Stable laminated structure positive electrode material of lithium ion battery and its preparing method

A technology for lithium-ion batteries and cathode materials, applied in electrode manufacturing, battery electrodes, structural parts, etc., can solve problems such as increased production costs, large energy consumption, and fluctuations in the phase composition of precursors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] (1) Weigh Ni(NO 3 ) 2 ·6H 2 O and Mn(NO 3 ) 2 ·6H 2 O, dissolved in distilled water to form a mixed nitric acid solution;

[0021] (2) with Na 2 CO 3 As a precipitating agent, control pH=9.5 to obtain NiCO 3 and MnCO 3 Co-precipitate;

[0022] (3) The precipitate is pretreated at 600°C;

[0023] (4) The pretreated powder and Li 2 CO 3 Mix according to Li:(Ni+Mn) molar ratio 7:5;

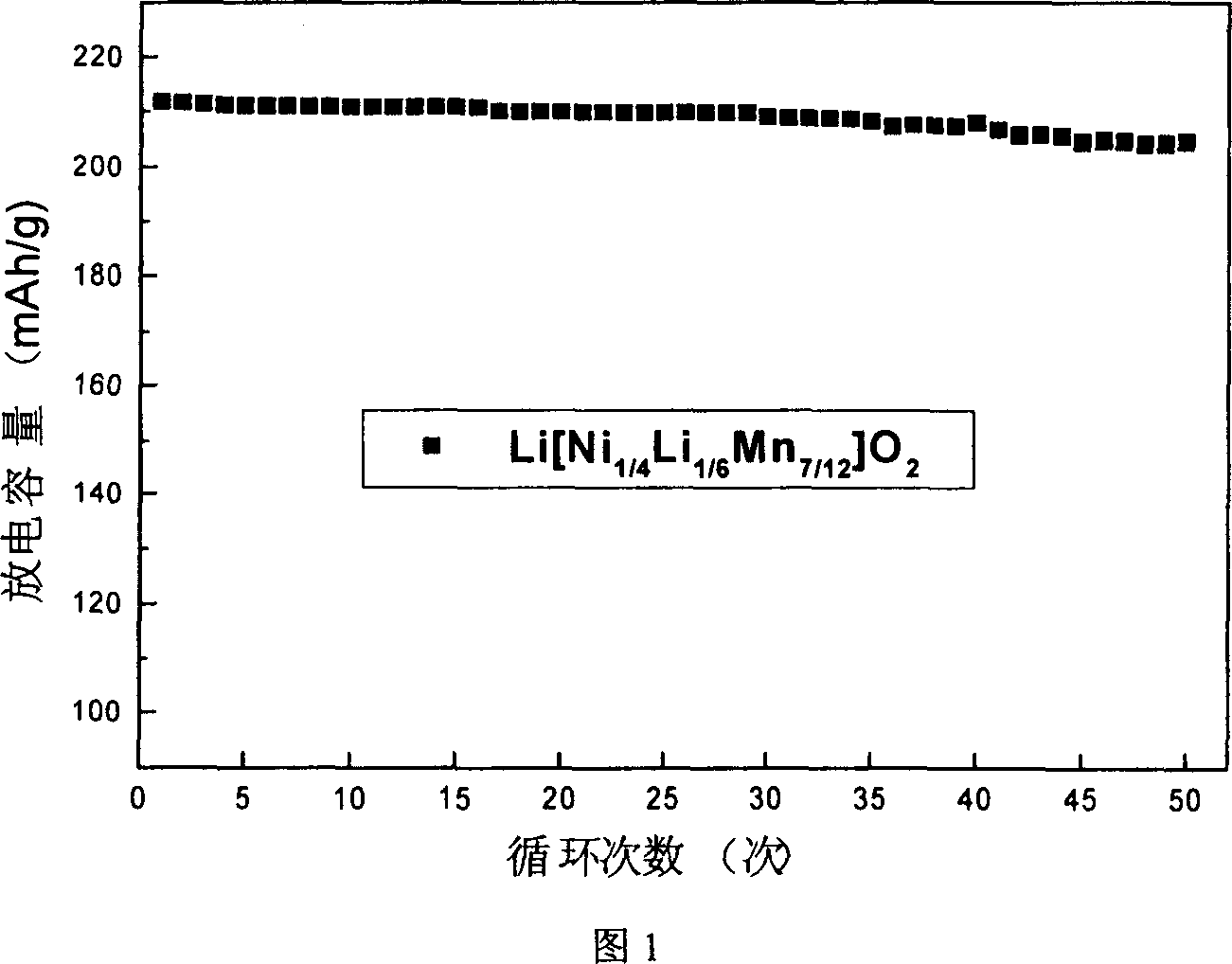

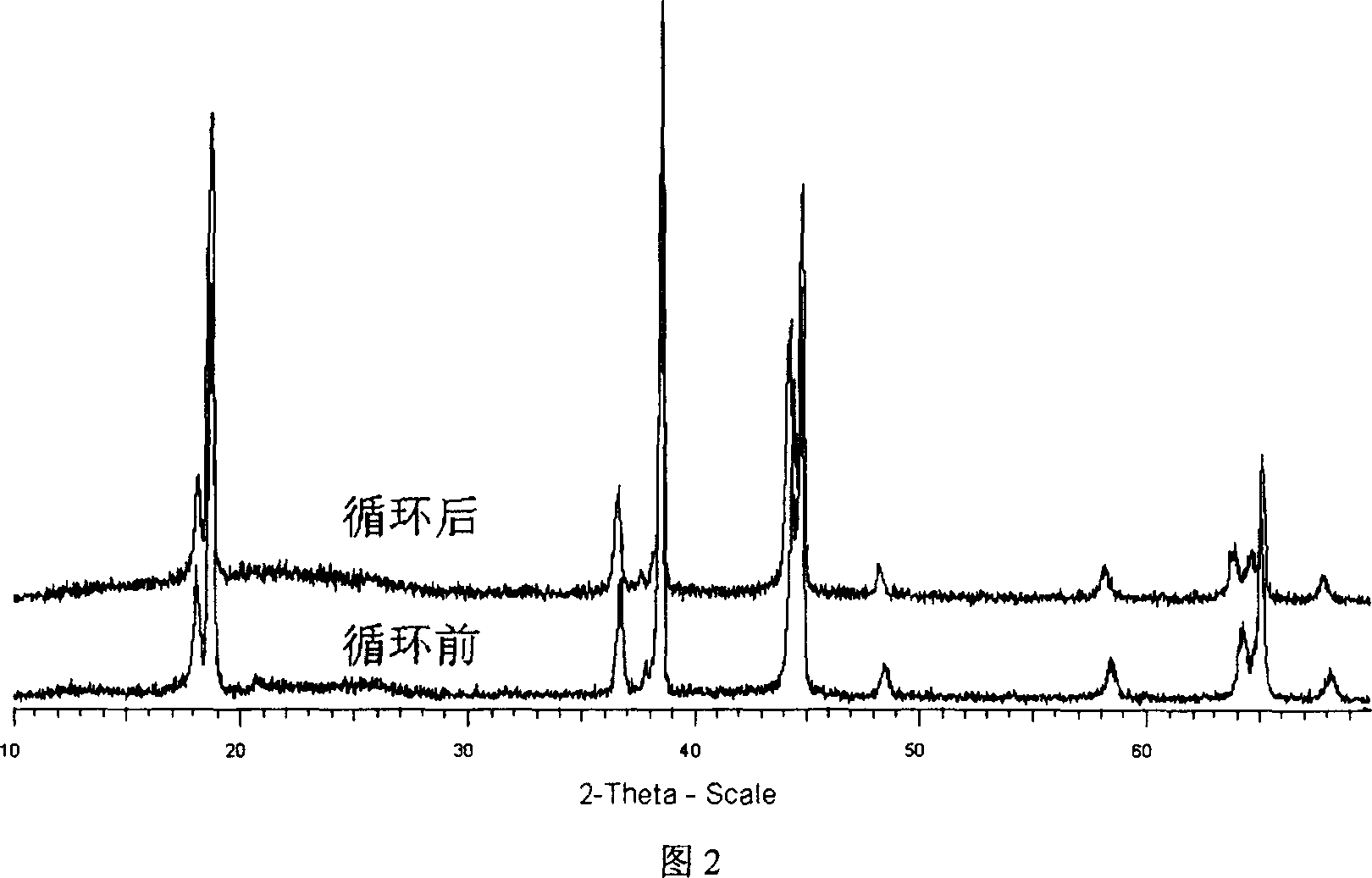

[0024] (5) The uniformly mixed powder is kept at 900°C for 12 hours in an air atmosphere, then the furnace power is turned off, and the furnace is lowered to room temperature to obtain Li[Ni 1 / 4 Li 1 / 6 mn 7 / 12 ]O 2 (Li[Ni X Li 1 / 3-2X / 3 mn 2 / 3-X / 3 ]O 2 (X=1 / 4) powder.

example 2

[0026](1) Weigh NiSO with a molar ratio of 15:19 4 ·6H 2 O and MnSO 4 ·H 2 O, dissolved in distilled water to form a mixed sulfuric acid solution;

[0027] (2) with Li 2 CO 3 As a precipitant, control pH=8 to obtain NiCO 3 and MnCO 3 Co-precipitate;

[0028] (3) The precipitate is pretreated at 500°C;

[0029] (4) The pretreated powder and LiOH·H 2 O is mixed according to Li:(Ni+Mn) molar ratio 19:17;

