Lithium ion battery electrolyte suitable for NCM811 and SiO-C material system and preparation method

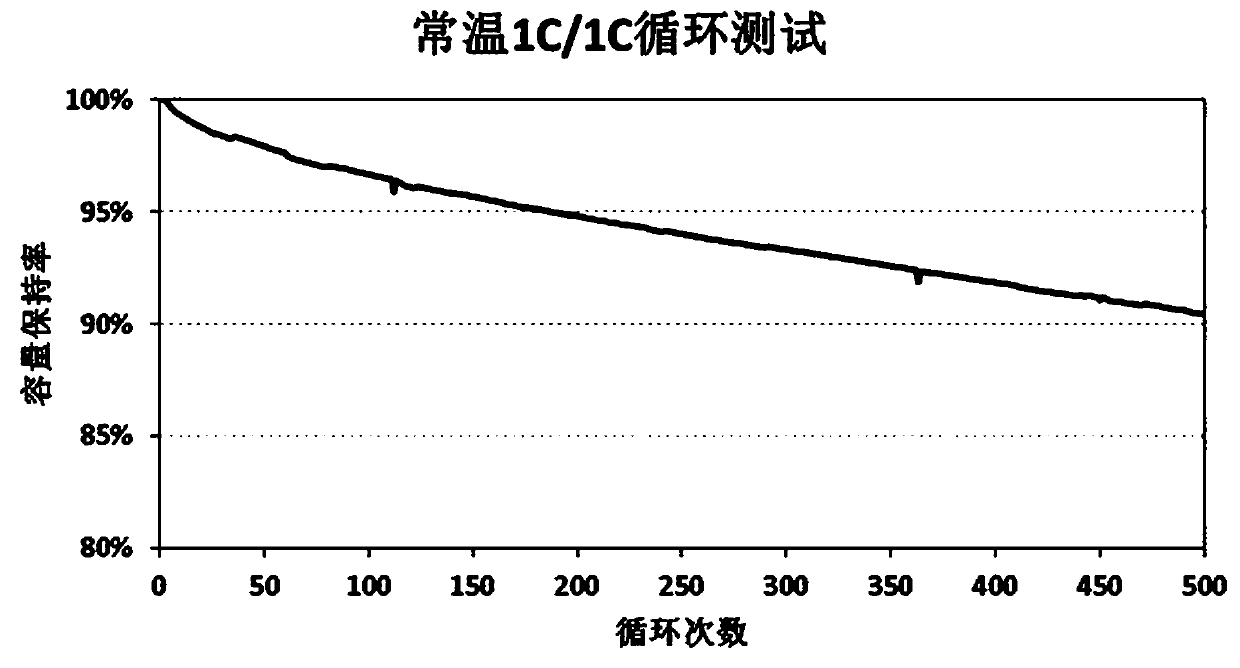

A lithium-ion battery and electrolyte technology, which is applied in secondary batteries, circuits, electrical components, etc., can solve the problems of inability to form a stable solid-state electrolyte film, low cycle stability, and capacity decay, so as to alleviate the phase transition of materials and metal Effects of ion dissolution, excellent cycle performance, and low orbital energy level

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0036] In a second aspect, the present invention provides a method for preparing a lithium-ion battery electrolyte suitable for NCM811 and SiO-C material systems, comprising the following steps:

[0037] Step 1. In a glove box filled with argon and moisture less than 2 ppm, respectively add ethyl methyl carbonate, diethyl carbonate, and ethylene carbonate into the reaction vessel and stir well to obtain mixed solvent 1;

[0038] Step 2. Slowly add lithium hexafluorophosphate and lithium difluorophosphate into the above-mentioned mixed solvent 1 in a glove box filled with argon gas and the water content is less than 2 ppm, and stir well in the reaction vessel to obtain mixed solution 2;

[0039] Step 3. In a glove box filled with argon and moisture less than 2 ppm, vinylene carbonate, fluoroethylene carbonate, vinyl sulfate, and 1,3-propane sultone were added to the above mixed solution 2 respectively, and the Stir well in the reaction vessel evenly, and transfer it into a stor...

Embodiment 1

[0042] The lithium-ion battery electrolyte suitable for NCM811 and SiO-C material systems is made of the following components in proportion by weight: 86 parts of organic solvent, 13.2 parts of lithium salt and 9.6 parts of additives.

[0043] The organic solvent is composed of ethyl methyl carbonate, diethyl carbonate and ethylene carbonate; the mass ratio of the ethyl methyl carbonate, diethyl carbonate and ethylene carbonate is 42:25:19.

[0044] The lithium salt is composed of lithium hexafluorophosphate and lithium difluorophosphate; the mass ratio of lithium hexafluorophosphate to lithium difluorophosphate is 12:1.2.

[0045] The additive is composed of vinylene carbonate, fluoroethylene carbonate, vinyl sulfate and 1,3-propane sultone; the vinylene carbonate, fluoroethylene carbonate, vinyl sulfate and 1,3 - The mass ratio of propane sultone is 1.1:6:1.3:1.2.

[0046] Wherein, based on the total mass of the SiO—C material, the mass content of SiO is 5%.

[0047] The p...

Embodiment 2

[0052] The lithium-ion battery electrolyte suitable for NCM811 and SiO-C material systems is made of the following components by weight: 76 parts of organic solvent, 16 parts of lithium salt and 8 parts of additives.

[0053] The organic solvent is composed of ethyl methyl carbonate, diethyl carbonate and ethylene carbonate; the mass ratio of the ethyl methyl carbonate, diethyl carbonate and ethylene carbonate is 40:20:16.

[0054] The lithium salt is composed of lithium hexafluorophosphate and lithium difluorophosphate; the mass ratio of lithium hexafluorophosphate to lithium difluorophosphate is 14:2.

[0055] The additive is composed of vinylene carbonate, fluoroethylene carbonate, vinyl sulfate and 1,3-propane sultone; the vinylene carbonate, fluoroethylene carbonate, vinyl sulfate and 1,3 - The mass ratio of propane sultone is 1:5:1:1.

[0056] Wherein, based on the total mass of the SiO—C material, the mass content of SiO is 5%.

[0057] The preparation method of the l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com