Lithium cobalt oxide material and preparation method thereof as well as anode material

A lithium cobalt oxide and cobalt source technology, which is applied in chemical instruments and methods, battery electrodes, cobalt compounds, etc., can solve the problems of poor rate and cycle performance under high pressure, improve electrical conductivity and processing performance, and expand the scope of application , Improve the effect of magnification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

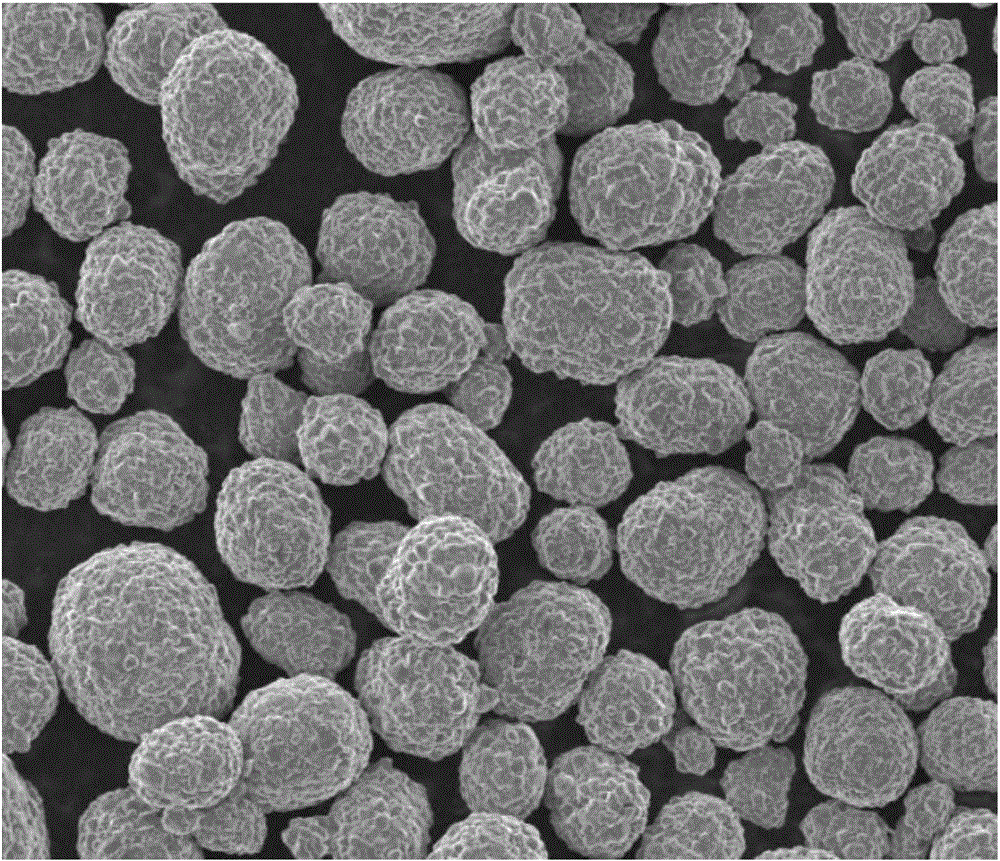

Image

Examples

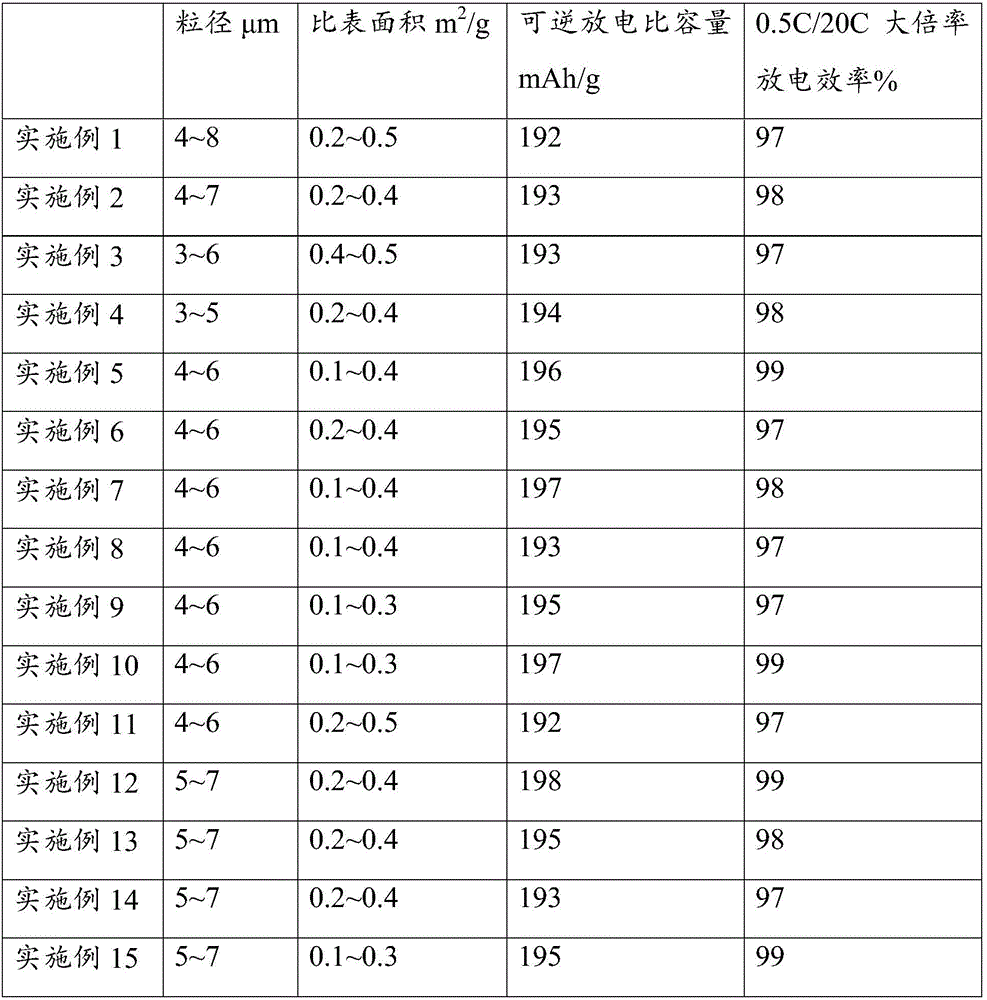

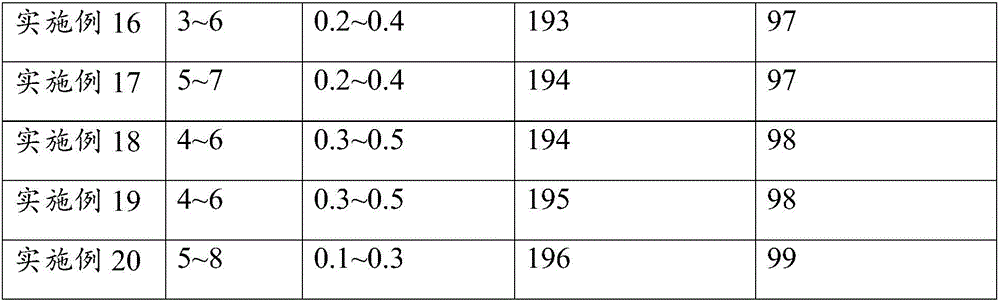

Embodiment 1

[0047] Make lithium cobalt oxide material, the chemical formula is Li 0.95 co 0.99 Mg 0.01 o 2

[0048] (1) Batching battery-grade cobalt tetroxide, battery-grade lithium nitrate and doping element MgO according to the preset stoichiometric ratio, and then performing sand grinding in a sand mill, adding a certain amount of pure water to the raw material sand grinding, The scope of solid content is 10wt%, will add the stearamide of 0.02wt% (compared with the mass sum of sanding raw materials) in the sanding process, through certain sanding time, the particle size of slurry reaches 0.1~ 0.5μm, stop the sanding, release the sanding slurry into a bucket with stirring (turn on the stirring, so that all parts of the slurry are in a uniform state), and wait for the next step.

[0049] (2) The slurry obtained in the step (1) is subjected to spray granulation to prepare a lithium cobaltate precursor with a spherical small particle size, the particle size is between 2 and 7 μm, and ...

