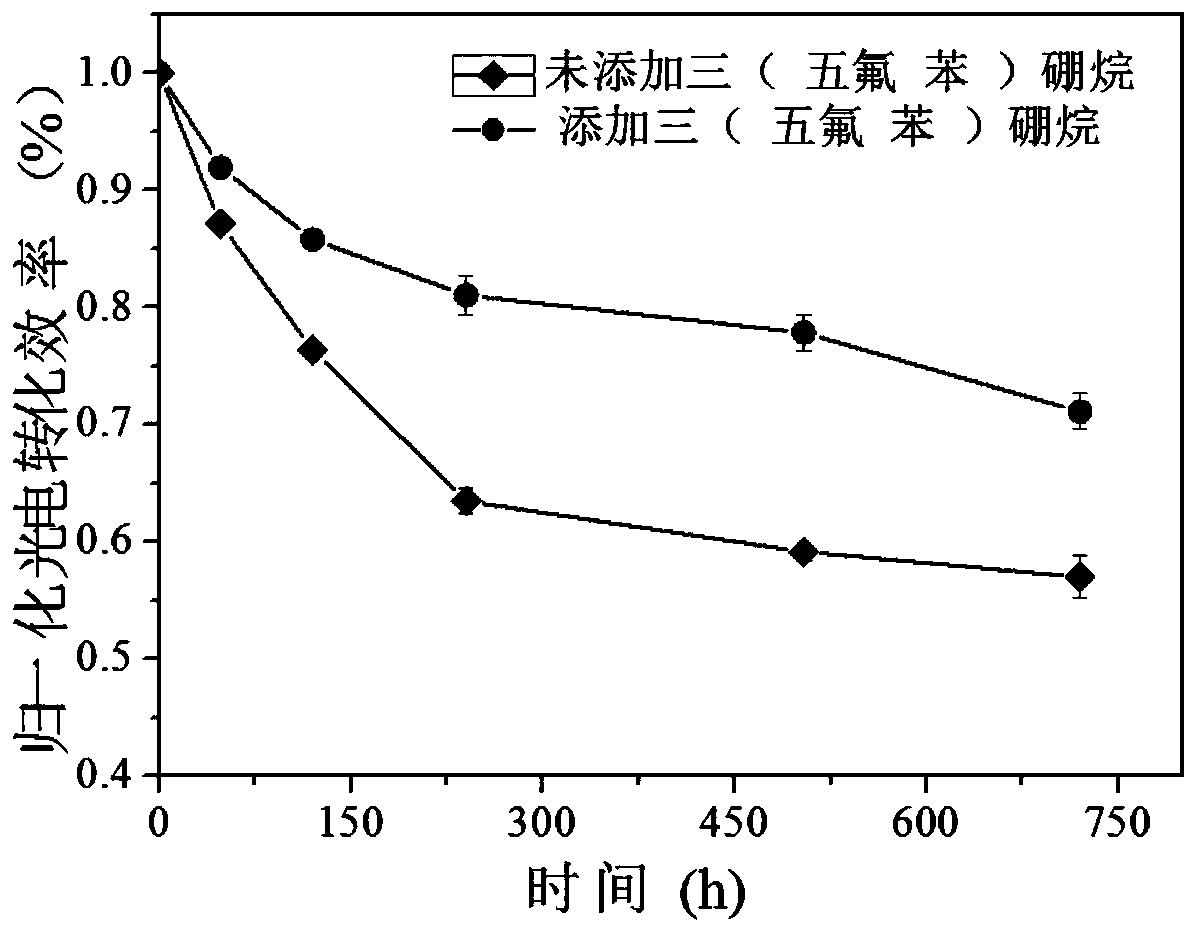

Novel passivated perovskite solar cell and preparation method thereof

ActiveCN109888105AInhibition of phase transitionEnhanced light absorptionFinal product manufactureSolid-state devicesAnti solventPerovskite solar cell

The invention discloses a novel passivated perovskite solar cell and a preparation method thereof. The perovskite solar cell optimizes the absorption of perovskite, so that a perovskite absorption layer contains an anti-solvent tris(pentafluorophenyl)borane to serve as a novel additive. On one hand, the addition of fluoride ions can change the crystallinity and the defect state of a perovskite film to form a high-quality perovskite film with a large grain size; the anti-solvent tris(pentafluorophenyl)borane can enhance the surface appearance of the perovskite and plays a passivation function at the grain boundary; and on the other hand, the fluoride ions can improve the hydrophobicity of the perovskite film and inhibit the phase change of the perovskite to better protect the perovskite from being destroyed by water, thereby further improving the air stability and the light stability of the cell to obtain a high-efficiency perovskite solar cell.

