High-nickel multi-element positive electrode material as well as preparation method and application thereof

A cathode material and multiple technologies, applied in electrical components, battery electrodes, circuits, etc., can solve the problems of material surface degradation, long sintering cycle, high pH value, improve structural stability, reduce synthesis costs, and improve product performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

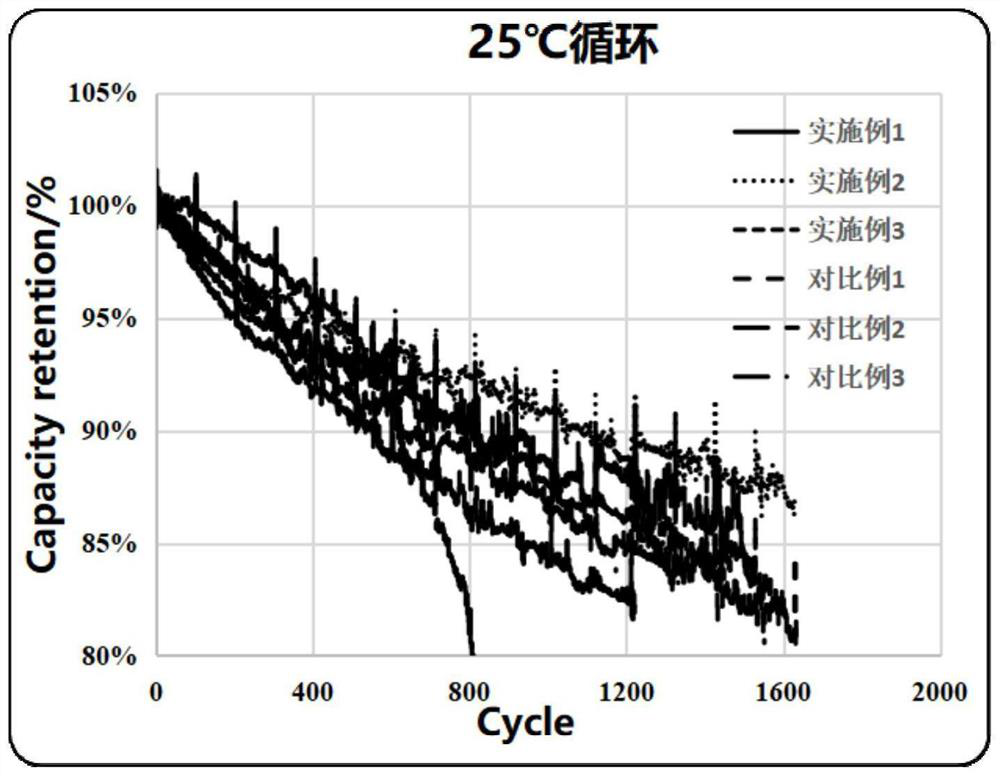

Examples

preparation example Construction

[0027] The first aspect of the present invention provides a method for preparing a high-nickel multi-element positive electrode material, comprising the following steps:

[0028] A precursor solution is provided, the precursor solution is a mixed salt solution of nickel salt, cobalt salt, and manganese salt and a metal dopant is added therein;

[0029] Transporting the precursor liquid to high-temperature reaction equipment under high pressure, and under the protection of a protective atmosphere, the precursor liquid is condensed to obtain precursor particles;

[0030] Spraying lithium source powder into the high temperature reaction equipment, the lithium source powder is in contact with the precursor particles, crystallized to obtain aggregated secondary particles;

[0031] The secondary particle is mixed with the surface coating additive and sintered to prepare a high-nickel multi-element positive electrode material.

[0032] On the basis of the traditional ternary composi...

Embodiment 1

[0045]According to the ratio of the amount n of metal elements to 0.907:0.045:0.044:0.003:0.001, nickel acetate, cobalt acetate, manganese acetate, aluminum oxide and magnesium oxide are mixed and dissolved in water, and ammonia solution is added to adjust the pH to 10-11 , stirred for 1h to obtain a precursor solution;

[0046] The precursor liquid is transported to a high-temperature reaction tower with a temperature of 650°C through a pressure of 1 MPa. Under the protection of nitrogen, the precursor liquid is condensed to obtain precursor particles, which are mixed with lithium hydroxide powder sprayed in the middle of the reaction tower, and the flow rate is controlled until the precursor particles and The mass ratio of lithium hydroxide powder is 1:1.05, and secondary particles are obtained at the bottom of the tower;

[0047] Combine the secondary particles with LiCoO 2 According to the mass ratio of 1:0.04 mixed, sintered at 600 ° C for 2 hours to obtain high-nickel m...

Embodiment 2

[0059] According to the ratio of the amount n of the metal element substance to 0.841:0.081:0.073:0.002:0.003, nickel acetate, cobalt acetate, manganese acetate, zirconium oxide and magnesium oxide are mixed and dissolved in water, and ammonia solution is added to adjust the pH value to 10 ~11, stir for 0.5h to obtain the precursor solution;

[0060] The precursor liquid is transported to a high-temperature reaction tower with a temperature of 550°C through a pressure of 2 MPa. Under the protection of nitrogen, the precursor liquid is condensed to obtain precursor particles, which are mixed with lithium hydroxide powder sprayed in the middle of the reaction tower, and the flow rate is controlled until the precursor particles and The mass ratio of lithium hydroxide powder is 1:1.1, and secondary particles are obtained at the bottom of the tower;

[0061] Al 2 o 3 Mix according to the mass ratio of 1:0.03, and sinter at 650°C for 2.5h to prepare LiNi, a high-nickel multi-eleme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com