Embodiment 2

[0055] Make lithium cobalt oxide material, the chemical formula is Li a co 1-b m b o 2

[0056] The difference from Example 1 is that the lithium cobalt oxide precursor is heat-treated before coating, and the process is as follows.

[0057] (1) Batching battery-grade cobalt tetroxide, battery-grade lithium nitrate and doping element MgO according to the preset stoichiometric ratio, and then performing sand grinding in a sand mill, adding a certain amount of pure water to the raw material sand grinding, The scope of solid content is 10wt%, will add the stearamide of 0.02wt% (compared with the mass sum of sanding raw materials) in the sanding process, through certain sanding time, the particle size of slurry reaches 0.1~ 0.5μm, stop the sanding, release the sanding slurry into a bucket with stirring (turn on the stirring, so that all parts of the slurry are in a uniform state), and wait for the next step.

[0058] (2) The slurry obtained in the step (1) is subjected to spra...

Embodiment 3-7

[0064] The difference from Example 1 is only that the doping elements and proportions are different, and the molecular formulas of the lithium cobaltate particles are respectively Li 1.15 co 0.997 Al 0.003 o 2 , Li 1.05 co 0.997 Mg 0.001 Al 0.001 Ti 0.001 o 2 , Li 1.1 co 0.99 Mg 0.004 Al 0.004 Ti 0.002 o 2 , Li 1.05 co 0.992 Ni 0.002 mn 0.004 Cr 0.002 o 2 , Li 1.05 co 0.991 Ni 0.003 mn 0.003 Cr 0.003 o 2 , the rest of the formula and process are the same.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com