Owner:SHAANXI NORMAL UNIV

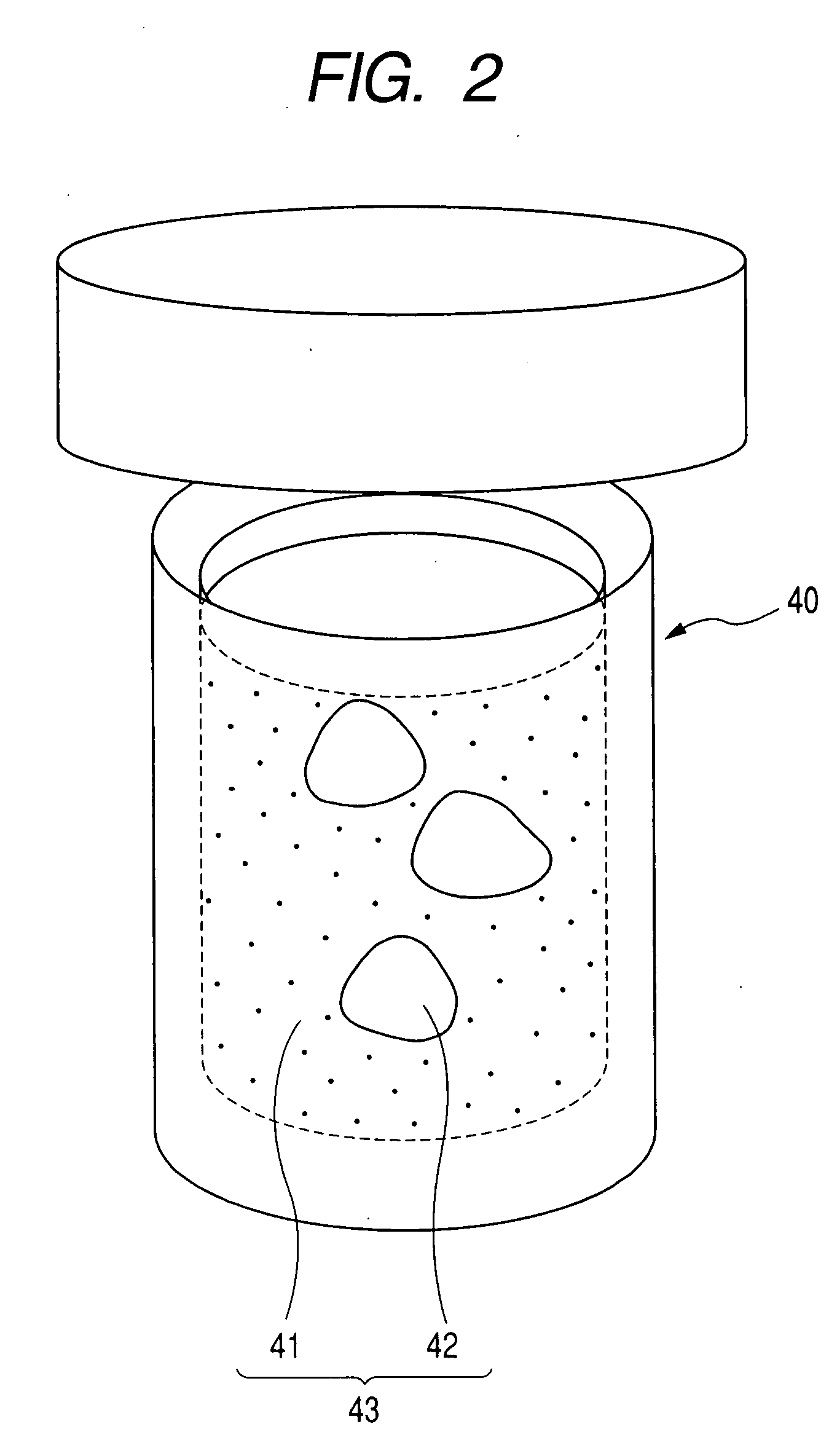

Reactor and Method for Supercritical Water Oxidation

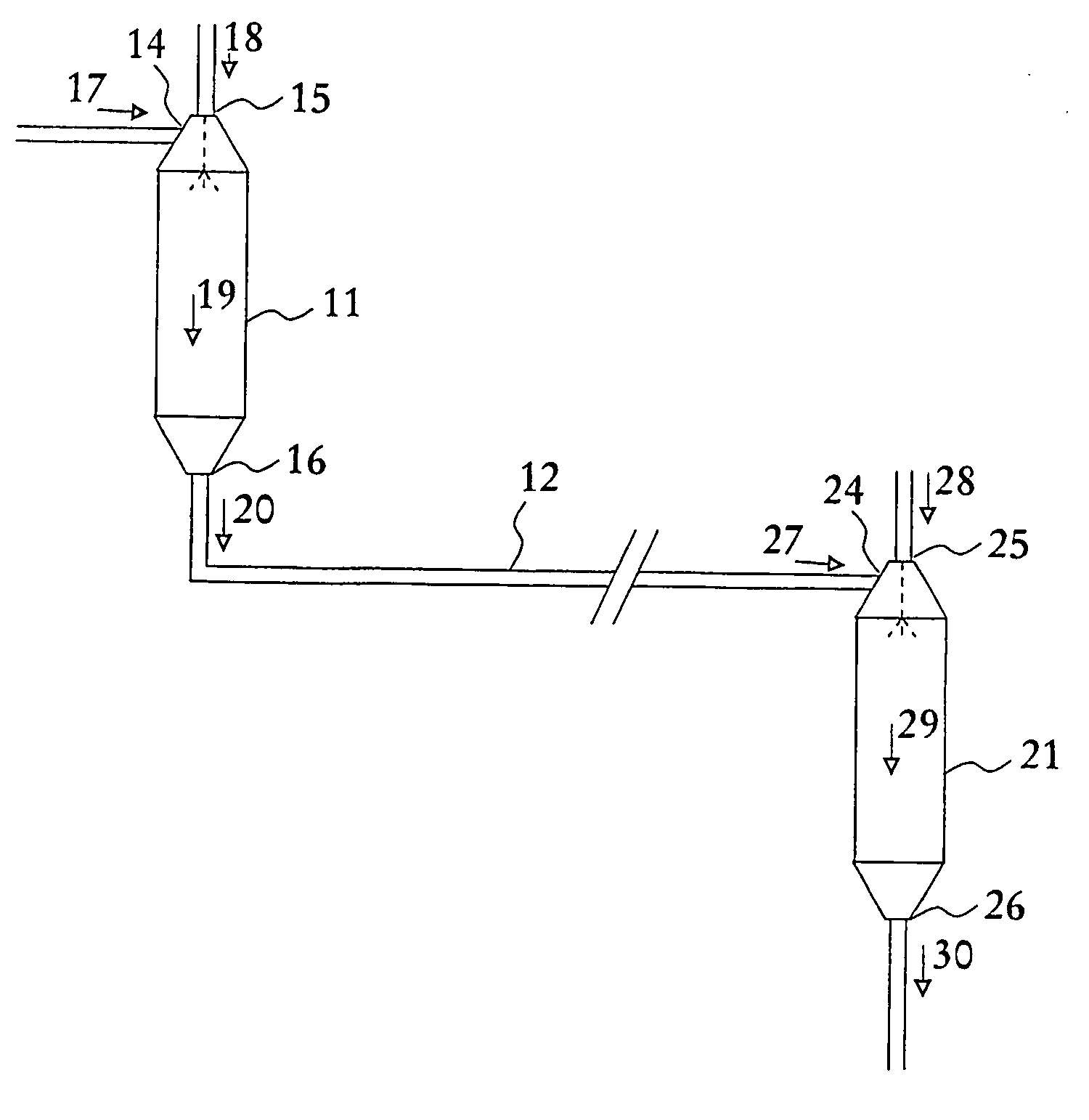

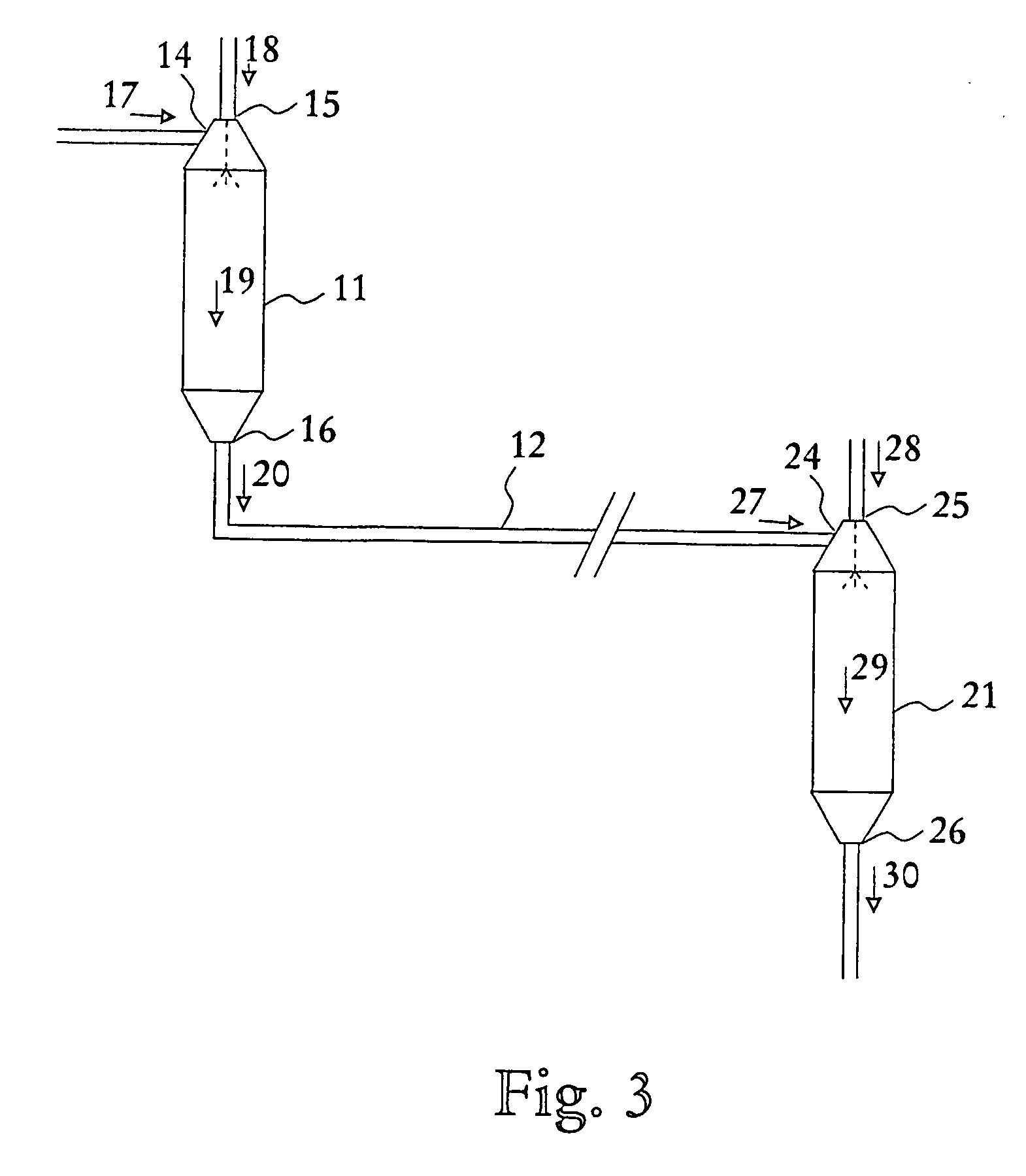

InactiveUS20080073292A1Increase the cross-sectional areaInhibition formationSludge treatment by oxidationChemical/physical/physico-chemical stationary reactorsNuclear engineeringOrganic matter

A reactor for supercritical water oxidation comprises an essentially vertical reactor section (11) and an essentially non-vertical reactor section (12), wherein the vertical reactor section has a cross-sectional area which is substantially larger than the cross-sectional area of the non-vertical reactor section. The vertical reactor section has an inlet (14) in an upper portion thereof for receiving (17) a flow containing organic material and water, and an outlet (16) in a lower portion thereof for outputting (20) the flow. Both the vertical and the non-vertical reactor sections are configured to oxidize organic material in the flow through supercritical water oxidation.

Owner:HOLLINGFORD

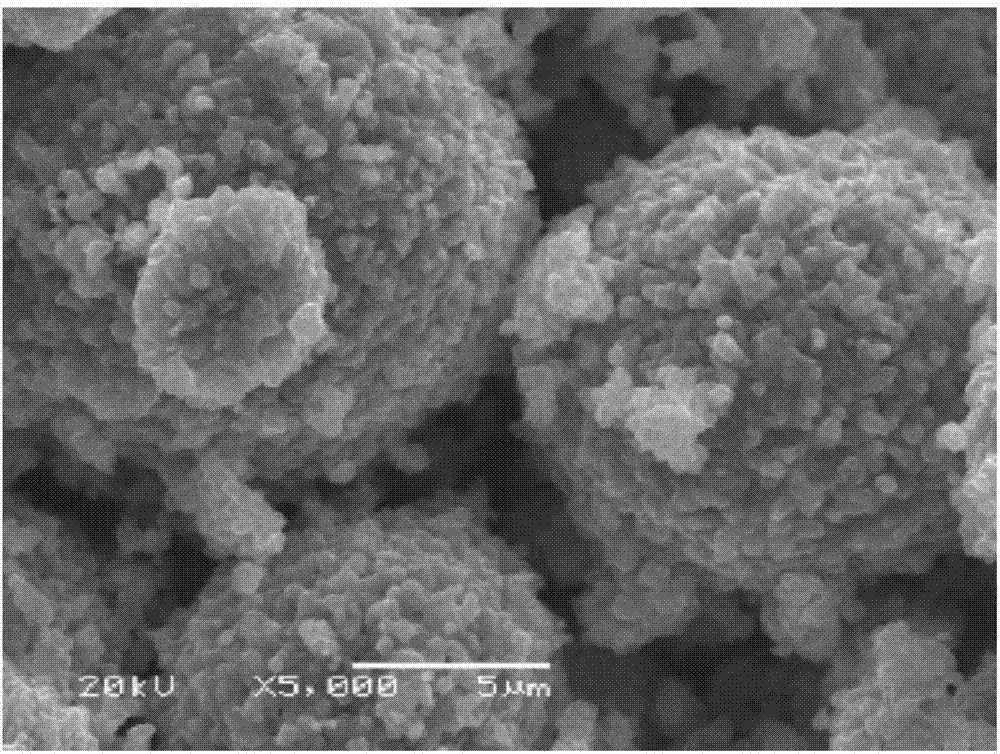

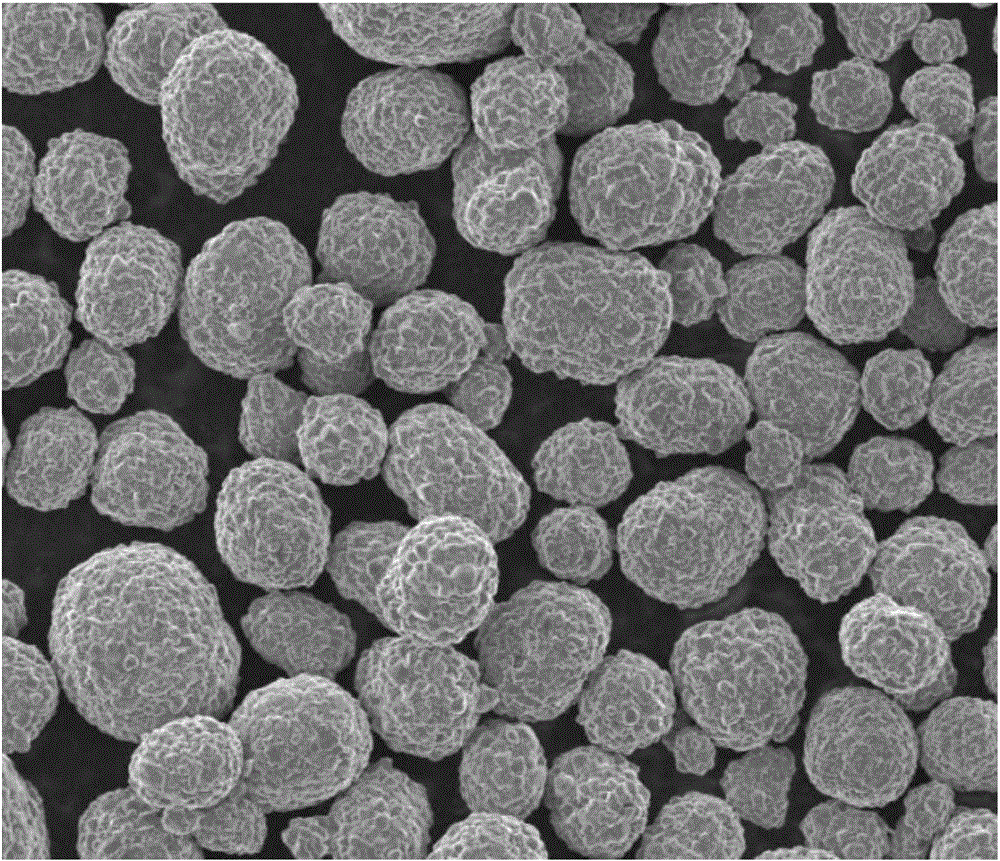

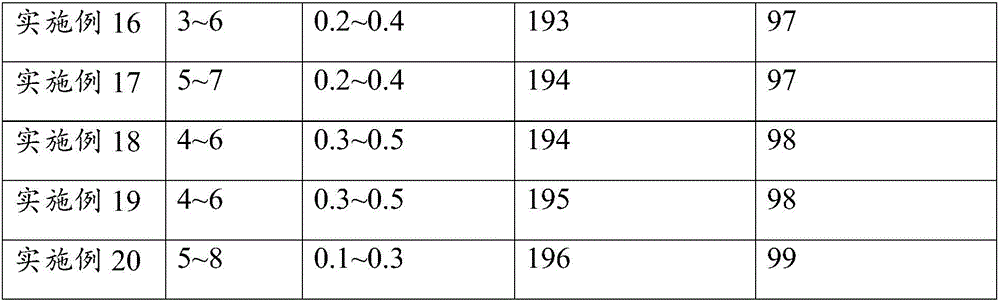

Preparation method of high-compaction density 523-type ternary positive electrode material

InactiveCN107799764AIncrease compaction densityLower pHCell electrodesSecondary cellsManganateSingle crystal

The invention provides a preparation method of a high-compaction density 523-type ternary positive electrode material, and belongs to the technical field of preparation of a lithium ion battery positive electrode material. A high-compaction density and low-pH value lithium nickel cobalt manganate NCM523-type ternary positive electrode is in a spherical shape, grain D50 of secondary agglomeration particle is 10-12 micrometers, and the size of primary single-crystal particle is 1.5-3 micrometers. The preparation method of the high-compaction density 523-type ternary positive electrode material comprises the steps of doping 0.1-1.0% of metal oxide into a mixture of lithium carbonate and a ternary precursor LiNi<0.5>Co<0.2>Mn<0.3>(OH)<2>, performing primary sintering, paste washing, secondarysintering, breakage, iron removal, sieving and mixing, and finally, obtaining an NCM523-type ternary positive electrode material. By the method, the compaction density of the NCM523-type ternary positive electrode material is effectively improved, a pH value is reduced, the compaction density of the prepared NCM523-type ternary positive electrode material is larger than 3.7g / cm<3>, and the pH value is smaller than 10.80.

