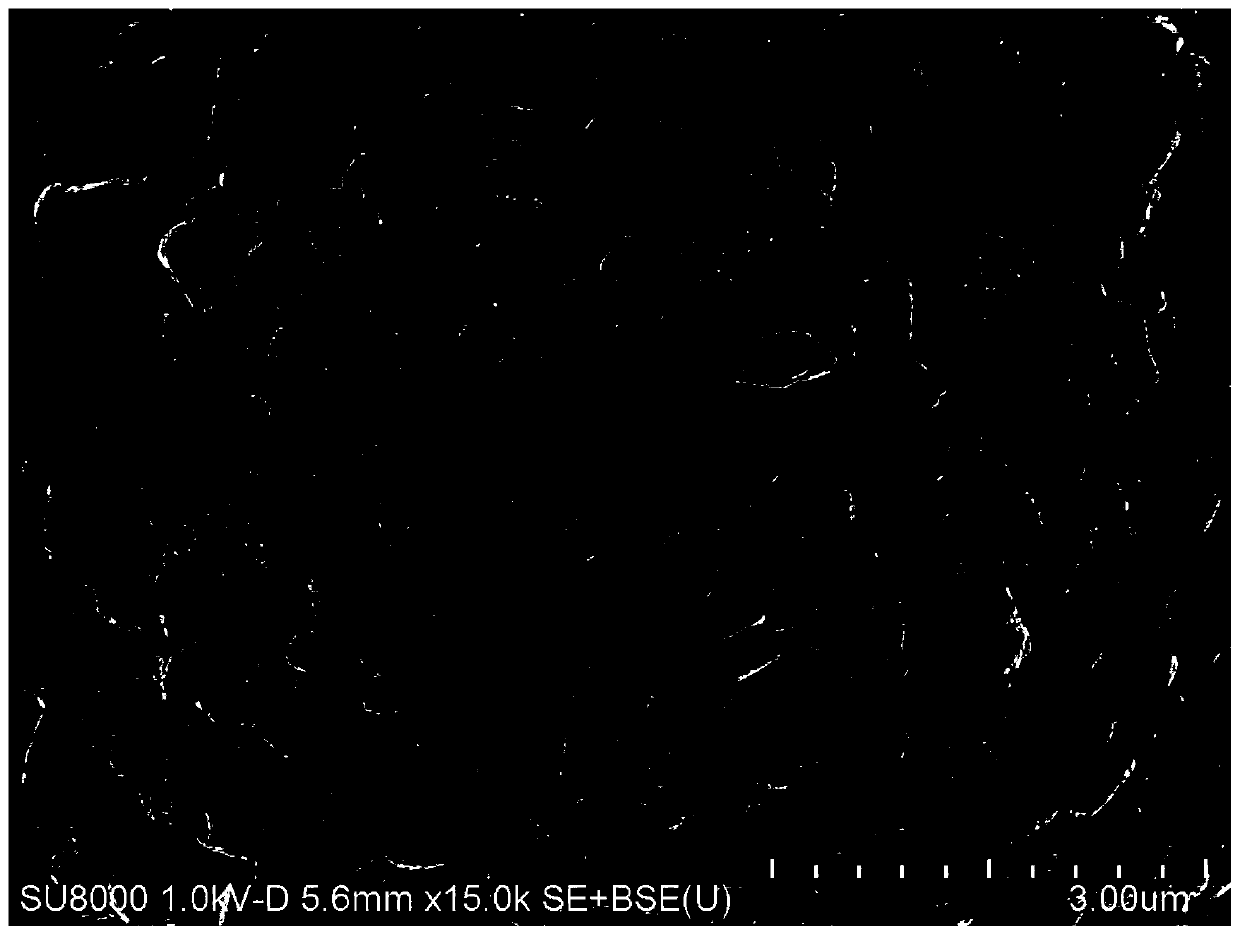

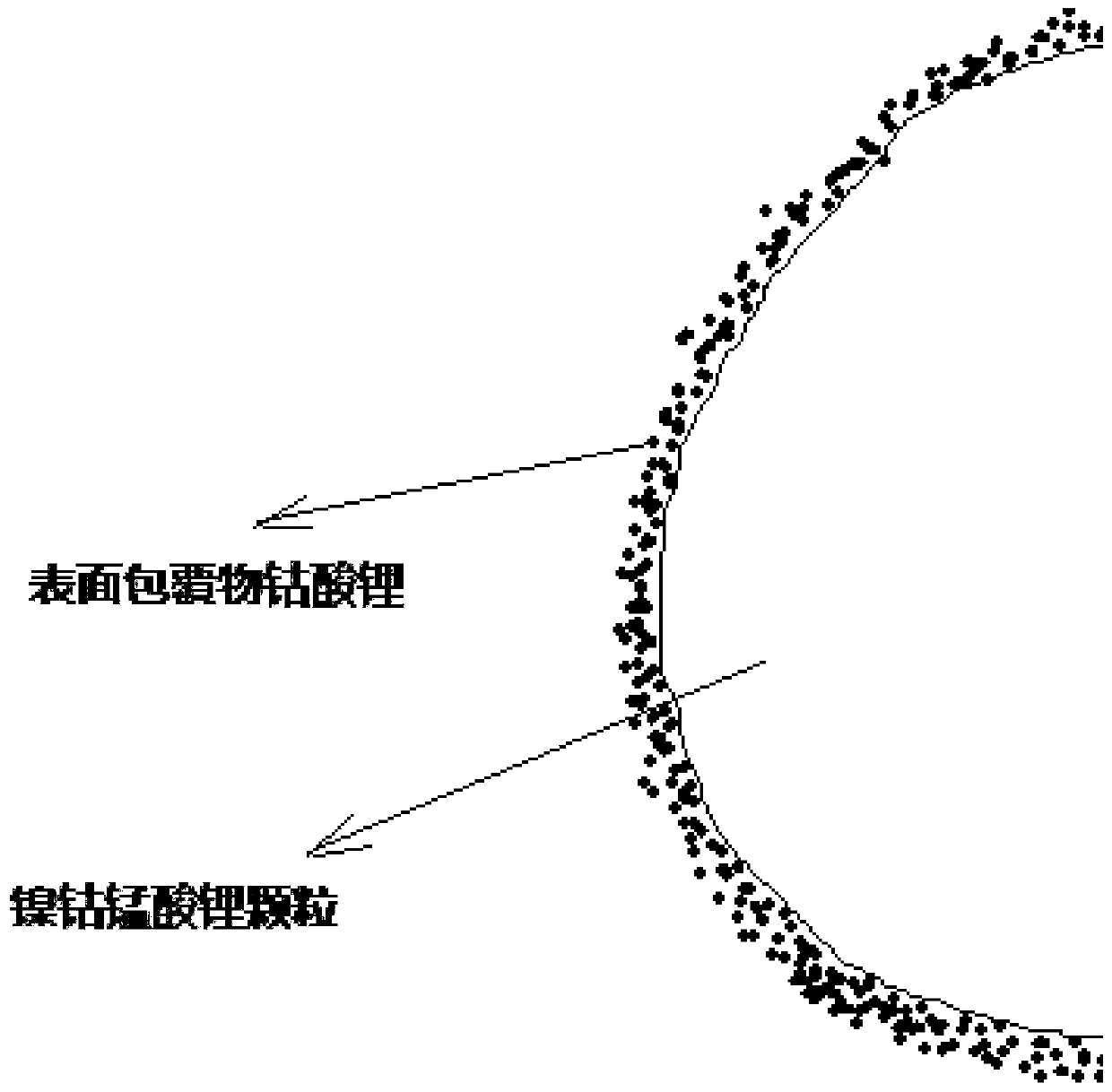

Lithium cobaltate-coated high-nickel ternary positive electrode material and preparation method thereof

A positive electrode material, lithium cobalt oxide technology, applied in the field of lithium cobalt oxide coated high-nickel ternary positive electrode materials and its preparation, can solve the problems of reducing lithium carbonate content, reducing the residual alkali on the surface, avoiding direct contact with air The effect of contact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

