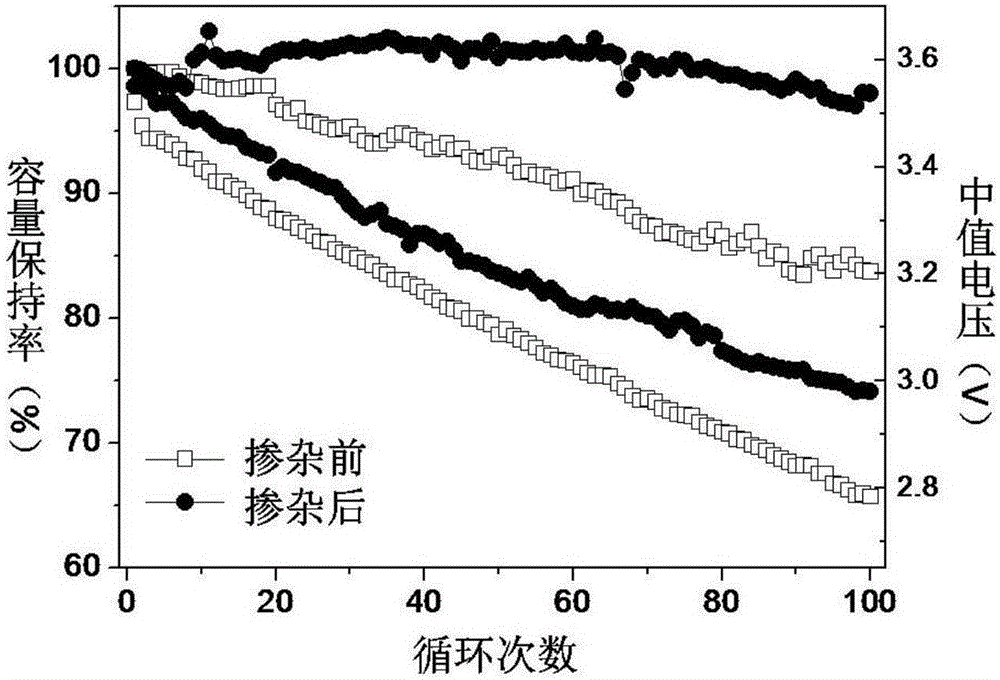

Preparation method of Mg and Ti composite doped lithium-rich manganese based positive electrode material

A lithium-rich manganese-based, positive electrode material technology, applied in the direction of battery electrodes, structural parts, electrical components, etc., can solve the problem of material capacity reduction, etc., to achieve the effect of low dosage, suppressed median voltage drop, and slow median voltage drop

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Embodiment 1: prepare Li 1.17 mn 0.55 Ni 0.16 co 0.08 Mg 0.003 Ti 0.016 o 2

[0027] like figure 1 As shown, prepare a metal sulfate solution with a molar ratio of Ni, Co, and Mn of 2:1:7, divide the metal salt solution into two parts with a volume ratio of 95:5, and add a certain amount of titanic acid to one part of 95% volume Tetrabutyl ester, so that the Ti element accounts for 1% of the total mass of the precursor, a certain amount of magnesium nitrate is added to a part of 5% volume, so that the Mg element accounts for 0.1% of the total mass of the precursor, and the Ti-containing mixed solution is first added to the reaction In the kettle, add a certain concentration of sodium hydroxide and ammonia solution at the same time, add ammonia and salt solution dropwise at a constant speed, control the pH of the reaction to 10.0-10.8, and control the reaction temperature to 50-60°C; after all the mixed solutions containing Ti are added , add the mixed solution c...

Embodiment 2

[0028] Embodiment 2: prepare Li 1.20 mn 0.55 Ni 0.16 co 0.08 Mg 0.03 Ti 0.001 o 2

[0029]Prepare a metal sulfate solution with a molar ratio of Ni, Co, and Mn of 2:1:7, divide the metal salt solution into two parts with a volume ratio of 60:40, and add a certain amount of tetrabutyl titanate to one part of 60% volume , so that the Ti element accounts for 0.05% of the total mass of the precursor, and a certain amount of magnesium nitrate is added to a part of 40% volume, so that the Mg element accounts for 1% of the total mass of the precursor, and the mixed solution containing Ti is first added to the reaction kettle, Add a certain concentration of sodium hydroxide and ammonia solution at the same time, add ammonia and salt solution dropwise at a constant speed, control the pH of the reaction to 10.0-10.8, and control the reaction temperature to 50-60°C; after all the mixed solution containing Ti is added, add the solution containing Mg mixed solution, the control cond...

Embodiment 3

[0030] Embodiment 3: prepare Li 1.20 mn 0.56 Ni 0.16 co 0.08 Mg 0.01 Ti 0.001 o 2

[0031] Prepare a metal sulfate solution with a molar ratio of Ni, Co, and Mn of 2:1:7, divide the metal salt solution into two parts with a volume ratio of 80:20, and add a certain amount of tetrabutyl titanate to one part of 80% volume , so that the Ti element accounts for 0.05% of the total mass of the precursor, and a certain amount of magnesium nitrate is added to a part of 20% volume, so that the Mg element accounts for 0.3% of the total mass of the precursor, and the Ti-containing mixed solution is first added to the reaction kettle, Add a certain concentration of sodium hydroxide and ammonia solution at the same time, add ammonia and salt solution dropwise at a constant speed, control the pH of the reaction to 10.0-10.8, and control the reaction temperature to 50-60°C; after all the mixed solution containing Ti is added, add the solution containing Mg mixed solution, the control c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com