Owner:JINCHUAN GROUP LIMITED +1

High-voltage lithium cobaltate based composite cathode material of lithium ion battery and preparation method of high-voltage lithium cobaltate based composite cathode material

ActiveCN104466099AInhibition of phase transitionGuaranteed stabilityCell electrodesSecondary cellsComposite cathodePhysical chemistry

The invention discloses a high-voltage lithium cobaltate based composite cathode material of a lithium ion battery. Metal element M is doped into lithium cobaltate; meanwhile, Li2MnO3 is introduced into lithium cobaltate to form the composite cathode material; the phase change of lithium cobaltate in a charging / discharging cyclic process under high voltage is inhibited, and the cyclic performance under high voltage (more than 4.5V) is improved; the molecular formula of the composite cathode material is xLi2MnO3.(1-x)LiCo(1-y)MyO2, wherein x is more than or equal to 0.01 and less than or equal to 0.20 and y is more than or equal to 0.005 and less than or equal to 0.10; and the doped metal element M is one or more of Mg, Ca, Ni, Mn, Cr, Fe, Al, Y, Ti, Zr, Cu, Zn, Ce, V, Nb and Mo. The lithium cobaltate based composite cathode material is prepared by a liquid phase mixing-spray drying-high temperature sintering combined method, and dual modification operations (material compounding and doping) are finished in one step, so that the preparation process of the material is simplified.

Owner:CENT SOUTH UNIV

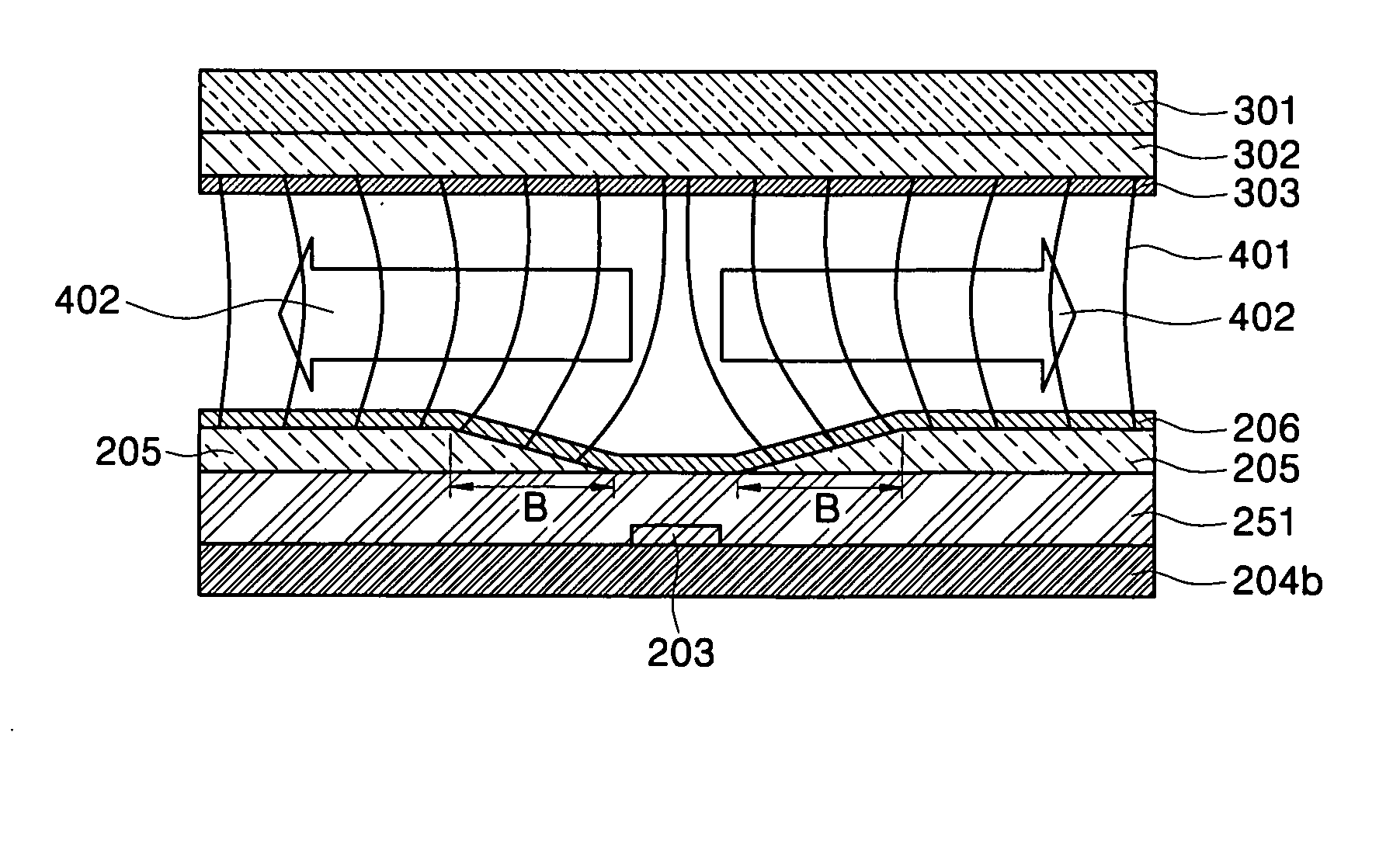

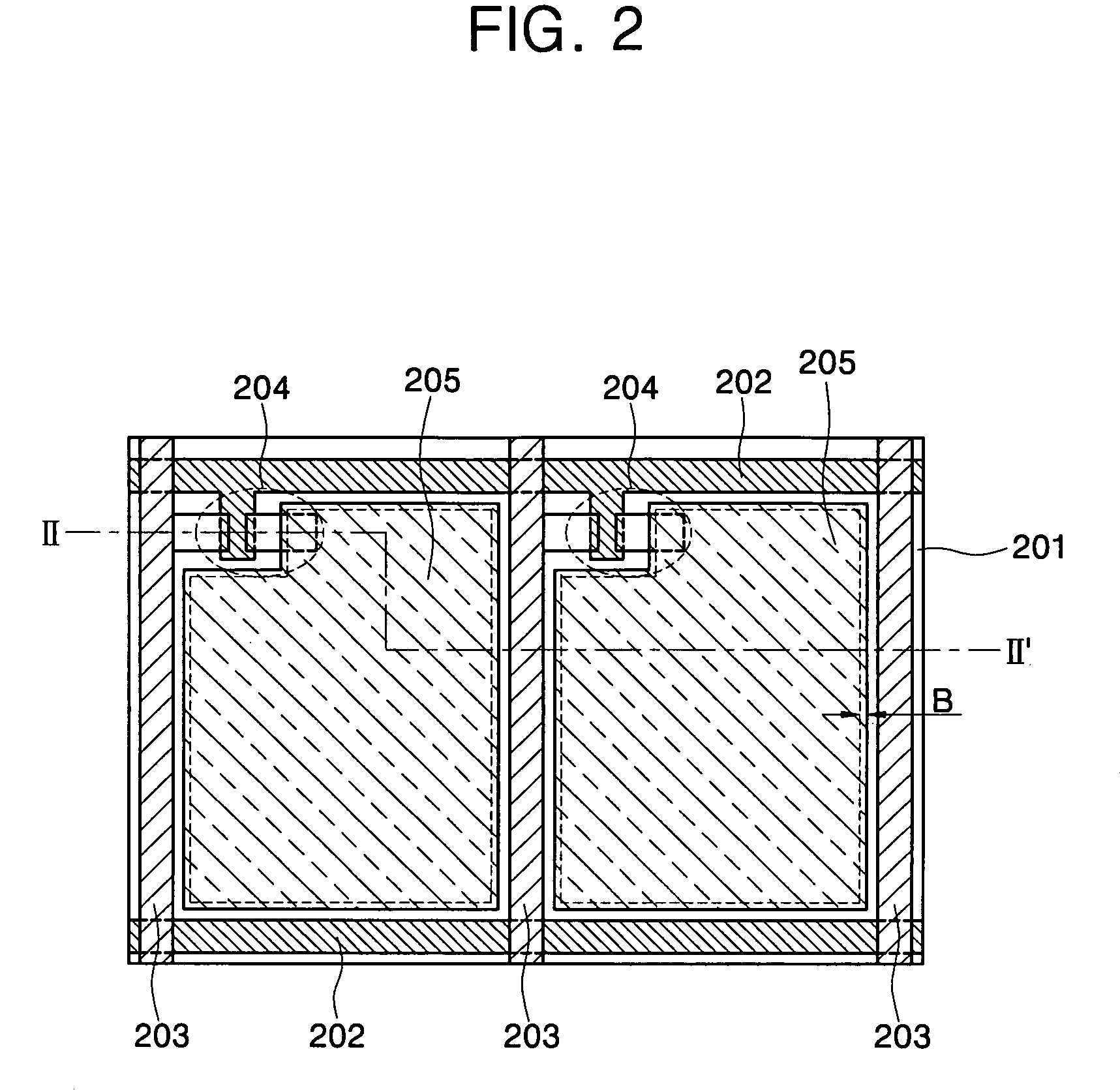

Liquid crystal display device and method of fabricating the same

A liquid crystal display device (LCD) and method of fabricating the same are provided, in which in an OCB mode LCD, an edge portion of a first electrode is formed with a taper angle of not less than approximately 25° and less than 90°, thus an electric field in the edge portion of the first electrode becomes nonuniform so that a transitional nucleus is easily created and liquid crystals are readily transitioned to a bend phase at a low transition voltage. As a result, the phase transition of the liquid crystals can be easily controlled.

