Composite cathode material for medium and low-temperature proton-conductive solid oxide fuel cells

A solid oxide and composite cathode technology, applied in battery electrodes, circuits, electrical components, etc., can solve the problems of electrode performance impact, proton transmission limitation, low ion conductivity, etc., and achieve the improvement of electrode performance, high oxygen Effects of ion conductivity and high electrocatalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

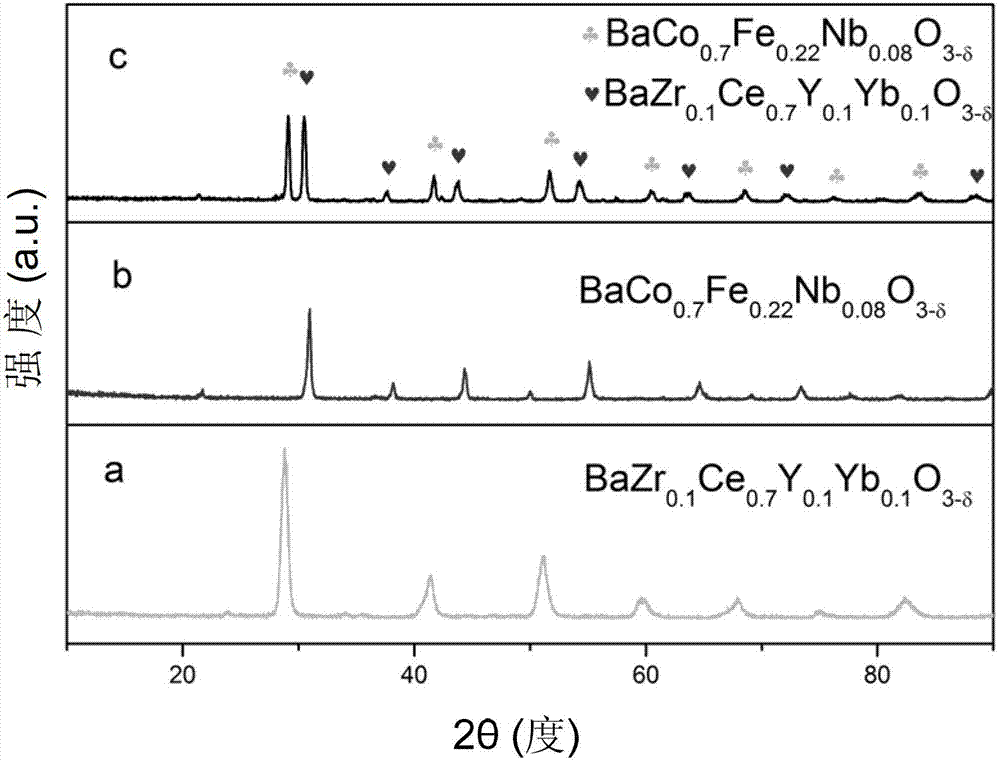

[0019] Example 1: BaCo 0.7 Fe 0.22 Nb 0.08 o 3-δ Synthesis and chemical compatibility test of 50 wt% composite cathode material

[0020] By BaCo 0.7 Fe 0.22 Nb 0.08 o 3-δ The stoichiometric ratio, weigh an appropriate amount of BaCO 3 , Nb 2 o 5 , Fe 2 o 3 , Co(CH 3 COO) 2 4H 2 O is the raw material, using alcohol as the medium, put the raw material mixture into ZrO 2 Ball milled in a ball mill tank for 6 hours at a speed of 400 r / min to mix the raw materials evenly, put the suspension of the mixture in a glass dish, dry it in an oven, and pass through 1100 o C heat treatment for 10 h to obtain a pure-phase perovskite structure oxide, and then put the obtained oxide into a ball mill jar for grinding for 4 h to obtain a finer powder as the oxygen ion-proton phase BaCo 0.7 Fe 0.22 Nb 0.08 o 3-δ . Preparation of BaZr 0.1 Ce 0.7 Y 0.1 Yb 0.1 o 3-δ , weigh an appropriate amount of Yb 2 o 3 , will Yb 2 o 3 Dissolve in concentrated nitric acid solutio...

