Alumina in high hydrothermal stability, and preparation method

A technology of spherical alumina and thermal stability, applied in the preparation of alumina/hydroxide, alumina/aluminum hydroxide, etc. The effect of thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] A. Preparation of spherical alumina

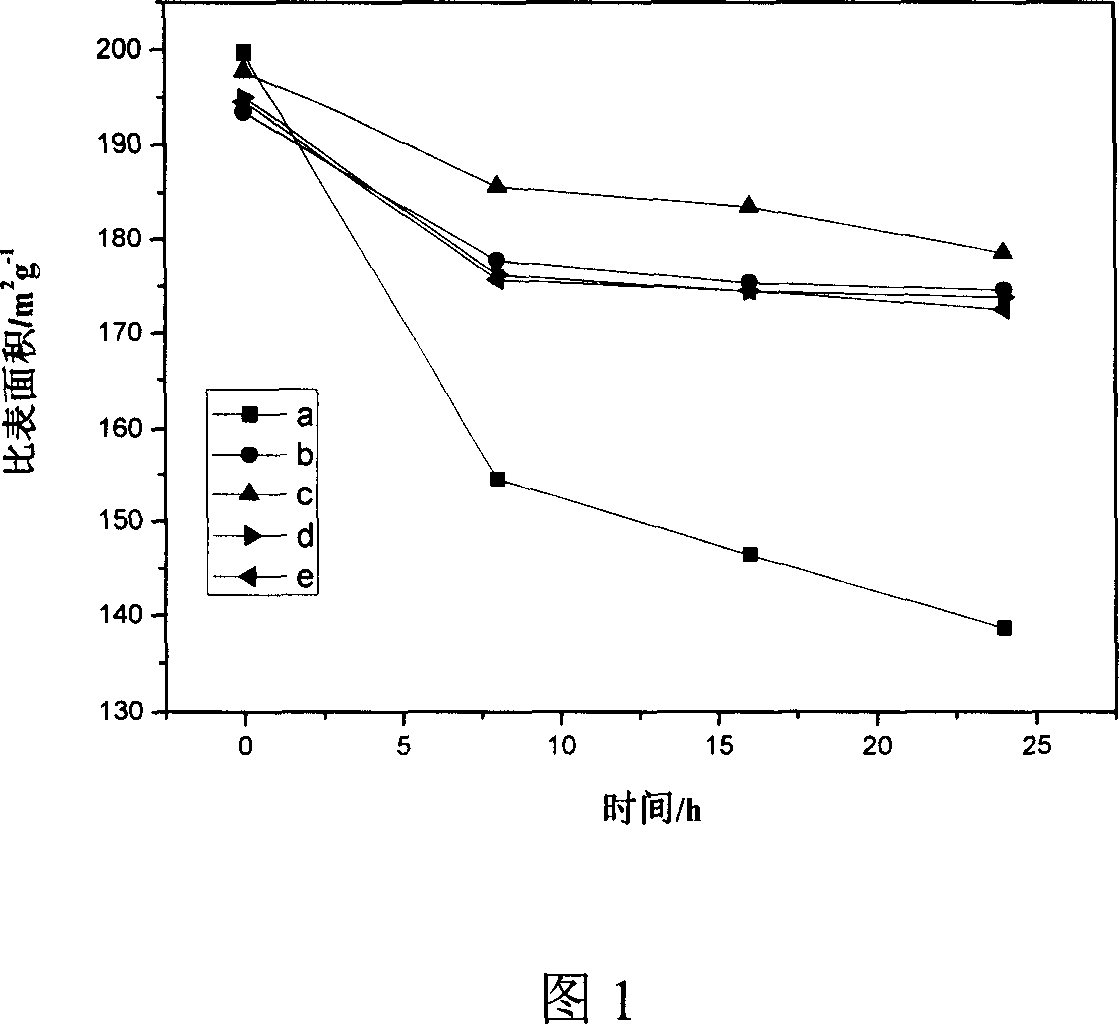

[0027] Dissolve 30g of aluminum powder with a particle size of 50μm in 250g of 10% hydrochloric acid to prepare aluminum sol, and dissolve 20g of hexamethylenetetramine in 55g of deionized water to prepare a coagulant solution. Drop into molding oil at 70°C for molding, separate the shaped pellets from the oil, age at 130°C for 5 hours, wash the obtained product, dry at 120°C for 10 hours, and roast at 600°C for 6 hours to obtain spherical alumina . After measurement, the specific surface area of the obtained spherical alumina is 199.77m 2 / g, the pore volume is 0.85ml / g, the particle diameter is 1.5mm, and the bulk density is 0.5g / cm 3 .

[0028] B. Surface modification

[0029] 0.0541g (NH 4 ) 3 PO 4 ·3H 2 O was dissolved in 5ml of deionized water to form a solution, and 3 g of spherical alumina obtained in step A was immersed in the solution for 4 hours, and the solution was poured out; the spherical alumina was dried a...

Embodiment 2

[0032] 0.1073g (NH 4 ) 3 PO 4 ·3H 2 O was dissolved in 5ml of deionized water to form a solution, 3 g of the spherical alumina obtained in step A of Example 1 was immersed in the solution for 4 hours, and the solution was poured out; the spherical alumina was dried at 100 ° C for 8 hours, 550 ℃ for 4 hours to obtain modified spherical alumina. where P 2 o 5 The mass percent content is 1.25%. After 24h hydrothermal treatment, the specific surface area of the sample is 178.57m 2 / g.

Embodiment 3

[0034] 0.2147g (NH 4 ) 3 PO 4 ·3H 2 O was dissolved in 6ml of deionized water to form a solution, and 3 g of the spherical alumina obtained in step A of Example 1 was immersed in the solution for 5 hours, and the solution was poured out; the spherical alumina was dried at 110° C. for 10 hours, and then dried at 600 ℃ roasting for 5 hours to obtain modified spherical alumina, where P 2 o 5 The mass percent content is 2.5%. After 24h hydrothermal treatment, the specific surface area of the sample is 173.9m 2 / g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com