Owner:SAMSUNG MOBILE DISPLAY CO LTD

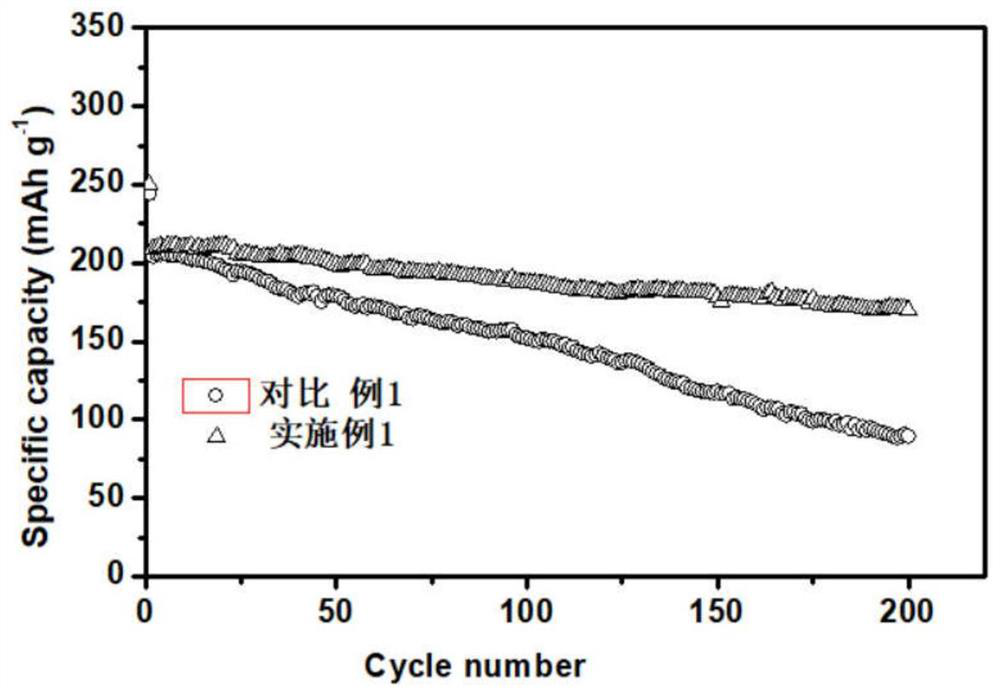

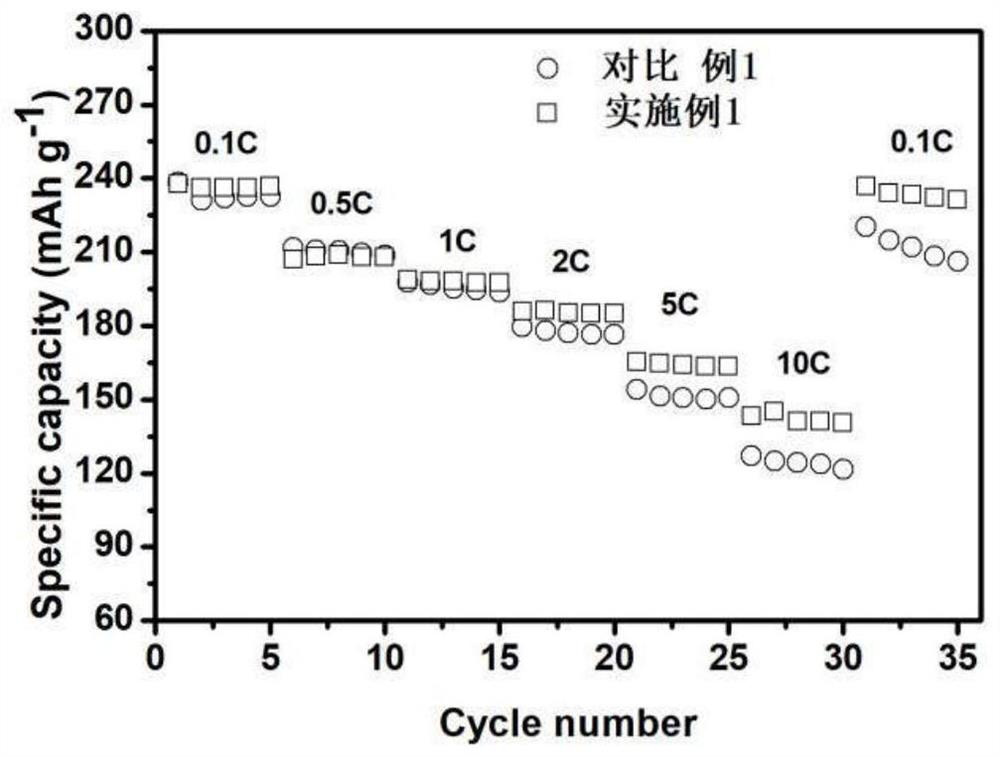

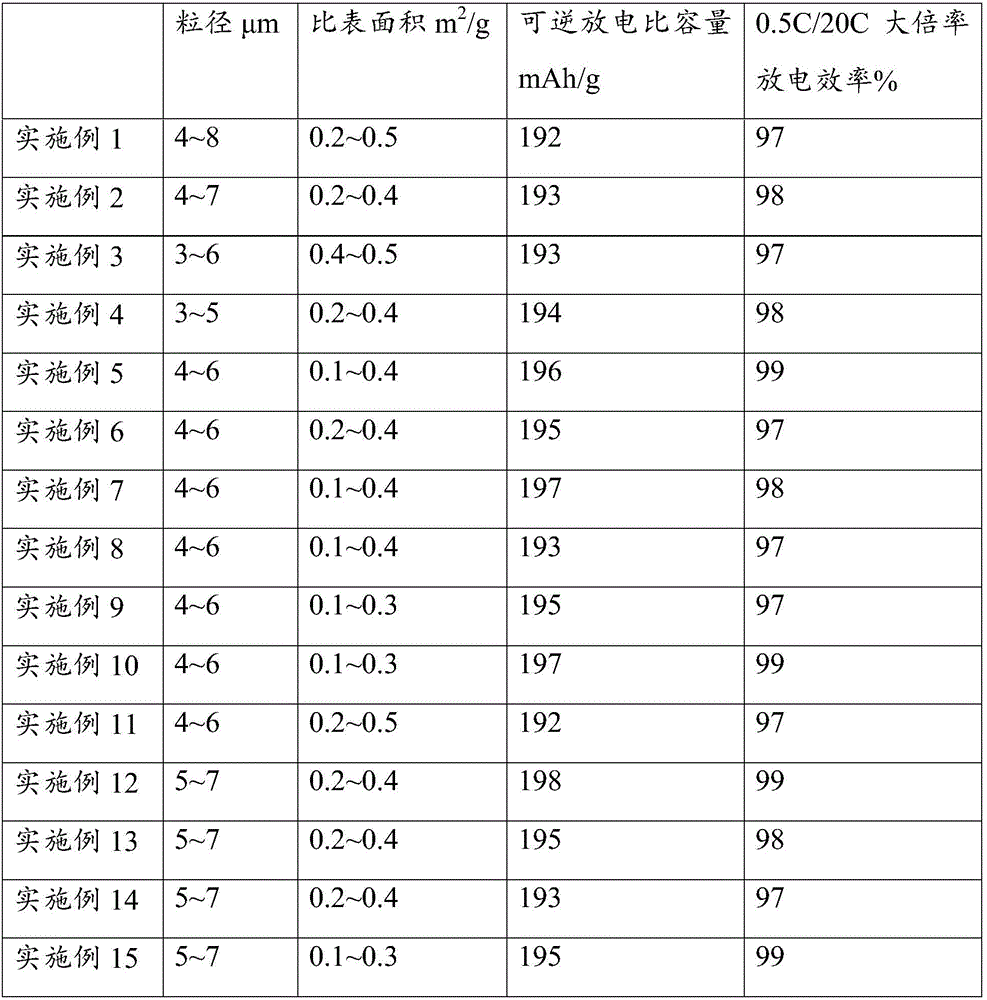

Ion conductor and heterostructure co-modified lithium ion battery positive electrode material and preparation method and application thereof

ActiveCN111799468AInhibition releaseInhibition of phase transitionSecondary cellsPositive electrodesHeterojunctionElectrical conductor

The invention provides an ion conductor and heterostructure co-modified lithium ion battery positive electrode material and a preparation method and application thereof. The modified lithium ion battery positive electrode material is coated by an ion conductor and is co-acted with a heterostructure; the modified lithium ion battery positive electrode material comprises an ion conductor coating layer, a heterostructure layer and a material body, the ion conductor coating layer is formed by reaction of a polyanionic compound, doped element salt and residual lithium on the surface of the material, and the phase of the heterostructure layer is a spinel phase or / and a rock salt phase and is located between the coating layer and the material body. The preparation method comprises the following steps of uniformly mixing lithium ion battery positive electrode material powder with polyanionic salt, doped element salt, weak acid and other compounds in a solution, drying by distillation, and sintering to obtain the product. The product obtained by the invention is used in energy storage equipment.

Owner:CENT SOUTH UNIV +1

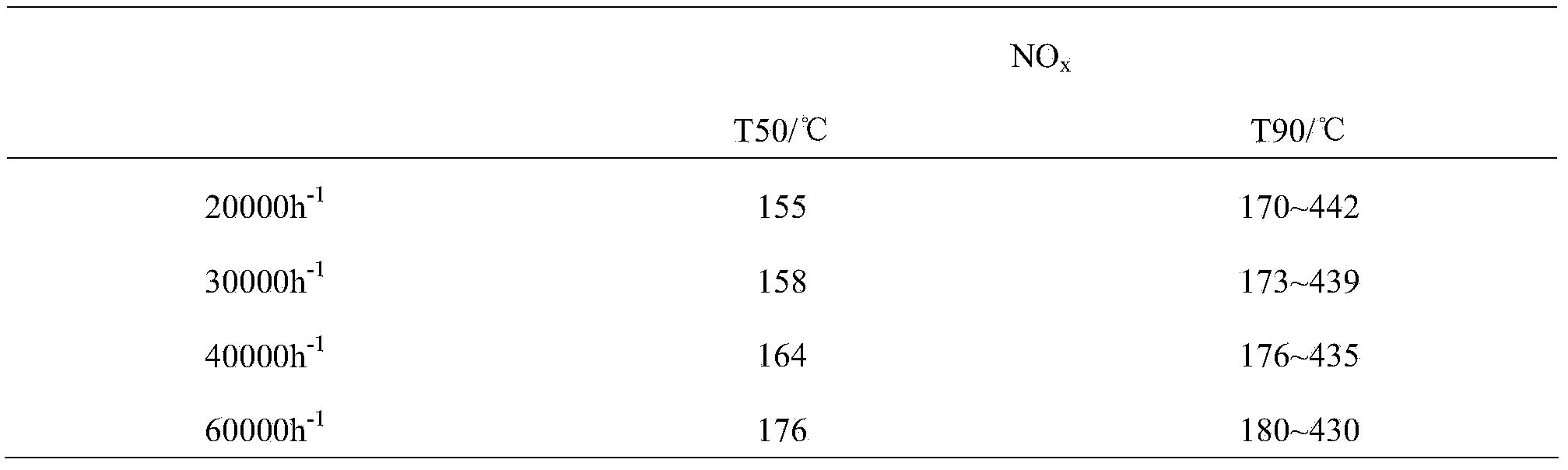

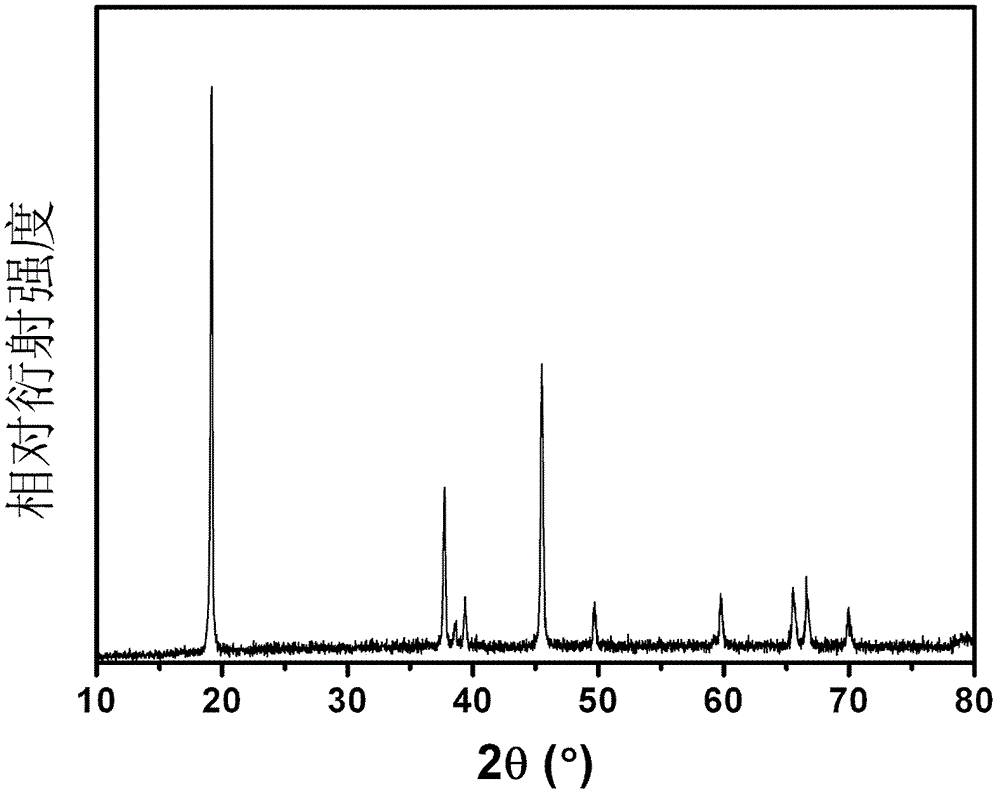

Diesel vehicle exhaust purification SCR (Selective Catalytic Reduction) catalyst and preparation method thereof

ActiveCN103769080AImprove performanceWide active temperature windowMetal/metal-oxides/metal-hydroxide catalystsTungstateAmmonium metavanadate

The invention discloses a diesel vehicle exhaust purification SCR (Selective Catalytic Reduction) catalyst. The catalyst comprises a cordierite honeycomb ceramic carrier and a coating which is loaded on the cordierite honeycomb ceramic carrier; the coating comprises the following raw materials: titanium dioxide / silicon dioxide composite oxide powder, ammonium tungstate and ammonium metavanadate according to a mass ratio of 100:(12-18):(3-6). A preparation method of the catalyst comprises the steps of mixing the ammonium tungstate with the titanium dioxide / silicon dioxide composite oxide powder firstly to prepare TiO2-SiO2 / WO3 pccowder, then mixing the ammonium metavanadate with TiO2-SiO2 / WO3 to prepare slurry to be coated, and then coating the cordierite honeycomb ceramic carrier with the slurry to be coated by using an impregnation method. The catalyst is wide in activity temperature window, high in high-temperature activity and water / heat resistant stability, and good in reproducibility.