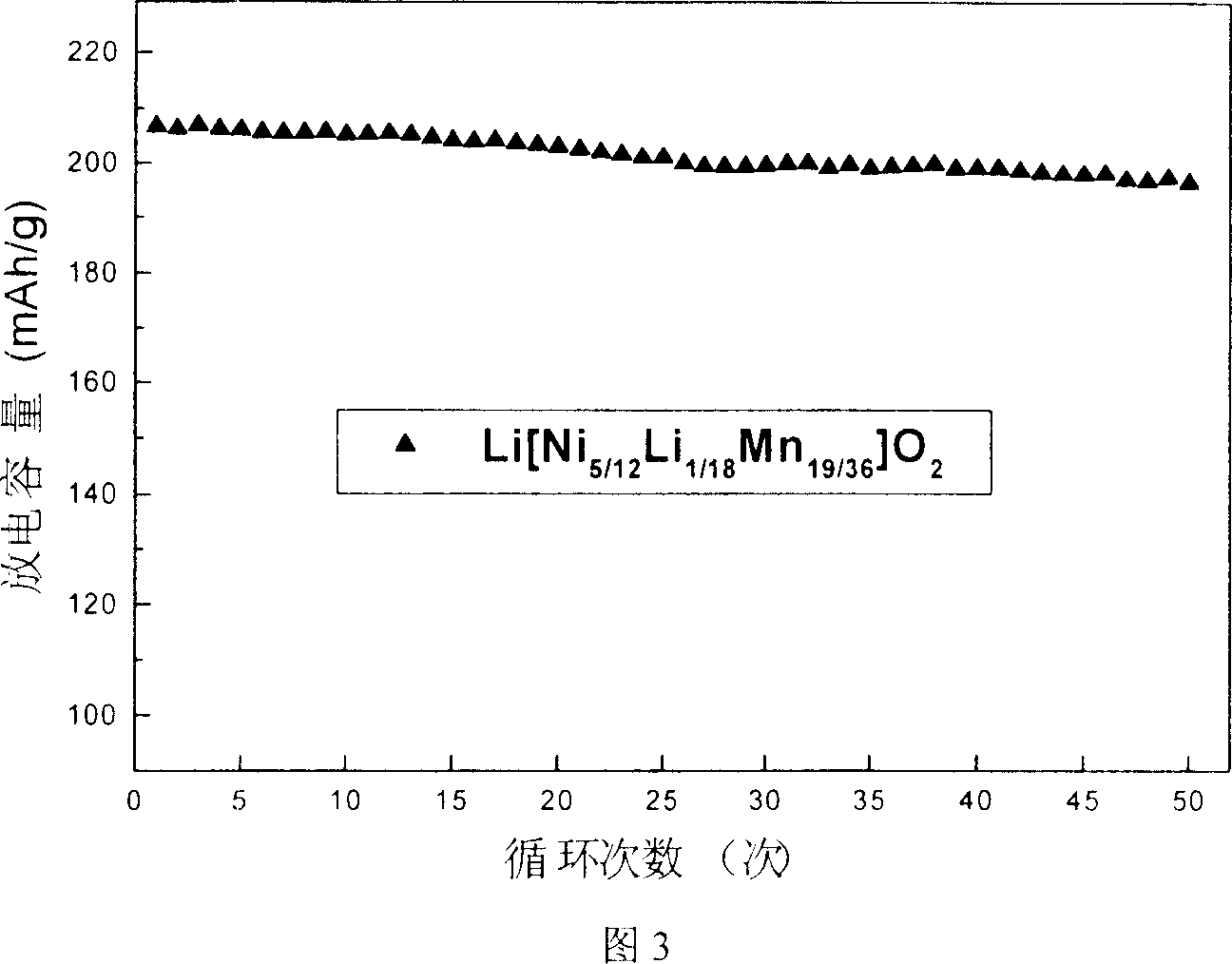

[0030] (5) The uniformly mixed powder is kept at 850°C for 16 hours in an air atmosphere, then the furnace power is turned off, and the furnace is lowered to room temperature to obtain Li[Ni 5 / 12 Li 1 / 18 mn 19 / 36 ]O 2 (Li[Ni X Li 1 / 3-2X / 3 mn 2 / 3-X / 3 ]O 2 (X=5 / 12) powder.

example 3

[0032] (1) Weigh NiSO with a molar ratio of 3:5 4 ·6H 2 O and MnSO 4 ·H 2 O, dissolved in distilled water to form a mixed sulfuric acid solution;

[0033] (2) with Na 2 CO 3 As a precipitant, control pH=9 to obtain NiCO 3 and MnCO 3 Co-precipitate;

[0034] (3) The precipitate is pretreated at 700°C;

[0035] (4) The pretreated powder and LiOH·H 2 O is mixed according to Li:(Ni+Mn) molar ratio 5:4;

[0036] (5) The uniformly mixed powder is kept at 1000°C for 10 hours in an air atmosphere, then the furnace power is turned off, and the furnace is lowered to room temperature to obtain Li[Ni 1 / 3 Li 1 / 9 mn 5 / 9 ]O 2 (Li[Ni X Li 1 / 3-2X / 3 mn 2 / 3-X / 3 ]O 2 (X=1 / 3) powder.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com