Embodiment 2

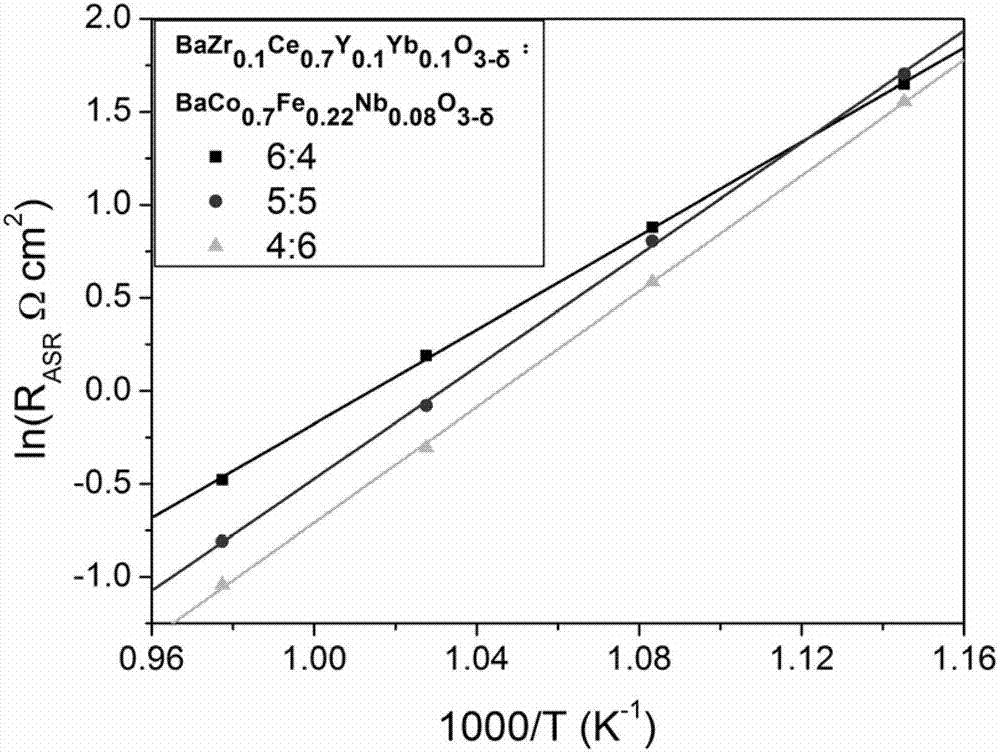

[0022] Embodiment 2: BaCo with different ratios of two phases 0.7 Fe 0.22 Nb 0.08 o 3-δ -BaZr 0.1 Ce 0.7 Y 0.1 Yb 0.1 o 3-δ Polarization resistance test

[0023] Press the two-phase material as BaZr 0.1 Ce 0.7 Y 0.1 Yb 0.1 o 3-δ :BaCo 0.7 Fe 0.22 Nb 0.08 o 3-δ Mass ratios of 6:4, 5:5 and 4:6 were mixed evenly to obtain composite cathode powder. Mix the composite cathode powder and pore-forming agent soluble starch evenly at a mass ratio of 8:2, then add terpineol containing 10% ethyl cellulose as a binder to the powder, and the powder and binder The mass ratio is 6:4. The mixture was thoroughly ground until a homogeneous viscous cathode material slurry was obtained. The paste was uniformly coated on the dense BaZr by the screen printing method 0.1 Ce 0.7 Y 0.1 Yb 0.1 o 3-δ After the surface of the electrolyte sheet is dried in an oven, it is placed in a high-temperature furnace at 1200 o C for 3 h to obtain a symmetrical battery.

[0024] Th...

Embodiment 3

[0025] Example 3: Preparation of anode-supported batteries composed of composite electrodes with different ratios and voltage-current density-power density curve test

[0026] According to the mass ratio of 4:6:2 BaCe 0.7 Zr 0.1 Y 0.1 Yb 0.1 o 3-δ , NiO and soluble starch are mixed, ball milled with absolute ethanol as the medium, and anode powder is obtained after drying, and an appropriate amount of PVA is added to the anode powder for dry pressing, and evenly sieved on one side of the formed anode body A small amount of electrolyte powder BaCe 0.7 Zr 0.1 Y 0.1 Yb 0.1 o 3-δ , secondary dry pressing to form the anode-electrolyte double-layer green body, after 1350 o C calcined at high temperature to obtain a dense circular diaphragm of the electrolyte.

[0027] Press the two-phase material as BaZr 0.1 Ce 0.7 Y 0.1 Yb 0.1 o 3-δ :BaCo 0.7 Fe 0.22 Nb 0.08 o 3-δ Mass ratios of 6:4, 5:5 and 4:6 were mixed evenly to obtain composite cathode powder. Mix t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com