Owner:DONGFENG COMML VEHICLE CO LTD

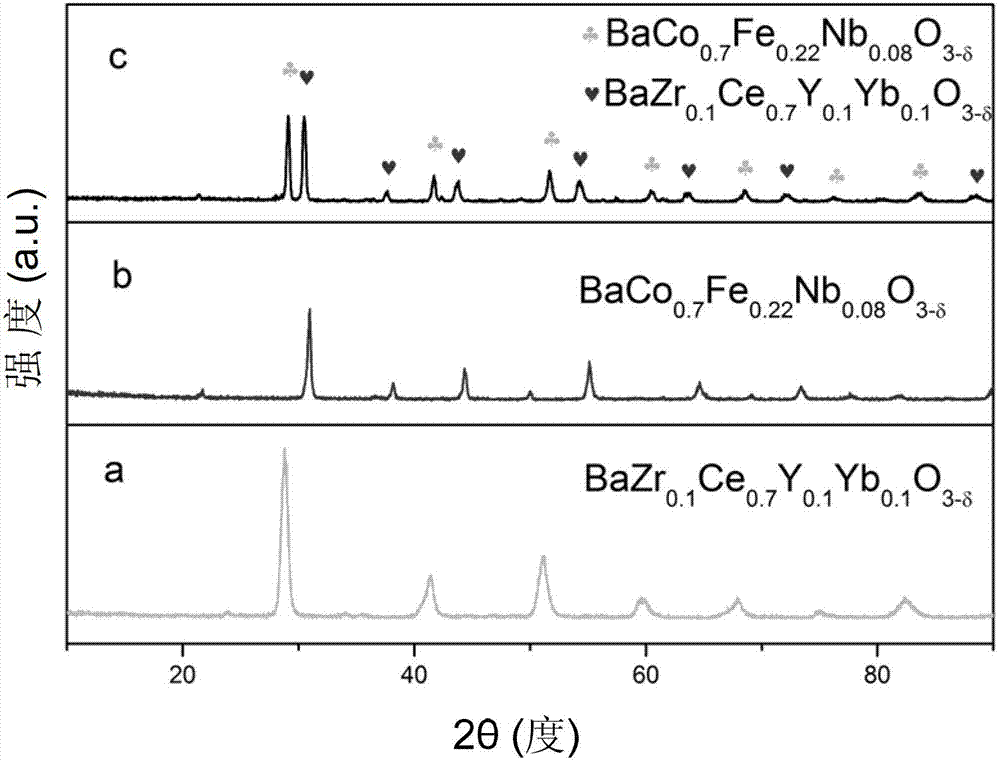

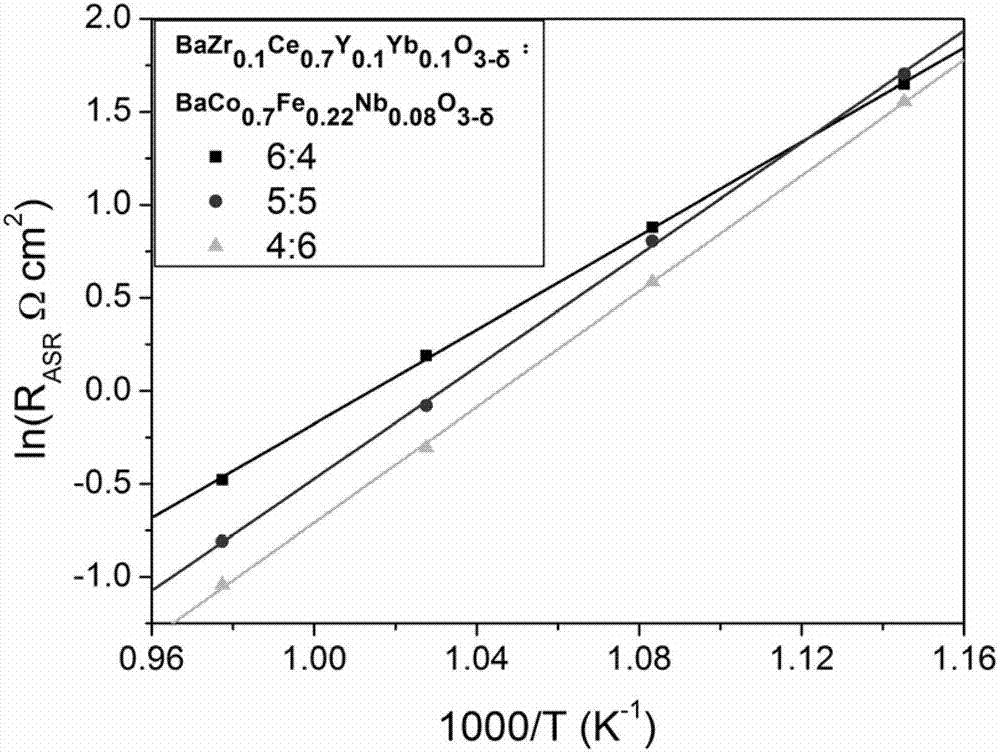

Composite cathode material for medium and low-temperature proton-conductive solid oxide fuel cells

ActiveCN103208634AInhibition of phase transitionImprove electrocatalytic performanceCell electrodesChemical compatibilityElectron

The invention discloses a composite cathode material for medium and low-temperature proton-conductive solid oxide fuel cells, and belongs to the field of fuel cells. The composite cathode material is characterized in that BaCo<0.7>Fe<0.22>Nb<0.08>O<3-delta> with high oxygen ionic conductivity and high electronic conductivity and BaZr<0.1>Ce<0.7>Y<0.1>Yb<0.1>O<3-delta> with high proton conductivity are composited with each other to manufacture the novel cathode material, a chemical formula of the novel cathode material is BaCo<0.7>Fe<0.22>Nb<0.08>O<3-delta>-BaZr<0.1>Ce<0.7>Y<0.1>Yb<0.1>O<3-delta>, and a ratio of the phase BaCo<0.7>Fe<0.22>Nb<0.08>O<3-delta> to the phase BaZr<0.1>Ce<0.7>Y<0.1>Yb<0.1>O<3-delta> is changeable. The composite cathode material can be used for the medium and low-temperature proton-conductive solid oxide fuel cells. The composite cathode material has the advantages that after the BaCo<0.7>Fe<0.22>Nb<0.08>O<3-delta> and the BaZr<0.1>Ce<0.7>Y<0.1>Yb<0.1>O<3-delta> are composited, the cathode material has oxygen ionic conductivity, proton conductivity and electronic conductivity, a three-phase interface is expanded, the composite cathode material is excellent in electrode performance, the two phases of the composite cathode material are excellent in chemical compatibility and stable in performance, the cathode material is good in electro-catalysis performance owing to the presence of Co in the phase BaCo<0.7>Fe<0.22>Nb<0.08>O<3-delta>, interface resistance of each cell can be reduced, and the working performance of each cell can be improved.

Owner:UNIV OF SCI & TECH BEIJING

Polycrystalline ternary positive electrode material as well as preparation method and application thereof

PendingCN111668476AStrong forceReduce crackingPositive electrodesSecondary cells servicing/maintenanceMetallurgyPhysical chemistry

The invention relates to a polycrystalline ternary positive electrode material as well as a preparation method and application thereof. The polycrystalline ternary positive electrode material comprises secondary particles formed by stacking single crystal primary particles, wherein the single crystal primary particles are in contact with one another to form grain boundaries, and boron elements aredistributed in the grain boundaries. A high-strength B-O-Ni chemical bond is formed between the boron element and the nickel element, so that the acting force between the single crystal primary particles is relatively strong, the contact damage caused by anisotropic volume change between the single crystal primary particles is relieved, and the structural stability is good. The polycrystalline ternary positive electrode material, especially the polycrystalline high-nickel ternary positive electrode material, can slow down the cracking phenomenon in the use process, and has excellent cycle performance.

Owner:EVE ENERGY CO LTD

High-nickel ternary material with cobalt-rich surface layer and preparation method and application thereof

ActiveCN106898751ALamellar structure is stableSmall volume changeCell electrodesSecondary cellsElectrolyteNickel based

The invention discloses a high-nickel ternary material with a cobalt-rich surface layer and a preparation method thereof. The method comprises the following steps: (1) preparing a cobalt chloride solution by spray pyrolysis to obtain porous spherical Co3O4; (2) uniformly mixing the porous spherical Co3O4 with a high-nickel ternary hydroxide precursor and lithium salt, and then sintering the mixture to obtain a nickel-based ternary anode material with the cobalt-rich surface layer. The surface of the anode material has a uniform cobalt-rich coating layer, and reaction of Ni4+ and electrolyte at the position of an interface is reduced. Meanwhile, phase change of H2-H3 is inhibited in charging and discharging processes of the material, volume change of unit cells due to phase change is reduced, therefore, a layer structure of the material is stable, and the cycle performance is improved. The raw materials used in the preparation method are simple and easy to obtain, the process is simple, and the technological process is short.

Owner:CENT SOUTH UNIV

Puddling additive and predation method thereof

The invention relates to a puddling additive which is prepared from the following materials by weight percent: 60-120 percent of boric sludge and 5-40 percent of calcium oxide. Adding the puddling additive in sintering and pellet materials can ensure stable operation of a blast furnace, increase the yield by as high as 6 percent, reduce coke ratio by 35kg / t iron, improve the quality of cast iron, reduce the sulphur content, increase the first-grade product rate, ensure abundant heat of slag iron and favorable flowability, reduce the iron condensing amount of liquid iron in the slag iron runner and liquid iron tank, lower the consumption of metal iron, make it easy to discharge iron slag, reduce the labor intensity for furnace men, reduce the consumption of auxiliary materials such as lime stone and reduce the blowout amount of furnace dust.

Owner:张旭东

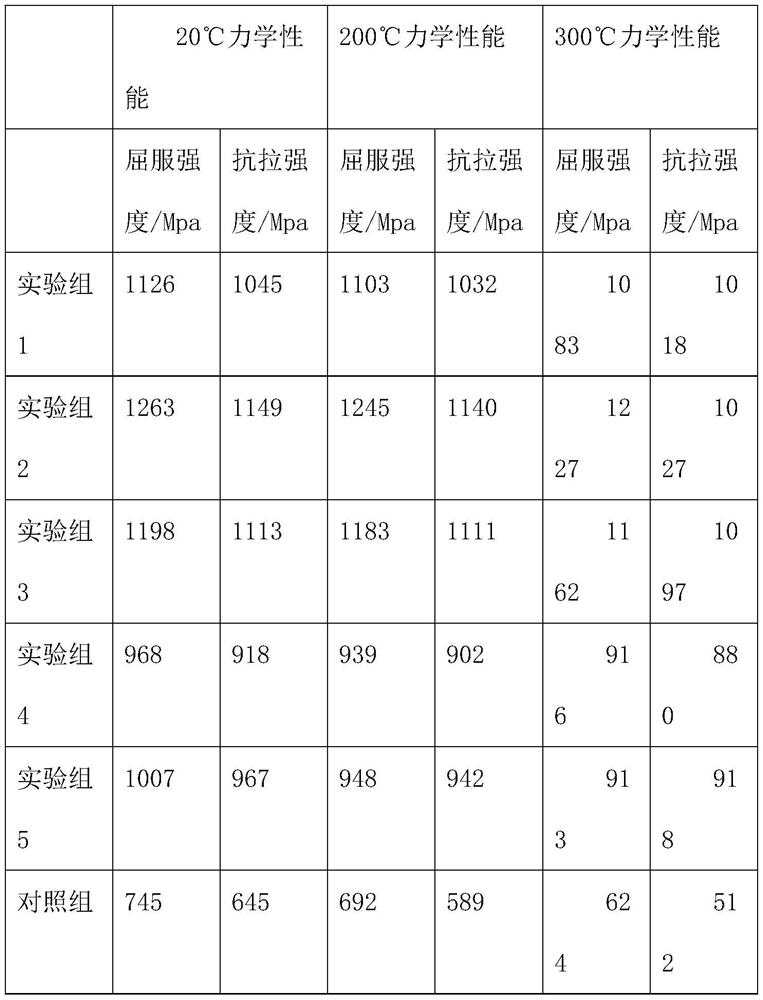

High-strength beryllium-copper alloy bar and preparation process thereof

ActiveCN113174509AHigh strengthGrain refinementFurnace typesHeat treatment furnacesRare-earth elementVanadium atom

The invention discloses a high-strength beryllium-copper alloy bar, and particularly relates to the technical field of beryllium-copper alloys. The high-strength beryllium-copper alloy bar comprises the following elements: Be, Si, Ni, Co, Zr, Ti, V, rare earth elements, and the balance of Cu and inevitable impurities. According to the produced high-strength beryllium-copper alloy bar, nickel, cobalt, zirconium, titanium, vanadium and rare earth elements are added, the addition of nickel and cobalt can refine crystal grains in an alloy material and improve the uniformity of an internal structure, so that the beryllium-copper alloy material has good mechanical properties, zirconium can improve the softening temperature of the beryllium-copper alloy and refine recrystallized crystal grains, and titanium can effectively enhance the strength of the beryllium-copper alloy, the vanadium can purify, deteriorate and refine crystal grains and can improve the wear resistance of the beryllium-copper alloy bar, and the rare earth elements can refine the crystal grains to make the crystal grains uniform and can effectively improve the strength and corrosion resistance of the beryllium-copper alloy bar. The practicability of the beryllium-copper alloy bar can be improved, and the beryllium-copper alloy bar can meet the use requirements of people.

