A kind of ternary cathode material and preparation method thereof

A cathode material and treatment solution technology, which is applied in the field of preparation of ternary cathode materials, can solve the problems of failure to meet the use requirements of power batteries, the decline of the rate and cycle performance of ternary materials, and the increase of costs, and achieves further suppression of residual alkali. The effect of generating, reducing the amount of residual alkali on the surface, and reducing flatulence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] This embodiment provides a method for preparing a ternary positive electrode material, which specifically includes the following steps:

[0035] The lithium-ion battery high-nickel ternary cathode material LiNi 0.6 co 0.2 mn 0.2 o 2 placed in a confined space;

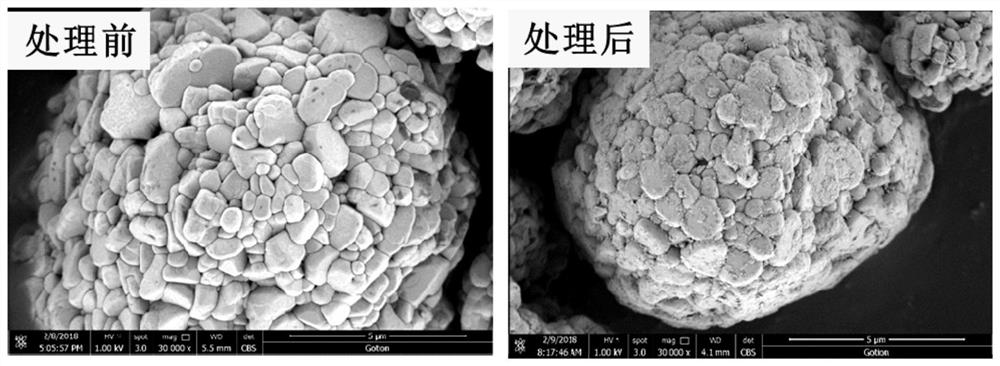

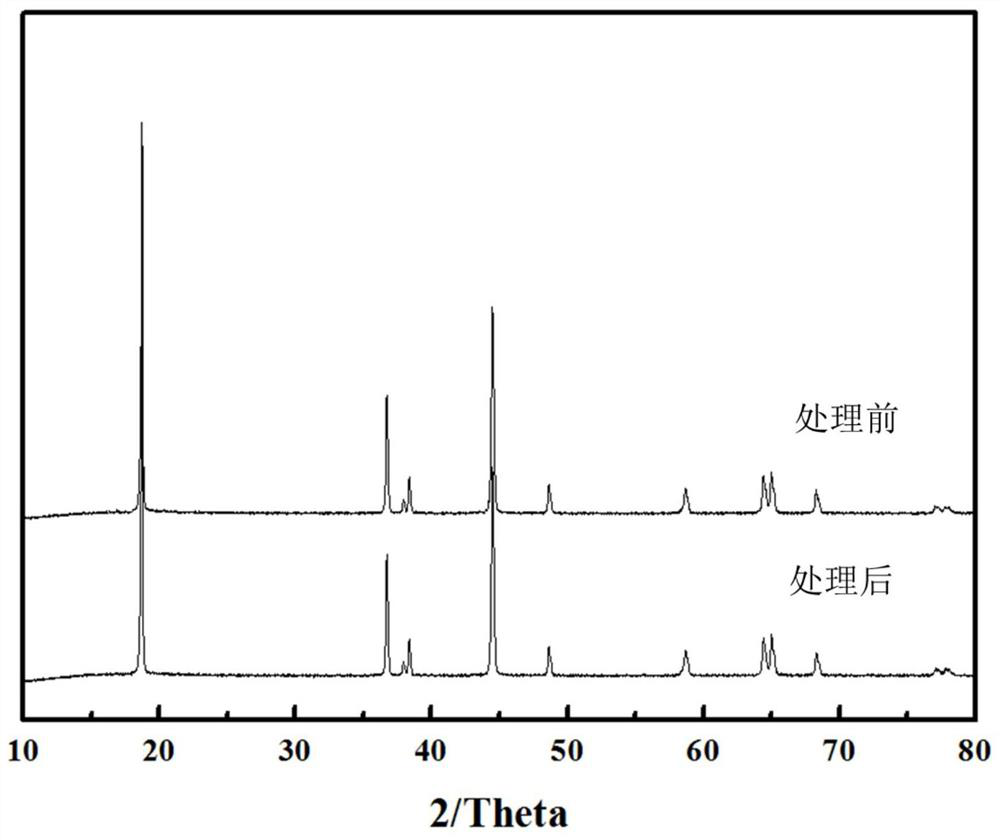

[0036] The citric acid aqueous solution of 0.5wt% zirconium nitrate is used to generate ultrafine particles by an ultrafine particle generator;

[0037] The ultrafine particles are transported to a closed space, and treated for 20 minutes under normal temperature and pressure conditions. The dried samples are placed in a muffle furnace with an oxygen atmosphere, and sintered at 500 ° C for 4 hours, and then naturally cooled to room temperature to obtain low residual alkali content of the ternary cathode material. The residual alkali content after treatment is 0.2wt% Li 2 CO 3 , 0.09 wt% LiOH. The residual alkali content of this material before treatment is 0.421wt% Li 2 CO 3 , 0.32 wt% LiOH.

[0038] ...

Embodiment 2

[0042] This embodiment provides a method for preparing a ternary positive electrode material. The high-nickel material used in this embodiment is LiNi 0.8 co 0.1 mn 0.1 o 2 , the surface residual alkali treatment steps are as follows:

[0043] The lithium-ion battery high-nickel ternary cathode material LiNi 0.8 co 0.1 mn 0.1 o 2 placed in a confined space;

[0044] The citric acid aqueous solution of 0.5wt% aluminum nitrate is used to generate ultrafine particles by an ultrafine particle generator;

[0045] Transport the ultrafine particles to a closed space, and treat them for 20 minutes under normal temperature and pressure conditions. The dried samples are placed in a muffle furnace with an oxygen atmosphere, and sintered at 600 ° C for 2 hours, and then naturally cooled to room temperature to obtain low residual alkali content of the ternary cathode material. The residual alkali content after treatment is 0.31wt% Li 2 CO 3 , 0.12wt% LiOH; the residual alkali co...

Embodiment 3

[0047] This embodiment provides a method for preparing a ternary positive electrode material, which specifically includes the following steps:

[0048] The lithium-ion battery high-nickel ternary cathode material LiNi 0.6 co 0.2 mn 0.2 o 2 placed in a confined space;

[0049] The citric acid aqueous solution of 0.5wt% zirconium nitrate is used to generate ultrafine particles by an ultrafine particle generator;

[0050] The ultrafine particles are transported to a closed space, and treated for 20 minutes under normal temperature and pressure conditions. The dried samples are placed in a muffle furnace with an oxygen atmosphere, and sintered at 500 ° C for 4 hours, and then naturally cooled to room temperature to obtain low residual alkali content of the ternary cathode material. The residual alkali content after treatment is 0.25wt% Li 2 CO 3 , 0.11wt% LiOH; the residual alkali content of this material before treatment is 0.5wt% Li 2 CO 3 , 0.35 wt% LiOH.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com