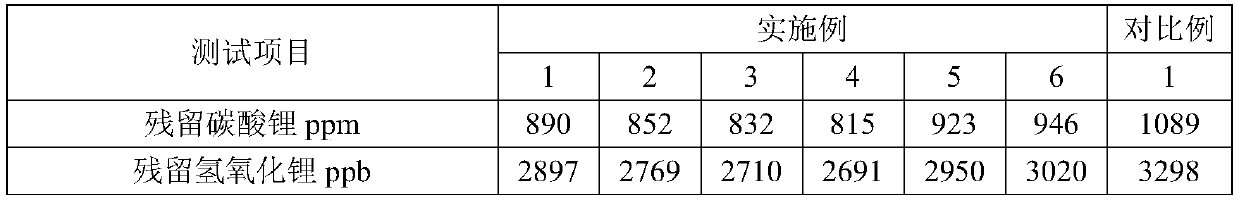

Examples

Embodiment 1

[0043] This embodiment provides a lithium cobalt oxide coated high nickel ternary cathode material, and the preparation process is specifically as follows.

[0044] (1) Put the nano cobalt tetroxide (D50: 20-50nm) and 811 nickel cobalt manganese ternary precursor into the high mixer at a mass ratio of 0.05:1, and put the lithium hydroxide according to (nanometer cobalt tetroxide mole number + 811 nickel cobalt manganese high The number of moles of nickel ternary precursor): The number of moles of lithium hydroxide is 1.05:1 into the high-mixer, that is, 0.5kg of nano-cobalt tetroxide, 10kg of 811 nickel-cobalt-manganese ternary precursor and 4.87kg of lithium hydroxide are put into the high-mixer. The machine is then mixed at a high speed of 550r / min for 20min;

[0045] (2) Put the uniformly mixed powder in a box furnace with an oxygen content> 95% oxygen atmosphere, heat up to 800°C at a heating rate of 5°C / min, keep it for 13 hours, and sinter the product;

[0046] (3) The sintere...

Embodiment 2

[0048] This embodiment provides a lithium cobalt oxide coated high nickel ternary cathode material, and the preparation process is specifically as follows.

[0049] (1) Put nano cobalt tetroxide (D50: 20-50nm) and 811 nickel cobalt manganese ternary precursor into the high mixer at a mass ratio of 0.1:1, and put lithium hydroxide according to (nanometer cobalt tetroxide mole number + 811 nickel cobalt manganese high The number of moles of nickel ternary precursor): The number of moles of lithium hydroxide is 1.05:1 into the high-mixer, that is, 1.0kg nano-cobalt tetroxide, 10kg 811 nickel-cobalt-manganese ternary precursor and 4.96kg lithium hydroxide are put into the high-mixer. The machine is then mixed at a high speed of 550r / min for 20min;

[0050] (2) Put the uniformly mixed powder in a box furnace with an oxygen content> 95% oxygen atmosphere, heat up to 800°C at a heating rate of 5°C / min, keep it for 13 hours, and sinter the product;

[0051] (3) The sintered product is then ...

Embodiment 3

[0053] This embodiment provides a lithium cobalt oxide coated high nickel ternary cathode material, and the preparation process is specifically as follows.

[0054] (1) Put nano cobalt tetroxide (D50: 20-50nm) and 811 nickel cobalt manganese ternary precursor into the high mixer at a mass ratio of 0.15:1, and put lithium hydroxide according to (nanometer cobalt tetroxide mole number + 811 nickel cobalt manganese high The number of moles of nickel ternary precursor): The number of moles of lithium hydroxide is 1.05:1 into the high mixer, that is, 1.5kg of nano cobalt tetroxide, 10kg of 811 nickel cobalt manganese ternary precursor and 5.05kg of lithium hydroxide are put into the high mixing machine. The machine is then mixed at a high speed of 550r / min for 20min;

[0055] (2) Put the uniformly mixed powder in a box furnace with an oxygen content> 95% oxygen atmosphere, heat up to 800°C at a heating rate of 5°C / min, keep it for 13 hours, and sinter the product;

[0056] (3) The sinter...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com