Owner:江阴金湾合金材料有限公司

Lithium cobalt oxide material and preparation method thereof as well as anode material

ActiveCN106784739AImproved magnification performanceImprove cycle performanceCell electrodesSecondary cellsRare-earth elementHigh pressure

The invention provides a lithium cobalt oxide material and a preparation method thereof as well as an anode material. The lithium cobalt oxide material is mainly prepared from an element M doped lithium cobalt oxide particle and a coating which coats the surface of the lithium cobalt oxide particle; the molecular formula of the lithium cobalt oxide particle is LiaCo1-bMbO2, wherein a is not less than 0.95 but not more than 1.15; b is not less than 0.003 but not more than 0.01; M is at least one or several of Mg, Al, Ti, Zr, Ni, Mn, Cr, Mo, W and a rare earth element; the coating is selected from one or a mixture of ZnO and SnO2, and has a weight which is 0.5wt% to 5 wt%, preferably 1wt% to 5wt%, preferably 2wt% to 5wt% and preferably 2wt% to 4wt%, of that of the lithium cobalt oxide particle. By using the lithium cobalt oxide material, the problems that the rate capability and the cycle performance of an existing material are poor under high pressure are solved.

Owner:HUNAN RESHINE NEW MATERIAL

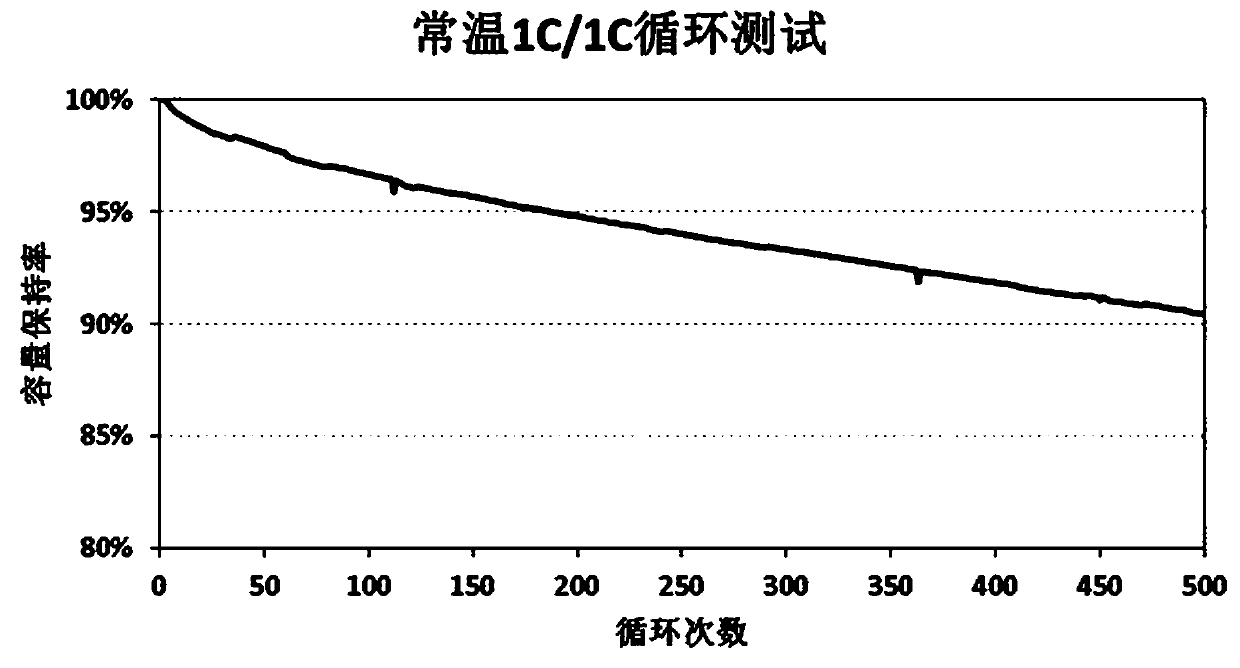

Lithium ion battery electrolyte suitable for NCM811 and SiO-C material system and preparation method

ActiveCN110600804AImprove cycle performancePromote circulationSecondary cellsDifluorophosphateSolid state electrolyte

The invention discloses a lithium ion battery electrolyte suitable for a NCM811 and SiO-C material system and a preparation method. In the electrolyte of the present invention, an organic solvent composed of ethyl methyl carbonate, diethyl carbonate, and ethylene carbonate, a lithium salt composed of lithium hexafluorophosphate and lithium difluorophosphate, and an additive composed of vinylene carbonate, fluoroethylene carbonate, ethylene sulfate, and 1,3-propane sultone are compounded in a certain proportion, and cooperate to react, during a lithium ion battery cycle, on the surface of NCM811 and SiO-C and form a stable solid electrolyte protective film to prevent direct contact between the electrolyte and NCM811 and SiO, thereby reducing the side reactions between the electrode and theelectrolyte, and reducing the phase transition and volume change of the material, and further improving the cycling performance of the lithium ion battery. Experimental results show that by using theelectrolyte of the present invention, the lithium ions of the NCM811 and SiO-C material system has a capacity retention rate of more than 90% after 500 cycles of 1C / 1C at room temperature, and has excellent cycle performance.

Owner:SHENZHEN BAK POWER BATTERY CO LTD

Method for preparing Mo-ZrO2 metal ceramic electrode by utilizing sol-gel method

InactiveCN102896317ALow costImprove conductivityTurbinesOther manufacturing equipments/toolsMuffle furnaceVacuum drying

The invention discloses a method for preparing a Mo-ZrO2 metal ceramic electrode by utilizing a sol-gel method. The method comprises the following steps: utilizing ammonium molybdate, zirconium nitrate, citric acid and nitric acid or ammonia water to adjust pH value; preparing a sol in 80-90 DEG C water bath; realizing the conversion from sol to gel after aging for a period of time; placing the gel into a vacuum drying oven and drying for 3-4h, wherein the drying temperature is above 100 DEG C, but cannot be too high and generally is within a scope of 110-130 DEG C; firing the dry gel in a muffle furnace, thereby forming a mixture of molybdenum oxide and zirconium oxide; reducing for 2-3 hours in a hydrogen furnace respectively at 560-580 DEG C and at 960-980 DEG C; cold-pressing and molding the reduced molybdenum and zirconium oxide compound material under a pressure; and firing and forming in an inert gas shielding furnace. According to the method, the molybdenum and the zirconium oxide are more uniformly mixed, a netted structure formed by the metal molybdenum is benefited and the conductivity is further promoted.

Owner:SHANGHAI UNIV

Surface-modified lithium-rich layered transition metal oxide as well as preparation method and application thereof

ActiveCN111081994AImprove structural stabilityImprove cycle stabilitySecondary cellsPositive electrodesMolten saltBattery cell

The invention belongs to the technical field of lithium ion battery anode materials, and discloses a surface-modified lithium-rich layered transition metal oxide as well as a preparation method and application thereof. The surface-modified lithium-rich layered transition metal oxide is prepared by the following steps that: a transition metal compound precursor, a lithium source and molten salt aremixed, and an obtained mixture is heated to 780-980 DEG C, is cooled to room temperature, cleaning, filtering and drying are performed, so that a lithium-rich layered transition metal oxide can be obtained; and the lithium-rich layered transition metal oxide is uniformly mixed with a carbon-nitrogen source, the mixture is placed in a protective atmosphere so as to be subjected to a hydrothermal reaction at 130-230 DEG C, an obtained product naturally cools, water washing, suction filtration, and drying are performed, so that the surface-modified lithium-rich layered transition metal oxide canbe obtained. The structure of the surface-modified lithium-rich layered transition metal oxide sequentially comprises the lithium-rich layered transition metal oxide, an oxygen vacancy-rich lithium-rich layered transition metal oxide-spinel structure oxide symbiotic layer and a nitrogen-doped carbon nano layer. The surface-modified lithium-rich layered transition metal oxide shows relatively highspecific discharge capacity and cycling stability as an anode material.

Owner:GUANGDONG UNIV OF TECH

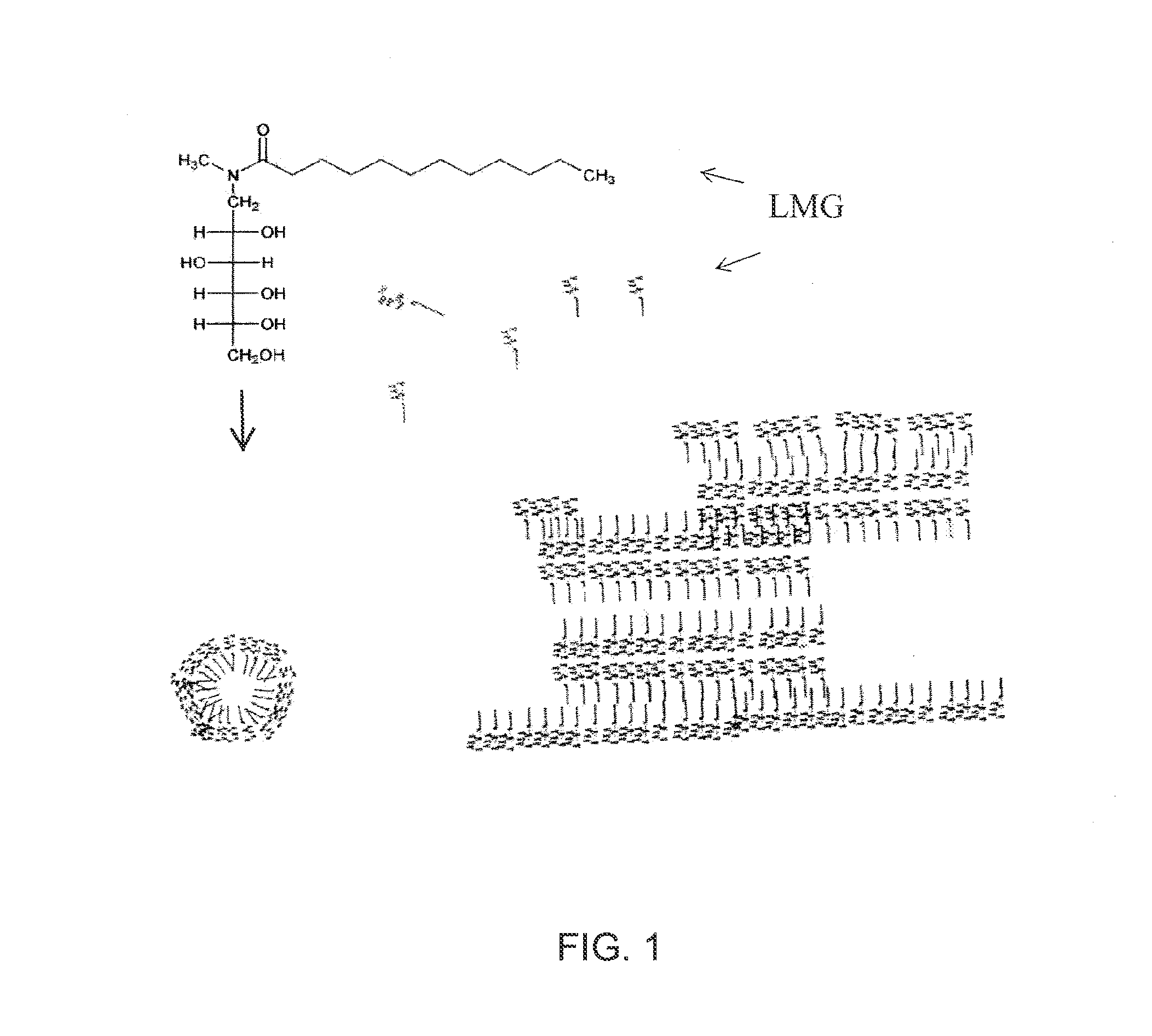

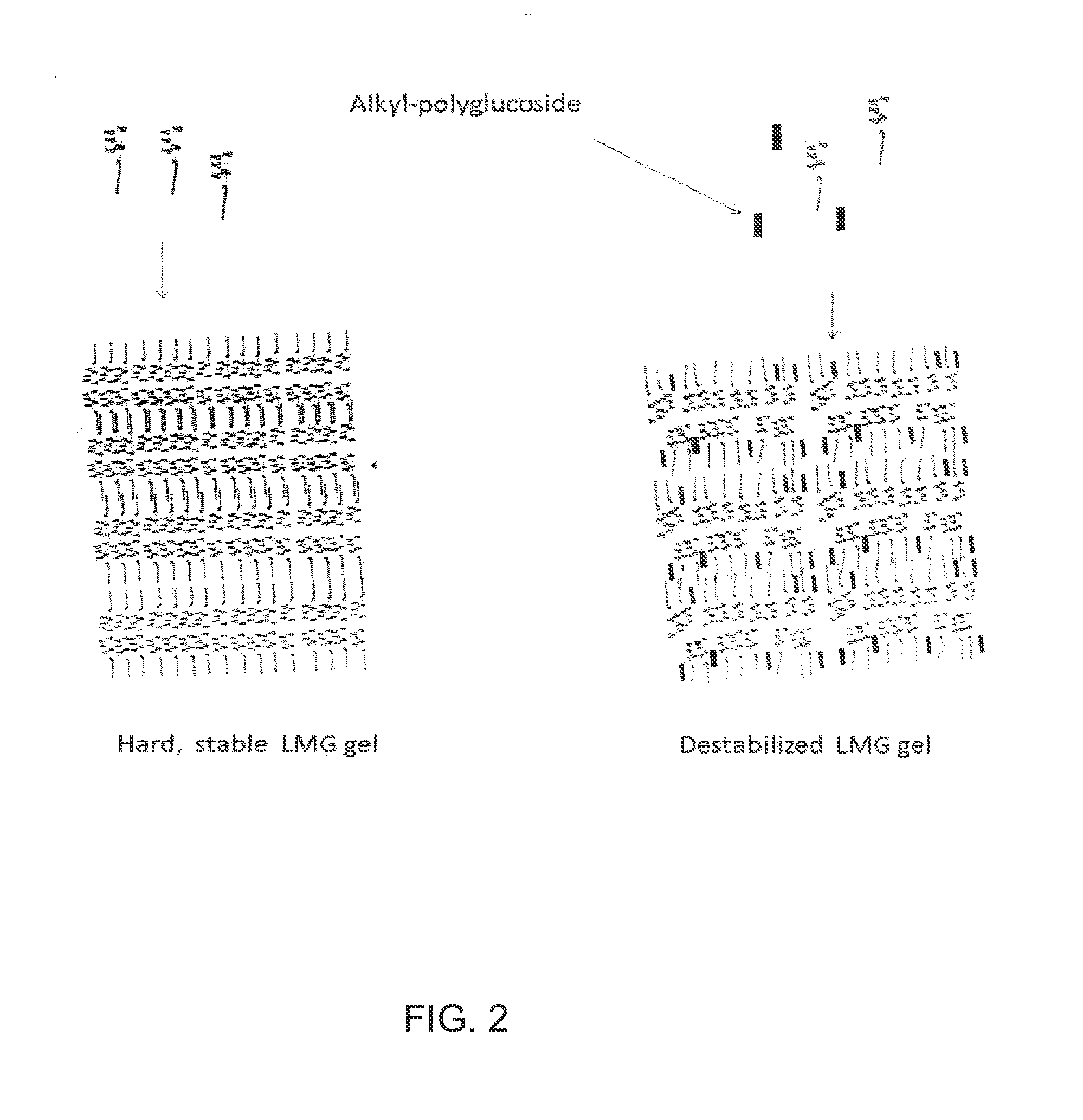

Liquid non-ionic salt-free skin and hair treatment composition that contains n-methyl lauroyl glucamide

ActiveUS20140242018A1Simple methodInhibition of phase transitionCosmetic preparationsBiocideGlycosideSalt free

Compositions and methods for of their use in treating human or other mammalian skin and hair. Non-ionic, salt-free non-solidifying formulations of Lauroyl N methyl-C10, C12, C14, C16 alkanoyl-N-methyl-glucamide and alkyl glycosides are disclosed that impart beneficial barrier properties to skin and hair.

Owner:FORMULA XO

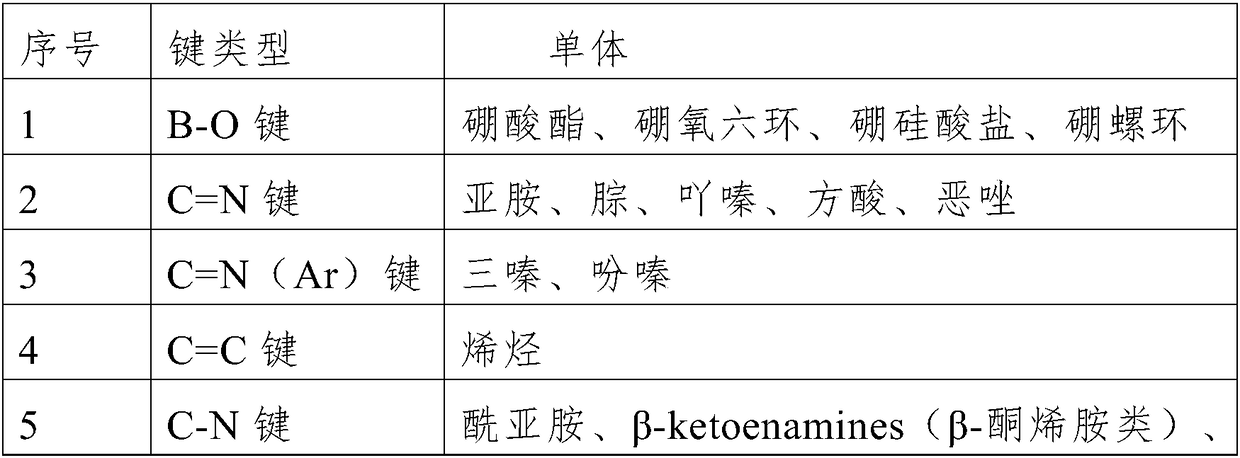

Lithium-rich manganese-based cathode material coated with composite carbon material and preparation method thereof, and lithium battery

ActiveCN109167042AImprove conductivityImproved magnification performanceCell electrodesSecondary cellsPorous carbonManganese

The invention relates to a lithium-rich manganese-based cathode material coated with a composite carbon material derived from a COFs material containing at least one element of N and B, and a preparation method thereof, and a lithium battery, wherein the surface of the lithium-rich manganese-based cathode material is coated with a composite carbon material. The lithium-rich manganese-based cathodematerial coated with the composite carbon material can obviously improve the conductivity of the material and the rate performance and cycle performance of the battery containing the composite carbonmaterial, and the composite carbon material is coated more uniformly. The invention adopts a simple one-step carbonization method to prepare a composite porous carbon material coated with a lithium-rich manganese-based cathode material, the prepared porous carbon has controllable specific surface area and pore size, and the preparation method is simple and efficient, and is suitable for large-scale preparation and synthesis.

Owner:桑德新能源技术开发有限公司 +1

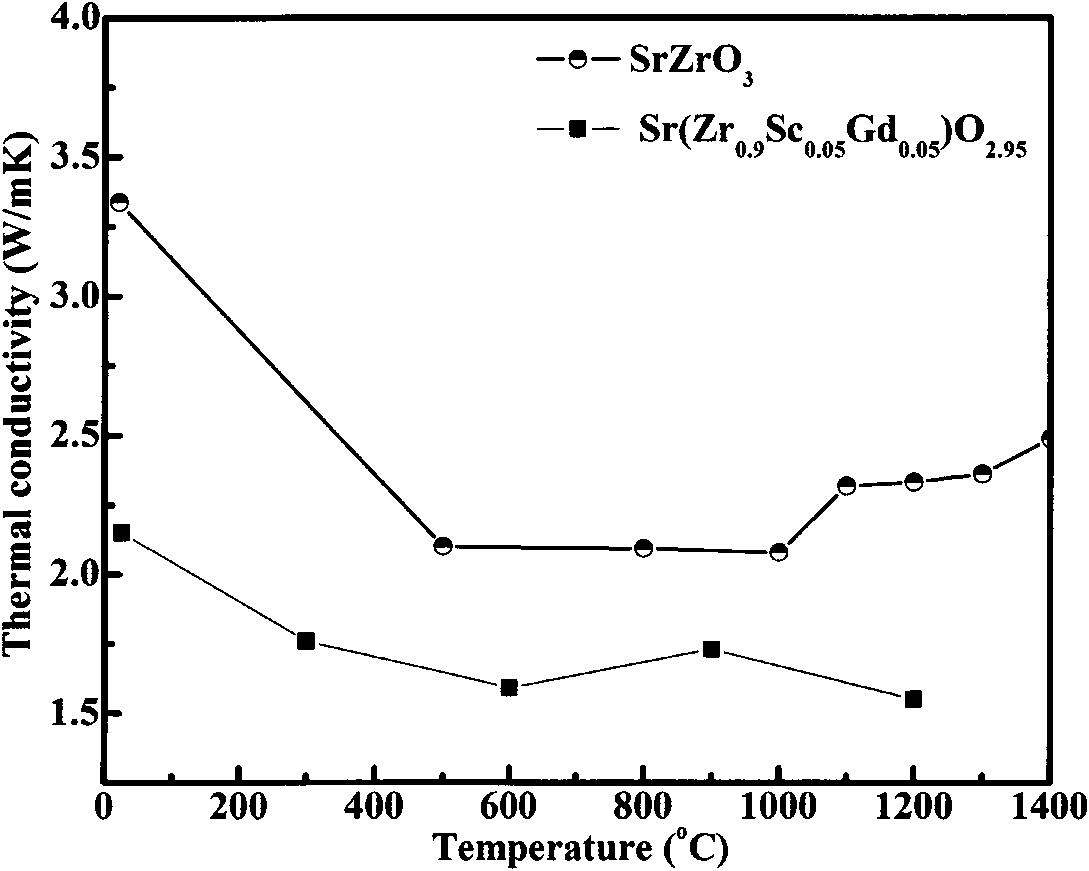

Ceramic high-temperature insulation material

The invention discloses a ceramic high-temperature insulation material. The material has a chemical formula of Sr1+w(A1-xB'yB''z)O3+delta, wherein A is Zr or Hf or a combination of the Zr or the Hf; B' is one or a combination of more than one of Ta, Nb, Ti or Sc; and B'' is La, Ce, Nd, Sm, Eu, Gd, Dy, Er, Yb, Lu, Y and is one or a combination of more than one of Al, Cr, Co and Ni. A multi-metal oxide-modified perovskite structure ceramic material which has the characteristics of low thermal conductivity and high phase stability is obtained by codoping a plurality of metal oxides.

Owner:INNER MONGOLIA UNIV OF TECH

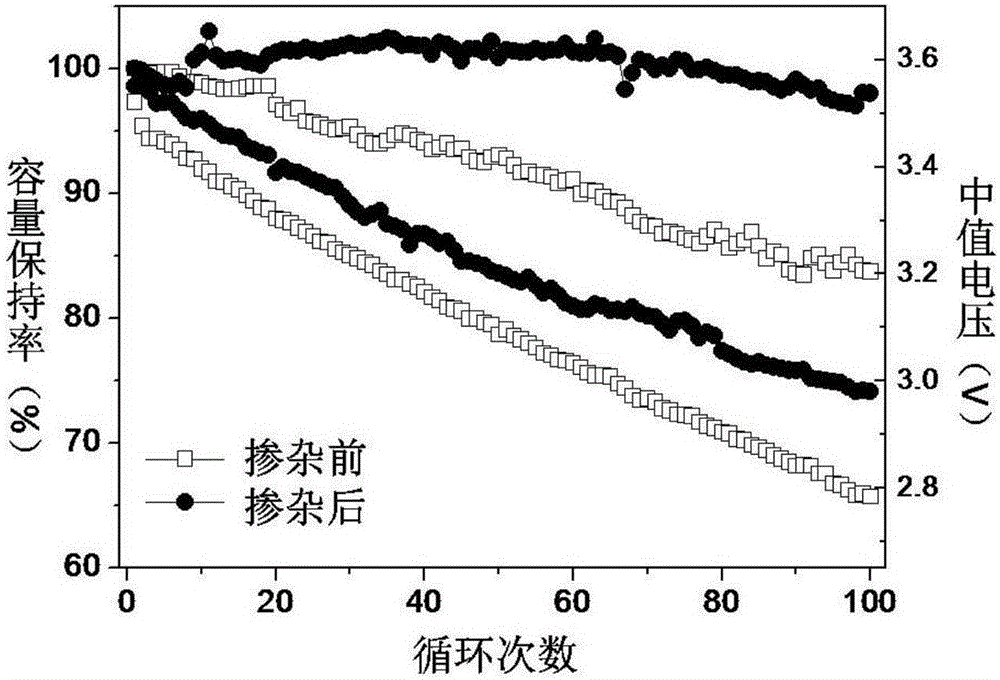

Preparation method of Mg and Ti composite doped lithium-rich manganese based positive electrode material

ActiveCN106711439AImprove cycle lifeMedian voltage dropCell electrodesSecondary cellsSurface layerManganese

The invention discloses a preparation method of an Mg and Ti composite doped lithium-rich manganese based positive electrode material, and belongs to the field of positive electrode materials of lithium ion batteries. A co-precipitation method is used for preparing a lithium-rich precursor, and Mg and Ti elements are added step by step for doping in the precursor co-precipitation preparing process. The preparation method comprises the following steps: adding the Ti element in the first half of a co-precipitation reaction, adding the Mg element in the latter half of the co-precipitation reaction, making the Ti element mainly distributed in a bulk phase, and making the Mg element mainly distributed in a surface layer of the precursor. The material properties are improved by controlling the distribution of the doping elements, so that on one hand, the doping amount of the doping elements can be reduced so as to improve the capacity per gram, and on the other hand, the functions of the two elements can be fully played, the effect superposition is achieved, and the interference between the elements during co-doping is reduced. At the same time, the preparation method is simple and is easy to industrialize.

Owner:HEFEI GUOXUAN HIGH TECH POWER ENERGY

Doped high-nickel high-voltage NCM positive electrode material and preparation method thereof

PendingCN110797529AReduce consumptionIncrease profitCell electrodesSecondary cellsHigh energyManganese

The invention discloses a doped high-nickel high-voltage NCM positive electrode material and a preparation method thereof, and belongs to the field of lithium ion batteries. The preparation method comprises the following steps: simultaneously doping manganese and cobalt to obtain an NCM precursor; and adding a dopant M into the precursor, and sintering the precursor in a high-pressure oxygen atmosphere to obtain a lithium ion battery positive electrode material. The positive electrode material has very high specific discharge capacity and excellent cycling stability, can meet the high-rate charging and discharging requirement, and can achieve long-life safe cycling under high voltage. The positive electrode material is prepared by combining four-solution parallel-flow co-precipitation witha high-pressure solid-phase synthesis method, and the prepared product has the advantages of high purity, high crystallization quality, high particle density, uniform distribution of particles, excellent electrochemical performance and low manufacturing cost, is an ideal positive electrode material with high energy density, and has a wide application prospect.

Owner:SICHUAN FUHUA NEW ENERGY HIGH TECH CO LTD

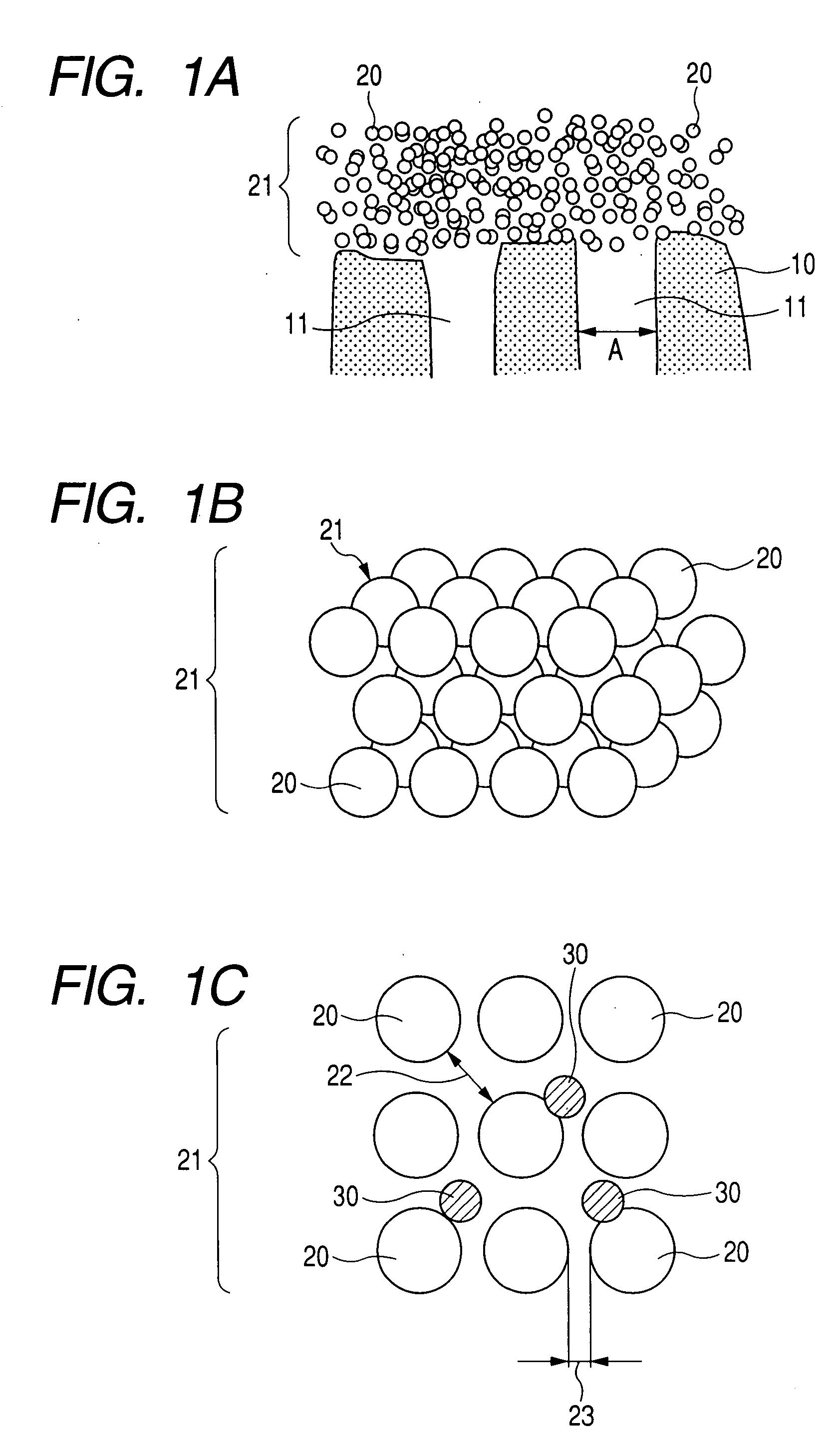

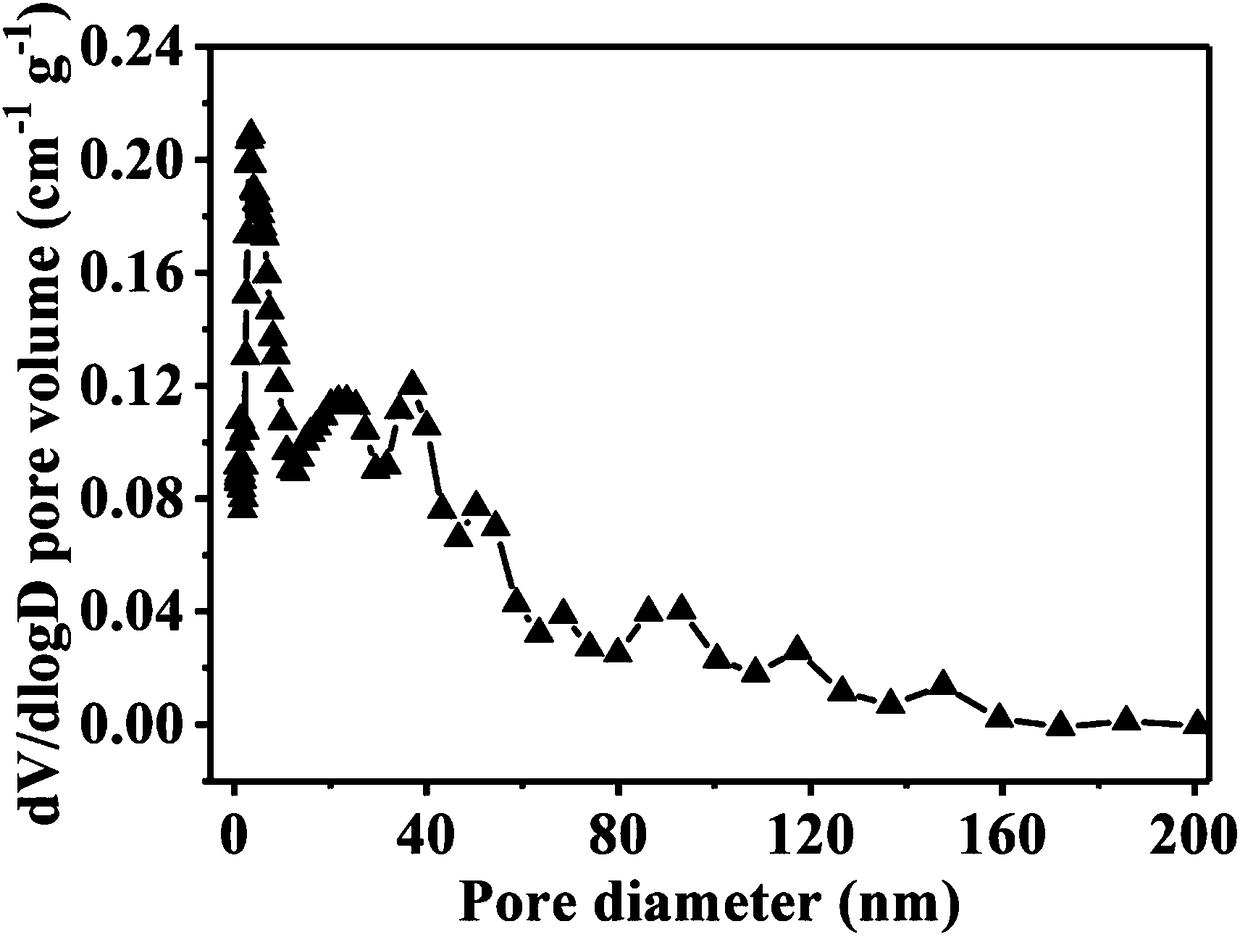

Method of producing catalyst support particles and a catalyzer using the catalyst support particles

InactiveUS20070281856A1Slow changeImprove heat resistanceMaterial nanotechnologyAluminium compoundsHeat resistanceHeat treated

Catalyst support particles and a catalyzer are produced by using γ-alumina particles or alumina precursor particles treated in advance by hydrothermal treatment in an autoclave. Performing the hydrothermal treatment improves the thermal resistance of the alumina particles because of suppressing deformation of the alumina particles when used at a high temperature such as 1000° C.

Owner:DENSO CORP

Three-dimensional porous graphene-vanadium disulfide composite electrode material, and preparation method and application thereof

ActiveCN108597908AImprove conductivityAvoid volumeHybrid capacitor electrodesHybrid/EDL manufactureIonCvd graphene

The invention provides a three-dimensional porous graphene-vanadium disulfide composite electrode material, and a preparation method and an application thereof. The composite electrode material comprises porous graphene oxide and vanadium disulfide coated with porous graphene oxide. The composite electrode material adopts porous graphene oxide for coating vanadium disulfide, and porous graphene oxide provides more ionic channels and larger specific surface area, so that ion storage and transportation can be performed conveniently; by virtue of porous graphene oxide, electrical conductivity ofvanadium disulfide can be improved, so that the problems of volume expansion and phase change of vanadium disulfide in the charging-discharging processes can be suppressed; meanwhile, vanadium disulfide can provide pseudocapacitance, so that relatively high specific capacity and rate performance can be realized; the composite electrode material shows high capacitance characteristic in a supercapacitor; and by virtue of the three-dimensional macro body of the composite electrode material, stability of the composite material can be obviously reinforced.

Owner:GUANGDONG UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com